ProFire PF3100 Series Technical manual

1

www.profireenergy.com | 1.855.PRO.FIRE

PF3100

ION PILOT CARD

3

www.profireenergy.com | 1.855.PRO.FIRE

INTRODUCTION ..........................................................................................4

1.1 Functional Description.............................................................................4

1.2 System Requirements .............................................................................4

HARDWARE..............................................................................................6

2.1 Card Specifications ...............................................................................6

2.2 Card Diagram ....................................................................................6

2.3 Terminal Specifications ............................................................................7

2.4 Terminal Descriptions .............................................................................7

2.5 Enclosure Specifications ..........................................................................8

2.6 Enclosure Diagram................................................................................9

2.7 Enclosure Ports...................................................................................9

CONTROLS AND DIAGNOSTICS .............................................................................10

3.1 Ports ...........................................................................................10

3.2 LEDs and Buttons................................................................................10

3.3 Important Safety Information ...................................................................... 11

APPENDIX A: NETWORK TERMINOLOGY .....................................................................12

TABLE OF CONTENTS

PF3100 ION PILOT CARD INFORMATION GUIDE

All content is subject to copyright and may not be reproduced in any form without the express written consent of the author. ©2016 Profire Energy. All rights reserved.

All the information described in this document is “as is,” without warranty of any kind and is published in good faith and for general information purposes only. Profire does not

make any guarantees about the completeness, reliability and accuracy of this information. Profire may make changes in this manual or in the product(s) described in this manual

at any time.

Contact your Profire Sales representative for questions, comments or further assistance.

DOC-001008-A

4

INTRODUCTION

1.1 | Functional Description

The PF3100 Ion Pilot card is used to generate a spark to ignite a pilot burner and to detect the flame of

both a pilot and main burner. This card is powered through the PFRN network via a Controller class or

Network class card (typically a BMS Controller card or a Network Switch Card).

1.2 | System Requirements

Specific system requirements will vary according to which Controller class card is connected to the Ion

Pilot card. For additional information, refer to the Hardware Guide corresponding to the Controller type

card (e.g., BMS Controller card) specific to your application.

IGNITION COIL WIRING

The Ion Pilot card is usually sold in a Class I, Div 1 / Zone 1 explosion proof enclosure (EPX) which also

includes an ignition coil. This allows the ignition and flame monitoring to be located close to the associat-

ed burner which reduces the need for long ignition wires.

Ignition

Coil Straight

Silicone

Boot Ferrule

EGND

+

Ion

{

Coil

+

+

Main Ion

Internal Ignition Coil

Ignition

Rod

10

Main Flame

Detect Rod

Pilot Ignition and

Flame Detect Rod

Straight

Silicone

Boot

Ferrule

Ignition

Coil

Straight

Silicone

Boot Ferrule

EGND

+

Ion

{

Coil

+

Pilot Flame Detect Rod

Pilot Ignition Rod

Main Flame

Detect Rod

Straight

Silicone

Boot

Ferrule

Straight

Silicone

Boot

Ferrule

8

9

10

6

10

7

5

8

9

6

7

5

Dual Rod Pilot

Single Rod Pilot

+

Main Ion

Red

White

Black

Ignition Wire

Ion +

Coil +

Coil -

6

9

8

WIRE REQUIREMENTS

WIRE LOCATION CONNECTION DESCRIPTION WIRE TYPE AND MIN GAUGE MAX LENGTH

5 Board to Main Flame Detect

Rod

7 mm ignition wire Each wire should be limited to

25 ft maximum

10 Coil to Pilot Ignition Rod 7 mm ignition wire

7 Board to Burner 14 AWG

6 Board to Pilot Flame Detect

(Dual Rod Pilot only)

7 mm ignition wire

5

SINGLE VS DUAL ROD PILOT WIRING

Use the single rod pilot configuration when using a single rod for flame detection and pilot ignition. Use

the dual rod configuration when using two separate rods for pilot ignition and flame detection.

Ignition

Coil Straight

Silicone

Boot Ferrule

EGND

+

Ion

{

Coil

+

+

Main Ion

Internal Ignition Coil

Ignition

Rod

10

Main Flame

Detect Rod

Pilot Ignition and

Flame Detect Rod

Straight

Silicone

Boot

Ferrule

Ignition

Coil

Straight

Silicone

Boot Ferrule

EGND

+

Ion

{

Coil

+

Pilot Flame Detect Rod

Pilot Ignition Rod

Main Flame

Detect Rod

Straight

Silicone

Boot

Ferrule

Straight

Silicone

Boot

Ferrule

8

9

10

6

10

7

5

8

9

6

7

5

Dual Rod Pilot

Single Rod Pilot

+

Main Ion

Red

White

Black

Ignition Wire

Ion +

Coil +

Coil -

6

9

8

6

HARDWARE

2.1 | Card Specifications

TYPE SPECIFICATIONS

Model Number PF3102-00

PFRN Class IO

PFRN Power Power Consumer

PFRN Ports 1 PFRN IO Network Port

Voltage Input Powered via PFRN

Inputs Power: EGND

LEL In, Main Ion, Pilot Ion

Outputs Pilot Valve, Coil

2.2 | Card Diagram

7

2.3 | Terminal Specifications

This table provides connection details and a brief description of each terminal.

TERMINAL EXPECTED CONNECTIONS INPUT/OUTPUT SAFETY RATED

Main Ion + Connect to main flame rod. Flame Ionization Input Ye s

Ion + For a Dual Rod configuration,

connect to the pilot flame rod.

For a Single Rod configuration,

connect to the Ion+ Terminal

of the coil (red wire).

Flame Ionization Input Ye s

Coil + Connect to the primary

winding of the ignition coil.

(white wire)

Coil Drive Output Ye s

Coil - Connect to the primary

winding of the ignition coil.

(black wire)

Ye s

LEL In + Connect to an external LEL

sensor (4-20 mA or Dry).

12/24 VDC Power Output Ye s

LEL In- Digital / 4-20 mA Input Ye s

Valve + Connect to Pilot Valve

terminal 1.

Powered Output Ye s

Valve - Connect to Pilot Valve terminal

2. Do not connect to ground.

Ye s

EGND Earth Ground Ground N/A

2.4 | Terminal Descriptions

MAIN ION, PILOT ION

Connect each of these inputs to a Kanthal flame rod placed directly in the pilot/main flame. The pilot and

main nozzles must be grounded for the flame detection to function properly. These inputs are protected

from high voltage and can be connected in series with the high voltage terminals of an external ignition

coil, allowing a single flame-rod to be used for both pilot ignition and pilot flame detection. A 65 VAC

signal is applied to the flame rod. The source impedance is very high so there is no danger of sparking

during detection.

COIL

The primary of the ignition coil should be connected to these terminals. A 12 V pulsed DC signal is ap-

plied by the card to the coil. This output is protected by a 250 mA thermal fuse.

LEL IN

This input can be connected to an optional LEL sensor to detect explosive gas concentrations in the burn-

er housing. The input can be configured in software to be disabled, to require an LEL switch, or to require

an LEL 4-20 mA transmitter. The system will not start if the contact is open or the 4-20 mA LEL input is

above the trip point.

8

VALVE

Solenoid valves must be connected between the “+” and “-” terminals. The negative terminal is not

directly connected to ground. This output is driven by 12 V and will only work with 12 V valves.

EGND

This terminal must be connected to the same ground as the pilot and main burner assemblies. Modules

come pre-wired with a connection to the enclosure ground lug.

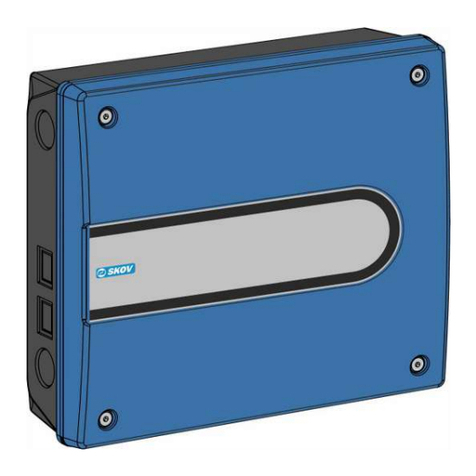

2.5 | Enclosure Specifications

The Ion Pilot card is mounted in the EPX enclosure.

SPECIFICATIONS EPX ENCLOSURE

Dimensions Top Width 11.7 cm (4.61 in)

Base Width 16.8 cm (6.63 in)

Height 21.7 cm (8.53 in)

Depth 13.3 cm (5.25 in)

Hazloc Rating Class I, Div 1, GRP BCD, Type 4X; Class I, Zone 1, AEx d IIB +

H2 T6 Gb; Ex db IIB+H2 T6 Gb, IECEx

Mounting Channel Bar or Direct Mount

Enclosure Construction Aluminum

Operating Temperature -40°C to 60°C

Storage Temperature -40°C to 60°C

Standards: Complies with IEC 60079-0:2011, 6th Edition and IEC 60079-1:2014, 7th Edition

9

2.6 | Enclosure Diagram

Enclosure options compatible with this card include the EPX enclosure.

Port 1

Port 3

Port 4

Port 2

(not shown)

All ports are ¾-14 NPT and must have appropriate pipe fittings or plugs installed. A minimum of 5

threads must be engaged in each port to maintain Div 1 / Zone 1 ratings.

10

CONTROLS AND DIAGNOSTICS

The following is a list of all of the user interface items on the Ion Pilot card.

3.1 | Ports

PFRN PORTS

1 PFRN IO Network Port

This port is classified as an IO class port and is also the port through which the card is

powered. See the Card Diagram for the port location.

3.2 | LEDs and Buttons

POWER LED

A Power LED is located next to the PFRN port indicating whether the port is receiving power from the

network.

INDICATION COLOR STATE

Off - Port is not powered

On Blue Port is powered

LINK LED

A link LED is located next to the PFRN port indicating traffic on the PFRN port.

INDICATION COLOR STATE

Off - PFRN network is not available

On Green PFRN network is ready for

communication

Blinking Green Indicates that network traffic is going

through the link

FAULT LED ERRORS*

A bank of Fault LEDs corresponds to the state of a specific input or output as noted below.

INPUT/OUTPUT COLOR ERROR

Pilot Red Wiring error. Reporting as open, grounded, etc.

Main Red Wiring error. Reporting as open, grounded, etc.

Coil Red Fault in ignition.

LEL Red Fault in LEL wiring / signaling.

*If one of these lines is not required for the application and is left unused, a fault will be present but the

system will still be functional.

11

3.3 | Important Safety Information

Before installing the PF3100 Ion Pilot card, please review the following list of warnings.

Failure to observe the following may result in death, electrocution, property damage,

product damage, and/or government fines.

WARNING: EXPLOSION HAZARD

• Do not disconnect while circuit is live unless area is known to be non-hazardous or

equivalent.

• Substitution of components may impair suitability for specified zones.

• Do not service unless area is known to be non-hazardous.

• Do not open enclosure while energized.

• Installation and use must conform to the provided installation instructions.

• System must be properly connected to earth-ground for effective operation of flame

detection circuitry.

• Electrical devices connected to the controller must meet certain electrical standards and be

within voltage limits.

INSTALLATION WARNINGS

• Failure to properly ground the pilot assembly back to the PF3100 Ion Pilot Module’s EGND

terminal may result in accidental electric shock, product damage, failure to ignite the pilot, or

failure to detect flame.

• The PF3100 Ion Pilot Module generates 20 kV- 40 kV at the high voltage output terminal of

the ignition coil which can cause cardiac arrest. Do not touch or place any object near the

ignition coil’s high voltage terminal or connected ignition wire while the product is operating.

Even without making physical contact with the terminal, it is possible to draw a spark from

several inches away, especially if the pilot bracket is not properly grounded.

• Make sure that the enclosures are securely closed each time after opening. To properly close

the enclosure, the lid must be fully threaded on and the set screw tightened. This protects

the internal circuitry from moisture damage and other environmental concerns. Moisture

damage is not covered by the product warranty. To properly close the enclosure, the lid must

be fully threaded on and the set screw tightened.

12

• Do not drill holes in or otherwise modify the EPX enclosure. Any such modifications will

compromise suitability for Class I, Div 1/Zone 1.

• The flame rods are not intended to be installed and mounted in a Class I, Division 1

or Division 2 hazardous location. Routing and installation of the flame rods shall be in

accordance with the Canadian Electrical Code or National Electrical Code as per local

requirements.

• Unused 3/4” NPT conduit ports must be plugged using appropriately rated pipe plugs in

order to maintain the Div 1 / Zone 1 rating of the enclosure. Refer to the Canadian Electrical

Code or National Electrical Code as applicable.

APPENDIX A: NETWORK TERMINOLOGY

The following terms are used to explain the network operations:

Interface Class Card- Any PF3100 card that provides a control or monitoring interface to a user or remote

PLC. Examples include the User Interface card and the Modbus card.

Controller Class Card- Any PF3100 card that provides safety control for a specific application. Examples

include the BMS Controller card and Combustor Controller card.

Network Class Card- Any PF3100 card that provides multiple network ports so that additional cards may

be connected together on the PFRN network. Examples include the Network Switch card, Modbus card,

and the BMS Controller card.

IO Class Card - Any PF3100 card that provides input and output terminals for control and monitoring.

Examples include the Ion Pilot card and the Thermocouple card.

PFRN- Profire Reliability Network. A proprietary safety network developed by Profire which can also be

used to distribute power. The PFRN has two sub-networks: the Controller Network and the IO Network.

Controller Network- A sub-network of PFRN Interface class and Controller class cards talk to each other

on this network. There is usually only one of these networks in an installation.

IO Network- A sub-network of PFRN IO class card talk to a single Controller class card. There is one of

these networks for each Controller class card in the system.

13

14

www.profireenergy.com

© 2016 PROFIRE

Other manuals for PF3100 Series

6

Table of contents

Other ProFire Control System manuals

Popular Control System manuals by other brands

Roger

Roger MC16-PAC-2-KIT installation manual

Beninca

Beninca ZED24 operating instructions

Beninca

Beninca EVA.7 instruction manual

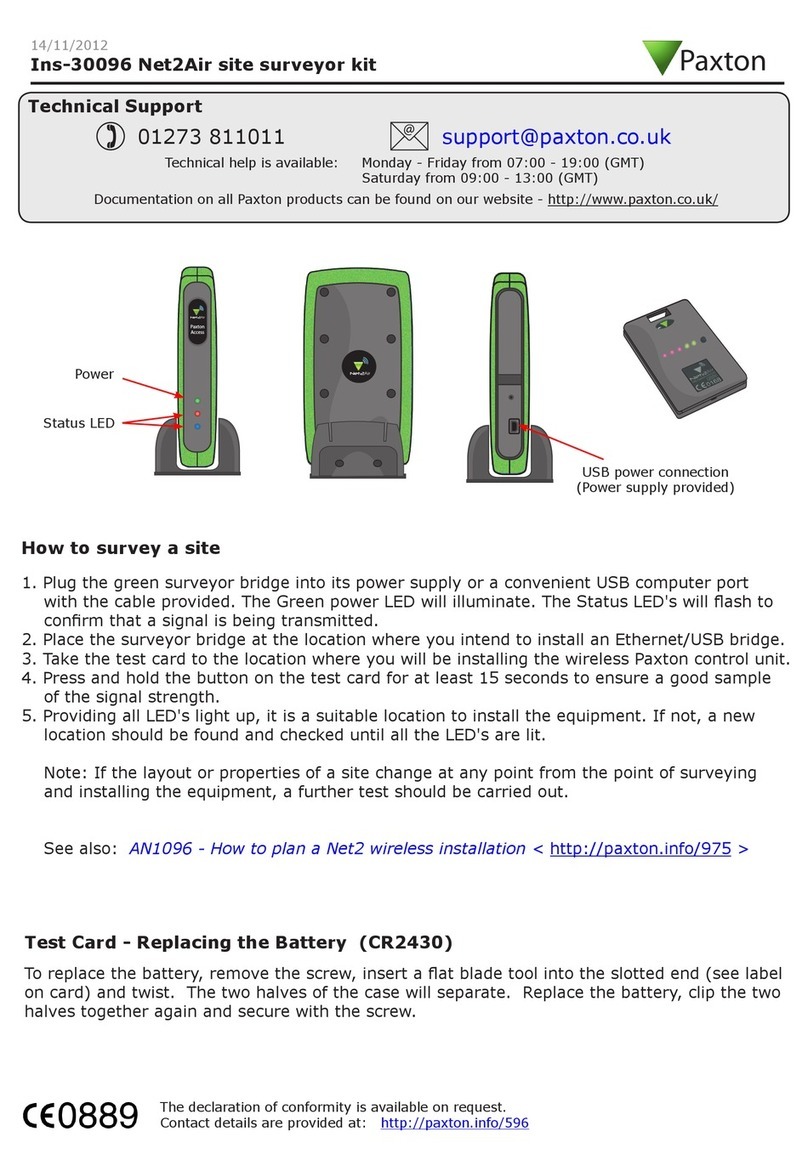

Paxton

Paxton Net2Air quick guide

Snap-On

Snap-On LEVEL5ATC Installation and operation manual

Carrier

Carrier PRO-DIALOG PLUS 50AZ Installation, operation and maintenance instructions