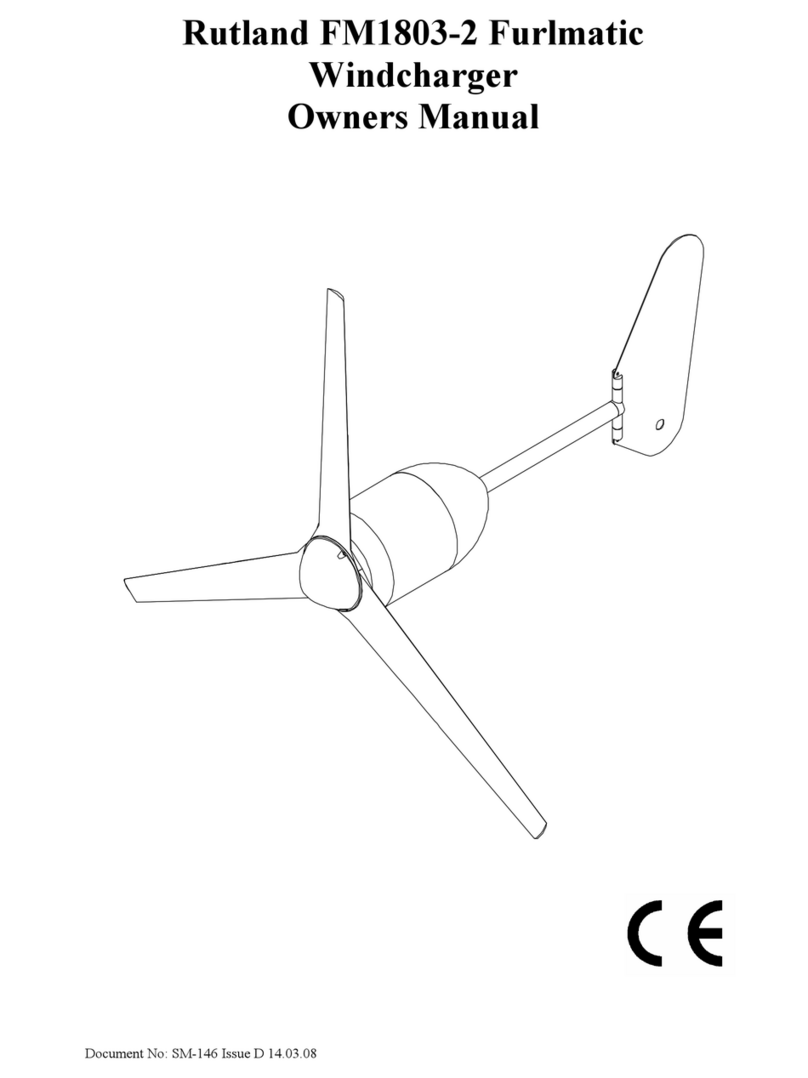

Rutland FM1803-2 Installation& Operation

Document No: SM-146 IssueG 01.11.20 MarlecEngineeringCoLtd

3

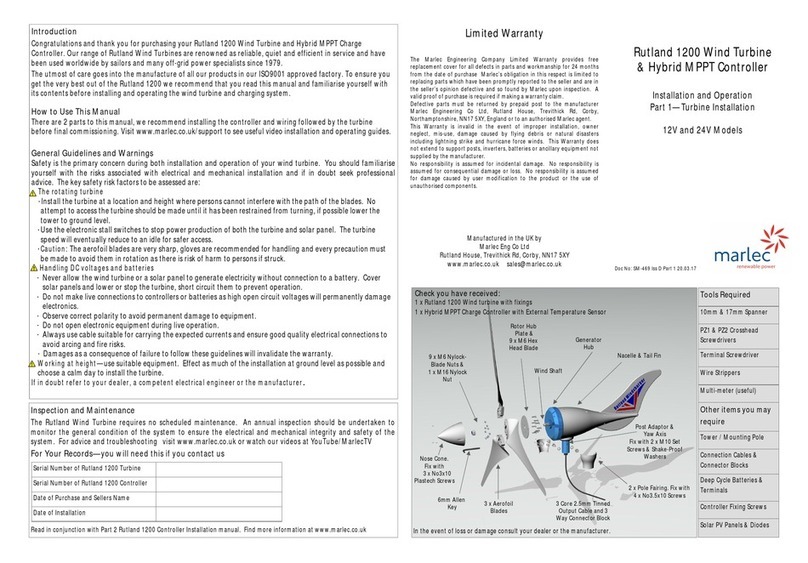

INTRODUCTION

Congratulations and thank you for purchasing your Rutland 1803-2 Wind Turbine with MPC2

Charge Controller. Our range of Rutland Wind Turbines are renowned for reliable, quiet and

efficient service and have been used worldwide by sailors and off-grid power specialists since

1978. The utmost of care goes into the manufacture of all our products in our ISO9001

approved UK factory.

It is essential that the turbine and controller are installed in accordance with these instructions

and failure to comply invalidates the warranty. To ensure you get the very best out of the

Rutland 1803-2 please read and understand this manual before commencing installation and

operating the wind turbine and charging system.

The FM1803-2 Furlmatic turbine is designed to provide a direct current (DC) power supply via a

battery bank for low voltage equipment, inverters etc in professional and off grid applications.

It is essential to the turbine’s operation that it is installed on a stable vertical pole on land to

ensure that the furling mechanism efficacy is maintained in service.

Note: The selected turbine must matchthe battery voltage of the system.

General Guidelines and Warnings

Safety is the primary concern during both installation and operation of your wind turbine. You

should familiarise yourself with the risks associated with electrical and mechanical installation

and if in doubt seek professional advice. The keysafetyrisk factors to be assessed are:

The rotating turbine – Risk of injury to persons

•Install the turbine at a location and height where persons cannot interferewith the path of

the blades. No attempt to access theturbine should be made until it hasbeen restrained

from turning, if possiblelower the tower to ground level.

•Never allow the turbine to run disconnected from the controller and batteries. Usethe

RUN/STOP switch if fitted or built in stall switch to stop power production of the turbine. The

turbine speed will eventually reduce to an idle for safer access to theturbine or batteries.

•Do not allow the turbine to run with damaged blades, replacement partsare available at

www.marlec.co.uk

Handling DC voltages and batteries – Risk of electric shock

•Never make live connections to the controller. Eg: High open circuit voltagesgenerated by a

rotating turbine will permanently damage electronics. Lower orstop the turbine to prevent

operation. Similarly, batterycables must be wiredinto the controller without being

connected to the battery.

•Observe correct polarity to avoid permanent damage to equipment.

•Do not open electronic equipment duringlive operation.

•Alwaysuse cable suitable forcarrying the expected currents and ensure good quality

electrical connectionsto avoid arcing and fire risks. The use of smaller cables will cause

system overload and damage the generator. See Table 1.

•Damages asa consequence of failure to follow these guidelines will invalidatethe warranty.