Esu 54677 User manual

Instruction manual

2. Edition, December 20212. Edition, December 2021

P/N 05020-24306

54677 Smoke Unit „Dual“

ESU Smoke Unit

2

1. EU Declaration of Conformity................................. 2

2. WEEE Declaration..................................................... 2

3. Important hints – Please read this first!................. 3

4. General properties................................................... 3

5. Scope of delivery ..................................................... 3

6. Installation of the smoke generator ...................... 4

6.1 Filling the system ...........................................................4

6.2. Wiring ..........................................................................4

6.3. Connecting with LS 5 XL & LS 5 L decoder....................5

7. Programming the smoke generator....................... 6

7.1.1. Basic settings .............................................................6

7.1.2. Sound flow settings ...................................................7

7.1.3. Optimising functions................................................10

7.2. Cylinder steam function..............................................10

7.3. Firmware update with the LokProgrammer .................12

8. Support ................................................................... 12

9. Guarantee certificate............................................. 15

Content

1. EU Declaration of Conformity

ESU electronic solutions ulm GmbH & Co. KG, Edisonallee 29,

D-89231 Neu-Ulm, herewith declares in its sole responsibility that the

product complies in terms of

Product name: Smoke Unit „Dual“

Type number: 54677

with all relevant regulations regarding Electromagnetic Compatibility

(2004/108/EG). The following harmonized standards were applied:

EN 55014-1:2006 + A1:2009: Electromagnetic compatibility – Requi-

rements for household appliances, electric tools and similar apparatus

– Part 1: Emission

EN 55014-2:1997 + A1:2001 + A2:2008: Electromagnetic compatibi-

lity – Requirements for household appliances, electric tools and similar

apparatus – Part 2: Susceptibility.

2. WEEE Declaration

Directive (RoHS) and Waste Electrical and Electronic Equipment Direc-

tive (effective in the European Union and other European countries

with separate collection system).

This symbol displayed on the product, the packaging or in the do-

cumentation implies that this product may not be disposed of as

household refuse. Instead the product should be ta-

ken to the suitable waste disposal facility for recycling

of electrical and electronic products. By disposing of

the product in the correct manner you help to avoid

negative environmental effects and damage cause to

someone´s health that may be caused by inappropri-

ate disposal. Recycling of material will help to preserve our natural

resources. For further information regarding recycling of this product

please contact your local council, your collector of household refuse

or the shop where you purchased this product. All brands or trade-

marks are registered trademarks of the respective owners and are

not identified in all cases. One may not assume that due to a missing

trademark or identification that a term or a picture are not a registe-

red brand or trademark.

3

Important hints

3. Important hints – Please read this first!

We congratulate you to your purchase of an ESU smoke generator.

This manual aims to inform you step by step regarding the electri-

cal connection of this module.

In order avoiding any defects or damages please read this manual

carefully prior to installing the product!

•The smoke generator is exclusively to be used in electric model

trains and model train layouts. It may only be operated with the

components described in this manual.

•The smoke generator gets quite hot (more than 100°C). Avoid

touching it and choose the location for installing it in such a man-

ner that no damage can occur.

•Never turn the smoke generator upside down if its tank is filled.

Leaking oil may lead to burns.

•Only work on the electrical connections when the power is tur-

ned off.

•Adhere to the wiring principles when connecting the product as

presented in this manual.

•Protect the product against moisture and humidity.

•Wires may never touch any metal parts of the locomotive.

•For preventing short circuits please make sure there are no wires

squeezed when reassembling the locomotive.

4. General properties

The ESU smoke generator Dual for G and 1 Gauge models as well

as for larger 0 Gauge models generators realistic smoke and steam

clouds of your models. Both an exhaust steam and a cylinder

steam are integral to the housing. Two fan motors and two hea-

ting systems are separately controlled by the electronics subject to

state of movement. Sensors keep the desired heating temperature

independently of track voltage and fill level and prevents a burn

out in case of an empty tank.

The smoke generator is optimised for operating with our Lok-

Sound 5 XL and LokSound 5 L decoders. In combination with

these decoders the desired amount of smoke can be precisely

adapted to the sound flow. When connected to an ESU decoder

there is no need for any programming of the smoke generator.

5. Scope of delivery

With its dimensions of 69 x 33 mm (39 mm including the moun-

ting tabs) the smoke generator is relatively compact. The electro-

nics are separated from the mechanical part and connected with

a wire harness.

The following parts are contained in the scope of delivery:

•Smoke generator with separate circuit board (connected with wire

harness)

•Wire harness

•PVC tube (9 mm diameter) for cylinder steam

4

6. Installation of the smoke generator

Install the smoke generator at a suitable spot below the exhaust.

The spacing between the smoke generator and the opening of

the body should be as small as possible, but you should assure a

minimum distance of 1cm from the plastic locomotive body. Assu-

re a straight line for the exhaust for allowing condensed smoke to

drop back into the tank.

You may use the supplied silicone tube for establishing an airtight

connection between smoke generator and the opening in the

body. Shorten the silicone tubing as necessary.

6.1 Filling the system

The smoke distillate is filled into the tank through the exhaust ope-

ning. There is only one tank for both exhaust smoke and cylinder

steam. Only use ESU smoke distillate (part number 51990). Using

other liquids may cause damage to the paint finish, blocking the

system or destroying the heater unit due to accumulated residue.

Only activate the smoke function if somebody is present in well

aired (ventilated) rooms. The maximum filling capacity is 3.5ml.

This serves for about 10 minutes of operation.

Never exceed the maximum filling capacity of the system. If in

doubt, use a bit less rather than too much! The smoke generator

cannot be damaged even when the tank is empty!

Installation

Make sure the locomotive is on level ground when filling the tank,

never on gradient´, do not turn the locomotive sideways or upside

down! This avoids leaking distillate.

6.2. Wiring

Only use the supplied wire harness for connecting the smoke ge-

nerator. Simply plug the 6-pole plug directly on the circuit board

of the smoke generator.

The other end of the harness has a 4-pole plug as well as two

separate wires.

•The smoke generator receives the exhaust chuff pulses via the

green wire. The pulses may be supplied directly by a HALL sensor

or (preferably) be generated directly by the decoder.

•The smoke generator receives its commands via the yellow cable,

when connected to a LokSound 5 XL or LokSound 5 L decoder.

Connection to decoder

Figure 2: Wiring harness

Occupancy Colour

GND (ground) Black

not used Grey

not used Blue

U+ (Power supply) Red

AUX1 (Data transfer from the decoder) Yellow

Wheel sensor input Green

Figure 1: Smoke unit with connected electronics

5

6.3. Connecting with LokSound 5 XL & LokSound 5 L decoder

In this case the 4-pole plug is not needed. Cut it off and establish

the connection as shown in Fig. 3 respectively in Fig. 4.

The smoke generator receives its commands via the yellow wire.

Connection to decoder

This MUST be connected to the AUX1 output of the decoder.

The AUX1 output is the only one that can supply the appropriate

data for the smoke generator after it has been configured accor-

dingly (also refer to chapter 6.1).

Figure 4: Connecting to LokSound 5 L Decoder

Figure 3: Connecting to LokSound 5 XL Decoder

6

Programming Programming

7. Programming the smoke generator

There are several options for adjusting the performance of the

smoke generator. This helps to achieve optimum performance of

the smoke generator in conjunction with your model. Subject to

the decoder type different adjustments are required.

7.1. ESU LokSound 5 XL & LokSound 5 L decoder

You can configure the smoke generator in many ways to meet

your personal preference. This can only be done with the ESU Lok-

Programmer 53451 because some adjustments in the sound flow

are necessary. First load the desired sound project into the Lok-

Programmer followed by the individual adjustments. Sound and

smoke control work closely together and are both essential for

achieving optimal performance. As an example we illustrate the

process with the sound file S0010 (class 50). All required settings

have already been done. For all other sound projects you have to

adjust the required settings.

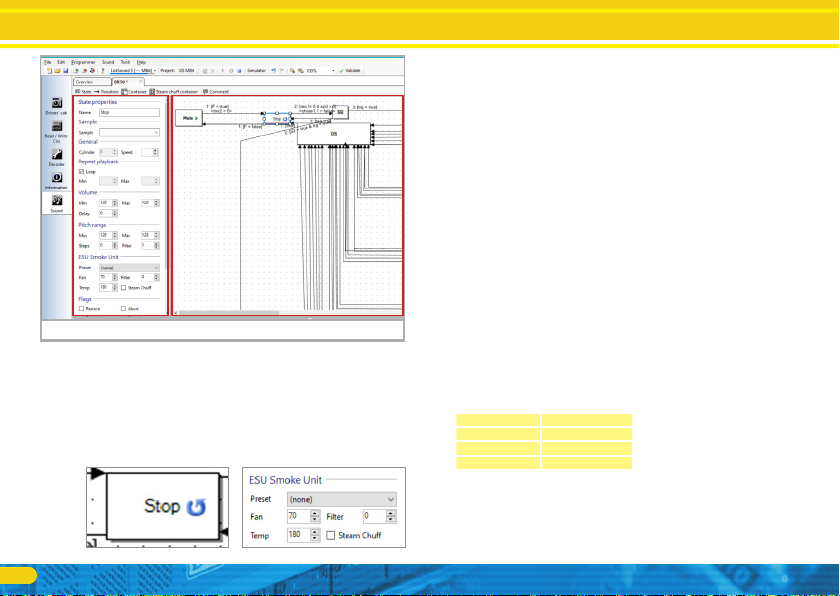

7.1.1. Basic settings

Initially the output AUX1 must be configured in such a way that it

provides the data for the smoke generator instead of functioning

as an ordinary function output.

•Select “AUX1[1]” in the register “Function Outputs and select

“Smoke generator with external circuit board”. Then click on the

last entry as shown in Fig. 5.

•Then the output connected to the green wire must be configured

such that an exhaust trigger is transmitted. In this example it is

AUX2.

•Select “Exhaust trigger” and adjust smoke and blower to the value

31 and the “Timeout” to 0. Fig. 6 shows the relevant settings.

Figure 5: Settings AUX1

Figure 6: Settings AUX2

7

Programming Programming

•Now you must assign the function button for triggering the smoke

generator in the register “Function Mapping”. Select the func-

tion “ESU Smoke generator” in the row of the desired function

button. The ex-works setting for most LokSound 5 decoders is

configured to F15.

7.1.2. Sound flow settings

The most important and comprehensive settings are found in the

“Sound” register. Adjust the desired heating temperatures and

the revs in the sound flow. Of course, for most projects this has

already been set ex-works, so you hardly need to change any of

these parameters.

First select sound slot 1 by double clicking it in the list of available

sound slots.

Figure 7: Function Mapping settings

Figure 8: Open Soundslot 1

8

Programming Programming

This opens a window similar to Fig. 9:

a) Conditions and transitions

b) Properties of the selected condition respectively transition

The properties shown on the left of part b) change subject to what

has been marked in the square at top right. Transitions are shown

as white rectangles. Mark the “Stop” condition with the mouse

as shown in the Fig. 9.

You will find the most interesting parameters in the chapter „ESU

Smoke generator”.

•Fan: Here you may adjust the revs of the fan motor. The higher the

value the faster turns the fan and the more smoke is ejected. The

value “255” means “full throttle” (maximum). Please determine

suitable values for your model. High fan revs usually also require

a higher temperature to assure that sufficient smoke is generated.

•Temperature: Here you may adjust the temperature in °C. Higher

values generate more smoke but also lead to a high thermal load

for the smoke generator. The maximum temperature of the smoke

generator is internally limited and is also subject to the mechanics.

The theoretically possible value of 255 °C will therefore not be

reached in practice.

•Filter: Here you may adjust how quickly the fan motor responds

to changes of the desired revs. The value 0 facilitates immediate

adaptation while higher values effect a soft transition. In some

case this may facilitate more realistic exhaust effects.

•Exhaust chuff: Enter this tick wherever smoke should be ejected.

Only if you enter a tick at these positions the LokSound decoder

will “instruct” the smoke generator to produce an exhaust chuff.

Otherwise smoke will continuously be ejected (Diesel mode).

It is necessary to enter meaningful values for every condition.

We recommend the following procedure:

STOP Condition:

Here low values should be entered, e.g.

Fan 59

Temperature 165

Filter 0

Exhaust chuff Not applicable

Figure 9: Soundslot 1 open

a)b)

9

Programming

SD Conditions (“Stop to Drive”), DS (“Drive to Stop”):

Here you may start with the following values:

Fan 42

Temperature 235

Filter 0

Exhaust chuff Not applicable

“Coast” as well as “DCX” conditions

Fan 42

Temperature 155

Filter 0

Exhaust chuff Not applicable

The actual speed steps are called Dx in all ESU projects. Some

sound projects contain D1 to D4, others go up to D8. These are

the normal exhaust chuffs.

Here you should experiment with the following values:

Fan 212

Temperature 220

Fan 0

Exhaust chuff Set

For acceleration steps A (mostly A1 to A4, sometimes to A8) we

recommend entering higher heating values and fan revs, e.g.

Fan 245

Temperature 235

Filter 0

Exhaust chuff Set

You may mark several conditions simultaneously by holding down

the shift button while marking the induvial squares one after the

other. If you now change the fan and temperature values, these

changes are valid for all currently marked conditions.

Figure 10: All D levels marked

10

Programming

If sound slot 2 is active in the list of available sound slots but is

marked in grey, there is no reason to be concerned. This means

that two sound channels are used for the exhaust chuff. A copy of

the smoke motor in Sound slot 1 will automatically be generated

and applied. Here you do not need to enter any changes.

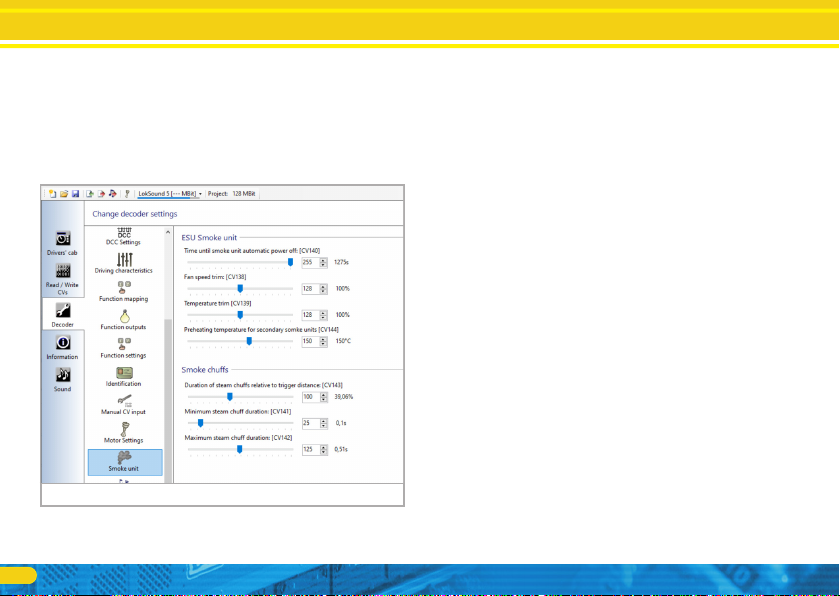

7.1.3. Optimising functions

In the final step you can optimize further options in the “Smoke

generator” register. Fig. 11 show all available options.

•Time until automatic switch off: Here you can set an automatic

switch-off time. Generally, a duration of about 10 minutes is

practical. This prevents excessive current draw when the tank is

empty. Whenever the smoke generator is turned off automatically

one must reactivate it by turning it off and then on again.

•Adaptation of the fan speed: Here you can adjust the fan speed

relative to the values set in the sound flow.

•Adaptation of the heating temperature: Here you can adjust the

temperature relative to the values set in the sound flow.

•Preheating temperature for secondary smoke generators: If so

desired, one can preheat the cylinder steam for achieving a faster

response. Please bear in mind that the preheating is active, until

the smoke generator is switched on and therefore draws extra

current.

•Duration of exhaust chuffs: Subject to wheel diameter and instal-

lation situation the exhaust chuffs may be a bit short. Increase the

value for triggering more powerful exhaust chuffs. The duration

is given in a ratio to their interval in %. A value of 50% triggers

exhaust chuffs whose duration is half of their interval.

•Minimum duration of exhaust chuffs: Regardless of how quickly

the pulses from the wheel sensor arrive, the duration of the ex-

haust chuffs will never fall below the value set here.

•Maximum duration of exhaust chuffs: Here you may adjust and

limit the duration of the exhaust chuffs to the desired value.

7.2. Cylinder steam function

For utilising cylinder steam you must first establish a mechanical

connection between the outlet of the smoke generator (in front,

at the bottom) and the opening on the locomotive.

Ideally the outlet is located between the cylinders. Some silicone

tube is supplied with the smoke generator.

Figure 11: Smoke generator settings

11

Programming

Now all you need to do is set appropriate values for heating tem-

perature and fan speed in the “Cylinder blow-out” register. In our

example this is entered in sound slot 9 “Cylinder blow-out”.

The LokSound decoder “assumes” in case of sound slot greater

than 4 that this must be cylinder steam and transmits the re-

levant commands to the smoke generator. The number of the

sound slot facilitates triggering the corresponding smoke gene-

rator. Sound slots 1 and 2 control the main exhaust, all sound

slot 4 or higher control cylinder steam.

Finally, please make sure that you write the CV values AND the

sound to the decoder once again. The entries regarding the smoke

generator will only be written in conjunction with the sound data.

Figure 12: Cylinder steam outlet

Cylinder steam

outlet

Figure 13: Soundslot 9 Cylinder steam smoke generator settings

12

Support

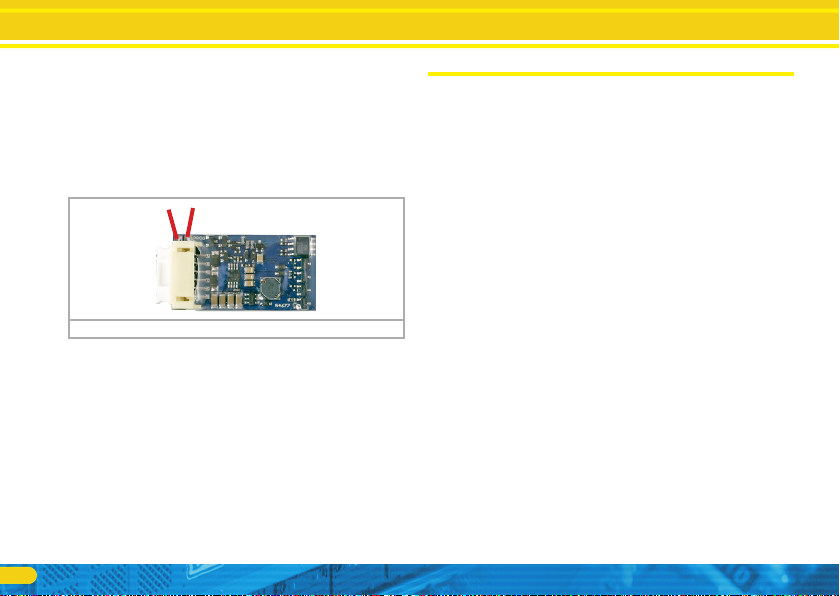

7.3. Firmware update with the LokProgrammer

Of course, the firmware of ESU smoke generators can be updated

with the LokProgrammer. However, the smoke generator must be

removed from the model and directly connected to the LokPro-

grammer. There are two separate solder points for this purpose.

They are marked with “PROG”. Fig. 14 shows where they are lo-

cated. These two outputs must be wired to the LokProgrammer.

Disconnect all other wires to the decoder by removing the white

plug. The connection to the smoke generator does not have to

be separated.

Figure 14: 54677 Solder connections for LokProgrammer

8. Support

Should you have questions regarding your smoke generator to

which you have not found the right answer in this manual please

first contact your hobby shop. The people there are your compe-

tent contact for all questions relating to model trains. In difficult

cases, you can contact us directly. Look first on our website under

«Support / FAQ» to see whether the question has already been

answered. If this is not the case, we ask you to make these availab-

le to us either in our support forum or to contact us by e-mail. We

also provide a telephone hotline, which should only

be used in the case of really special requests.

For Germany

by phone: +49 (0) 731 - 1 84 78 - 106

Tuesday & Wednesday

from 10.00 to 12.00 o‘ clock

by Fax : +49 (0) 731 - 1 84 78 - 299

by E-Mail: www.esu.eu/kontakt

by mail: ESU GmbH & Co. KG

Edisonallee 29

D-89231 Neu-Ulm

www.esu.eu

For USA, Canada, Australia

by phone: +1 570-980-1982

Tuesday & Thursday

from 8am to 4pm (EST)

by Fax : +1 866-591-6440

by mail: ESU LLC

1304 Jordan Ave

Montoursville PA 17754

www.loksound.com

13

Notices

14

Notices

Copyright 1998 - 2021 by ESU electronic solutions ulm GmbH & Co KG. Irrtum, Änderungen die dem technischen Fortschritt dienen, Liefermöglichkeiten und alle sonstigen

Rechte vorbehalten. Elektrische und mechanische Maßangaben sowie Abbildungen ohne Gewähr. Jede Haftung für Schäden und Folgeschäden durch nicht bestimmungs-

gemäßen Gebrauch, Nichtbeachtung dieser Anleitung, eigenmächtige Umbauten u. ä. ist ausgeschlossen. Nicht geeignet für Kinder unter 14 Jahren. Bei unsachgemäßem

Gebrauch besteht Verletzungsgefahr.

Märklin® und mfx® sind eingetragene Warenzeichen der Firma Gebr. Märklin® und Cie. GmbH, Göppingen. RailCom® ist ein eingetragenes Warenzeichen der Firma Lenz®

Elektronik GmbH, Gießen. RailComPlus® ist ein eingetragenes Warenzeichen der Firma Lenz® Elektronik GmbH, Gießen.

LocoNet™ ist ein eingetragenes Warenzeichen der Fa. Digitrax, Panama City, USA.

Alle anderen Warenzeichen sind Eigentum ihrer jeweiligen Rechteinhaber.

ESU electronic solutions ulm GmbH & Co. KG entwickelt entsprechend seiner Politik die Produkte ständig weiter. ESU behält sich deshalb das Recht vor, ohne vorherige

Ankündigung an jedem der in der Dokumentation beschriebenen Produkte Änderungen und Verbesserungen vorzunehmen.

Vervielfältigungen und Reproduktionen dieser Dokumentation in jeglicher Form bedürfen der vorherigen schriftlichen Genehmigung durch ESU.

15

Guarantee certificate

9. Guarantee certificate

24 months warranty from date of purchase

Dear customer,

Congratulations on purchasing this ESU ECoS command station. This quality product was manufactured applying the most advanced produc-

tion methods and processes and was subject to stringent quality checks and tests.

Therefore ESU electronic solutions ulm GmbH & Co. KG grants you a warranty for the purchase of ESU products that far exceeds the national

warranty as governed by legislation in your country and beyond the warranty from your authorised ESU dealer.

Manufacturer’s warranty of 24 months from date of purchase.

Warranty conditions:

This warranty is valid for all ESU products that have been purchased from an authorised ESU dealer.

Any service, repair or replacement under this warranty requires proof of purchase. The filled in warranty certificate together with the receipt

from your ESU dealer serves as proof of purchase. We recommend keeping the warranty certificate together with the receipt.

In case of a claim please fill in the enclosed failure report card as detailed and precise as possible and return it with your faulty product.

Please use the appropriate postage when shipping to ESU.

Extend of warranty / exclusions:

This warranty covers free of charge repair or replacement of the faulty part, provided the failure is demonstrably due to faulty design, manu-

facturing, material or transport. Any further claims are explicitly excluded.

The warranty expires:

•In case of wear and tear due to normal use.

•In case of conversions of ESU – products with parts not approved by the manufacturer.

•In case of modification of parts.

•In case of inappropriate use (different to the intended use as specified by the manufacturer).

•If the instructions as laid down in the user manual by ESU electronic solutions ulm GmbH & Co. KG were not adhered to.

There is no extension of the warranty period due to any repairs carried out by ESU or replacements.

You may submit your warranty claim either with your dealer or by shipping the product in question with the warranty certificate, the receipt

of purchase and the fault description directly to ESU electronic solutions ulm GmbH & Co. KG at:

ESU GmbH & Co. KG

- Guarantee Section -

Edisonallee 29

D-89231 Neu-Ulm

16

1. Personal data (Please write in block letters)

Name:...................

Street:...................

ZIP/City: ................ ||||||

Country: ...............

Email:....................

Phone: ..................

Date:.....................

Signature: .............

2. Error

No Function (please describe the error in more detail)

3. Error description (use extra page if needed)

4. Receipt

Please enclose your receipt / invoice. Otherwise no warranty possible!

5. Additional information: 6. Your retailer:

Retailer´s stamp or address

Trouble shooting sheet

Table of contents

Popular Portable Generator manuals by other brands

DTI Dyna Technology

DTI Dyna Technology Winco W3000H Installation and operator's manual

Wagan

Wagan SOLAR e POWER CASE 800 user manual

Fabco Power

Fabco Power HYDRO 300CX-4.5-60HZ-G instruction manual

GENTRON

GENTRON 950W Series owner's manual

CAMPAGNOLA

CAMPAGNOLA POWER 12 Use and maintenance manual

Rigol

Rigol DSG3000 Series user guide