Table of Contents

Table of Contents ................................................................................................................................ 2

Chapter 1 Overview ............................................................................................................................ 4

1.1 Introduction .......................................................................................................................... 4

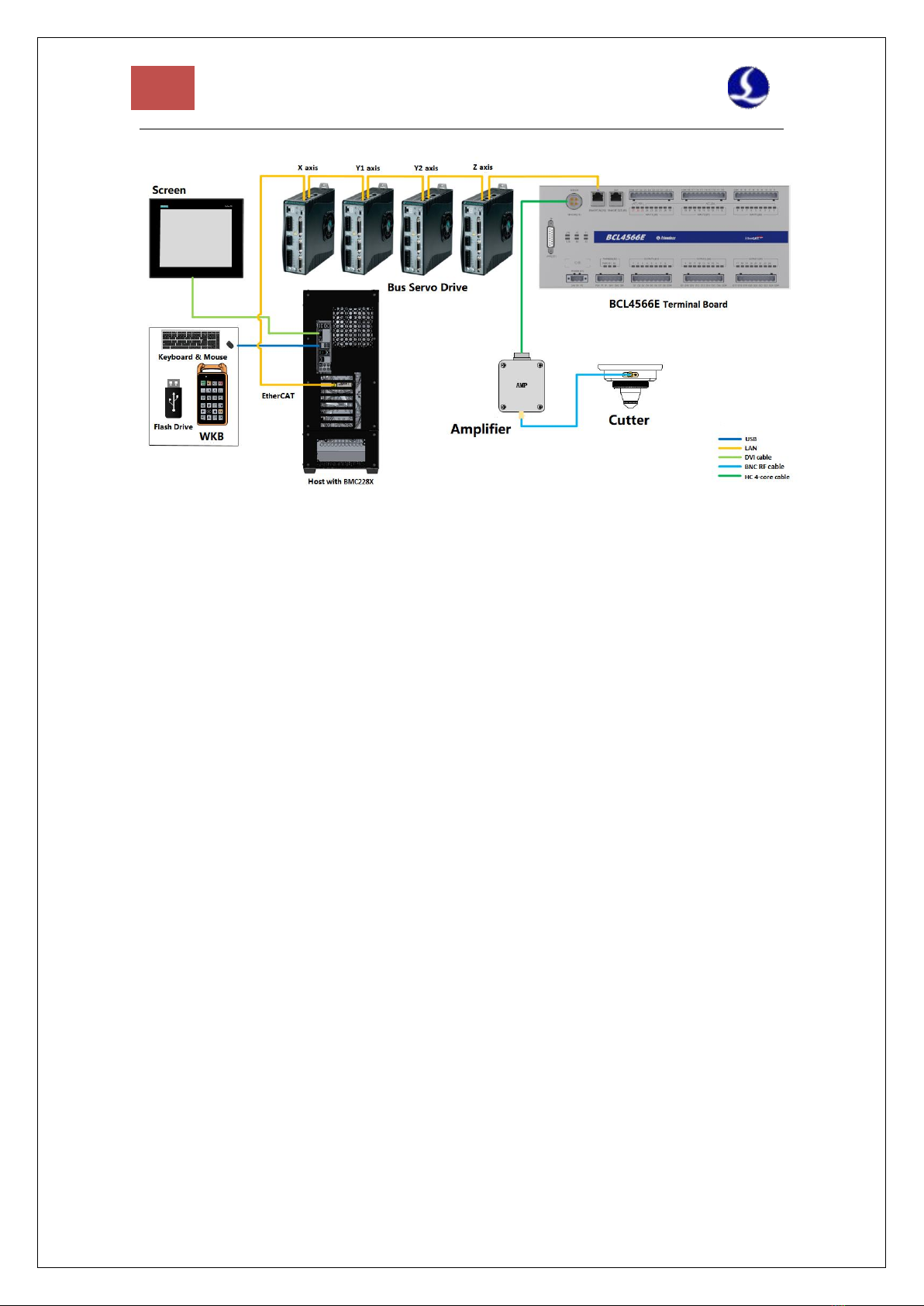

1.2 System Diagram .................................................................................................................... 4

1.3 Product Details ......................................................................................................................6

Chapter 2 Wiring Instruction .............................................................................................................. 8

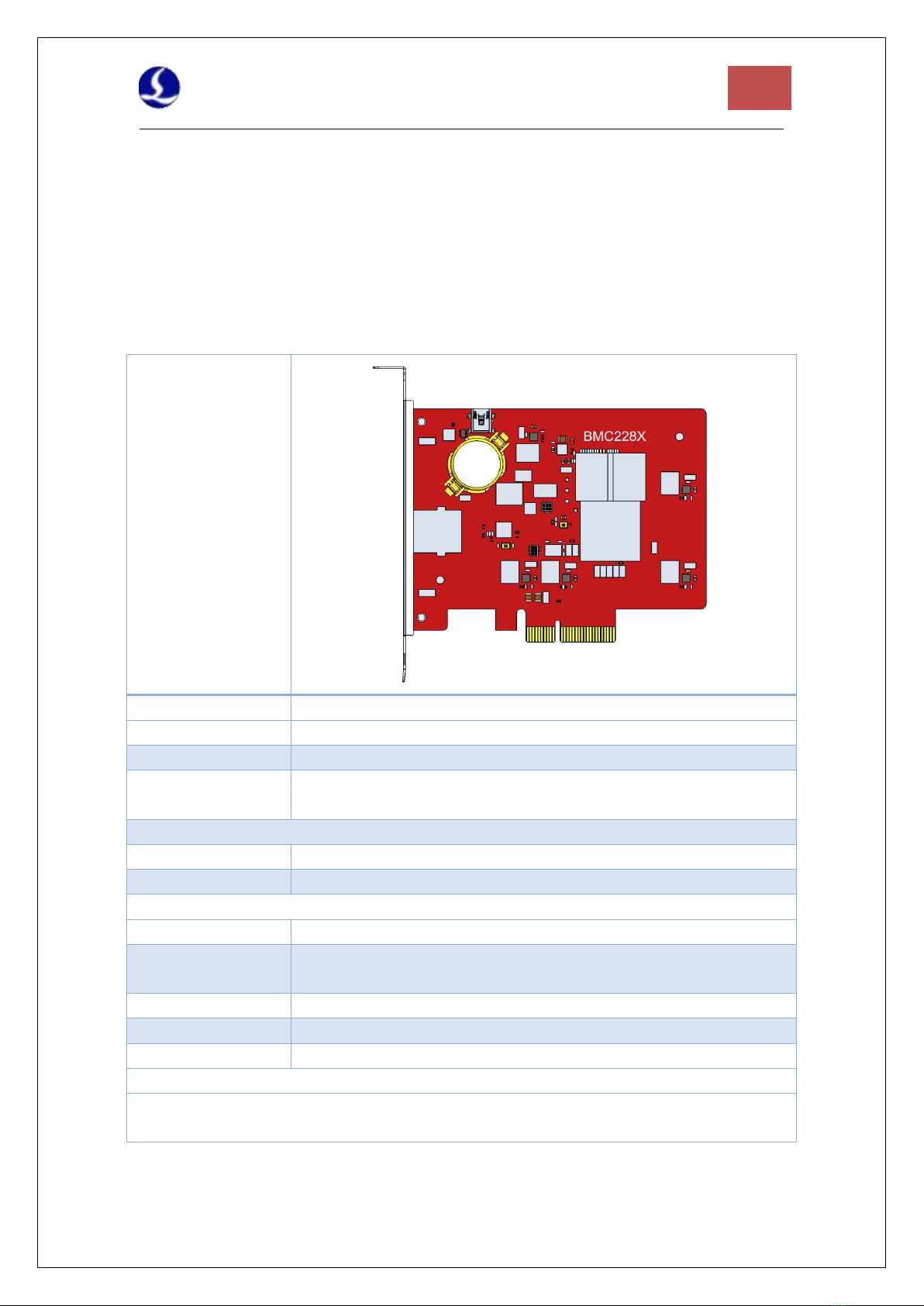

2.1 BMC228X Installation ............................................................................................................8

2.1.1 Dimension Diagram ................................................................................................... 9

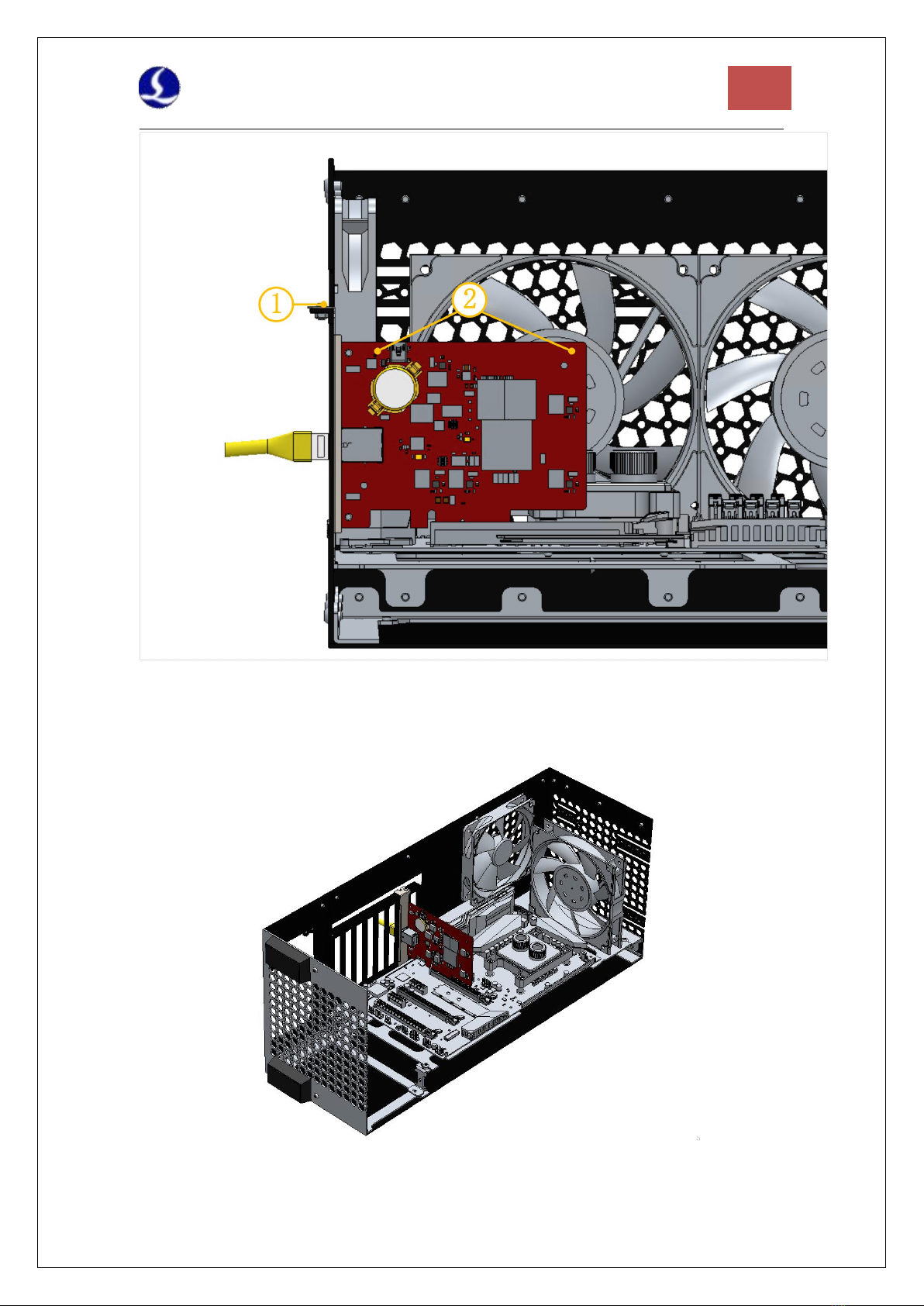

2.1.2 Installation Diagram ...................................................................................................9

2.1.3 Ethernet Terminal .................................................................................................... 11

2.1.4 PCIE Socket ...............................................................................................................12

2.2 HPL2720E Wiring ................................................................................................................ 13

2.2.1 Interface Layout ....................................................................................................... 14

2.2.2 J01 EtherCAT Input Terminal ....................................................................................14

2.2.3 J02 EtherCAT Output Terminal .................................................................................14

2.2.4 J03 Power Input Terminal ........................................................................................ 14

2.2.5 J04 PWM Output Terminal ...................................................................................... 15

2.2.6 J05 DAOutput Terminal ............................................................................................16

2.2.7 J06 Common Output Interface ................................................................................ 16

2.2.8 J07 Common Input Interface ................................................................................... 17

2.3 BCL4566E Wiring .................................................................................................................19

2.3.1 Interface Layout ....................................................................................................... 20

2.3.2 J01 Power Supply ..................................................................................................20

2.3.3 J02PWM/DA Terminals .........................................................................................21

2.3.4 J03/J04/J05 Output Terminal ................................................................................22

2.3.5 J06/J07/J08 Input Terminal ...................................................................................22

2.3.6 J09/J10 Network ................................................................................................... 24

2.3.7 J11 Sensor ............................................................................................................. 25

2.3.8 J12DB15 Servo Axis Interface ............................................................................... 25

2.4 Cutter Wiring .......................................................................................................................29

2.4.1 ProCutter Wiring ......................................................................................................29

2.5 Laser Wiring ........................................................................................................................ 30

2.5.1 IPG_ YLS Germany ....................................................................................................30

2.5.2 IPG_ YLS American ...................................................................................................31

2.5.3 Raycus ...................................................................................................................... 32

2.5.4 Trumpf ......................................................................................................................33

Chapter 3 Installation ........................................................................................................................34

3.1 Installation Steps .................................................................................................................34

3.1.1 Step 1. Install BMC228X Control Card ..................................................................... 34

3.1.2 Step 2. Install MC228X Driver ..................................................................................34