4

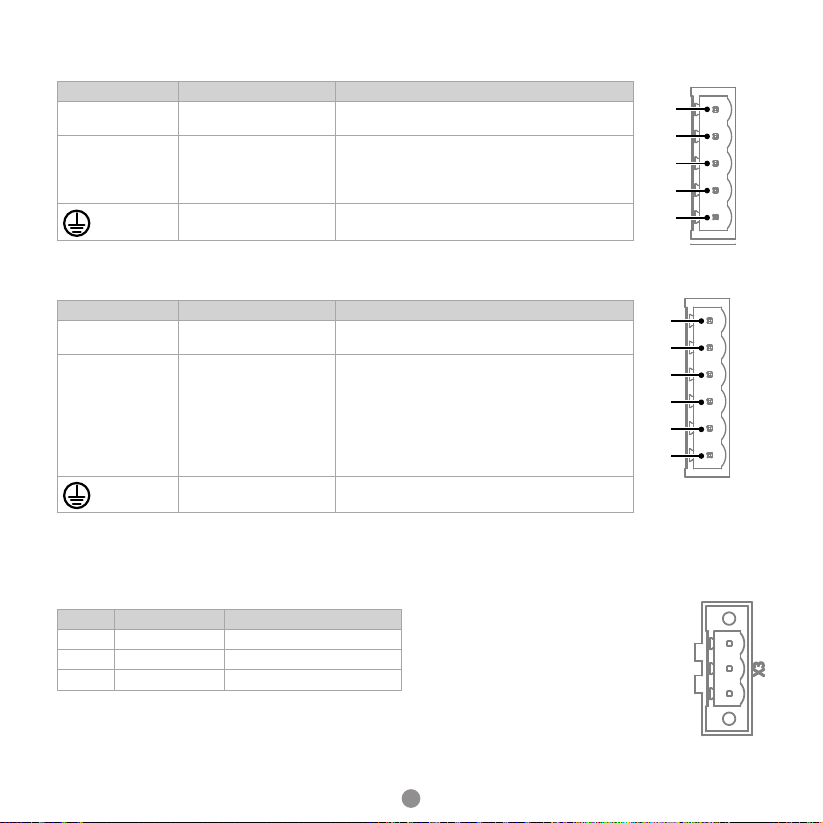

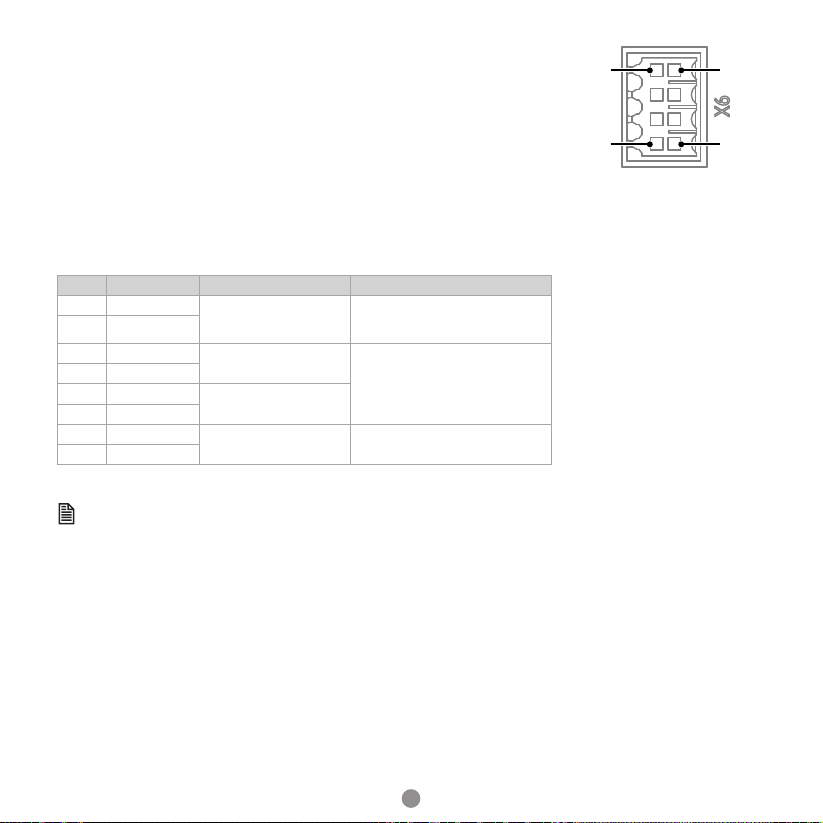

POWER SUPPLY CONNECTORS (X1, X2)

Symbols Name Specications and Reference

L1C, L 2C Control power supply

terminals

Single-phase, 200V ac to 240V ac, -15% to +10%,

50Hz or 60Hz

B1, B2, B3 Regenerative Resistor

terminal

There is a factory t short between B2 and B3.

When the busbar capacitance is insucient,

remove the short wiring, and connect an external

regenerative resistor between B1 and B2.

Ground terminal Always connect this terminal to prevent electric

shock.

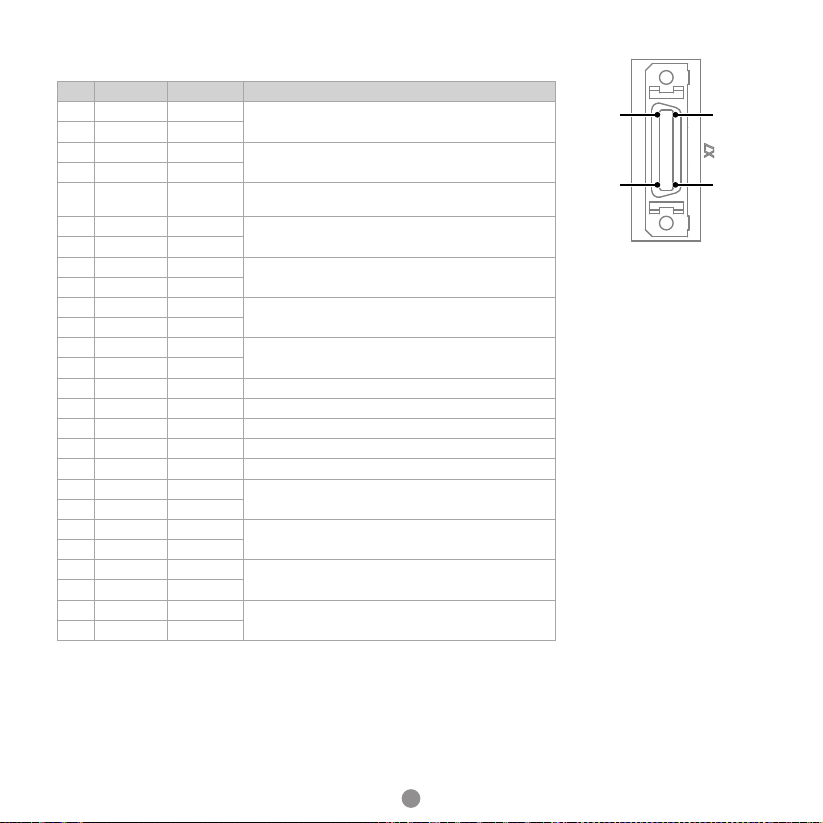

POWER SUPPLY CONNECTORS (X2)

Symbols Name Specications and Reference

L1, L2, L3 Main circuit power supply

input terminals

Three-phase, 200V ac to 240 V ac, -15% to +10%,

50Hz or 60Hz

P1, P2, N DC terminals

There is a factory t short between P1 and P2.

For using a DC reactor, remove the short wiring,

and connect a DC reactor between P1 and P2.

For using a DC power supply, connects P2 to the

positive pole, and connects N to negative pole.

For the common DC bus, connect all P2 of Drive to

the positive pole, and N to the negative pole.

Ground terminal Always connect this terminal to prevent electric

shock.

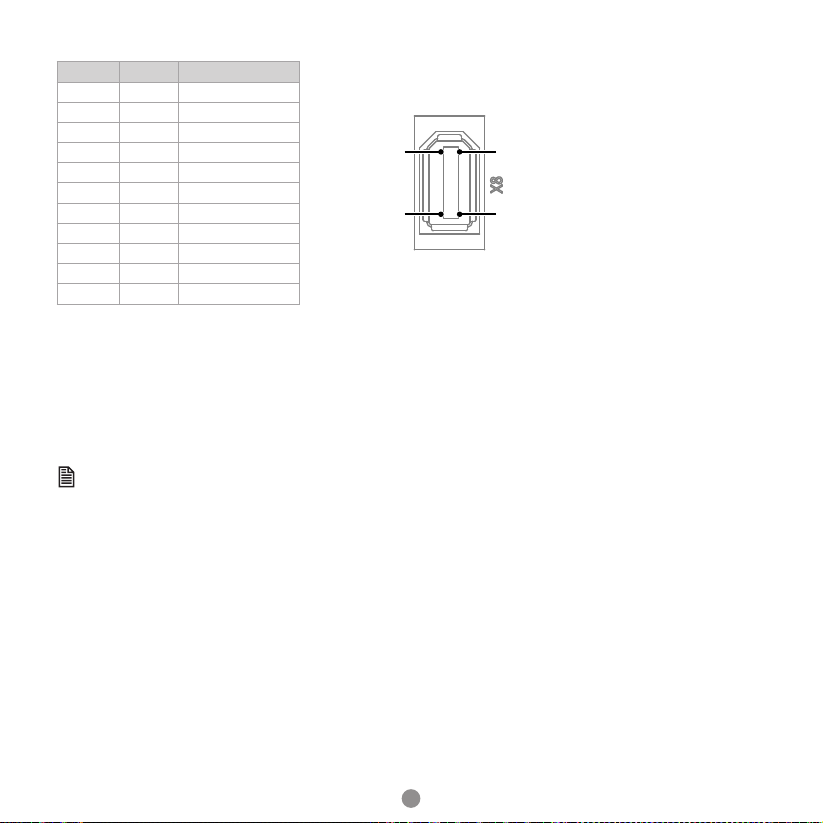

MOTOR POWER CONNECTOR (X3)

Pin Symbol Colour

1 U Brown

2 V Gray

3 W Black

X1

X2

L1C

L2C

B1

B2

B3

L1

L2

L3

P1

P2

N

X1

X2

L1C

L2C

B1

B2

B3

L1

L2

L3

P1

P2

N