EVEREADY Kestrel e400nb User manual

Document No. 1112M001 Revision 1.8 Date: June 2013

1

Kestrel e400nb

250Vdc,

Type 1112-3500-250 (3.5kW 250Vdc)

110Vdc,

Type 1112-3500-110 (3.5kW 110Vdc)

048Vdc,

Type 1112-3500-048 (3.5kW 048Vdc)

With Conditional Two Year Warranty

Important Note: Only the e400nb 3.5kW 250V grid tie version when installed with the Power

One Aurora 3.6 Inverter is MCS and SWCC certified.

Document No. 1112M001 Revision 1.8 Date: June 2013

2

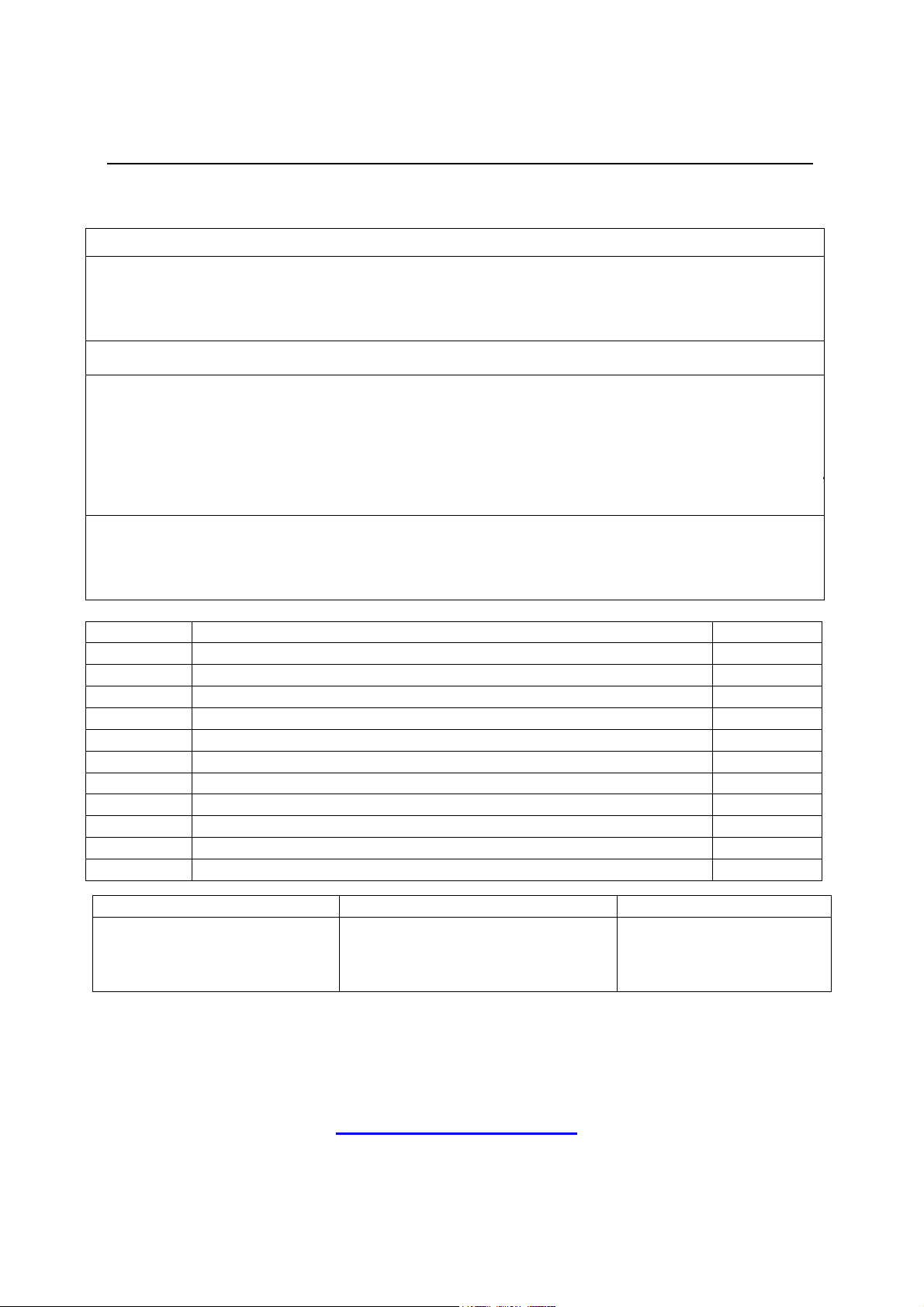

Warranty Registration (Failure to return may render the warranty to be void)

Please complete and return this page within three months after the product delivery date or

within one month following the commissioning date. Attach a picture of your installation

Name of Product: _________________________________

Product Serial Number _________________________________

Pitch Control Serial Number _____________________________

Blade Serial No. (1)_______________ (2)_______________ (3)_____________

Delivery Date____________or Commissioning Date___________

Name and Address of Owner

____________________________________________________________

____________

________________________________________________________________________

________________________________________________________________________

Telephone: ___________________________________________________

___________

Email: ______________________________________________________________

Installation / Site Address (GPS co-ordinates are appreciated)

_____________________________________________________________________

___

________________________________________________________________________

Commissioning Check List

Section

Operation / Procedure

Verified

4.2 All tail assembly M6 fasteners torqued to 10Nm (7.5ft lb)

4.3 Tail boom weld assembly 2 x M12 to 50Nm (36ft lb)

4.3 Tail boom weld assembly 8 x M10 to 50Nm (36ft lb)

4.4 Generator electrical connection secure and insulated

4.4 Generator fitted to the tower 8 x M16 to 120Nm (88ft lb)

4.5 Tail assembly to the boom 2 x M10 to 35Nm (25ft lb)

4.6 Blades properly installed (serial number forward)

4.6 Blade bolts 6 x stainless M16 torqued to 90Nm (65ft lb)

4.8 Nacelle 2 x M6 nuts + 4 x M5 screws stainless to 3Nm (3ft lb)

4.8 Nosecone to stiffener ring 6 x M6 stainless to 4Nm (3ft lb)

4.8 Nosecone to posts 3 x M8 stainless to 10Nm (7.5ft lb)

GENERAL COMMENTS:

………………………………………………………………………………………………………………

………………………………………………………………………………………………………………

Send to: Kestrel Wind Turbines, P.O. Box 3191, North End, Port Elizabeth, 6056, Eastern

Cape, South Africa Or email to: kestrel.admin@eveready.co.za OR Fax: +27 41 394 8183

Type of Tower Installation Engineer Comissioned Date

Document No. 1112M001 Revision 1.8 Date: June 2013

3

Index

1.0 Safety Warnings and Notes 4

1.1 Safety Symbols 5

1.2 Turbine Operating Procedures 6

2.0 The Tower 8

2.1 Mounting Flange and Tower Top 9

3.0 Unpacking the Wind Turbine 10

4.0 Turbine assembly and Installation 12

4.1 Identification Marking 12

4.2 Tail Assembly 13

4.3 Generator to the Tower with Damper Kit 14

4.4 Tail Boom Weld assembly to the Generator 16

4.5 Tail Assembly to the Boom 17

4.6 Blades and Nosecone Stiffener Ring 19

4.7 Mechanical Brake Assembly 20

4.8 Nacelle and Nosecone 23

5.0 Electrical Installation 24

5.1 Lightning Protection 24

5.2 Earthing (Grounding) 25

5.3 Cable Sizes and Installation 25

5.4 Electrical Installation (e400nb 250Vdc and Grid Tie) 27

5.5 Electrical Installation (e400nb 48Vdc and MPPT Charge Control) 28

5.6 Electrical Installation (e400nb 110Vdc, limiter and MPPT) 30

6.0 Installation Commissioning 31

7.0 Maintenance Schedule 32

7.1 Wind Power Class 32

7.2 Planned Maintenance Schedule 33

8.0 Questions and Answers 34

9.0 Technical Specification 35

10.0 Compliance 36

11.0 Warranty 37

12.0 Annexures

Annexure 1 General Information 38

Annexure 2 Choosing a Site 41

Annexure 3 Grid Tie Inverters 43

Annexure 4 Manual Brake Operation 44

Annexure 5 Brake Fitment Instructions 45

Annexure 6 Power One Aurora Settings 54

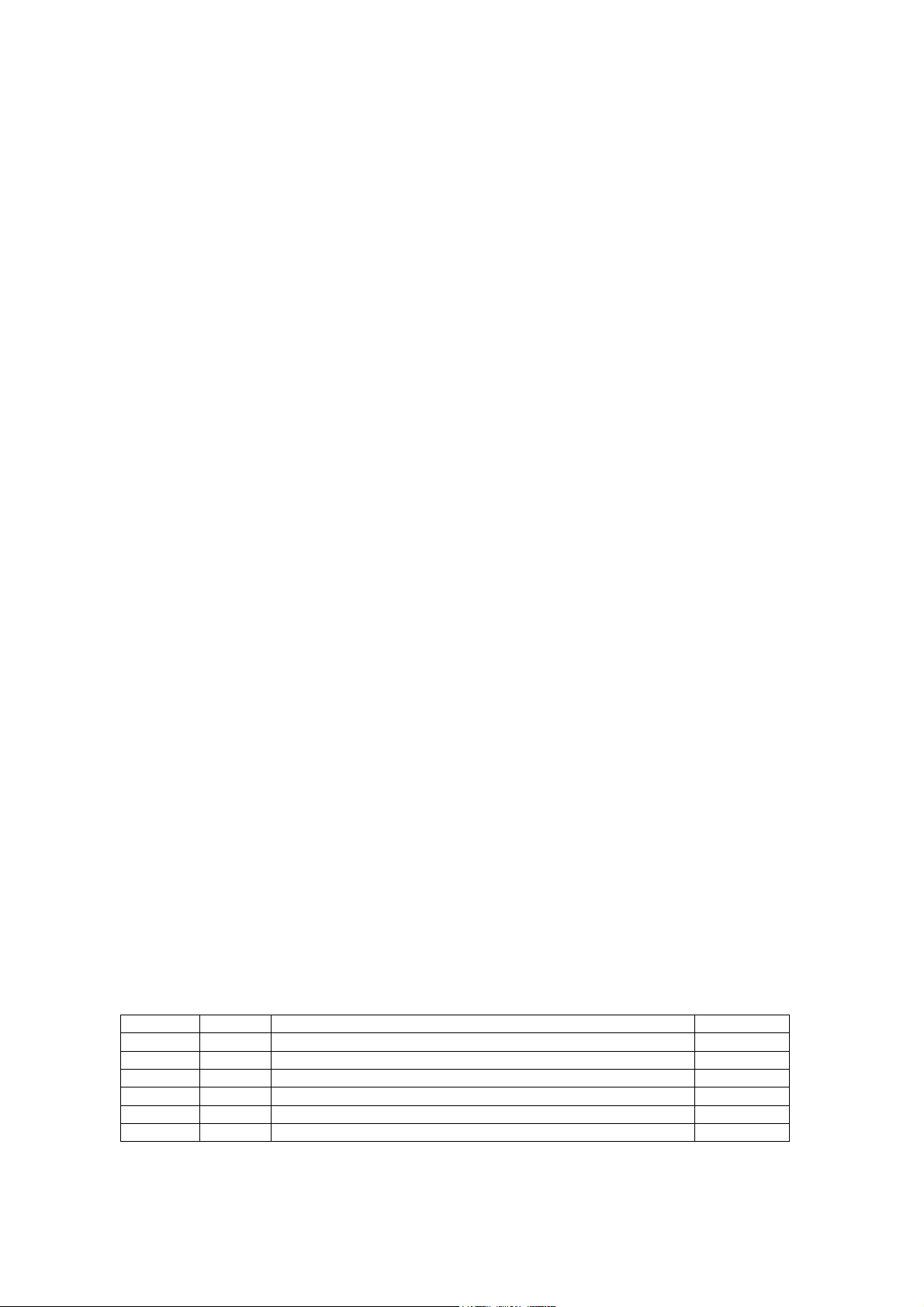

Revision History

Revision

Date

Comments

Author

1.8 06/13 Add SWCC Logo, technical specification and Annexure 6 J. Carpy

1.7

12/12

Revised technical specification

B.Singh

1.6 11/12 Blade fitment guide improved, brake fitment added J. Carpy

1.5 09/12 MCS Logos added, blade bolts reversed, brake cable turns J. Carpy

1.4

07/12

Add sect. 1.2 Operating procedures, revise main

tenance

J. Carpy

Document No. 1112M001 Revision 1.8 Date: June 2013

4

Disclaimer

Kestrel Wind Turbines makes every effort to give accurate information in this

manual and is in no way liable for any error or omission. The user of this manual

assumes full responsibility and risk

Please carefully read and apply the safety notes. Consult a professional engineer

and take advice if you are unsure.

Note: The Kestrel e400nb has a mechanical brake and the Kestrel e400n is

supplied without this mechanical brake.

1.0 Safety and Warning Notes

Accidents can easily occur and there are always inherent dangers

associated with any type of machine. Tower installations pose their own

dangers. Always work carefully and have an assistant wherever possible.

All installation work should be completed at ground level wherever possible.

Be very aware of the blades during installation. Consult a civil engineer or

reputable builder if you are unsure.

Use caution when working with this wind turbine. Use good handling

methods and take precautions to avoid physical injury. The Kestrel e400nb

output voltage can become dangerous and even lethal when running on

open circuit. Always short the output wires together when the turbine is

disconnected. Do not work on the system when the turbine is running or

when lightning is possible.

Disconnecting any wire may result in a spark. The presence of explosive

hydrogen from battery charging is always a possibility. Adequate ventilation

must be provided for battery installations. Wire sizes must be correct for the

powers supplied. Fire can result from shorts created on a battery. Consult a

qualified electrician if you are unsure.

Slack bolts, poor workmanship and loose electrical connections must be

avoided. The turbine blades are dangerous therefore exercise caution.

Always shut the turbine down before approaching by operating the brake

switch on the controller or the mechanical safety brake. Preventative

maintenance is always the best. Checks are best carried out in calm

weather conditions. Avoid any maintenance or inspection during windy

weather.

Document No. 1112M001 Revision 1.8 Date: June 2013

5

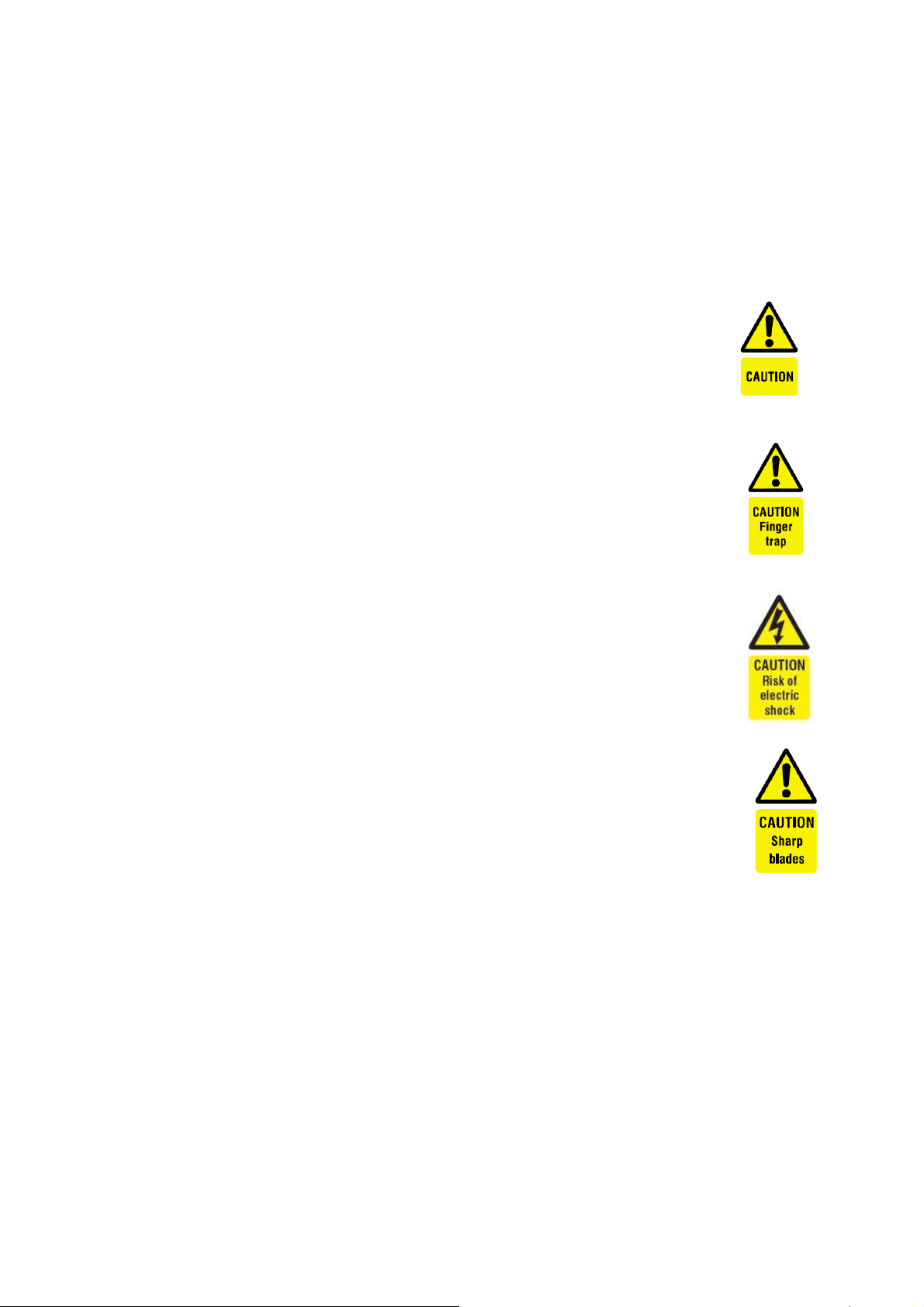

1.1 Safety Symbols

The symbols shown are used throughout this manual to highlight safety

points

General caution warning

Danger of hand injury

Danger of electrical shock

Injury from blades

Work Instructions

Asterisk denotes a special instruction or reminder.

►Arrow head denotes an assembly/build instruction.

Document No. 1112M001 Revision 1.8 Date: June 2013

6

1.2 Turbine Operating Procedures

A standard start and stop procedure is included in this product manual

(Annexure 4). It is recommended that a label showing this procedure be

visible adjacent to the wind turbine tower.

A “T” bar is supplied to operate the tower brake. This “T” bar should be

stored in a safe but accessible location and never left in position on the

tower.

Standard Operating Procedure

This procedure gives a clear action sequence for the following procedures:

i) Procedure for starting and activation

ii) Procedures during normal running

iii) Procedure for stopping and de-activation

iv) Procedure for routine maintenance

Procedure for Starting

(Assumption: The turbine is braked and electrically isolated)

•Ensure that all personnel and animals are well clear of the

turbine tower

•Engage the turbine fuse holder F1/F2 in the interface unit to

connect the turbine.

•Release the electrical brake switch S1 located in the interface

unit

•Approach the tower base and insert the “T” bar into the brake

winch.

•Apply light pressure to the brake and release the ratchet

lever.

•Release the mechanical brake by unwinding the brake winch.

•Observe the turbine to start rotation in the wind.

•Re-apply the ratchet lever and remove the “T” bar.

Document No. 1112M001 Revision 1.8 Date: June 2013

7

Procedures During Normal Running

(Assumption: The turbine is running normally)

•No operating procedures are required. Take every opportunity

to visually observe the system in operation and to listen for

any unusual noise. This is always a good practice.

Procedures for Stopping and De-activation

IMPORTANT NOTE: A stopped turbine will still yaw and align to follow

the wind. A braked machine although stopped, can still cause serious

injury to personnel. The machine must be fully secured before

approaching and must only be approached in calm or very light wind

conditions.

(Assumption: The turbine is to be stopped and electrically isolated)

•Procure the brake “T” bar and approach the tower base.

•Verify that the brake ratchet mechanism is engaged.

•Insert the “T” bar into the brake and wind the handle a little to

verify the ratchet operation.

•While observing the turbine, slowly wind the brake handle until

the brake tension is detected and the turbine slows down to be

stationary.

•Wind the handle two more “clicks” and remove the brake

handle.

•At the interface module, operate the stop switch S1 and pull

out (disengage) the turbine fuses F1/F2.

Procedures for Routine Maintenance

Routine maintenance is described is Section 7.0 of this manual. The

same start and stop procedures are used for maintenance.

The tower brake “T” bar must be removed to prevent accidental brake

release and to “Lock out” the turbine brake.

Document No. 1112M001 Revision 1.8 Date: June 2013

8

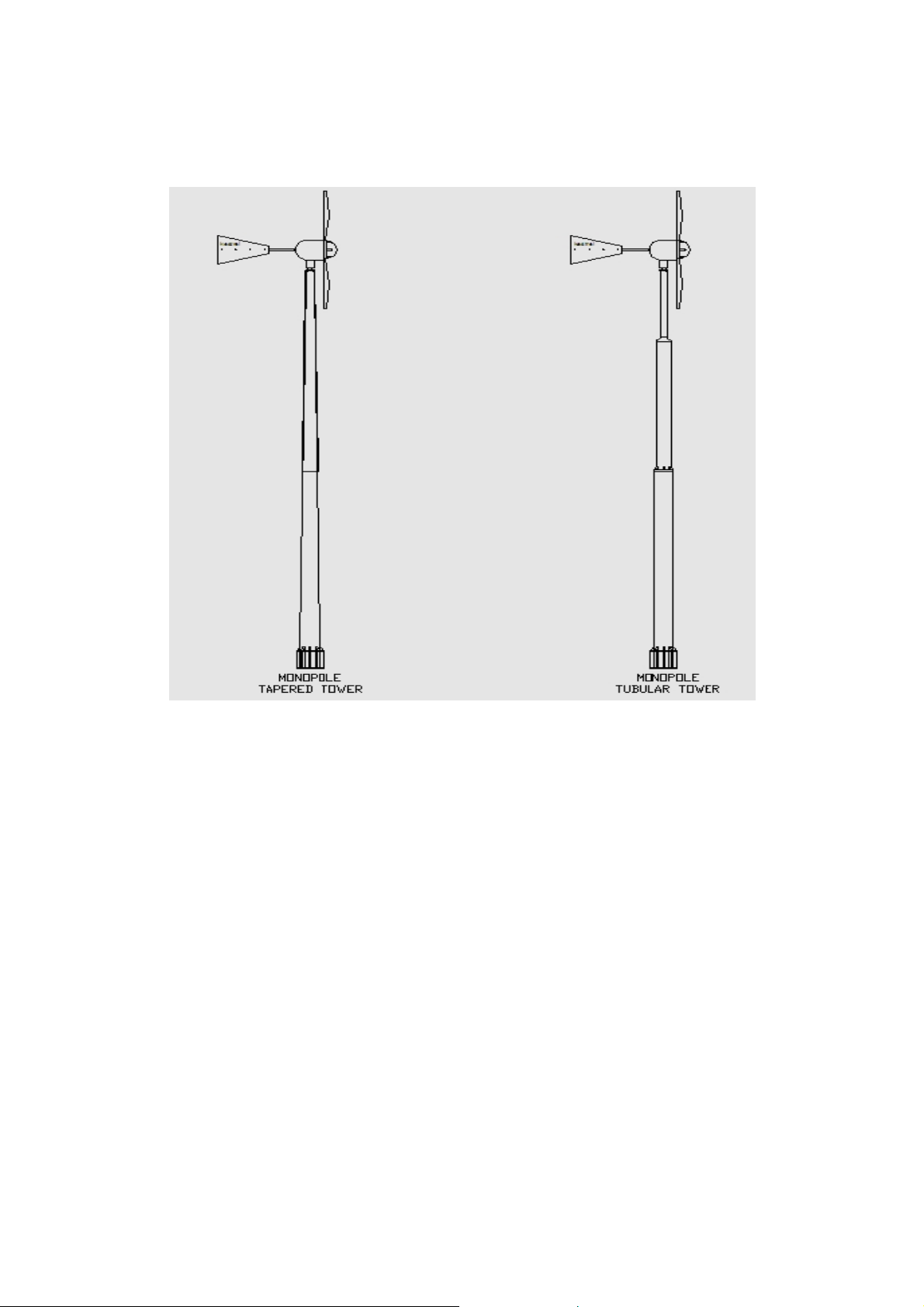

2.0 The Tower

A monopole free standing tower is preferred for the Kestrel e400nb.

The tower sections can be taper formed or parallel tubular. These

towers use larger diameter sections to increase rigidity and strength

but optimise the total tower weight. This tower type is also the easiest

to assemble and install due to its simple design and optional hydraulic

or electro-mechanical lifting pack.

Monopole towers are usually available in 12m (40’) and 18m (60’)

versions. Consult the factory for higher options.

Other acceptable tower types include lattice construction and tripod

towers. Guyed towers are preferred when much greater heights are

desired. Although Kestrel only supplies standard approved towers, the

turbine characteristics and parameters for tower design are available

from the factory.

Document No. 1112M001 Revision 1.8 Date: June 2013

9

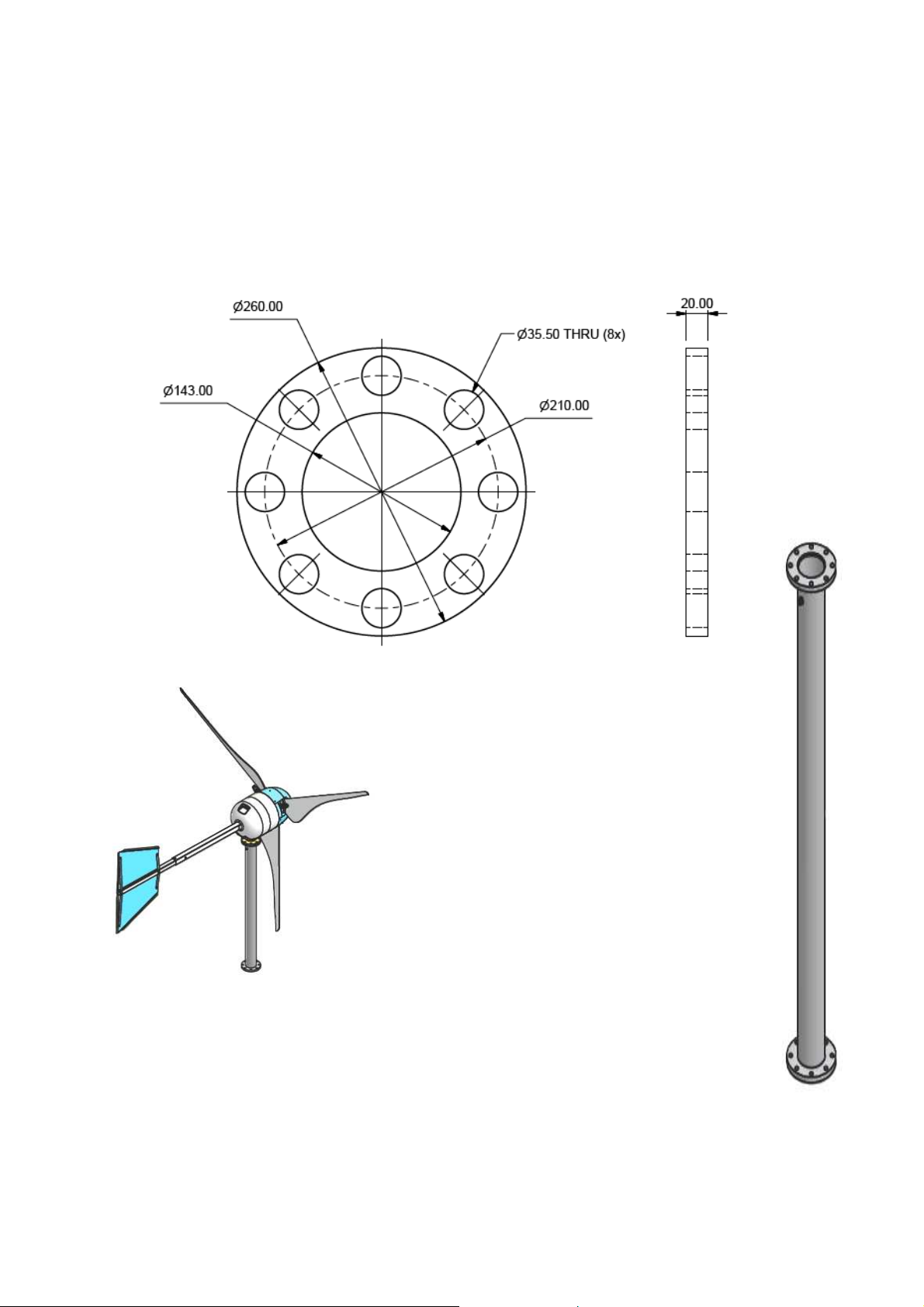

2.1 Mounting Flange and Tower Top

The tower for the Kestrel e400nb is fitted with a circular flange made

from 20mm 300WA mild steel. The dimensions are shown below.

The following specification is

recommended for the top pipe

section of the tower. Mild steel

pipe grade 350WA Nom. Dia

125mm (5.5”) SCH 40 by 1.8m

long

A standard adapter pipe is

available from Kestrel where the

turbine will be fitted to an

alternative structure. The pole

includes a securing point for the

tower cable. Consult your dealer

for more details.

Document No. 1112M001 Revision 1.8 Date: June 2013

10

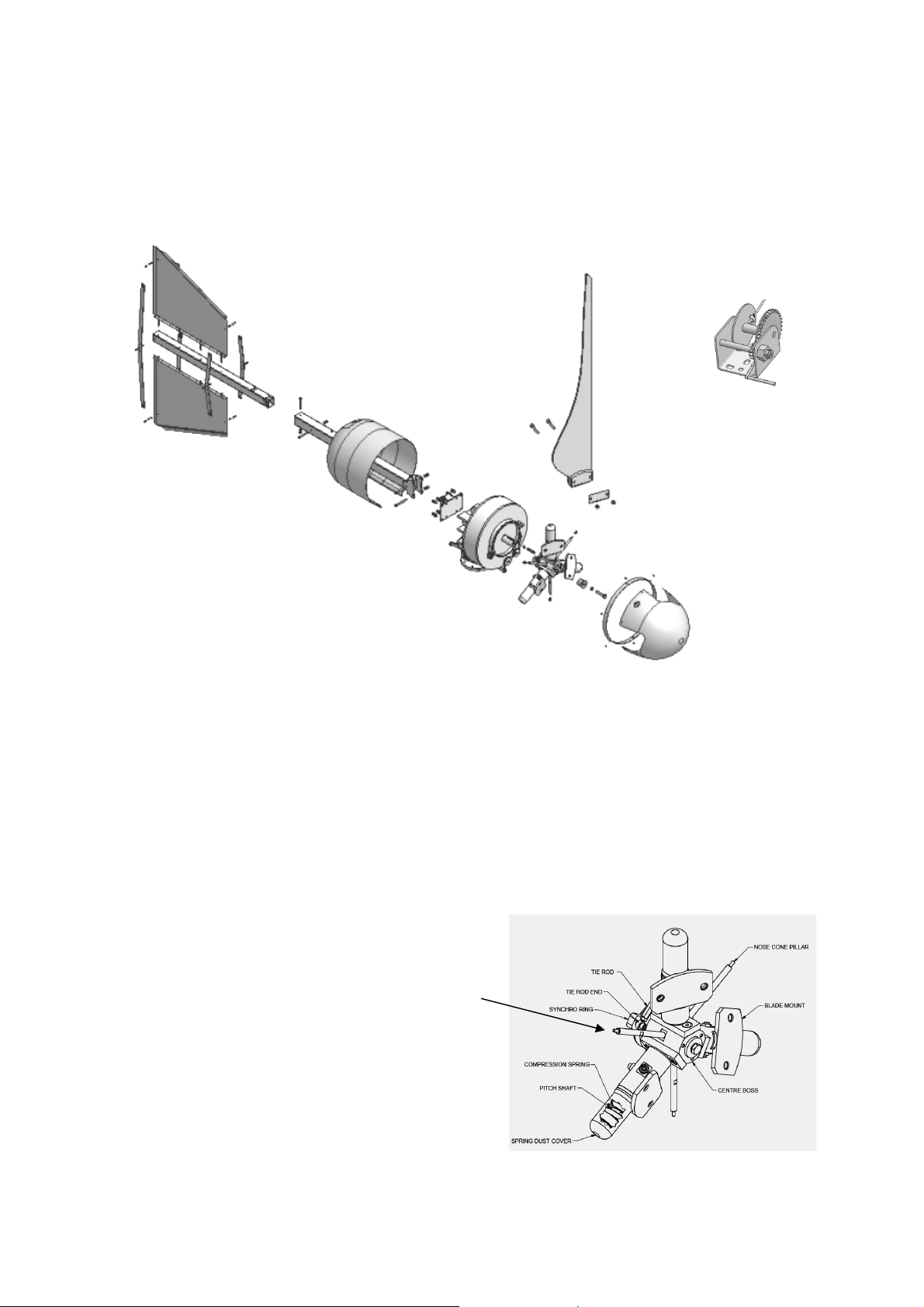

3.0 Unpacking the Wind Turbine

A Packing list is packed with the product. Ensure that all parts are

present. Notify your dealer of any shortages.

The e400nb is contained in one shipping crate. Check the crate for any

transit damage and then carefully remove the top of the crate to reveal

the contents. Check that everything is intact. Pay special attention to

the blade package. Carefully remove all the parts for safe storage. The

last item to be removed is the generator assembly, which is fully

secured to the packing case base.

IMPORTANT NOTE:

Do not lift or maneuver the generator

USING THE NOSE CONE PILLARS.

This will damage the pillars and cause

unbalance.

Document No. 1112M001 Revision 1.8 Date: June 2013

11

The bare generator and pitch control is factory assembled. This

complete sub-assembly weighs approximately 170kg (375lb).

Unpack and check the following parts. Inform your supplier of any

defects or shortages.

►Remove the blade package and store

safely.

►Remove the nacelle and nosecone with

ring and store safely.

►Remove the two boom sections.

►Remove the two tail plates.

►Remove any other accessories that were

shipped for you.

►Locate and remove the fastener pack

(assembly grease inc.).

►Remove the complete generator assembly.

Note: The fasteners are supplied in marked packs. Each pack

contains a set of fasteners for different parts of the turbine. The

enclosed grease is used on all nuts that are M10 or larger.

Note: One additional fastener pack contains one spare unit of every

fastener used on the turbine.

It may be useful to remove the sides of the packing case to access the

assembly. Remove the securing bolts and pads to free the generator

assembly. If possible, use lifting gear to remove the assembly from the

case. Otherwise have at least three other assistants to lift the

assembly from the case. Two lifting straps may be fitted to the

generator for lifting. Beware of the generator tipping forward and

causing injury to hands.

Beware not to damage the output cables below the generator. The

generator assembly is heavy at the front and will easily tip over. When

installed, the turbine is balanced on the yaw shaft.

Document No. 1112M001 Revision 1.8 Date: June 2013

12

4.0 Turbine Assembly and Installation

You will need the following hand tools.

►Trestle, table or other support to support the turbine that is safe for

250kg (550lbs).

►Plastic or rubber mallet, brass mallet/ hammer & 8mm pin punch.

►Full set of ring spanners from 10mm – 24mm.

►Metric socket wrench set.

►Set of standard screwdrivers (plain and Philips).

►Torque wrench suitable for torques of 0 – 180Nm (132ft lb).

►Electrical pliers, cutters & crimping tool.

Refer to the diagrams and follow the instructions to assemble the

complete wind turbine.

This manual assumes that the support tower is already installed and

lowered to ground level ready for turbine installation.

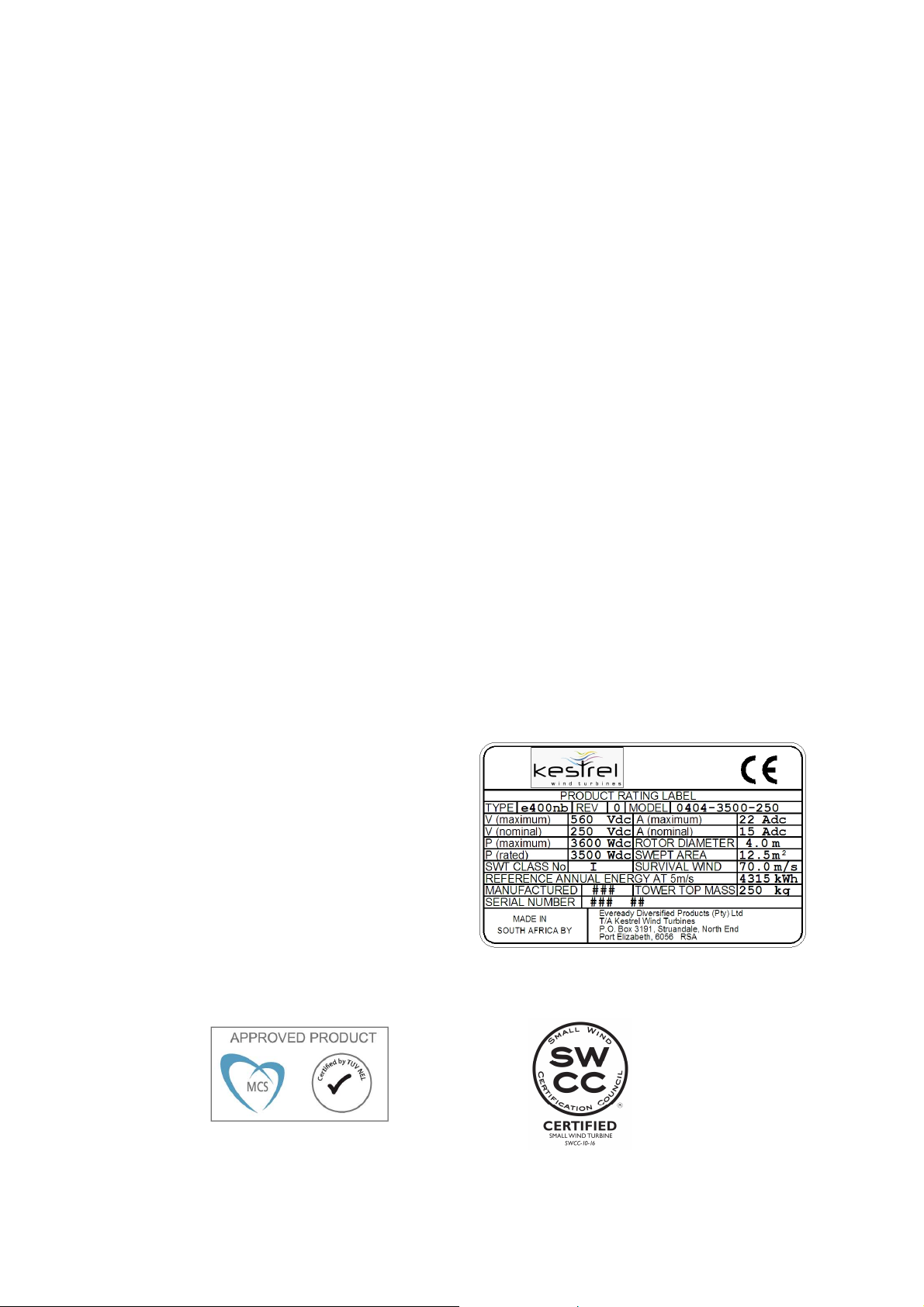

4.1 Identification Marking

The turbine is fitted with a rating

label similar to the image.

Note down your turbine serial

number for future reference!

Note: Only the e400nb 3.5kW 250V version has MCS or SWCC Labels

Document No. 1112M001 Revision 1.8 Date: June 2013

13

4.2 Tail Assembly

ASSEMBLE EXACTLY AS SHOWN IN THE DIAGRAM. FIT ALL THE

FASTENERS BEFORE TIGHTENING.

The tails will be in the middle line of the boom

You need the fastener pack marked “Tail Assembly” for this work.

►Top (2) and bottom (3) tail plate to boom (1) with four off stainless

bolt sets (6). Nuts and washers on the bottom.

►Two rear stiffeners (4) to boom (1) with one stainless bolt set (6).

►Two front stiffeners (5) to boom (1) with one stainless bolt set (6).

►Bolt all stiffeners (4) and (5) to top and bottom tail plates (2) and

(3) with four off bolt set (7).

►All tail fasteners are M6. Torque all fitted bolts to 10Nm (7.5ft lb).

PARTS LIST

ITEM

QTY

DESCRIPTION

1 1 Tail Boom Extension

2 1 Top Tail Plate

3 1 Bottom Tail Plate

4 2 Rear Stiffener

5 2 Front Stiffener

6 6 Hex Bolt M6 x 80 long, washer and nut

7 4 Hex Bolt M6 x 16, washer and nut

Document No. 1112M001 Revision 1.8 Date: June 2013

14

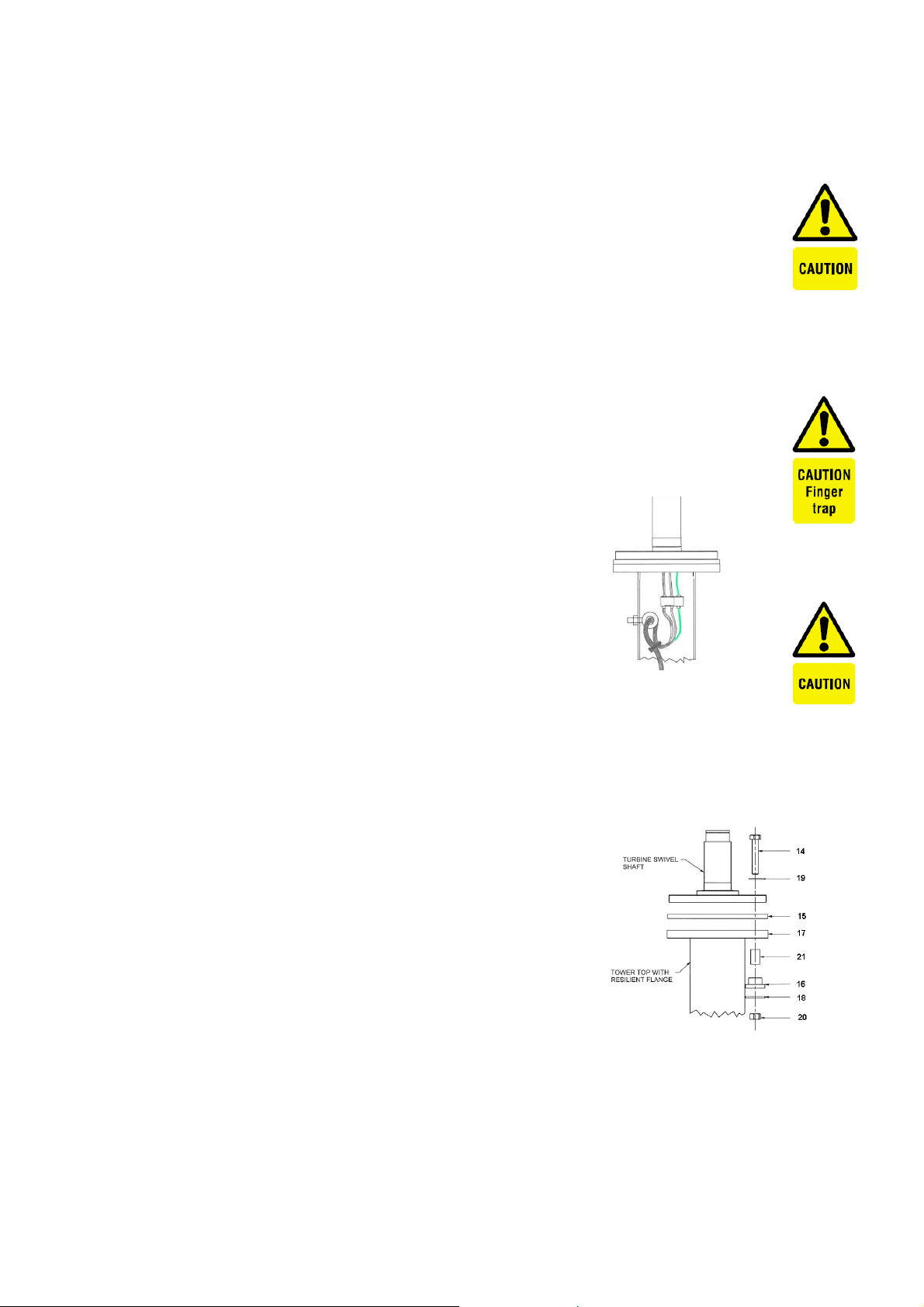

4.3 Generator to the Tower with damper kit

The steel flange (17) is fitted and welded to the tower top to adapt

non-Kestrel towers. Kestrel accepts no responsibility for any third

party tower design or application.

Each e400nb turbine is supplied with a standard rubber mounted

resilient kit. The purpose of the kit is to eliminate generator acoustical

noise being transferred down the length of the tower. The kit consists

of the following components:

PARTS LIST

ITEM

QTY

DESCRIPTION

14 8 Hex Bolt M16 x 90 H.T 8.8 ZP

15 1 Rubber flange

16 8 Rubber sleeve

17 1 Steel Flange (for welding to tower)

18 8 Fender washer

19 8 16mm standard washer

20 8 M16 Hex Nut

21 8 Compression sleeve

Take note that the damper kit includes a steel resilient flange (17)

that must be welded to third party towers and surface treated

before turbine installation.

The already installed tower is lowered to ground level before

mounting the generator. The power cable is also fitted.

Secure the tower cable at the top of the tower. The tower cable

must not hang or pull on the generator cables. Leave enough

tower cable to make the connection to the generator.

Do not “spin” the generator by hand. Short the red (+ve) and

black (-ve) generator output cables until wiring is to be done.

Document No. 1112M001 Revision 1.8 Date: June 2013

15

Avoid damage to any paint finishes by protecting with suitable

sundry material (HD foam, carpet tiles, cloth rags etc).

Make all power cables ends safe by insulation before installing

the generator.

►Support the lowered tower at a suitable height to receive the

generator. Be sure that the support can bear the total weight

after the generator is mounted. Allow for 250kg (550lbs).

►Support the generator at a similar height with the mounting

flange in line with the tower flange. Allow for 250kg (550lbs)

Observe polarity on electrical connections.

Connect +ve (red) and –ve (black) generator

output cables correctly. Reverse polarity will

damage the generator and any connected

equipment.

►Remove the short across the generator

wires. Make and complete the electrical

connection between the generator and the tower cable. The

250Vdc generator can output up to 550Vdc when unloaded.

The 48Vdc generator can deliver up to 80A.Use properly rated

connectors and ensure that this connection is good and secure and

completely watertight. The generator earth wire

is connected and extended down to the

ground earth for the tower.

►Fit the generator to the tower while storing the

cable and connector down the inside of the

tower. Fit the resilient kit in the order as

shown above. Ensure that no cable is

damaged during this operation

►. Torque the flange bolts to 120Nm (88ft lbs).

Document No. 1112M001 Revision 1.8 Date: June 2013

16

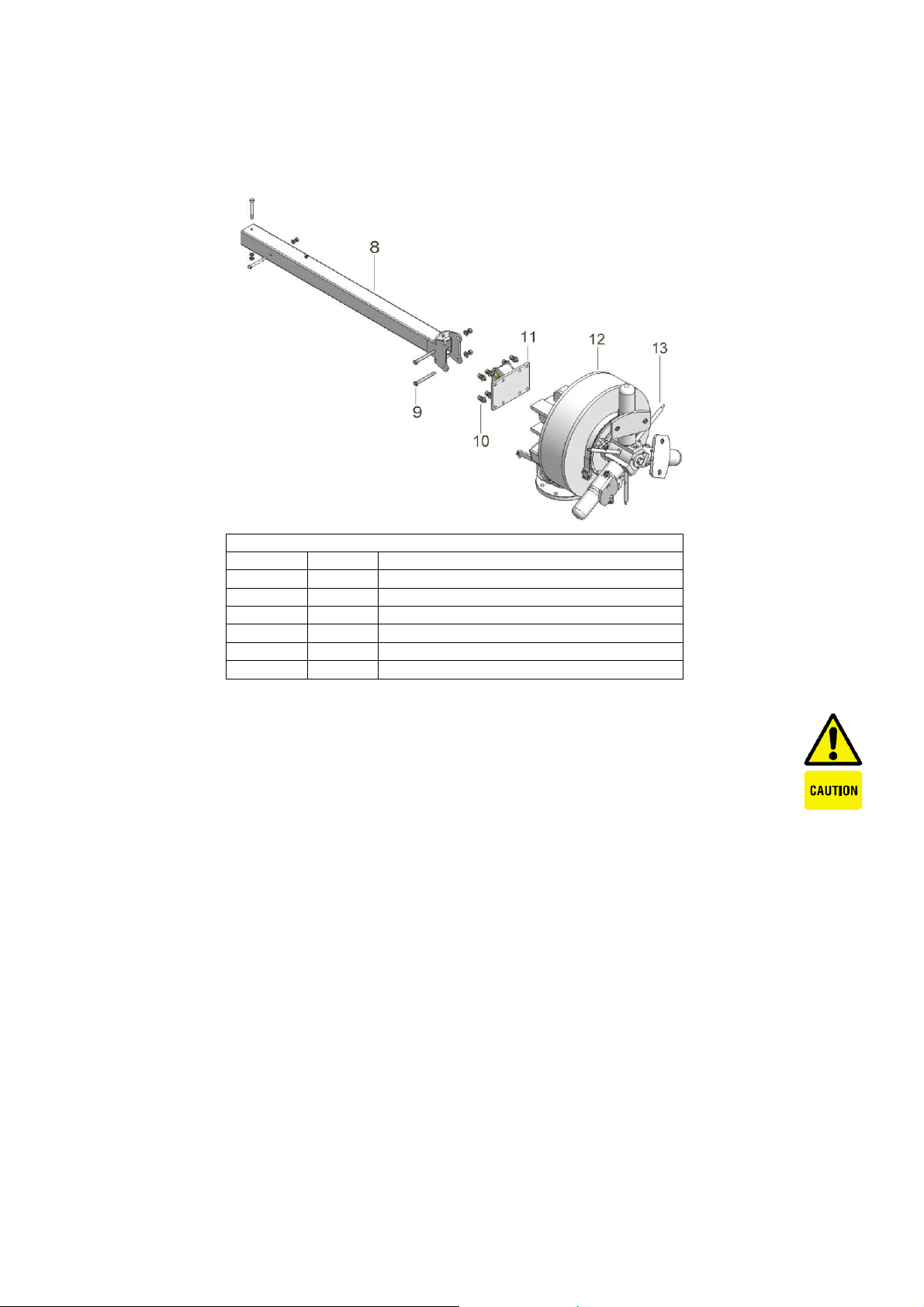

4.4 Tail Boom Weld Assembly to the Generator

PARTS LIST

ITEM

QTY

DESCRIPTION

8 1 Tail Boom Weld Assembly

9 2 M12 Tail Boom Bolt, washer and nut

10 8 M12 Allen cap bolts and washers

11 1 Tail Boom Flange

12 1 Generator

13 1 Pitch Control

THE GENERATOR SHOULD BE FITTED ON THE TOWER

BEFORE FITTING THE BOOM ASSEMBLY TO THE

GENERATOR.

FIT ALL THE FASTENERS BEFORE TIGHTENING AND

ASSEMBLE EXACTLY AS SHOWN IN THE DIAGRAM.

Take note of the “this way up” orientation indicators on each

component.

You need the fastener pack marked “Tail Boom weld Assembly” for

this work.

►Fit the flange weld assembly (11) with yellow bushes to the rear

end of the generator (12) using the 8 M12 bolt sets (10). Torque to

50Nm (36ft lb)

►Fit the boom (8) to the flange weld assembly (11) using the 2 M12

bolt sets (9). Torque to 50Nm (36ft lb).

►Store the remaining fasteners for later use.

Document No. 1112M001 Revision 1.8 Date: June 2013

17

The finished generator installation is shown below

4.5 Tail Assembly to the Boom

PARTS LIST

ITEM

QTY

DESCRIPTION

22 2 Hex Bolt M10 x 90, washer and nut

23 1 e400nb Nacelle

24 1 Complete tail assembly

You need the fastener pack marked “Tail Boom weld Assembly” for

this work.

Slide the nacelle over the boom weld assembly before fitting the

tail assembly !!

Document No. 1112M001 Revision 1.8 Date: June 2013

18

►Slide the tail assembly (24) to the boom as shown. Place a little

grease inside the two nut threads. Fit the two stainless M10 bolt

sets (22). Torque to 35Nm (25ft lb).

►Raise the tower and generator to a suitable height from the ground

for blade fitment.

Document No. 1112M001 Revision 1.8 Date: June 2013

19

4.6 Blades and Nosecone Stiffener Ring

You need the fastener pack marked “Blade Fasteners” for this work.

Fit the Nosecone stiffener ring (29) over the pitch control

before fitting the blades (25) and leave it loose in place !! The ring is

tapered and the smaller diameter must face forward to match the

shape of the nosecone. The ring is later bolted inside the nosecone.

Each blade is fitted with 2 steel positioning sleeves. The protruding

end of each sleeve must locate in the recessed hole on the blade

mount.

►Insert the two bolts (28) from the rear, through the blade mount and

push them through to the front.

►Offer the first blade (25) to the blade mount and slide the blade

over the two fixing bolts. The blade serial number must face

forward and be visible from the front.

►Fit the compression plate (27) on to the blade and protruding bolts.

PARTS LIST

ITEM

QTY

DESCRIPTION

25 3 Blade

26 6 Hex Nut M16 Nylock

27

3

Compression plate

28 6 Hex Bolt M16 x 100

29 1 Nose Cone stiffener ring

Document No. 1112M001 Revision 1.8 Date: June 2013

20

Stainless nuts can sieze on the bolt. Put a little waterproof

grease inside the stainless nut before fitting.

►Fit the two M16 nylock nuts (26). Tighten to 90Nm (65ft lb)

►Repeat the fitment for the two other blades.

Note that no balancing procedure of the turbine blades is required.

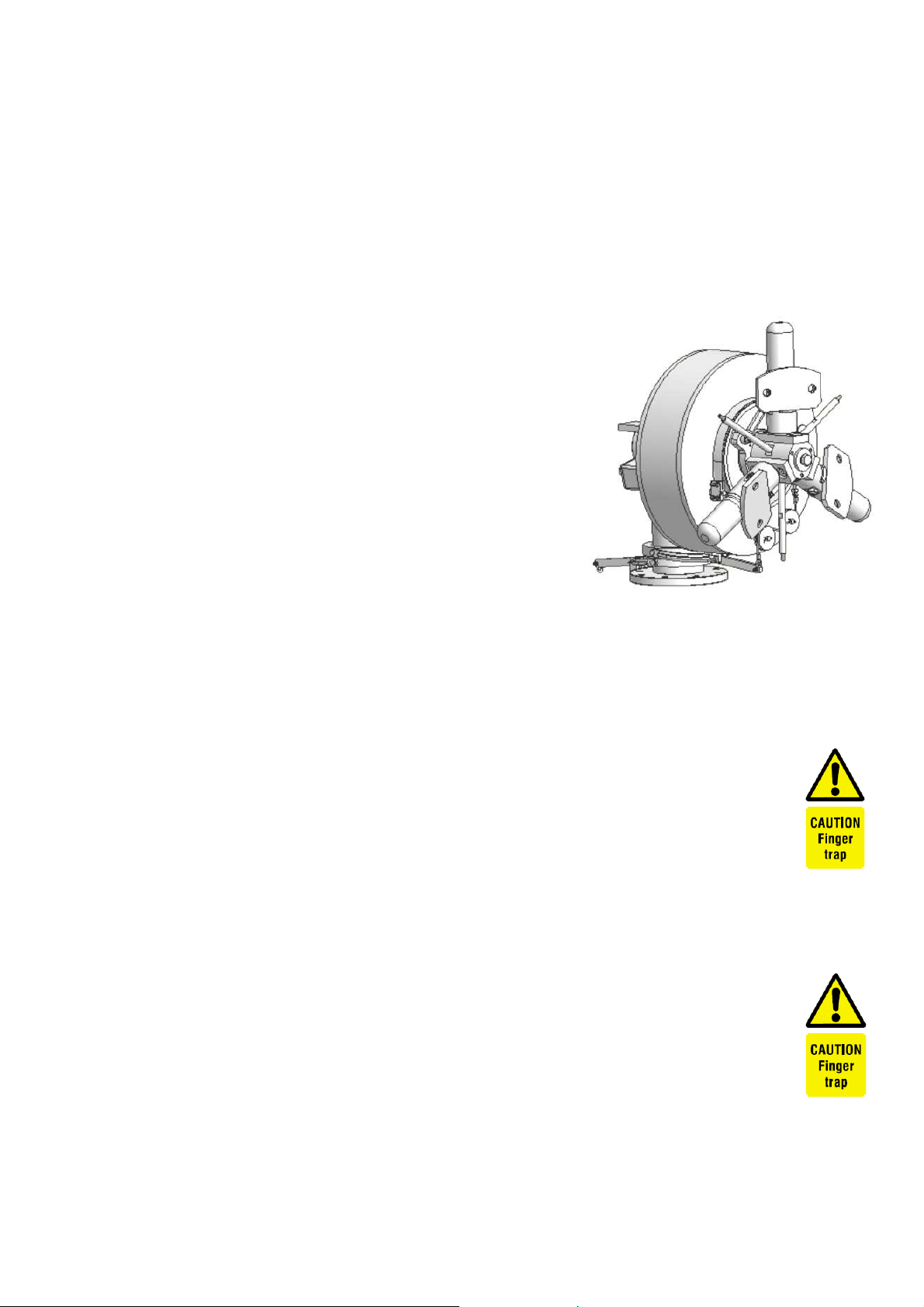

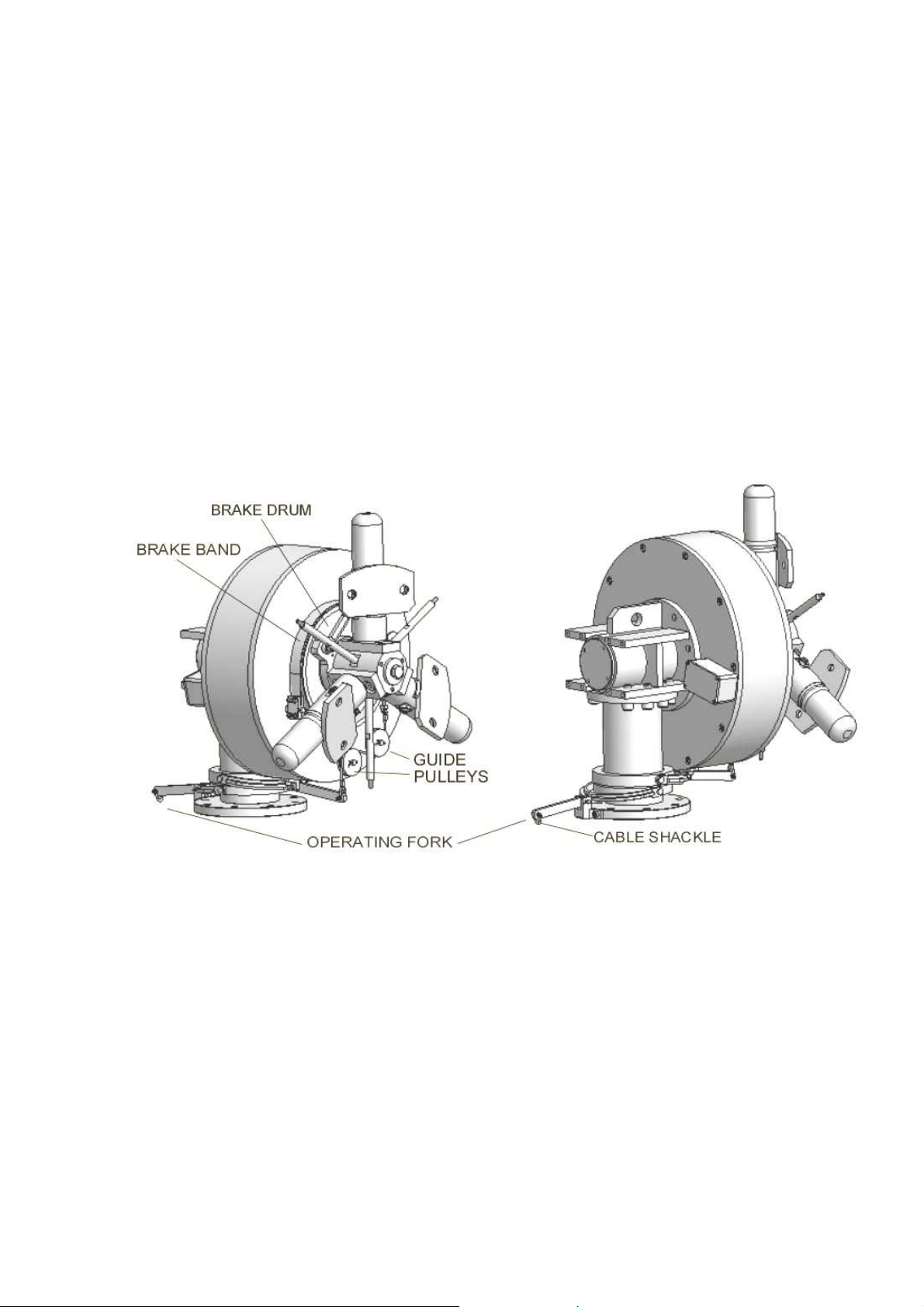

4.7 Mechanical Brake Assembly (e400nb only)

The Kestrel e400nb is fitted with a mechanical band brake. This brake

is activated by a manual cable winch and a drop cable that are shipped

with the turbine. A “T” bar is also included that is inserted into the tower

to operate the winch.

The brake mechanism is a factory fitted assembly and is operated by

one singular drop cable. No adjustment is required to the brake

mechanism on the generator assembly.

This manual suits for next models

3

Table of contents

Popular Wind Turbine manuals by other brands

Superwind

Superwind 1250 Operation manual

Tumo-Int

Tumo-Int 3000W 5 Blades Wind Turbine user manual

Bergey

Bergey 24 VDC B owner's manual

Leading Edge

Leading Edge LE-v50 Installation & operation guide

ista Breeze

ista Breeze i-1500 Windsafe Translation of the original instructions

Enair

Enair E70PRO user manual

Guang Mang

Guang Mang EW200 user manual

Primus Wind Power

Primus Wind Power Air X owner's manual

Missouri Wind and Solar

Missouri Wind and Solar Freedom manual

Automaxx

Automaxx 400 Watt Turbine user manual

Spreco

Spreco SHARKY User and installation guide

Nature's Generator

Nature's Generator Powerhouse Wind Turbine user manual