2

1ˊProduct Description

POWER STICK 200K DC Inverter Arc Welder is designed to be used with the advanced IGBT and rapid recovery

diode as its main control and transfer components and assisted with the specially developed control circuit, it has

uniformly regulated welding current which enable the welding power source to achieve the adaptability to the

excellent welding procedures. It largely enhanced the welder’s protection abilities to ensure safety welding

operation. It is quite popular in welding the materials like low-carbon steel, stainless steel, high-intension steel,

alloy steel and cast iron.

The highlighted characteristics of POWER STICK 200K DC Inverter Arc Welder:

1) Featured with small volume and light weight, it widely used in upholstering field, repairing

field and fieldwork.

2) Excellent arc-piloting feature and melt & drip transition feature.

3) By various sound protection performance, it can keep the welding machine from overheating,

over voltage, under voltage, over current and so on. When the main supply compensation

is not less than ±15%, it can increase while the welding current reduces. Because of its

anti jamming high performance, the control system can respond to the power source, work

piece, electrode and operational changes with less than 1m/s speed in order to keep steady

output of the current.

4)Speical arc character , suitable to all welding processes

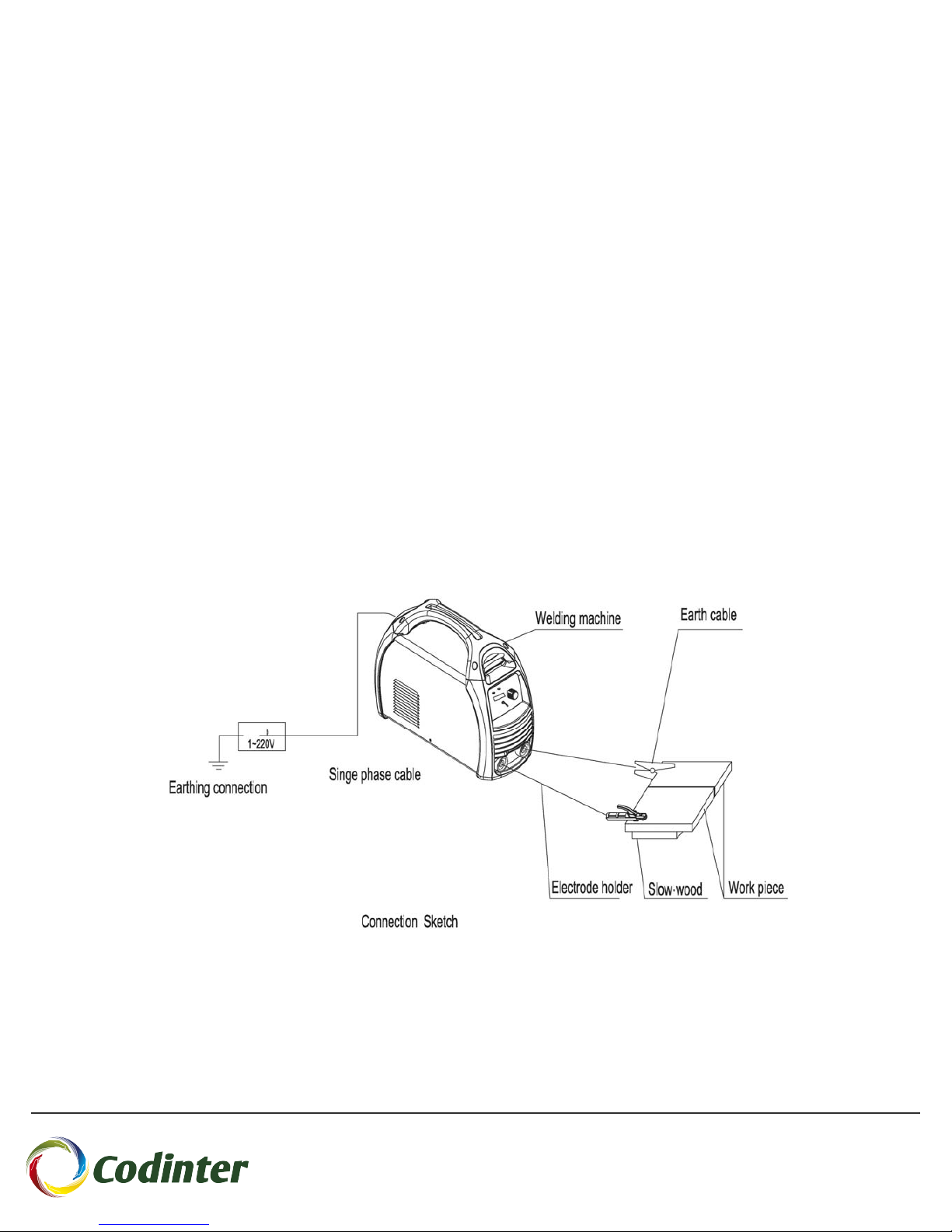

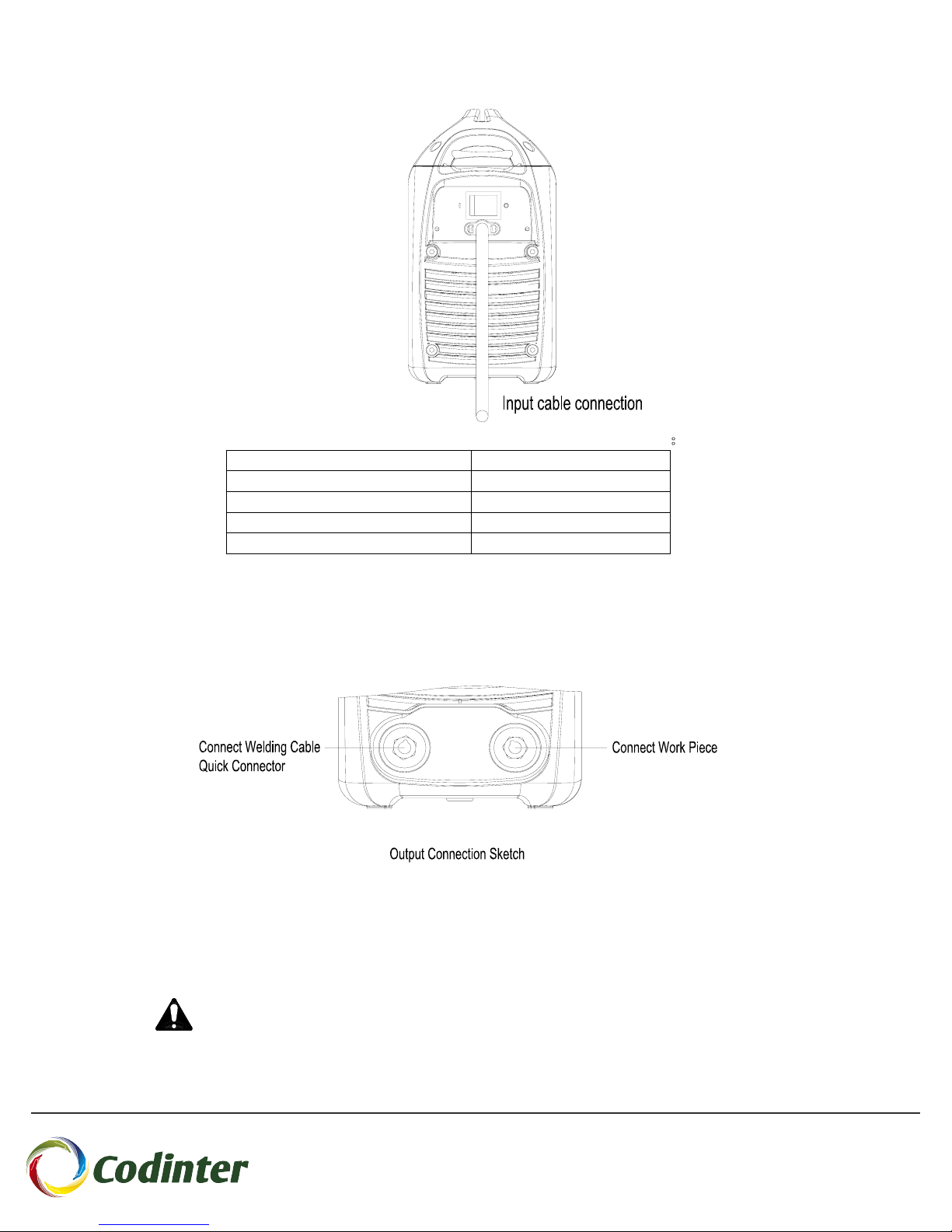

5) Easy connection. To conduct external connection, POWER STICK 200K use all the

connectors, which can facilitate quick and safe connection with simple but reliable performance.

No notification will be given if the manual’s content or welder’s function change.

2ˊSafety Operation

Operator’s Self Protection

* Please always follow the rules that conform to safety and hygiene. Wear protective garments to

avoid injuries to eyes and skins.

* Use the welding helmet to cover your head while working with the welding machine. Only by

viewing through the filter lens on the welding helmet can you watch your operation.

* Under no circumstance can you allow any part of your body to touch the welder’s output

bipolarity (the handle of electrode holder and work piece.).

Attention

* POWER STICK 200K DC Inverter Arc Welder is electronic products whose spare parts are very tender, do not

change or adjust with a rush otherwise the switch will be damaged.

* Check the connection to see if it is well connected, whether the earth (ground) connection is reliable, etc.

* Fumes and gases produced when welding are hazardous to health. Make sure to work in places where there are

exhaust or ventilation facilities to keep fumes or emissions away from the breathing zone.

* Please remember to keep arc rays away from the other nearby people when welding. This is only due to the

interference from arc rays.

* Never allow anybody else other than the operator himself to dislocate or modulate the welding machine.

* Never allow the people with the cardiac pacemaker or any other things which are susceptible to the

electromagnetism to get close to the welding machine, which has interference with the pacemaker’s normal function.

* The welder can not be used for pipeline ice-out.

* Over-load is forbidden. Please noted the rated continuous loading factor

Cali

Teléfono: (2) 3351214

Carrera 31 A # 10 A - 129

mercadeo@codinter.com

Bogotá

Teléfono: (1) 7433131

Calle 18 # 25 - 41

mercadeo@codinter.com

Medellín

Teléfono: (4) 6053131

Calle 42 B # 64 - 08 Local 21

mercadeo@codinter.com

codinter.com