2 / 41

1CONTENTS

1

CONTENTS.................................................................................................................................................................................2

2

CAUTION....................................................................................................................................................................................3

3

NECESSARY REPAIRING TOOLS...........................................................................................................................................3

4

LUBRICANTANDADHESIVEAPPLICATION......................................................................................................................4

5

TIGHTENING TORQUE SPECIFICATIONS............................................................................................................................4

6

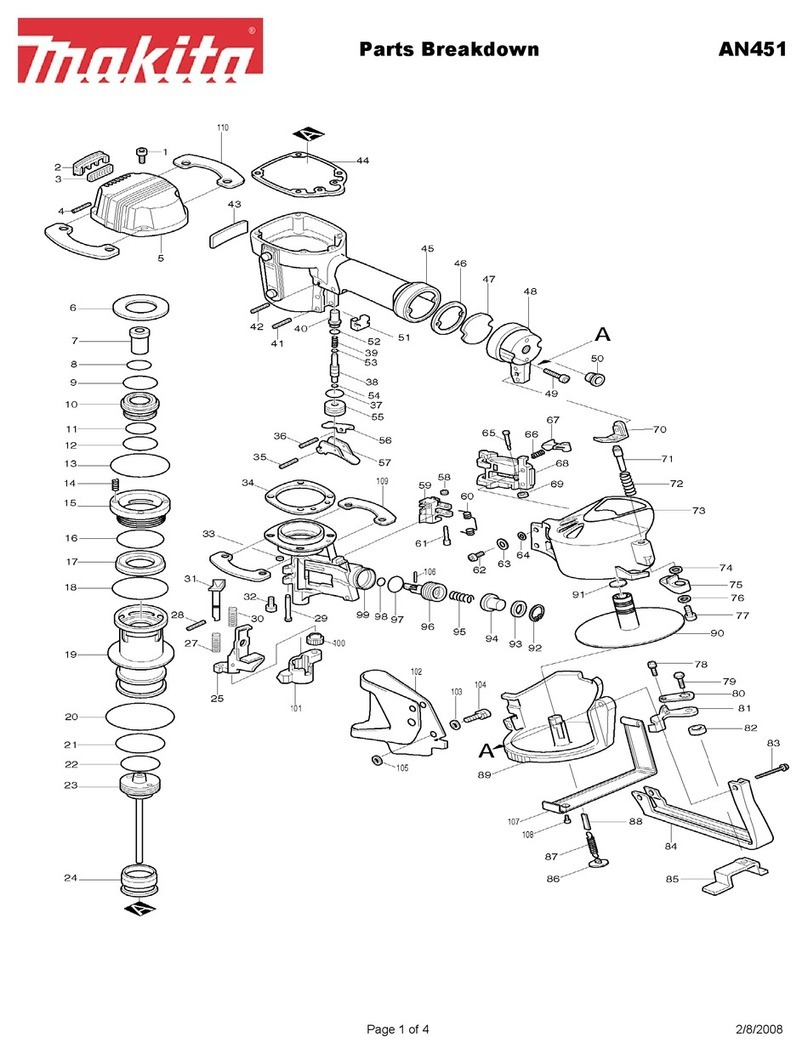

REPAIR........................................................................................................................................................................................6

6-1

Magazine section..................................................................................................................................................................6

6-1-1

Disassembling.............................................................................................................................................................6

6-1-2

Assembling..................................................................................................................................................................9

6-2

Armature and Gear assembly.............................................................................................................................................12

6-2-1

Disassembling...........................................................................................................................................................12

6-2-2

Assembling................................................................................................................................................................15

6-3

Crank section, Main piston section and Driver..................................................................................................................20

6-3-1

Disassembling...........................................................................................................................................................20

6-3-2

Assembling................................................................................................................................................................25

6-4

Door section.......................................................................................................................................................................31

6-4-1

Disassembling...........................................................................................................................................................31

6-4-2

Assembling................................................................................................................................................................32

6-5

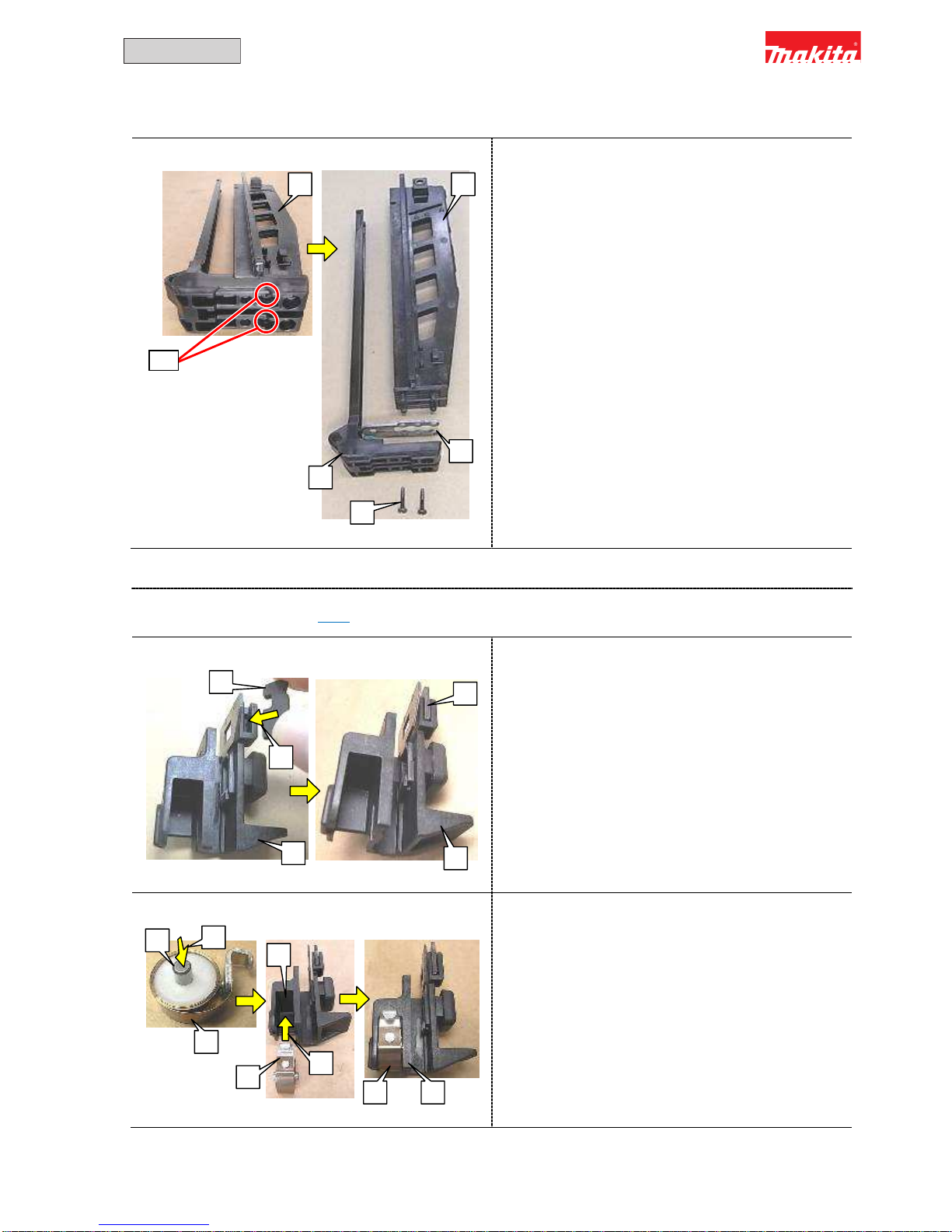

Arm section, Contact top, Driver guide .............................................................................................................................34

6-5-1

Disassembling...........................................................................................................................................................34

6-5-2

Assembling................................................................................................................................................................37

6-6

Pusher section ....................................................................................................................................................................37

6-6-1

Disassembling...........................................................................................................................................................37

6-7

Door section.......................................................................................................................................................................37

6-7-1

Assembling................................................................................................................................................................37

7

CIRCUIT DIAGRAM................................................................................................................................................................38

8

WIRING DIAGRAM.................................................................................................................................................................40