09820-52-00 MOBEX F- BIA W3 3

Contents

Contents.................................................................................................................................3

1.

General safety notes.......................................................................................................4

2.

Preventing mechanical hazards.....................................................................................6

3.

Preventing electrical hazards.........................................................................................6

4.

Preventing dust hazards.................................................................................................6

5.

Intended use ....................................................................................................................7

6.

Technical data and description......................................................................................8

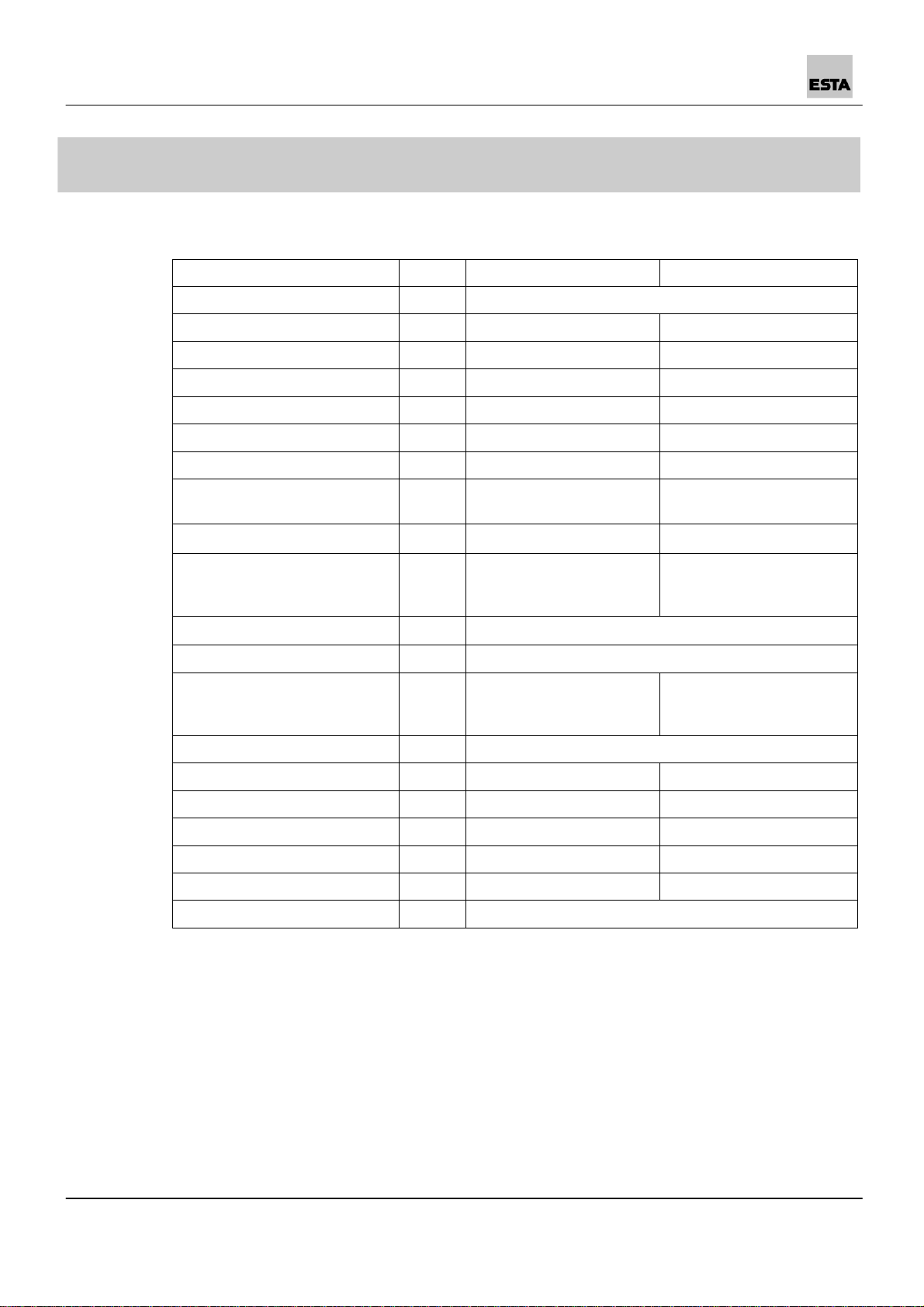

6.1 Technical data.............................................................................................................8

6.2 Functional description..................................................................................................9

7.

Delivery and commissioning........................................................................................10

7.1 Delivery and transport ...............................................................................................10

7.2 Commissioning..........................................................................................................10

8.

Maintenance and troubleshooting...............................................................................13

8.1 Maintenance instructions...........................................................................................13

8.2 Inspection and maintenance intervals .......................................................................14

8.3 Troubleshooting.........................................................................................................15

9.

Monitoring the minimum airflow volume.....................................................................17

10.

Cleaning.........................................................................................................................17

10.1 Jet filter cleaning......................................................................................................17

10.2 Replacing the filter...................................................................................................18

10.3 Cleaning the demisting mat.....................................................................................20

11.

Disposal .........................................................................................................................21

11.1 Disposing of collected dust materials ......................................................................21

11.2 Disposing of the welding fume exhaust device........................................................21

12.

Optional equipment.......................................................................................................22

13.

Device diagram..............................................................................................................23

14.

Declaration of conformity.............................................................................................24

Notes.....................................................................................................................................25

Notes.....................................................................................................................................26

Notes.....................................................................................................................................27