Estwing EFL50Q User manual

02

Table of Contents Safety Information

Do not nail on top of another nail. This can cause the

nail to be deflected and hit someone, or cause the

tool to react and result in a risk of injury to persons.

Alwaysweareyeprotection.Operatorandothersin

theworkareashouldalwayswearANSI-approved

safetygoggleswithsideshields.Eyeprotectionis

usedtoguardagainstflyingfastenersanddebris,

whichmaycausesevereeyeinjury.

Alwayswearhearingprotectionwhenusingthetool.

Prolongedexposuretohighintensitynoisemay

causehearingloss.

Use safety equipment. A dust mask, non-skid

safety shoes and a hard hat must be used for the

applicable conditions. Wear a full face shield if you

are producing metal filings or wood chips.

Dressproperly.Donotwearlooseclothingorjewelry.

Containlonghair.Keepyourhair,clothing,andgloves

awayfrommovingparts.Looseclothes,jewelry,or

longhaircanbecaughtinmovingparts.

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol, or medication. A moment of

inattention while operating the tool may cause

serious injury.

Keep proper footing and balance at all times.

Proper footing and balance enables better control

of the tool in unexpected situations.

Do not use on a ladder or unstable supports.

Stable footing on a solid surface enables better

control of the tool in unexpected situations.

Make sure the hose is free of obstructions or

snags. Entangled or snarled hoses can cause loss

of balance or footing and may become damaged,

resulting in possible injury.

Do not overreach. Keep proper footing and balance

at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

Do not attach the hose or tool to your body. Attach

the hose to the structure to reduce the risk of loss of

balance if the hose shifts.

WARNING: This product can expose you to

chemicals including lead, which is known to the

State of California to cause cancer and

birth defects or other reproductive harm.

Read operator’s manual: To reduce the risk of

injury, user must read and understand operator's

manual before using this product.

Eye protection: Always wear safety goggles,

safety glasses with side shields, or a full face

shield whenoperating this product.

Hearing protection: Always wear hearing

protector such as earplugs and ear muffs when

using this tool Failure to do so may result in .

hearing loss .

Risk of serious personal injury: Never place

hands or any other body parts in the fastener

discharge area of the nailer, the tool might eject

a fastener and could result in death or serious

personal injury.

Keep the work area clean and well . Cluttered lit

benches and dark areas increase the risks of

accidents.

Do not operate the tool in explosive atmospheres,

such as in the presence of flammable liquids,

gases, or dust. The tool creates a spark which may

ignite flammable liquids, gases or dust.

Keep bystanders, children, and others away while

operating the tool. Distractions could result in

improper use and cause injury.

Avoid unintentional misfires. Always use caution to

avoid accidentally firing. Do not point towards yourself

or anyone whether it contains fasteners or not.

SYMBOLS

WORK AREA SAFETY

1.

2.

3.

4.

WARNING: Instructions pertaining to a risk of fire,

electric shock, or injury to persons.

PERSONAL SAFETY

WARNING: To avoid serious personal injury, do

not attempt to use this product until you read the

manual thoroughly. Save this manual and review

frequently to ensure safe opeartion and instruct

others who may use this tool.

WARNING: When using tools, basic precautions

should always be followed, including the

followings.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

03

Table of contents---------------------------------------------2

Safety information--------------------------------------------3

Symbols----------------------------------------------------3

Work area safety-------------------------------------------3

Personal safety---------------------------------------------3

Tool use and care------------------------------------------4

Tool service-------------------------------------------------5

Air source---------------------------------------------------5

Operation---------------------------------------------------5

Air supply and connections-------------------------------5

Loading the tool--------------------------------------------6

Warranty-------------------------------------------------------6

Unpacking-----------------------------------------------------7

Specifications--------------------------------------------------7

Features-------------------------------------------------------8

Operation -----------------------------------------------------8

Loading cleat nails---------------------------------------8

Loading staples--------------------------------------------9

Unloading cleat nails and staples-----------------------9

Changing the foot plate---------------------------------10

Setting the air pressure---------------------------------11

Operating the tool---------------------------------------11

Clearing jams--------------------------------------------12

Maintenance-------------------------------------------------13

Anti-dust cap--------------------------------------------13

Lubrication-----------------------------------------------13

Cleaning--------------------------------------------------14

Cold weather operation--------------------------------14

Recommended hookup------------------------------------14

Troubleshooting---------------------------------------------15

05

04

Always assume that the tool contains fasteners. Do

not point the tool toward yourself or anyone whether

it contains fasteners or not.

Wash hands after handling. This product or its power

cord may contain chemicals known to the State of

California to cause cancer and birth defects or other

reproductive harm.

12.

13.

Useclamps tosecureandsupporttheworkpiece toa

stableplatform. Holding a tool by hand or against the

body is unstable and may lead to loss of control and

injury.

Keep the tool and its handle dry, clean and free from

oil and grease. Always use a clean cloth when

cleaning. Never use brake fluids, gasoline, petroleum-

based products, or any strong solvents to clean your

tool.

Do not use the tool as a hammer.

Never use this tool in a manner that could cause a

fastener to be directed toward anything other than

the workpiece.

Never use gasoline or other flammable liquids to

clean the tool. Never use the tool in the presence of

flammable liquids or gases. Vapors could ignite by a

spark and cause an explosion which will result in

death or serious personal injury.

Always fit the tool with a fitting or hose coupling in a

way that all of the remaining compressed air is

discharged when tool is disconnected. Do not use a

check valve or any other fitting which allows air to

remain in the tool. Death or serious personal injury

could occur.

Never place hands or any other body parts in the

fastener discharge area of the tool. The tool might

eject a fastener and could result in death or serious

personal injury.

Never carry the tool by the air hose or pull the hose to

move the tool or a compressor. Keep hoses away

from heat, oil and sharp edges. Replace any hose that

is weak, worn, or otherwise damaged. Personal injury

or tool damage could ocur.

Always assume the tool contains fasteners. Respect

the tool as a working implement; no horseplay.

Always keep others at a safe distance from the work

area in case of accidental discharge of fasteners. Do

not point the tool toward yourself or anyone whether

it contains fasteners or not. Accidental triggering of

the tool could result in death or serious personal

injury.

Do not drop or throw the tool. This could result in

damage that will make the tool unusable or unsafe. If

the tool has been dropped or thrown, examine the

tool closely for air leaks or bent, cracked or broken

parts. STOP and repair before using to avoid serious

injury.

Avoid using the tool when the magazine is empty.

Accelerated wear on the tool may occur.

Clean and check all air supply hoses and fittings

before connecting the tool to an air supply. Replace

any damaged or worn hoses or fittings to prevent

reduced performace or durability.

10.

11.

12.

13.

14.

Knowthistool.Readthismanualcarefully,learnits

applicationsandlimitations,aswellasthespecific

potentialhazardsrelatedtothistool.

Use only fasteners are recommended for your

models. Do not use the wrong fasteners or load

the fasteners incorrectly.

Use only accessories that are identified by the

manufacturer for the specific tool model. Use of

unauthorized parts or failure to follow maintenance

instructions may create a risk of injury.

Use only those fasteners recommended for use with

this tool. Fasteners not identified for use with this tool

by the tool manufacturer could result in a risk of injury

to persons or tool damage when used in this tool.

Checkformisalignmentorbindingofmovingparts,

breakageofparts,andanyotherconditionthatmay

affectthetool’soperation.Ifthetoolisdamaged,

havethetoolservicedbeforeusing to prevent

accidents.

Maintaintoolswithcare.Keepthemclean.Properly

maintainedtools are easier to control and reduce the

risk of injury.

Store tools out of the reach of children and other

untrained people. Tools are dangerous in the hands

of untrained users.

Check operation of the tool before use.

Use the right tool for the job. The correct tool will do

better and be safer than forcing the wrong tool to do

something other than it was designed for.

1.

2.

3.

4.

5.

6.

15.

16.

17.

Do not use the tool if it leaks air or does not

function properly.

Do not operate the tool if it does not contain a

legible warning label.

Always carry the tool by the handle. Never carry the

tool by the air hose.

18.

19.

20.

21.

23.

25.

22.

24.

Respect the tool as a working implement.

Neverengageinhorseplay.

Keepothersasafedistancefromthetoolwhile

toolisinoperationasaccidentalactuationmay

occur,possiblycausinginjury.

7.

8.

9.

Safety Information (Continued) Safety Information (Continued)

TOOL USE AND CARE TOOL SERVICE

Useonlyaccessories for thespecifictoolmodel as

identified by the manufacturer.

When servicing a tool, use of unauthorized parts of

failure of following maintenance instructions may

create a risk of injury.

Useonlythelubricantsspecifiedbythemanufacturer

or suppliedwiththetool.

Tool service must be performed only by qualified

repair professional.

1.

2.

3.

4.

PERSONAL SAFETY(CONTINUED)

WARNING: Disconnect the tool from the air

source before making adjustments, doing tool

maintenance, clearing jams, touching the safety

yoke, leaving work area, or unloading the tool.

Such precautionary measures reduce the risk of

injury.

TOOL USE AND CARE(CONTINUED)

AIR SOURCE

Never connect to an air source that is capable of

exceeding 200 psi. Over pressurizing the tool is able

to result in bursting, abnormal operation, breakage of

the tool or serious injury to persons. Use only clean,

dry, regulated compressed air at the rated pressure

or within the rated pressure range as marked on the

tool. Always verify prior to using the tool that the air

source has been adjusted to the rated air pressure or

within the rated air-pressure range.

Never use oxygen, carbon dioxide, combustible

gases or any bottled gas as an air source for the tool.

Such gases are capable of explosion and serious

injury to person.

1.

2.

OPERATION

Donotdrivefastenersnear theedgeofmaterial.The

workpiecemaysplitcausingthefastenertoricochet,

injuringyouorpeoplearound.

Duringnormalusethetoolwillrecoilimmediatelyafter

drivingafastener.Thisisanormalfunctionofthetool.

Attempting to prevent the recoil by holding the tool

against the work piece may cause a second fastener

to release. Restriciting the tool can result in serious

personal injury.

1.

2.

3.

4.

5.

Donotdrivefastenersontopofotherfastenersorwith

thetoolatanoverlysteepangleasthismaycause

deflectionoffastenerswhichcouldcauseinjury.

Donotactivatethetoolunlessyouintendtodrivea

fastenerintotheworkpiece.

Always handle the tool with care:

1)

2)

3)

AIR SUPPLY AND CONNECTIONS

Do not use a connector that allows the tool to hold

pressure when the air supply is disconnected. If an

incorrect fitting is used, the tool can remain

pressurized and will be able to drive a fastener even

after the air line is disconnected.

Use filtered, lubricated, regulated compressed air as

your only air source. Do not use any type of reactive

gases including, but not limited to oxygen and

combustible gases. Using reactive gas instead of

compressed air may cause the tool to explode, which

will cause death or serious personal injury.

Use only a pressure-regulated compressed air

source to limit the air pressure supplied to the tool.

Do not exceed 115 psi.

Always disconnect air source:

1.

2.

3.

4.

Before unloading or making adjustments.

When maintaining the tool.

When clearing a jam.

When touching the safety yoke.

When tool is not in use.

When moving to a different work area.

Such precautionary measures reduce the risk of injury to

persons.

1)

2)

3)

4)

5)

6)

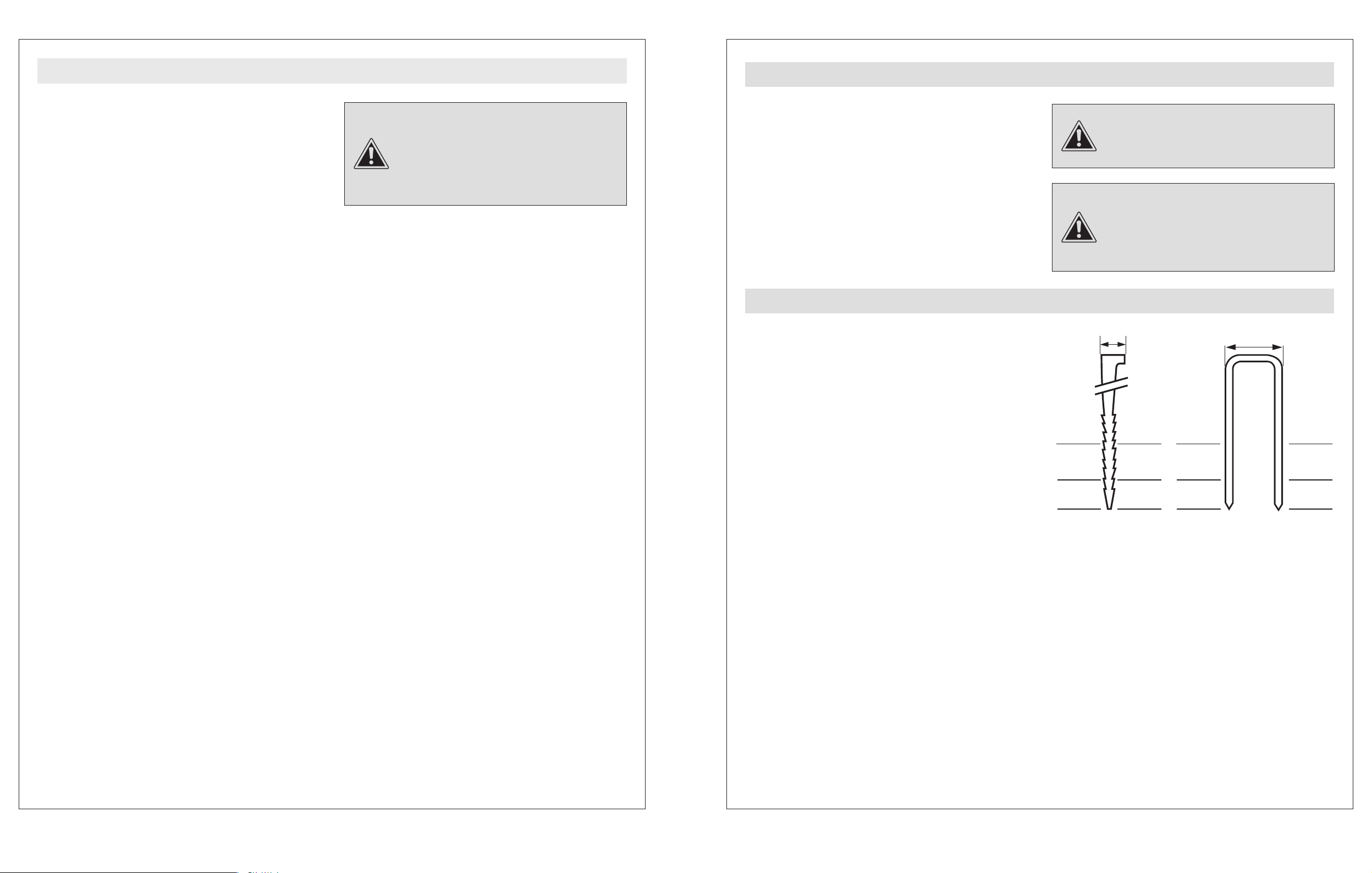

Compatible with generic brands of 15.5 gauge staples & 16

gauge L-cleats.

(16 Ga. L Cleats)

7.2mm (9/32”)

38 mm

45 mm

50 mm

1-1/2”

1-3/4”

2”

(15.5 Ga. Staples)

12.7mm (1/2”)

38 mm

45 mm

50 mm

1-1/2”

1-3/4”

2”

07 06

Safety Information (Continued)

LOADING THE TOOL

Do not load the tool with fasteners when any one of

the operating controls is activated.

Never place a hand or any part of body in the fastener

discharge area of the tool.

Never point tool at anyone.

1.

2.

3.

Unpacking

Air inlet: 1/4 inch NPT

Magazine capacity: L Cleat: 100 pcs Staple: 90 pcs

Weight: 8.0 lbs

Maximum pressure: 115 psi

Pressure range: 70 psi – 115 psi

Pin size range: 1-1/2 in. to 2 in.

WARNING: The warnings and precautions

discussed above cannot cover all possible

conditions and situations that may occur. It

must be understood by the user that common

sense and caution are factors which cannot be

built into this product, but must be supplied by

the user.

Specifications

1.

2.

3.

4.

5.

6.

1.

4.

2.

3.

This tool kit has been shipped completely

assembled.

Carefully remove the tool and any accessories from

thebox.

Inspectthetoolcarefullytomakesurenobreakageor

damageoccurredduringshipping.

Do not discard the packing material until you have

carefullyinspectedandsatisfactorilyoperatedthet

ool.

WARNING: If any parts are missing, do not

operate the tool until the missing parts are

replaced. Failure to do so could result in possible

serious personal injury.

WARNING: Do not attempt to modify the tool or

create accessories not recommended for use

with the tool. Any such alteration or

modification is misuse and could result in

hazardous condition leading to possible serious

personal injury.

09

08

Features

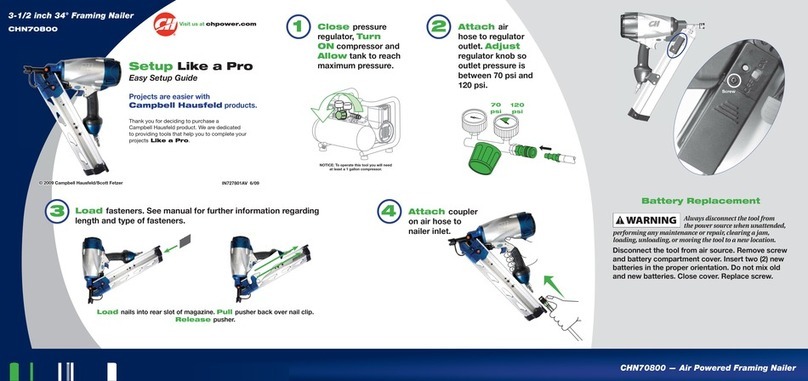

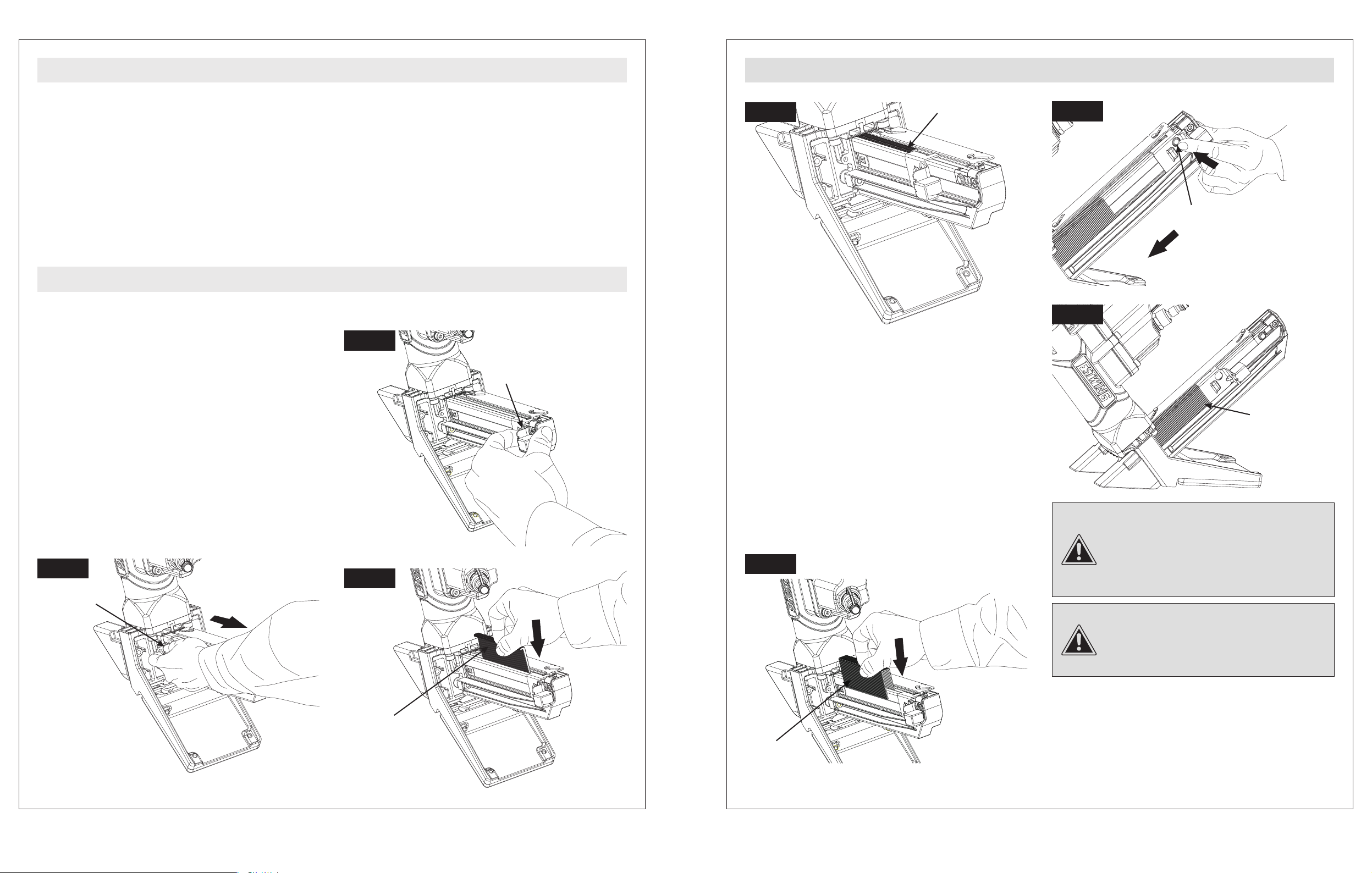

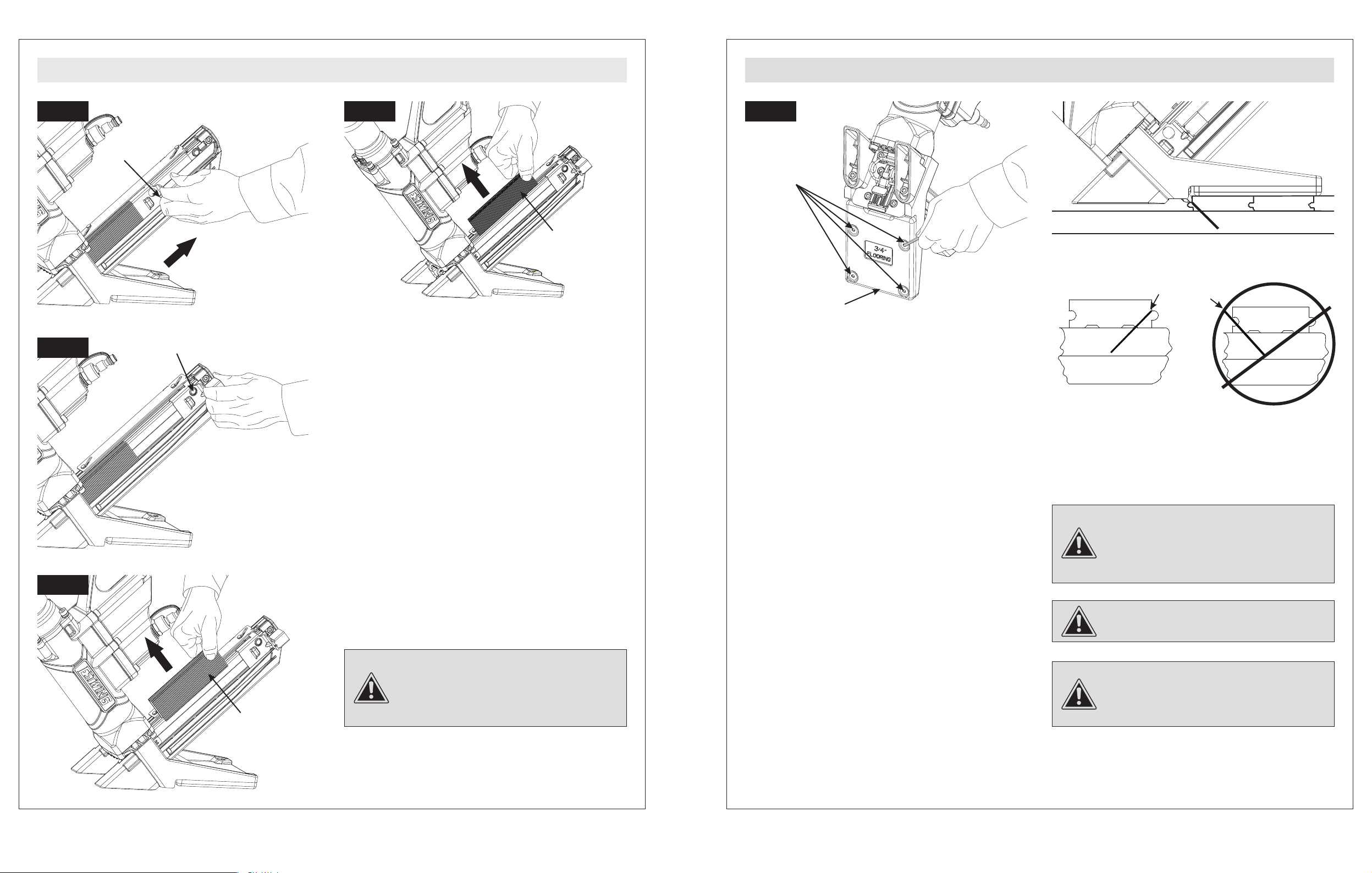

Loading cleat nails

1

Connect the tool to the air source.

Pull the pusher (A) back to the end of magazine. Lock

the pusher in the place by using the lock button(B).

(See figure 1 & 2)

Insert strip of L cleats into magazine from the top. Up

to 100 cleat nails can be loaded into the magazine.

Noted that, when loading the L cleats, the side with

the L head should be in the left of the magazine. (See

figure 3)

Press the lock button(B), allow the pusher (A) to slide

forward and engage the fastener. The pusher (A) will

stop when it rests against the end of cleat nails. (See

figure 4)

Operation (Continued)

Unloading cleat nails and staples

3

Figure 1

Operation

1.

2.

3.

4.

Slide Back

Pusher(A)

Lock Button(B)

Figure 3

Figure 2

L Cleat

Figure 7

Lock Button(B)

Staple

Staple

Slide Forward

Ergonomically designed handle

For ease of operation and reduced fatigue.

Non-marring design

Provides increased protection from marring when

working with a finished flooring surface.

Quick jam release

Allows for easy access clearing in the event of a jam.

1.

2.

3.

4. Durable construction

Lightweight, high-strength aluminum body with heat

treated steel parts.

Fiberglass mallet with rubber head included

5.

Figure 5

Figure 6

WARNING: The tool may fire when it is first

connected to the air source. Always connect the

tool to the air source before loading fasteners to

prevent injury from unintended cycling. Always

make sure the tool’s magazine is empty at the

beginning of each work session, before

connecting to air source.

WA R N I N G : U s e only those fasteners

recommended for use with this tool. Fasteners

not identified for use with this tool by the tool

manufacturer can result in a risk of injury to

persons or tool damage when used in this tool.

Disconnect the tool from the air source.

Pull the pusher back to the end of magazine until it is

locked into lock button. ( See figure 8 & 9)

Unload the cleat nails or staples from the magazine.

(See figure 10 & 11)

1.

2.

3.

L Cleat

Figure 4

Loading staples

2

Connect the tool to the air source.

Pull the pusher (A) back to the end of magazine. Lock

the pusher in the place by using the lock button (B).

(See figure 1 & 2)

Insert a full clip of 1/2 in. crown staples into magazine

from the top. You can load up to the 90 pieces into the

magazine. (See figure 5)

Press the lock button(B), allow the pusher (A) to slide

forward and engage the staples. The pusher (A) will

stop when it rests against the end of staples. (See

figure 6 & 7)

1.

2.

3.

4.

11

10

Operation (Continued) Operation (Continued)

Figure 8

Slide Back

Pusher(A)

Figure 9

Lock Button(B)

Figure 10

WARNING: Disconnect the tool from the air

source whenever changing the foot plate.

Make sure there is no fastener in the magazine

before changing the foot plate.

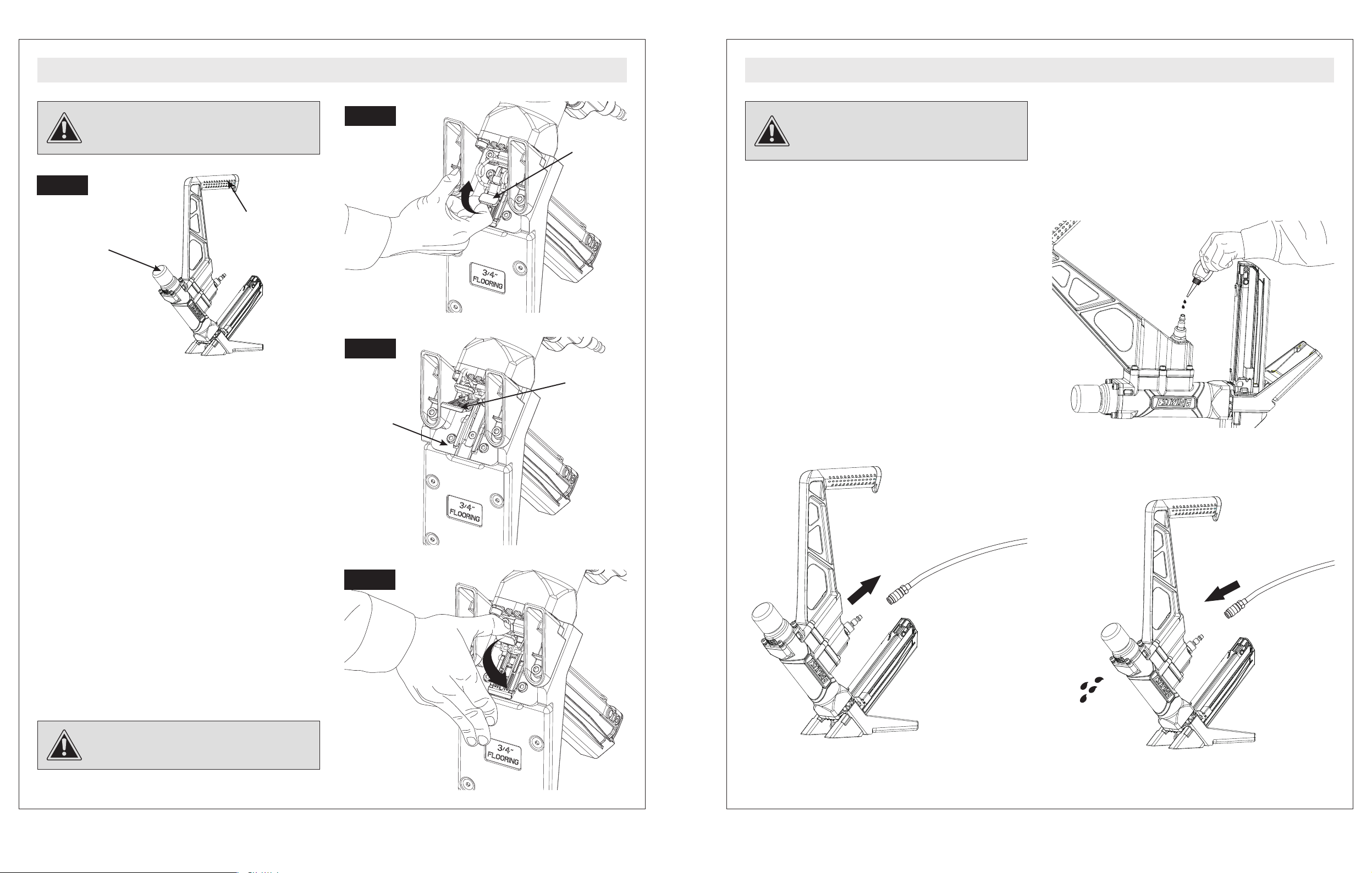

Changing the foot plate

4

Staple

L Cleat

Screws (E)

Foot plate (D)

Setting the air pressure

5The amount of air pressure required depends on the

size of the fasteners and the workpiece material.

Begin testing the depth of drive by driving a test nail

into the same type of workpiece material used for the

actual job.

Drive a test fastener with the air pressure set at 90-95

psi.

Raise or lower the air pressure to find the lowest

setting that will perform the job with consistent

results.

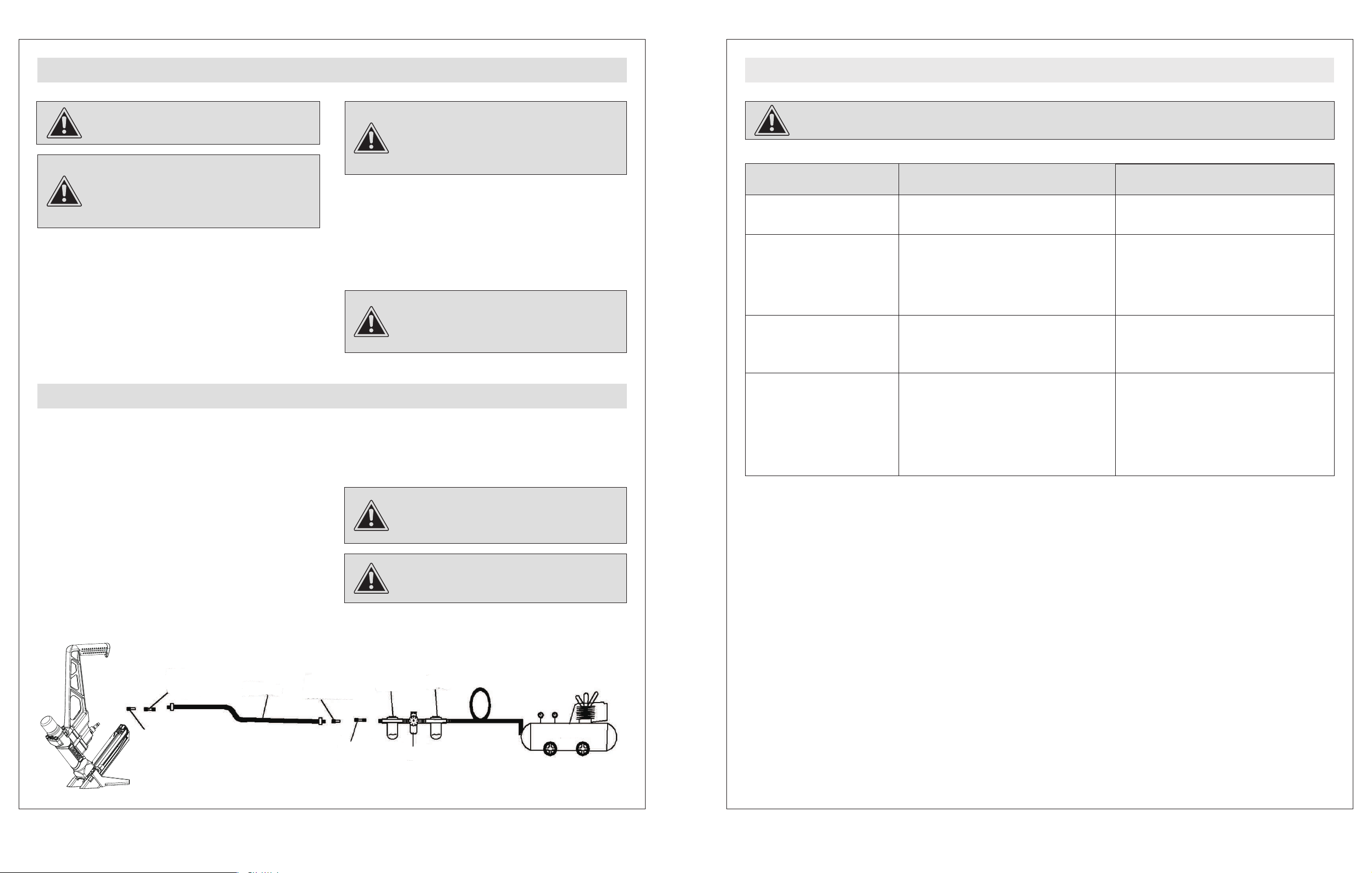

Operating the tool

6

Attach the tool to the air source. Start your

compressor and check the pressure, making sure it is

set between 70-115 psi. Do not exceed the maximum

115 psi.

Hold the hand grip (J) securely and press the foot

plate (D) to the work surface. Make sure the plate is

over the fastener target position.

Press down firmly so that the foot plate (D) is firmly

contacting the work surface. Then, using the mallet

packed with the tool, strike the hammer cap (K) firmly

to drive the fastener into work surface. Lift the tool off

the work surface. Repeat this process until the job is

completed.

1.

2.

3.

4.

1.

2.

3.

The flooring nailer is designed for tongue and groove

flooring only. Place the nailer flush onto the work surface

and ensure that you are striking at the tongue of the

hardwood floor.

Tongue and groove flooring

WARNING: Extreme caution must be used

whenever this tool is connected to an air source.

If the tool is dropped, or if the hammer cap (K) is

accidentally struck, then the tool will fire a

fastener, potentially causing SERIOUS

PERSONAL INJURY.

WARNING: Keep your feet off the tool.

When finished, make sure to store the tool in a clean,

dry, safe location out of reach of children and other

unauthorized People.

4.

Correct Placement

SUBFLOOR

Incorrect Placement

Lcleat

or

Staples

TONGUE & GROOVE

FLOORING TONGUE & GROOVE

FLOORING

SUBFLOOR

NOTE: Please follow your wood manufacture’s guideline

when doing your flooring installations.

WARNING: Before using the tool on a floor, test

the tool on a scrap piece of wood. Adjust the

driving depth by providing more or less air

pressure. Never exceed 115 PSI.

Figure 11 Figure 12

Disconnect the tool from the air source.

Empty the magazine completely.

Fire the tool into a piece of scrap wood to ensure

there is no compressed air or fasteners left in the tool.

Set the tool on its side to expose the four screws (E).

Remove the four screws (E), then remove the foot

plate(D). (See figure 12)

Align the four screw holes in the replacement foot

plate with the four threaded mounting holes.

Using the four screws you removed, secure the

replacement foot plate to the tool.

Ensure the correct foot plate is installed by firing into

a scrap piece of flooring and checking for proper

fastener placement.

The tool is equipped with a factory pre-installed 3/4 in.

foot plate (D), and an additional uninstalled 5/8 in. & 9/16

in. foot plate .

To change the plate:

1.

2.

3.

4.

5.

6.

7.

8.

Lcleat

or

Staples

13

12

Operation (Continued)

WARNING: An improperly functioning tool must

not be used. Do not actuate the tool unless the

tool is placed firmly against the work piece.

Hammer cap (K)

Hand grip (J)

Clearing jams

7

Occasionally, fasteners may become jammed in the firing

mechanism of the tool, making the tool inoperable. To

remove a jammed fastener, follow the steps below:

WARNING: Make sure there is no fastener in the

magazine before clearing a jam.

Figure 14

Figure 15

Figure 16

WARNING: Any time inspection, maintenance,

and cleaning are done:

Disconnect the tool from the air source.

Empty the magazine completely.

Anti-dust cap

Each tool is packed with an anti-dust cap on the air

connector, check it after unpacking.

Keep the anti-dust cap to cover the air connector when

the tool is not in use.

Maintenance

1)

2)

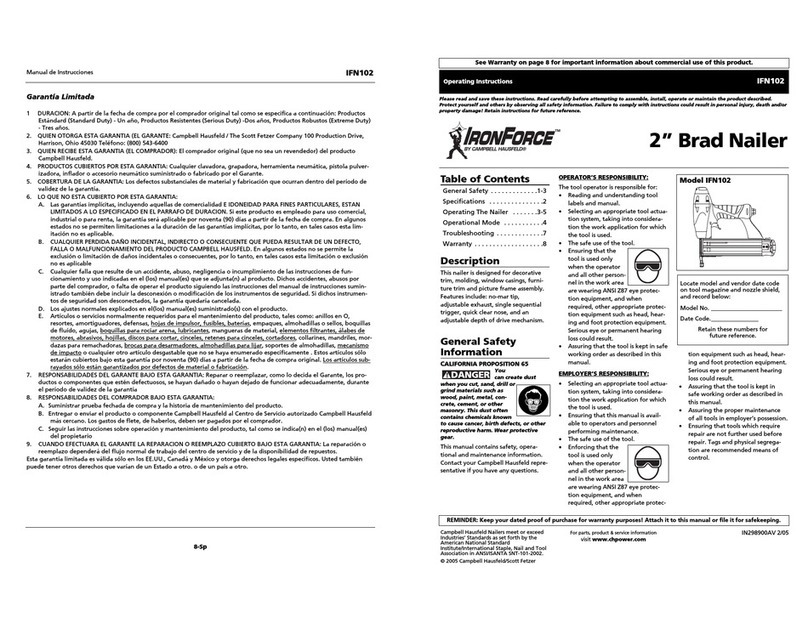

Lubrication

Frequent, but not excessive, lubrication is required for

best performance. Oil for the tool added through the air

line connection add will lubricate the internal parts. Do

not detergent oil or additives as these lubricants will

cause accelerated wear to the seals and bumpers in the

tool, resulting in poor tool performance and frequent tool

maintenance.

Disconnect the air supply from the tool to add

lubricant.

1.

Disconnect the tool from air source.

Empty the magazine. Make sure all fasteners are

removed.

Try to fire the tool into a piece of scrap wood or

flooring to make sure that it's incapable of firing any

fasteners.

Pull up on the latch (F) and open the jam release (G).

(See figure 14 & 15)

Remove the jammed fastener, using plier or a

screwdriver if required.

1.

2.

3.

4.

5.

Close the jam release (G) and latch (F). (See figure 16)

Reload the tool with fasteners, then reconnect the air

source to the tool.

Press the drive guide (H) against a piece of wood, and

test fire the fasteners several times to check for

proper operation. If the tool is properly firing, you may

continue using the tool. If the tool fails to perform

properly, immediately discontinue use and have the

tool repaired by a qualified service technician.

6.

7.

8.

Figure 13

Latch

(F)

Jam Release

(G)

Driver Guide

(H)

Turn the tool so the air inlet is facing up. Place 2-3

drops of pneumatic fastening tool oil into air inlet. Do

not use detergent oils, oil additives, or air -tool oils.

Do not use detergent oil or additives as these

lubricants will cause accelerated wear to the seals

and bumpers in the tool, resulting in poor tool

performance and frequent tool maintenance.

After adding oil, run tool briefly. Wipe off any excess

oil from the cap exhaust.

2.

3.

15

14

Maintenance (Continued)

CAUTION: Lubricate tool only with specified

lubricants.

CAUTION: The work surface can become

damaged by excessive lubrication. Proper

lubrication is the owner’s responsibility. Failure to

lubricate the tool properly will dramatically

shorten the life of the tool and void your warranty.

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust , oil, grease, etc.

CAUTION: Do not at any time let brake fluids,

gasoline, petroleum-based products, penetration

oils, ect. come in contact with plastic parts.

Chemicals can damage, weaken or destroy

plastic which may result in serious personal injury.

For cold weather operation, near and below freezing, the

moisture in the air line may freeze and prevent tool

operation. We recommend the use of air tool lubricant or

permanent antifreeze (ethylene glycol) as a cold weather

lubricant.

CAUTION: Do not store tools in a cold weather

environment to prevent frost or ice formation on

the tools’ operating valves and mechanisms that

could cause tool failure.

CAUTION: The air compressor must be able to

maintain a minimum of 70 psi when the tool is

being used. An inadequate air supply can cause a

loss of power and inconsistent driving.

The air compressor must be able to maintain a

minimum of 70 psi when the tool is being used. An

inadequate air supply can cause a loss of power and

inconsistent driving.

An oiler can be used to provide oil circulation through

the tool. A filter can be used to remove liquid and

solid impurities which can rust or gum up internal

parts of the tool.

Always use air supply hoses with a minimum working

pressure rating equal to or greater than the pressure

from the power source if a regulator fails, or 150

psi,whichever is greater. Use 3/8 in. air hose for runs

up to 50 ft. and use a 3/8 in. quick coupler on the air

hose.

Cleaning

Cold weather operation

Recommended hookup

1.

2.

3.

Use a pressure regulator on the compressor, with an

operating pressure of 0-125 psi. A pressure regulator

is required to control the operating pressure of the

tool between 70 and 115 psi.

4.

WARNING: Stop using tool immediately if any of the following problems occur. Serious personal injury could result. Any

repairs or replacements must be done by a qualified service person or an authorized service center.

Air leaking in head cap.

Loose screw.

Worn or damaged o-rings or seals.

Tighten screws.

Install overhaul kit.

Lack of power.

Slow to cycle.

Tool is too dry.

Air pressure too low.

Exhaust blocked.

Add about 2-3 drops of

lubrication into the air connector.

Make sure the air compressor is

set between 70 psi and 115 psi.

Clean exhaust channel.

Drive channel is worn.

Piston is broken or worn.

Bent fasteners.

Dirty magazine.

Loose magazine.

Wrong fasteners.

Fasteners are jammed

in the tool frequently.

Possible cause(s) Corrective action

Fix the drive channel.

Replace the piston.

Remove the bent fasteners

Clean magazine.

Tighten screws.

Verify that fasteners are the

correct size.

Problems

Damaged pusher spring.

Wrong size of fasteners.

Not shooting fasteners. Replace spring.

Use 16 gauge L cleat nails &

15.5 gauge staples.

Troubleshooting

1.

2.

1.

2.

3.

1.

2.

1.

2.

3.

4.

5.

6.

1.

2.

1.

2.

3.

1.

2.

1.

2.

3.

4.

5.

6.

WARNING: Do not connect with an air

compressor that can potentially exceed 200 psi.

As tool may burst and cause injury.

Quick

connector

Quick

Coupler Air hose Oiler

Regulator

Filter

Compressor

Quick

connector

Quick

Coupler

Learn more about air tools on our website.

Other manuals for EFL50Q

1

Table of contents

Popular Nail Gun manuals by other brands

Makita

Makita FN001G instruction manual

Campbell Hausfeld

Campbell Hausfeld IronForce IFN102 operating instructions

DeWalt

DeWalt D51844 instruction manual

Makita

Makita PT354D instruction manual

Senco

Senco FUSION F-35FRHXP Parts reference guide

Novus

Novus J-171 Translation of the original operating instructions