Esu Class 66 User manual

En g i n E E r i n g Ed i t i o n

Instruction manual

1. Edition, September 2014

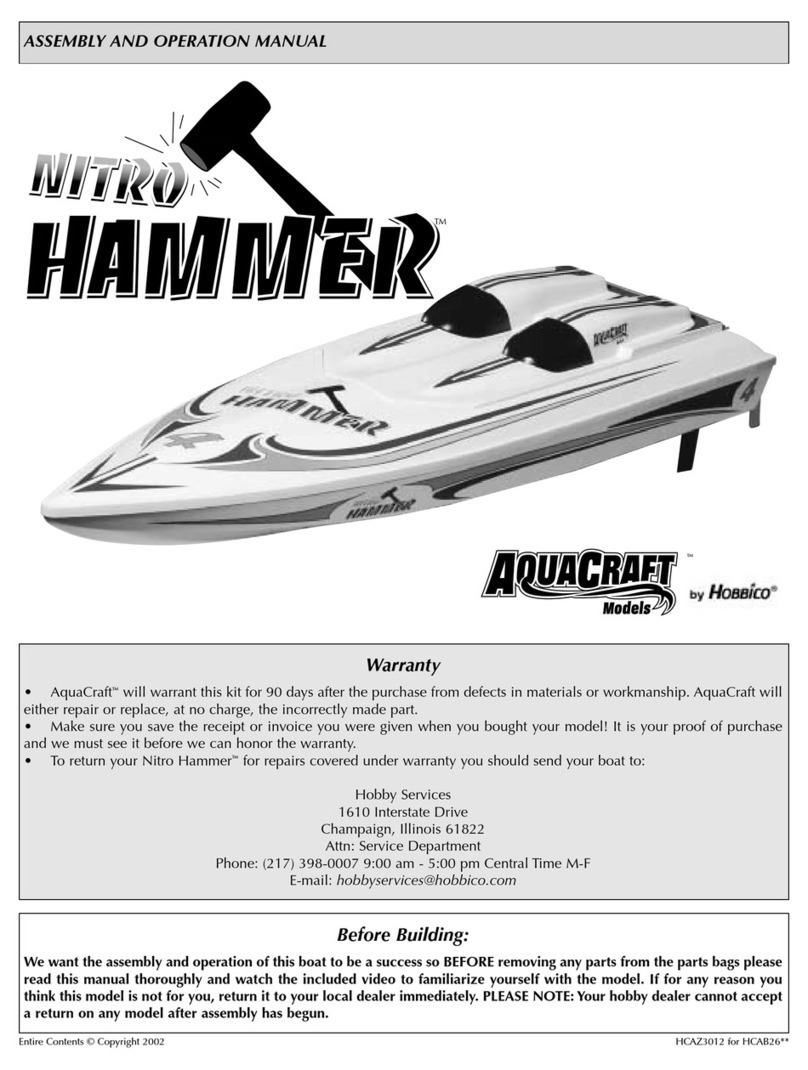

Class 66/77

2

Content

1. Declaration of Conformity

We, ESU electronic solutions ulm GmbH & Co. KG, Edisonallee 29, D-89231 Neu-Ulm, Germany, declare in sole responsibility that the product

„ESU H0-Diesellok Class 66/77“, part number: 31050, 31051, 31052, 31053, 31054, 31055, 31056, 31057, 31058, 31059, 31070, 31071,

31072, 31073, 31074, 31075, 31076, 31077, 31078, 31079 complies with all relevant regulations of the Directive for Electromagnetic Com-

patibility (2004/108/EG). The following harmonised standards have been applied:

EN 55014-1:2006 + A1:2009: Electromagnetic Compatibility - requirements for household appliances, electric tools, and similar apparatus - Part

1: Emission - Product

EN 55014-2:1997 + A1:2001 + A2:2008: Electromagnetic Compatibility - Requirements for household appliances, electric tools, and similar

apparatus - Part 2: Immunity - Product family standard.

1. Declaration of Conformity........................................2

2. Prototype.................................................................3

3. Model .....................................................................6

3.1. Important remarks - please read this first ......... 6

3.2. Unpacking the model ...................................... 6

3.2.2. Mounting & removing the centre pick-up ..... 6

3.3. Outward appearance and special features........ 7

4. The technology of the ESU model ............................8

4.1. Possible operating modes of the class 66/77 .... 8

4.1.1. Analogue mode ........................................... 8

4.1.2. Digital mode................................................. 8

4.1.2.1. Digital operation with DCC systems .......... 8

4.1.2.2. DCC with RailComPlus®............................ 9

4.1.2.3. Prerequisites for RailCom® Plus ................. 9

4.1.2.4. M4 registration.......................................... 9

4.1.2.5. Digital operation with Märklin® Digital...... 9

4.2. Your first ride................................................... 9

4.2.1. Lighting functions......................................... 9

4.2.2. Sound functions ......................................... 10

4.2.3. Curve and turnout sensors.......................... 10

4.2.4. Synchronised smoke generator ................... 10

4.2.4.1. Filling the smoke generator holding tank . 10

4.2.4.2. Operating the smoke generator............... 11

4.2.5. PowerPack energy storage.......................... 11

5. Decoder Settings (Programming)............................12

5.1. Configuration Variables (CVs) ........................ 12

5.1.1. Standardisation in the NMRA...................... 12

5.1.2. Bits and Bytes ............................................. 12

5.2. Programming the decoder ............................. 12

5.2.1. Programming with DCC systems................. 12

5.2.2. Programming with Märklin® 6021 ............ 12

5.2.2.1. Changing to the programming mode ...... 13

5.2.2.2. Short mode ............................................. 13

5.2.2.3. Long mode.............................................. 13

5.2.3. Programming with the Märklin® Central

Station®............................................................... 13

5.2.4. Programming with ESU LokProgrammer ..... 14

5.3. Adress settings .............................................. 14

5.3.1. Short Addresses in DCC mode.................... 14

5.3.2. Long Addresses in DCC mode .................... 14

5.3.3. Motorola® address..................................... 14

5.3.3.1 Consecutive addresses for more functions 14

5.4. Adapting the Driving Characteristics .............. 15

5.4.1. Acceleration and Deceleration .................... 15

5.4.1.1. Shunting mode........................................ 15

5.4.2. Starting Voltage, Vmax ............................... 15

5.5. Break sectors ................................................. 15

5.5.1. DC break mode .......................................... 15

5.5.2. Märklin® brake mode ................................ 15

5.5.3. Lenz® ABC brake mode ............................. 16

5.6. Adjusting the volume .................................... 16

5.6.1. Overall sound volume ................................. 16

5.6.2. Adjust individual sounds ............................. 16

5.6.3. Motor sound .............................................. 16

5.6.4. Auxiliary sounds ......................................... 16

5.7. PowerPack..................................................... 16

5.8. Decoder reset ................................................ 17

5.9. Adjusting the brightness of the lights ............ 17

5.10. Smoke generator ....................................... 17

5.10.1. Blower of the smoke generator ............... 17

5.10.2. Heating temperature ............................... 17

6. Maintenance..........................................................17

6.1. Removing the housing................................... 17

6.2. Lubrication .................................................... 17

6.3. Replacing wheel sets ..................................... 17

6.4. Replacing traction tires .................................. 18

6.5. Installing a coupler ........................................ 18

7. Accessories supplied with the model......................20

8. Technical support...................................................20

9. Spare parts ............................................................20

10. List of all important CVs.......................................21

12. Warranty Certificate.............................................23

3

En g i n E E r i n g Ed i t i o n

Original

Prototype

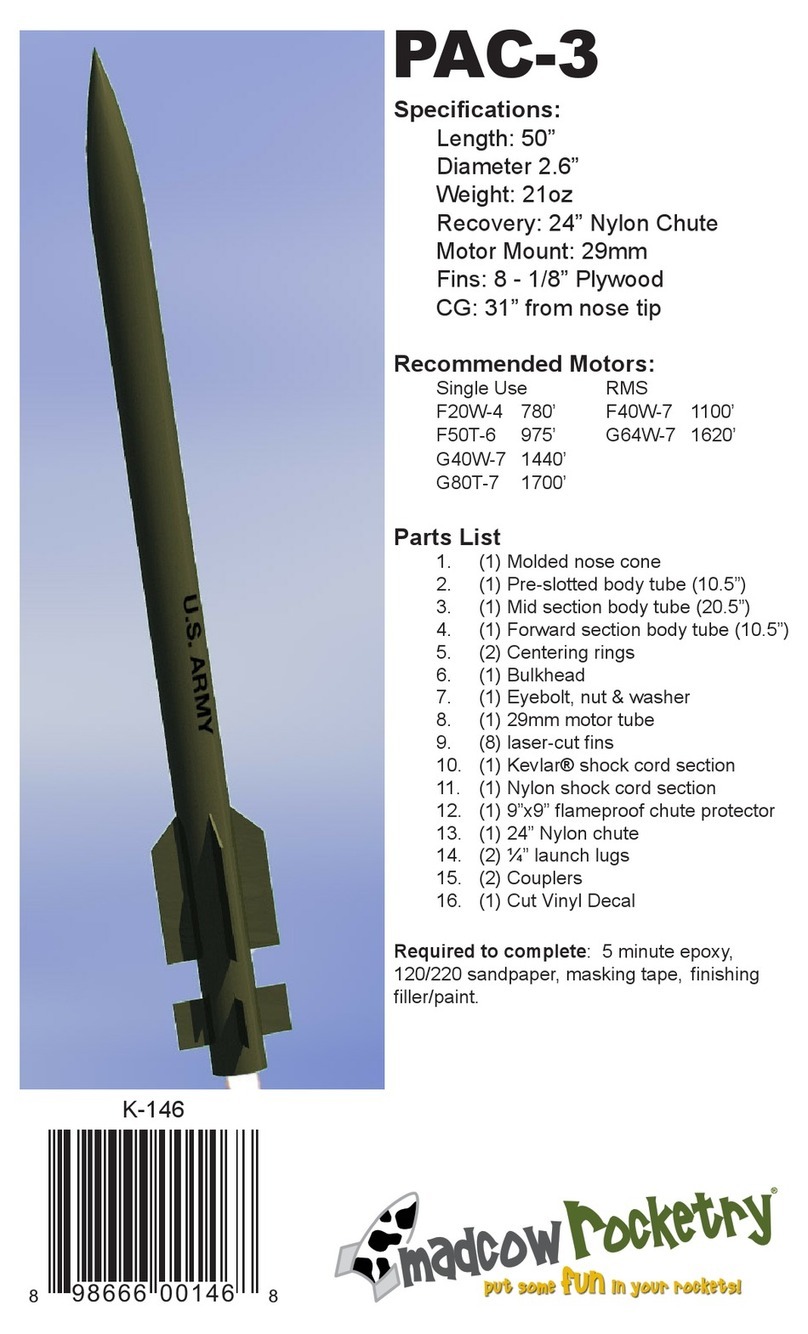

2. Prototype

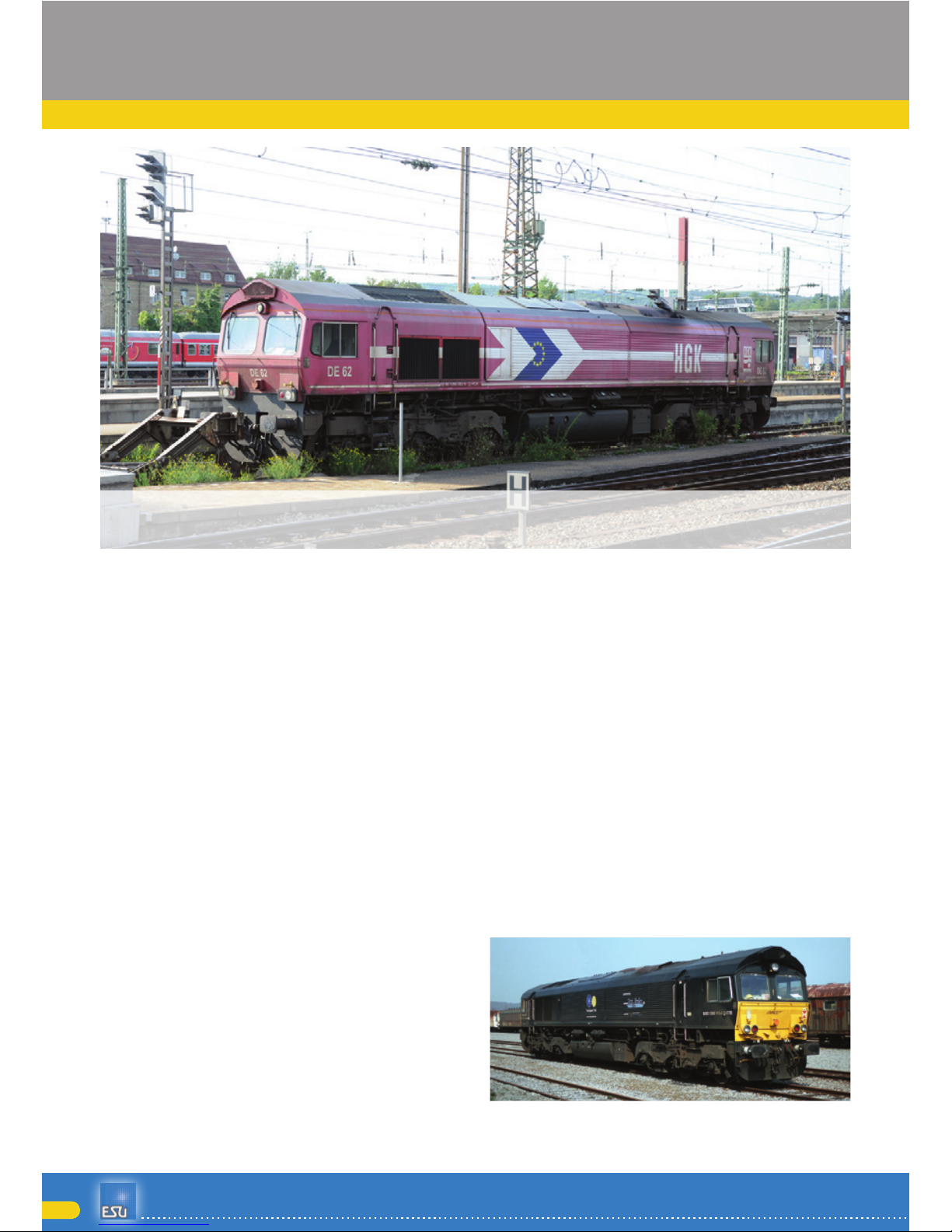

With the liberalisation of the international rail goods

traffic established in 2001 the newly founded rail

operators needed to procure motive power in order

to be able to handle the traffic they had fought so

hard to take away from the state owned railways.

The procurement of technically sophisticated new

vehicles was often not possible due to budgetary

restraints. A more cost effective solution was offe-

red by the American Electro Motive Division (EMD)

with the class 666 that had already been tested and

proven in Great Britain. The locomotives known as

the JT 42 CWR are based on the American SD40

and ongoing development culminating in the SD

40-2, which were found to be most reliable due to

their simple, but proven design.

The first railway institution employing the diesel

electric class 66 on German lines was the Harbour

and Freight Services AG in Cologne the so called

Häfen und Güterverkehr Köln AG (HGK). In 1999

this company purchased two units. Almost at the

same time the class 66 was introduced to other Eu-

ropean countries. Rail traffic corporations having

purchased or leased class 66 locomotives can be

found in France, Belgium, the Netherlands, Lux-

embourg and Norway. So far about 650 units have

been delivered in two different version to European

customers. The somewhat long and slim outline

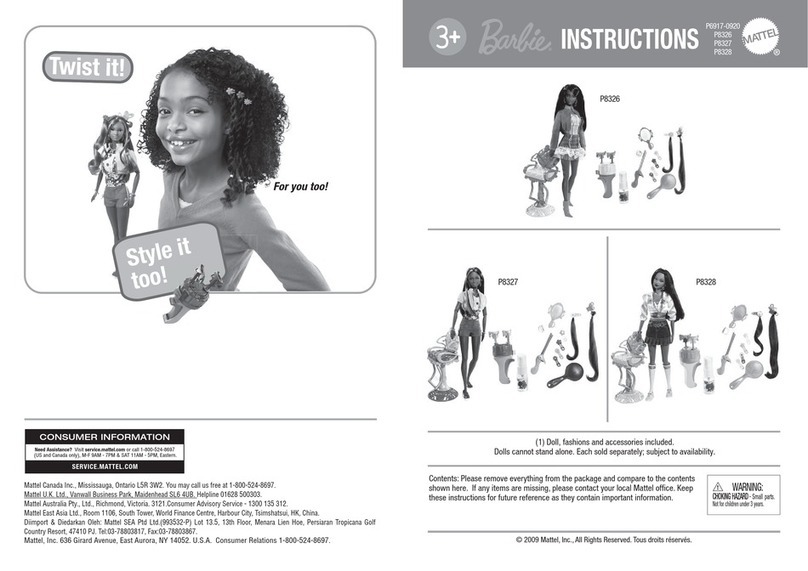

Class 66‘ predecessor is named JT 26 CW-66. The picture shows Deutsche Bahn 259 003 in Sed-

din on 28.9.1997

Picture: Rolf Wiemann

meets the clearance diagram of British Rail. The

square-edged design of the body and the chassis

with its massive boogies and quite a number of see-

mingly confusing pipes and cables give the class 66

an unmistakable appearance.

The General Motors twelve Cylinder Two Stroke

engine 12N-710G3B-EC can not only be heard but

also recognised due to its characteristic sound and

offers a power of 3194 HP (2350 kW). The starting

tractive effort amounts to 409 kN, the continuous

tractive effort is 260 kN. With a maximum speed of

120 km/h the class 66 locomotives can easily keep

pace with other trains using electric traction even

on mainlines. Due to the independence from cen-

tenary the client can, if need be, pick up the train

from the most remote spur or siding and take it

via DB mainlines right through to his own factory.

With their livery the class 66 locomotives form a

pleasant contrast to the standardized red livery of

the DB AG.

Since 1999 the HGK mainly handles block trains

with their class 66 locomotives albeit with varying

loads. Tank cars have been a standard load for HGK

class 66 locomotives taking the train over the entire

route to Braunschweig, Ingolstadt, Marktredwitz

and Aichstetten. But one can also find the locomo-

4

Prototype

tives from Cologne in central Germany whenever

they haul a train to Leuna or Berlin, amongst others.

We have chosen the DE671 built in 2003 and with

an extended concession issued in 2011 as the pro-

totype for our model that bears white stripes on

the front.

The livery of the class 66 locomotives is accentuated

by the sharp contrast of black or grey sides with

the light green contrast patches leading around the

cabs. In Germany, Belgium and the Netherlands the

Captrain locomotives are mainly deployed hauling

container traffic, block trains consisting of tank

wagons or coal cars. They also display their power

ahead of block trains made up of cars with sliding

sides carrying parts for the automotive industry. In

Germany these six axle locomotives regularly travel

from the Rhine Ruhr region as far as Berlin.

As from 2010 CB rail, a renter of locomotives sent

their German and Luxembourg subsidiaries under

the name of Ascendos Rail Leasing GmbH into the

game of rail freight traffic. For operations on only

partly electrified lines Ascendos has a stable of 20

class 66 locomotives and an extra three class 77.

For Modeltrain enthusiasts these locomotives with

their green livery accentuated by the turquoise and

yellow contrast stripes are highly attractive since

they are not only deployed to haul block trains with

containers, tank cars, construction materials, coal,

motor vehicles or machine parts but make them-

selves useful in track maintenance service of for

transfers of other vehicles. Particularly in the area

of construction site logistics these locomotives are

often seen with only a handful of cars. Well known

companies renting these six axle locomotives have

been and are the HGK, Crossrail, ITL or the Ruhr-

talbahn deploying them all over Germany, Belgium

and the Netherlands.

The four units owned by the SNCF Benelux and re-

gularly travelled through Belgium, the Netherlands

and Germany in their impressive and very elegant

blue silver livery. Initially it was quite easy to diffe-

rentiate them due to their different design of the

contrast areas on the front and rear. They were

mainly hauling two axle hoppers, container trains

and tank car trains.

HKG‘s DE 62 still owns the british style headlights with outer position lamp in contrast to DE

61. Picture taken on 24.08.2011 in Ulm Hbf

Picture: Jochen Frickel

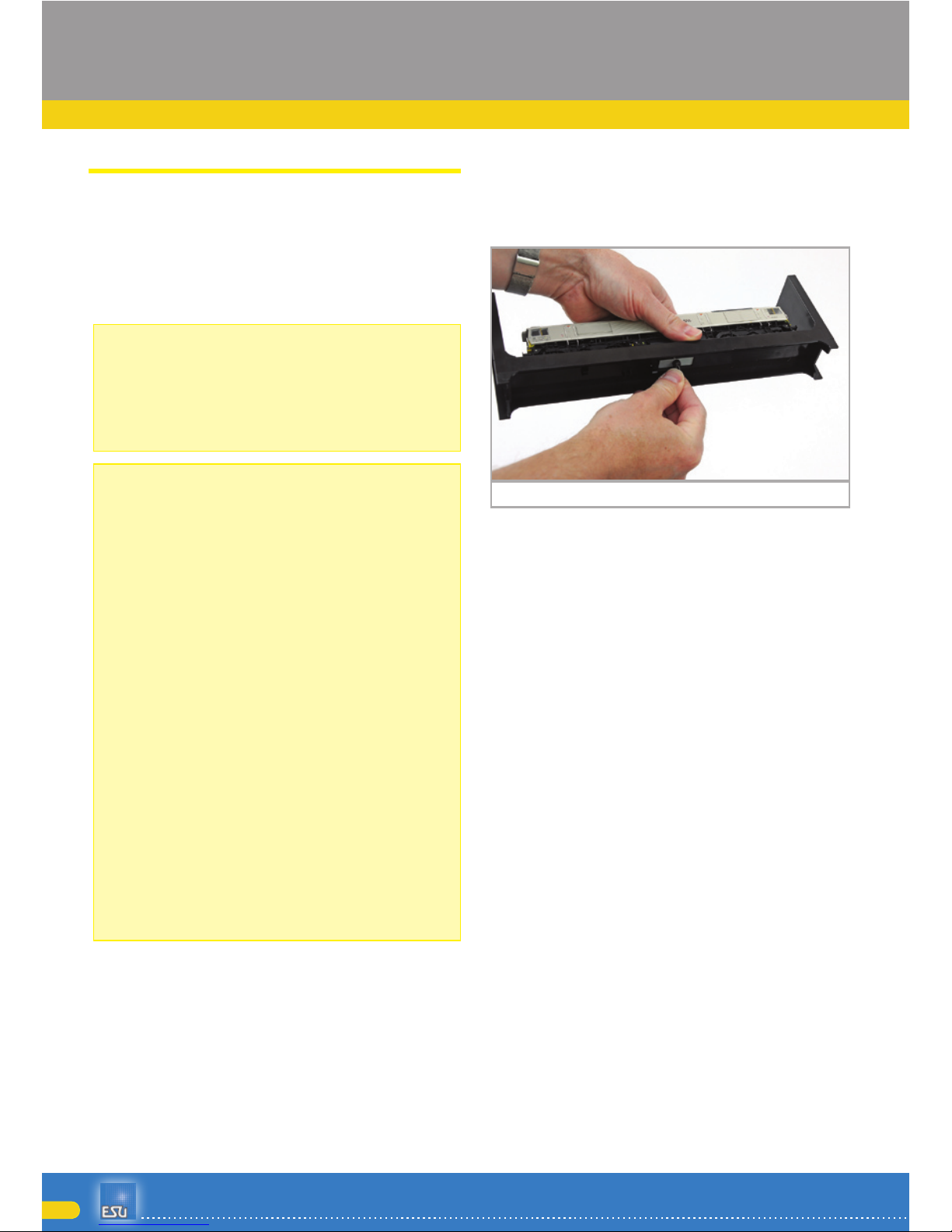

The prototype of the ESU model in Montzen

/ Belgium

Picture: Rolf Wiemann

5

En g i n E E r i n g Ed i t i o n

Original

Prototype

Section view of class 77 showing the components locationsFigure 1:

Drawing: ESU GmbH & Co. KG

DE61 of HGK is allowed to be used in ger-

many only

Picture: Jochen Frickel

Crossrail‘s class 77 DE 6311 in Neuwied train

station

Picture: Rolf Wiemann

6

Model

3. Model

3.1. Important remarks - please read this first

Congratulations to your purchase of the H0 diesel

locomotive class 66/77. Your H0 model offers va-

rious innovative functions. This manual provides a

step by step insight into the features of the class

66/77. Therefore we have one request:

Please read this manual prior to operating the mo-

del carefully. Although the model is quite robust,

inappropriate handling could lead to injury of the

operator or to damage of the locomotive. Do not

indulge in “costly” experiments.

This locomotive is not a toy and should only be•

operated under supervision.

Please make sure that the room has adequate•

ventilation when operating the smoke genera-

tor continuously!

Keep the smoke distillate away from children. It•

contains substances that may damage your he-

alth if consumed. In case of contact with your

eyes consult a doctor immediately.

Please return the pipette only into the packaging•

after you have emptied it completely. Otherwise

you may risk draining the smoke distillate.

Protect the model against wet conditions and•

humidity.

When working on the locomotive (maintenance)•

always make sure there is no power connected

to the model. Replace the housing on the chas-

sis prior to operating the locomotive after main-

tenance work.

Make sure that no wires are squeezed or that no•

short circuit may occur.

Please note: All models shown here are pre-produc-

tion samples. They may vary slightly from the series

production models!

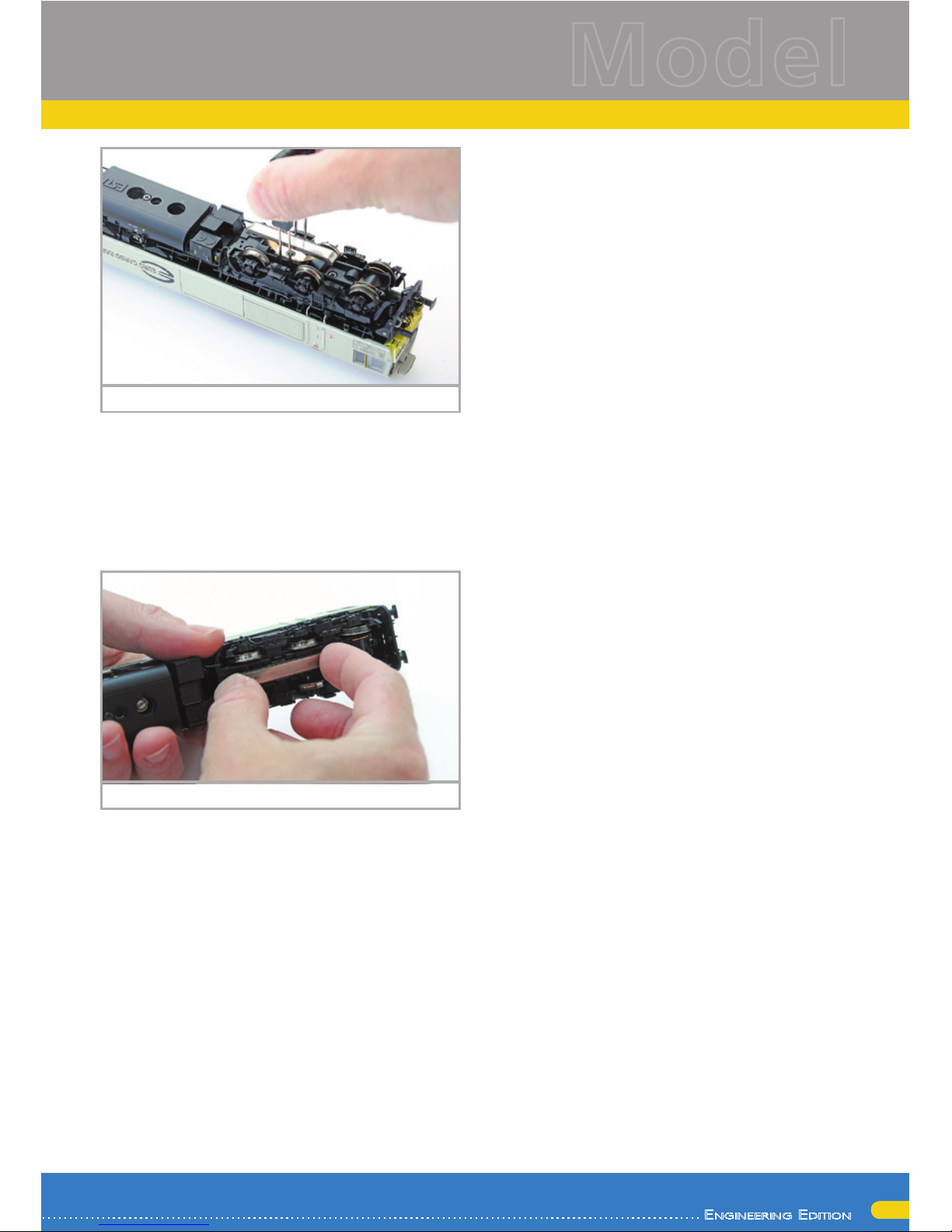

3.2. Unpacking the model

Pull the model screwed to the plastic holder with

both hands out of the foam insert. At the bottom of

the plastic holder you will find a hexagon spanner.

Now place the model on its side, hold the model

and the plastic holder with one hand and release

the hexagon bolt with the other hand.

For safe keeping of the spanner there are two retai-

ning clips at the bottom of the plastic holder.

Please keep all parts of the packaging and this

manual for later use. Only the original packaging

guarantees proper protection against transport da-

mage. Please fix the locomotive by means of the

hexagonal bolt to the plastic holder and place it into

the foam insert and put it into the carton and the

transport box prior to shipment.

Now you must adapt your class 66/77 to the control

mode of your layout. If you are a Märklin model

train enthusiast and therefore need a locomotive

with a centre pick-up you may simply place the lo-

comotive onto the track, enter address 3 and you

are ready to run.

The centre pick-up clipped onto the locomotive ser-

ves not only for current pick-up but also activates

the electrical connection of both rails. Thus all 12

wheels pick-up current from the tracks.

If you operate a two-rail layout you must remove

the centre pick-up. How you do this is described in

chapter 3.2.2.

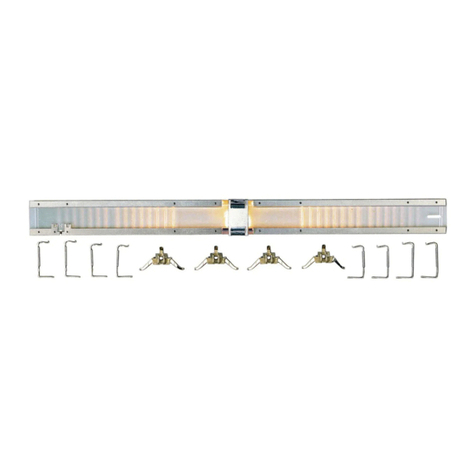

3.2.2. Mounting & removing the centre pick-up

Removal: Put the locomotive on its roof. Then you

apply the tool in such a way that the ends of the

four wire brackets fit into the four holes below the

base plate of the centre pick-up. Carefully(!) squee-

ze the tool and then lever the centre pick-up with a

slight tug from its position.

release of hexagon boltFigure 2:

7

En g i n E E r i n g Ed i t i o n

Model

Model

Mounting: For re-converting your locomotive to a

three-rail vehicle again hold the centre pick-up bet-

ween thumb and index finger and place it in the

receptacle. Please note that the centre pick-up must

be attached to bogie “1”. Finally press the centre

pick-up until there is an audible “click”. That´s it!

3.3. Outward appearance and special features of

your class 66/77

With your new class 66/77 you can operate your

model trains prototypically like never before. There

are many separately applied detail parts on the me-

tal housing as well as on the metal chassis. Of cour-

se, such details and modifications of the housing

are correct for the respective locomotive number.

All grab irons are made off sturdy plastic and are

separately applied. Separate plastic pipes are atta-

ched to the bogies.

The large speaker powered by the LokSound V4.0

M4 decoder distributes its powerful sound through

the cut-through radiator grills. New is also the sen-

sor triggering the squealing noise in curves and on

turnouts.

The ESU 5-pole high performance motor with a vir-

tually silent commutator and two flywheels assure

plenty of power and smooth running. All four axles

are powered.

Four traction tires assure considerable tractive ef-

fort. Model train enthusiasts who prefer to run their

locomotives without traction tires and rather enjoy

more prototypical wheels sets find a voucher for six

wheel sets (2-rail system) with RP 25 wheels (please

also refer to page 26!). In order to obtain these

wheel sets, simply send this voucher to ESU. In or-

der to assure perfect driving dynamics and excellent

sound without interruptions due to dirty tracks the

locomotive is equipped with a “PowerPack“energy

storage module.

A coupler shaft as per NEM 362 with short coupler

kinematics provides close coupling between loco-

motive and train in any situation.

In terms of its lighting the class 66/77 is just as

prototypically versatile as its full scale counterpart.

Of course there is directional lighting generated by

warm white LEDs that can be turned off at one end,

wherever the train is coupled to the locomotive.

During shunting all three headlights at either end

are switched on. In addition there is directional cab

lighting as well as illuminated driver’s cab-control

panel. Since these locomotives are employed inter-

nationally one can also set the lighting according to

the Belgian, Dutch and French lighting rules.

pickup shoe removalFigure 3:

Assembly of pickup shoeFigure 4:

8

Technical functions

4. The technology of the ESU model

The new LokSound V4.0 M4 decoder is a central

part of your new class 66/77. Its circuitry is responsi-

ble for design and control of all running and sound

functions of the class 66/77:•

Driving forward and in reverse•

Lighting functions•

Sound functions•

Smoke generator•

Besides M4 the LokSound V4.0 M4 also supports

DCC with RailComPlus, Motorola® and Selectrix®

and also be operated on analogue layouts. Pro-

gramming can be done either with DCC command

stations or with Märklin® central units, etc. the de-

coder automatically detects the mode of operation;

therefore you do not have to set anything in this

regard.

In case you wish to change any of the default set-

tings of the locomotive (such as the address or the

sound volume) we recommend to first reading

chapter 5. This chapter lists all parameters of the

LokSound V4.0 M4 decoder and how to change

them with the various command stations available

on the market.

4.1. Possible operating modes of the class 66/77

4.1.1. Analogue mode

The class 66/77 may also be operated on conven-

tional (=analogue) DC or AC model train layouts.

The number of available functions is, however, qui-

te limited:

Driving forward and backwards•

Directional lighting•

Engine sounds (automatic)•

The smoke generator cannot be turned on in ana-

logue mode. The engine sound sets in at about

6.5 V track voltage. At 8.5 V the locomotive slow-

ly starts moving. Both DC transformers (throttles,

e.g.: ROCO®) and AC transformers (e.g.: Märklin®,

Titan) are suitable for analogue operation. Please

note, that due to the large number of different sys-

tems on the market you may not achieve trouble-

free operation with electronic throttles employing

PWM (pulse width modulation).

Attention: the class 66/77 must have come to a

complete standstill before you activate the change-

of-direction command! Never switch to the opposi-

te direction while the locomotive is moving.

4.1.2. Digital mode

For prototypical operation we recommend using

a digital command control system. The numerous

functions are only available in digital mode.

The default address (ex works) is “03” (DCC and

Märklin® Motorola®)

14 speed steps with Märklin® Motorola®.

In DCC mode the decoder automatically detects the

speed steps set in the command station.

4.1.2.1. Digital operation with DCC systems

The class 66/77 can be operated with any DCC

compliant system. Sounds and other functions of

the class 66/77 can be triggered with the function

buttons F0 through F21.

Function mapping (ex works):

Functionmapping:

Button Function

F0 Directional lighting

F1 Engine sound

F2 Horn (high)

F3 Smoke generator

F4 Cab lighting

F5 Headlights off at cab 1

F6 Headlights off at cab 2

F7 Headlights as per lighting rules in BE/FR (Third headlight off)

F8 shunting lights DE/FR/BE

F9 Horn (low)

F10 Emergency stop

F11 Platform announcement

F12 Turnout sensor off

F13 Coupler sound

F14 Illuminated driver’s cab-control panel

F15 Shunting lights as per NL

F16 Air compressor / exterior lights as per CNet,TGOJ, CLF

F17 Station announcement

F18 Short horn (high)

F19 Short horn (low)

F20 Sanding

F21 Shunting mode

9

En g i n E E r i n g Ed i t i o n

Model

Technical functions

The number of the functions actually available is de-

termined by your command station respectively by

your throttle. Depending on the digital system there

may be fewer functions available.

4.1.2.2. DCC with RailComPlus®

The LokSound V4.0 M4 supports RailComPlus®,

which was jointly developed by Lenz® and ESU.

This means that the decoder automatically re-

ports to RailComPlus® capable command stations.

You will never ever have to change a locomotive

address manually! Simply put the locomotive onto

the track.

4.1.2.2. Prerequisites for RailCom® Plus

RailComPlus® implies an accordingly equipped di-

gital command station. The ESU ECoS command

station supports RailComPlus®-capable decoders

from software 3.4. You don´t need to change any-

thing about the decoder settings. It will be automa-

tically recognised.

Of course you can change the locomotive name,

all functional key and locomotive symbols and after

that write it back on your decoder. This happens

automatically in the background.

If you do not wish to have the automatic recogniti-

on, you can switch it off by deleting CV 28, bit 7.

4.1.2.4. M4 registration

If you use a Märklin® systems Central Station®,

Central Station 2 or mobile station®

The locomotive will be automatically detected and

registered by the system once you have put it onto

the track. This process occurs completely automati-

cally, you do not have to adjust any settings.

DCC with RailComPlus® has the highest priority

when registering the locomotive. Therefore the de-

coder will always register with RailComPlus® and

DCC on an ESU ECoS command station even when

M4 is active. If RailComPlus® is not available then

M4 will be treated as the second priority. Therefo-

re the decoder will register with M4 on a Märklin

Central Station®.

Whenever you run your class 66/77 with a Mär-

klin® central unit under M4, then the system limits

the number of available functions to 16.

4.1.2.5. Digital operation with Märklin® Digital (6021)

You may operate the class 66/77 with the Märklin®

6021 central unit without any problems. A special

feature allows you to assign three more addresses

besides the “actual locomotive address”. They are

known as following addresses. This enables you to

access 16 functions with your 6021. Details on how

to do this are described in chapter 5.3.3.1

4.2. Your first ride

Most certainly you wish to test your new locomo-

tive right away. We recommend going about this

step by step. Put the locomotive onto the track call

it up on your handheld throttle.

4.2.1. Lighting functions

First turn on the lights by pressing F0. Then the whi-

te forward headlights as well as the red rear lights

of the class 66/77 should light up. If you wish you

Beleuchtung Class 66/77

vorne hinten

Deutschland

Fahren

Rangieren

Belgien

Fahren

Rangieren

Nothalt:

Abwechselndes

Blinken der

weißen unteren

Lichter vorne

Niederlande

Fahren

Rangieren

Frankreich

Fahren

Rangieren

Lighting functionsFigure 5:

10

Technical functions

may switch on the cab lighting with F4 in order to

better see the cab interior.

If you now press F7 (while the headlights are turned

on) then the illuminated driver’s cab-control panel

will come to life. You will clearly see this through

the side windows of the cab.

It is common practice to turn of the head and tail

lights at the cab where a train is coupled to the

locomotive. Press F5 is the train coupled to cab 1

in order to switch off the head (tail) lights at that

end. When shunting without any vehicle coupled to

the locomotive you should press F8 in order to have

prototypical lighting for shunting.

In each bogie there are 4 LEDs, which are activated

during braking and thus simulate the sparks of the

brake shoes on the wheel rim as can be observed

on locomotives hauling heavy trains.

4.2.2. Sound functions

After pressing F1 (preliminary lubrication and star-

ting sequence) your class 66/77 comes to life and

continues with the typical sound of an idling two

stroke engine.

Once you go to speed step 1 the prime mover will

rev up before the locomotive slowly starts moving.

The response of the prime mover to different thrott-

le settings is for both - acceleration and slowing

down - somewhat delayed compared to diesel-

hydraulic locomotives, as is the case with the proto-

type. Shortly before coming to a standstill you will

hear the squealing brakes.

Of course you may trigger various user sounds with

your throttle (refer to the table on page 8). You may

also adjust the volume of each individual sound se-

quence. How to do this is described in chapter 5.6.

Another special feature is the station announce-

ments in different languages to suit different coun-

tries. Simply write the following values in the CV

mentioned below:

CV Value Language: station announcement

48 0 German

48 1 Dutch

48 2 French

4.2.3. Curve and turnout sensors

The class 66/77 has been equipped with a compre-

hensive set of sensors in order to reproduce proto-

typical sounds in curves and across turnouts.

Please take note of the following:

These sensors function only when the locomotive is

travelling at low speed. As soon as the locomotive

stops or drives faster than speed step 7 (of 28) the

squealing in curves and over turnouts will not be

replayed.

The curve and turnout sounds will only be active

if the engine sound is turned on. The curve sensor

works for radii of about 80 cm. The sensors may

not detect very large radii. Unfortunately certain

mechanical limits are unavoidable.

The contact brackets for the turnout sensors are lo-

cated below the axles 1 and 6 (in other words, the

outer axles). Also refer to Fig. 11 on page 18. These

brackets should not be pushed or bent manually!

Treat these brackets with great care.

Occasionally there may be some sparks at the con-

tact brackets when traversing a turnout. The cur-

ve sensors have been tested with all commonly

available DC and AC systems. While traversing a

turnout the bogies may be raised slightly.

If you do not wish to hear any sounds in curves or

on turnouts you can switch off this function with

function button F12.

4.2.4. Synchronised smoke generator

The class 66/77 is equipped with a load depen-

dent, synchronised smoke generator that can be

controlled with your command station respectively

handheld throttle. The system consists of a holding

tank for the smoke distillate, an evaporator unit

with temperature control and a blower thatch ex-

hausts the smoke in a controlled manner.

This system can adjust both the amount and the in-

tensity of the smoke discharged subject to the ope-

rating conditions and thus assures prototypical per-

formance. This system has been especially tuned for

the class 66/77 and also comprehensively tested.

Please bear in mind the following remarks in order

to assure safe operation:

Only use the ESU smoke distillate part

N0. 51990. Other liquids may lead to

damage of the paint finish, choking the

system or a faulty heating unit due to

unwanted deposits. Only activate the

smoke generator while observing the

model and in a well ventilated room.

4.2.4.1. Filling the smoke generator holding tank

First take the pipette from the packaging of the

model and pull about 0.4 to 0.5 ml smoke distillate

11

En g i n E E r i n g Ed i t i o n

Model

Technical functions

into it. Please observe the index markers on the

pipette in order to establish the appropriate quan-

tity. Then carefully inject the distillate into the large

opening of the red-brown silencer.

Do not exceed the maximum quantity of the hol-

ding tank of 0.5 ml. If in doubt rather put less liquid

into the system! Due to the integral temperature

sensor the smoke generator will not be damaged

even if there is no liquid in the system!

Fill the smoke system only while the locomotive is

on a horizontal sector but never on a gradient. Do

not turn the locomotive with liquid in the tank si-

deways or upside down! This avoids the drainage

of the distillate.

4.2.4.2. Operating the smoke generator

The smoke generator only works in conjunction

with the sound. Smoke without sound is not pos-

sible.

First activate the smoke generator with the function

button F3. As long as the engine (prime mover) is

not running nothing happens just like with the pro-

totype. After pressing F1 you will hear the sounds

of the starter motor. As soon as the prime mover

is firing acoustically the diesel locomotive blows a

strong cloud of smoke from the exhaust into the

“model sky”. Like with the prototype the intensity

of the smoke from the exhaust is reduced as soon

as the prime mover begins to idle.

More intense smoke will be emitted during accele-

ration and, of course, there is no smoke when the

locomotive slows down.

In order to protect the model the smoke generator

is turned off automatically after 6 minutes. Thus

overheating is avoided in case there is no distillate

in the holding tank. Switch off the F3 button and

then on again in order to reactivate the smoke

function.

The maximum capacity of the holding tank is 0.5

ml and is sufficient for about 10 to 15 minutes ope-

ration.

In some instances it may happen that the system is

clogged up due to an excessive amount of distillate

in the holding tank. Simply blow some air through

the exhaust opening in order to remove the drops

of condensation.

The smoke generator system as well as the entire

locomotive gets quite warm. Let the model cool

down before putting it back into its packaging.

You may adjust the amount and the intensity of

smoke as you desire. You find more information on

how to do this in chapter 5.10.

4.2.5. PowerPack energy storage

The class 66/77 is equipped with a maintenance

free “PowerPack” energy storage module. This fa-

cilitates uninterrupted power supply even on dirty

tracks. The PowerPack is only active in digital mode.

In analogue mode it will be automatically switched

off.

After turning on the power supply the “Power

Pack” must first be charged. This may take up to 60

seconds. Only then the full capacity will be availab-

le. The system supplies power to the lighting, the

motor and the sound functions. The maximum time

that the system should cover can be set (also refer

to chapter 5.7.).

Filling the smoke unitFigure 6:

12

Decoder settings

5. Decoder Settings (Programming)

Chapter 5 covers setting various parameters of the

LokSound decoder. Should you not be familiar with

the handling of CVs please take the time to read

these occasionally quite complex instructions.

After an introduction into the world of parameters

in chapter 5.1, we explain in the following section

5.2 how to change various parameters in DCC

mode and with Märklin® central units.

The chapters 9 to 16 explain which parameters

have what kind of influence on the behaviour of

the LokSound decoder.

5.1. Configuration Variables (CVs)

LokSound decoders follow the CV concept develo-

ped in the US. CV stands for „Configuration Varia-

ble“ and indicates that the storage cells described

above are not only variable but they also determine

the behaviour of the decoder.

5.1.1. Standardisation in the NMRA

The NMRA (National Model Railroad Association)

has defined which CVs determine certain parame-

ters of a decoder. The DCC standard allocates fixed

numbers for certain CVs (adherence is obligatory).

This greatly simplifies things for the user since deco-

ders of most manufacturers comply with this stan-

dard and therefore dealing with CVs requires the

same process with the same CV-numbers regardless

of the manufacturer.

The DCC concept permits to enter numbers ranging

from 0 to 255 into CVs. Each CV carries only one

number.

While the position number is predetermined, the

range of values may vary. Not all CVs must accept

values ranging from 0 to 255.

The permitted values for LokSound decoders are lis-

ted in the table in chapter 20.1. showing all availab-

le CVs.

5.1.2. Bits and Bytes

Most CVs contain numbers: CV 1 for instance

contains the locomotive address. This can be any

number between 1 and 127. While most CVs ex-

pect numbers to be entered, some others are rather

like a „collection point“ of various „switches“, that

administer different functions in one CV (mainly

„on“ or „off): CVs 29 and 49 are good examples:

you must calculate the value for these CVs yourself.

The value depends on which settings you want to

program:

Have a look at the explanations for CV 29 in the tab-

le in chapter 10: firstly, decide which options should

be active. The column „Value“ has two numbers

for each option. If the option is switched off, the

value is 0. Otherwise, it is a number between 1 and

128. Add all the values for the respective options to

arrive at the correct value for this CV.

Example: Let us assume you want to run trains with

the ECoS in DCC mode with 128 speed steps. Ana-

logue detection should be active (because you also

want to drive your locomotive in analogue mode).

All other options are not active.

Therefore you must write the value 6 in CV 29 (0 +

2 + 4 +0 = 6).

5.2. Programming the decoder

In this paragraph we explain how you can program

the decoder with the most commonly available di-

gital systems.

5.2.1. Programming with DCC systems

LokSound decoders support all NMRA program-

ming modes as there are the programming track

modes (Direct Mode, Register Mode, Paged Mode)

and the mode for the main („POM“, „Program-

ming on the Main“).

Programming on the Main enables you to program

your decoders comfortably without having to remo-

ve the locomotive form the layout. In this case, the

command station talks directly to the decoder by

using its locomotive address, for instance: „Loco-

motive number 50, write the value 7 into CV 3!“.

Thus knowing the locomotive address is a precondi-

tion. Unfortunately, you cannot read CV values.

However, with RailCom® you can read CV values

on the main. More on this topic in chapter 15.

Assuming you have a suitable DCC system you can

read CV values on the programming track. You can

also reprogram the locomotive address without

knowing the old address since the command sta-

tion simply transmits the command „Write value 7

in CV 3!“. Each decoder receiving this command

will execute it.

ESU counts the bits from 0 to 7 as laid out in the

standards while others (e.g.: Lenz®) count the bits

from 1 to 8.

5.2.2. Programming with Märklin® 6021

The LokSound V4.0 M4 decoder can be program-

med with all mfx® compatible central units directly

13

En g i n E E r i n g Ed i t i o n

Model

Decoder settings

via the decoder menu. However, in some cases not

all decoder options can be accessed. This compro-

mise is necessary in order to assure that all

mfx® central units on the market can be suppor-

ted. Read the manual of your central unit in order

to find out how to program mfx® capable deco-

ders. The procedure is identical to programming

Märklin® locomotives

5.2.2.1. Changing to the programming mode

Enter the programming mode with the 6020/6021:

The throttle must be set to „0“. No other locomoti-

ves may be on on the layout. Watch out for flashing

signals of the locomotive!

Press the „Stop“ and „Go“ buttons of the 6021•

simultaneously until a reset has been triggered (al-

ternately pull the mains plug of the transformer).

Press the „Stop“ button in order to switch off the

track voltage. Enter the current decoder address.

If you do not know the current address, simply

enter „80“.

Activate the change-of-direction button (turn the•

throttle knob to the left beyond the arrestor until

you hear a click sound), hold it in this position and

then press the „Go“ button.

Please bear in mind that the 6020/6021 only per-•

mits you to enter values from 1 to 80. The value 0

is missing. Always enter „80“ instead of „0”.

5.2.2.2. Short mode

The decoder is in the short mode (the headlights

flash periodically in brief intervals).

Now enter the number of the CV that you want to•

adjust e.g.: „01“. Always enter this number with

two digits.

For confirmation activate the change-of-direction•

routine (now the lights flash twice very quickly).

Now enter the new value for the desired CV, e.g.:•

15 (two digits).

For confirmation activate the change-of-direction•

routine (now the lights light up for about one se-

cond).

Then you can enter other CVs as desired.•

Selecting „80“ allows you to exit the programming

mode. Alternately you can switch off the track vol-

tage and then on again (press the „Stop“ button on

the 6021, then the „Go“ button).

5.2.2.3. Long mode

You access the long mode by entering the value

07 in CV 07 while in the short mode. The decoder

confirms the change to the long mode by slowly

flashing lights.

Enter the hundred-digit and the ten-digit (decade)•

of the CV that you want to change. Example: If

you want to adjust CV 124, you enter „12“.

For confirmation activate the change-of-direction•

routine (now the lights flash periodically: long –

short – long – short - etc.)

Now enter the unit of the CV („04“ in this ex-•

ample).

For confirmation activate the change-of-direction•

routine. Now the decoder expects the entry of the

CV value. The lights flash periodically: long – short

– short).

Now enter the hundred-digit and the ten-digit•

(decade) of the new CV value (as a two-digit num-

ber). Example: You want to write the value 135.

Therefore, you enter „13“.

For confirmation activate the change-of-direction•

routine. Now the lights flash periodically: long –

short – short – short).

Now enter the unit of the new CV value as a two-•

digit number („05“ in this example).

For confirmation activate the change-of-direction•

routine (now the lights light up for about one se-

cond).

Now you can adjust more CVs in long mode.•

Exit the long mode by switching off the track vol-•

tage and then on again (press the „Stop“ button

on the 6021, then the „Go“ button).

5.2.3. Programming with the Märklin® Central-

Station®

With the Central Station® until software version

2.04, you can program the CVs 1 to 80 via the Mo-

torola® programming menu. Unfortunately, you

can only enter values between 1 and 80. Find more

information regarding this programming mode in

chapter 8 of the manual of the Central Station®.

Owners of a Central Station “Reloaded” or a Cen-

tral Station 2 can program LokSound decoders in

DCC mode without any problems. With the CS1

“Reloaded” please proceed as described in the ma-

nual in chapter 18 (“Decoder programming”).

When using a Central Station 2, DCC programming

is somewhat trickier.

14

Decoder settings

Establish a new locomotive manually. This must be•

done even if the decoder registers itself via mfx®.

The locomotive address is not important in this

context.

Call up the new “Dummy” locomotive with a•

throttle.

Open the menu “Edit locomotive” and select type•

“DCC”.

Open the function “Edit locomotive”.•

Now enter all CVs you wish to configure in the•

list. Only then the command station will read out

the values and save any changes.

5.2.4. Programming with ESU LokProgrammer

The LokProgrammer 53451 offers the easiest and

most comfortable way of setting the CVs of Lok-

Sound decoders: simply by a few mouse clicks on

an MS-Windows® computer. The computer saves

you to look for the various CV numbers and values.

More information is contained in the manual for

the LokProgrammer.

You can access all properties of ESU decoders with

the LokProgrammer. Since this works independently

form the data format it also works for mfx® deco-

ders.

Please use the software version from V4.3.0 on-

wards for the LokSound V4.0 decoder. The software

is available for download on our website!

5.3. Adress settings

Each LokSound decoder requires a definite address

to be addressable for the central unit. Depending

on the type of decoder and the digital system, there

are several possibilities how to allocate addresses.

5.3.1. Short Addresses in DCC mode

Normally you would control LokSound decoders

with the short address that is stored in CV 1. In DCC

mode, the permitted values range from 1 to 127. In

order to enable the decoder to „listen“ to the short

address you must delete bit 5 in CV 29.

Some digital systems (e.g. ROCO® Lokmaus II,

Lenz® digital plus, Lenz® compact) only support

the values 1 – 99 as short address.

5.3.2. Long Addresses in DCC mode

You can operate LokSound decoders also with long

addresses (4-digit addresses). The supported values

range from 128 – 10239. The long address is stored

in the CVs 17 and 18. You must activate the long

address by setting bit 5 in CV 29.

Bit 5 in CV 29 switches between short and long

address. The decoder can only respond to one

address at a time.

If you want to use your LokSound with the long

address it is practical to program this address direct-

ly with your digital system: most modern digital sys-

tems (e.g. ESU ECoS, Bachmann E-Z Command®

Dynamis®) have a menu for programming long

addresses. The command station not only programs

CV 29 correctly but also assures the correct storage

of the values for the long address in CV 17 and 18.

If you want to enter the long address manually in

CV 17 and 18 please refer to 5.2.2.3.

5.3.3. Motorola® address

You can also operate many LokSound decoders

with the Motorola® format. The address for this

operating mode is stored in CV 1.

This address is identical to the short address in DCC

mode as described in chapter 5.3.1. The LokSound

decoder responds both to commands in DCC and in

Motorola® mode at the same time.

Märklin® digital devices (6020, 6021, Delta®) can

only work with addresses from 1 to 80. Should you

have entered a higher value in CV 1 you will not

be able to drive this locomotive with these central

units.

5.3.3.1 Consecutive addresses for more functions

The extended Motorola®-Format covered only the

lighting function (F0) and the auxiliary function F1

to F4. Of course, this is far too few for the many

functions of the LokSound V4.0.

Therefore one can assign up to three additional

addresses (4 addresses in total). The so called con-

secutive addresses follow immediately after the

actual address stored in CV 1 and serve to trigger

functions. Motor control is solely accomplished via

the base address in CV 1.

Example: You select the address 50 in CV 1 for a

class 50 locomotive. You want to set 3 consecutive

addresses. They are 51, 52 and 53. They will then

switch the consecutive functions whenever you call

up theses addresses on your 6021:

Name Example Functions

Base address 66 F0, F1 – F4

Consecutive address 1 67 (66+1) F5 – F8

Consecutive address 2 68 (66+2) F9 – F12

Consecutive address 3 69 (66+3) F13 – F16

15

En g i n E E r i n g Ed i t i o n

Model

Decoder settings

Please make sure that no other vehicle is program-

med to any of the consecutive addresses (in this ex-

ample 51 to 53). Otherwise you will inadvertently

run several vehicles at the same time!

The consecutive addresses are activated with bits 3

and 7 in CV 49. For reasons of compatibility they

are not next to each other. The relationship is as

follows:

Bit 7 Bit 3 Description

Value to be

added to

CV 49

00No consecutive address 0

01Consecutive address 1 active 8

10Consecutive address 2 active 128

11Consecutive address 3 active 136

First read out the value in CV 49 (default value: CV

49 = 1) and the value shown in column 4. If, for

instance, you wish to activate 3 consecutive addres-

ses then you must write the value 136 + 1 = 137

into CV 49. Consecutive addresses are only active in

Motorola® mode.

5.4. Adapting the Driving Characteristics

5.4.1. Acceleration and Deceleration

Acceleration and brake time can be set indepen-

dently from each other. Therefore, you could for

instance program a short acceleration and a much

longer brake time.

The time for accelerating is adjusted in CV 3 while

deceleration is set in CV 4. Permitted values are 0

(no delay) to 255.

The times set in these CVs work speed dependant.

Therefore, the acceleration distance and the brake

distance are longer at high speeds. In other words,

the faster the locomotive moves, the longer is the

distance until it stops.

5.4.1.1. Shunting mode

The default setting for the shunting mode is F3. It

reduces the speed to about 50%. Thus, you have

smoother control of your locomotive in the lower

speed ranges, which is important for shunting, par-

ticularly in the 14-speed-step mode.

5.4.2. Starting Voltage, Vmax

LokSound decoders know internally 256 speed

steps. They can be adapted to the characteristic

of the locomotive and allocated to the actually

available speed steps (14, 28, or 128).

The NMRA defined two options to facilitate this:

Motor characteristic via CV 2, 5, and 6. Enter the

start voltage in CV 2 and the maximum speed in CV

5. CV 6 corresponds with the speed at a medium

speed step. Thus, you can define a “kink” in the

speed curve. This mode is active if bit 4 = 0 in CV

29.

The values of the start, mid and maximum speed

are dependent on each other. Selecting a mid speed

that is lower than the start speed or higher than the

maximum speed could lead to some erratic driving

performance. Therefore always adhere to the prin-

ciple: start voltage < mid speed < maximum speed.

5.5. Break sectors

Brake sectors have the purpose to slow down the

locomotive independently from the commands

issued by the command station. Frequently, this

function serves for stopping a train in front of a red

signal. If a LokSound detects a brake command, it

will slow down with the programmed deceleration

and then stop. After this enforced stop, the loco-

motive will accelerate again as per the programmed

values in CV 3.

Depending on the type of digital system, there are

several options on how to influence the decoder so

that it stops the train.

5.5.1. DC break mode

In order to activate the DC brake mode you must

set bit 3 in CV 27. The LokSound decoder will start

brake once it moves from a digital sector into a DC

sector provided the brake mode is active and the

polarity of the track voltage does NOT match the

current direction of travel. The locomotive will stop

taking into account the programmed deceleration.

5.5.2. Märklin® brake mode

In principle, the Märklin® modules 72441 / 72442

apply a DC voltage to the track instead of the digital

signals. Provided bit 3 and bit 4 in CV 27 is set, then

LokSound decoders detect this voltage and will stop

the train (CV 27 = Value 24).

The signal generated by these modules looks the

same as DC from conventional DC-transformers.

The LokSound could possible misinterpret this and

switch to the analogue mode instead of brake.

If you wish to control the LokSound decoder with

DCC signals and keep your Märklin® brake sectors

then you should switch off the DC analogue mode

by deleting bit 1 in CV 50. The LokSound will stop

16

Decoder settings

as desired.

5.5.3. Lenz® ABC brake mode

As a new function the LokSound V4.0 decoder

supports the ABC braking technique introduced by

Lenz®. In order to use this function a group of anti-

parallel diods will be be soldered to one half of the

track. The resulting fall of voltage generates an as-

symetrical DCC signal. LokSound decoders are able

to detect the potential difference between the left

and right half of the signal. If desired, the decoder

will be stopped.

To be able to use the ABC technique you also need,

beside the adequate LokSound V4.0 decoder, an

appropriate brake module. The ABC technique can

only be operated with boosters offering an exact

symmetrical output. All command stations and

boosters by ESU and Lenz® garantuee a symme-

trical output. We don´t recommend to use other

boosters for the ABC technique.

If you wish to stop the LokSound decoder when•

the track signal is stronger on the right side than

on the left side (and the diods are also installed on

the left side), set bit 2 in CV 27.

If you wish to stop the LokSound decoder when•

the track signal is stronger on the left side than on

the right side (and the diods are also installed on

the right side), set bit 1 in CV 27.

If you want to stopp the decoder no matter in•

which half of the track the diods are set, please

set bit 2 and bit 1 in CV 27 (CV 27 = 3).

5.6. Adjusting the volume

The volume of all individual sounds of the class

66/77 can be independently adjusted. This enables

you to tune the model optimally according to your

preferences.

5.6.1. Overall sound volume

If you wish to reduce the overall volume simply en-

ter a lower value in CXV 63 (master volume). All

sounds will be adapted in the correct ratio.

5.6.2. Adjust individual sounds

If you wish to adjust the volume of individual sounds

you must set the volume for each individual sound

by changing the value of its corresponding CV. In

order to enable the decoder to describe these CVs

correctly you must assure that the so-called “Index

CV” CV 32 has the correct value:

Before you change any volume CV please make

sure thatch CV 32 = 1.

The CVs for the sounds are defined as follows:

CV Function Value

259 Motor 128

275 Horn 128

299 Air compressor 128

307 Announcement #1 128

315 Coupler 128

323 Horn short (low) 128

339 Sanding 128

363 Announcement #2 128

371 Squeal in curves 128

379 Horn short (high) 128

403 Turnout “bump” 128

451 Chance 128

459 Brake 80

467 Shifting gears 128

5.6.3. Motor sound

Of course the sound of the prime mover can also be

adjusted individually.

5.6.4. Auxiliary sounds

Auxiliary sounds can also be adjusted individually. If

you wish not to hear a certain sound (for instance,

no sanding) then you set the corresponding CV to

the value of “0”.

5.7. PowerPack

The PowerPack energy storage module continues to

provide electric current to the decoder in case of a

power interruption. Should you have installed iso-

late track sectors ahead of signal where the sector

is disconnected form the power source if the signal

aspect shows “red”, the locomotive will still be po-

wered by the “PowerPack” and will therefore conti-

nue running? Of course, in such a situation this may

be undesirable. Therefore it is possible to adjust the

buffer time in CV 113 as a multiple of 0.016384

seconds. The default value facilitates about 2.9 se-

conds. For smooth running the time should not be

17

En g i n E E r i n g Ed i t i o n

Model

Decoder settings

set to any value lower than 0.3 seconds.

5.8. Decoder reset

You may reset the decoder to default values at any

time. Simply write the value 8 in CV 8.

Schreiben Sie dazu in die CV 08 den Wert 08.

5.9. Adjusting the brightness of the lights

The brightness of all LEDs of the Class 66/77 can

be changed. The range is from value 31 (maximum

brightness, default value) down to the value 0

(lights are almost off, very dark).

Please change the following CV values:

Description

(*für CNet,TGOJ,CFL)

Decoder

output

Index

CV 32 CV Value

Lower right cab1 Light forward [1] 0262 31

Lower right cab1 (blinking) Light forward [2] 0358 31

Lower right cab2 Light rear [1] 0270 31

Lower right cab2 (blinking) Light rear [2] 0366 31

Lower left cab1 AUX1[1] 0278 31

Lower left cab1 (blinking) AUX1[2] 0374 31

Lower left cab2 AUX2[1] 0286 31

Lower left cab2 (blinking AUX2[2] 0382 31

Upper cab1 AUX3 0294 31

Upper cab2 AUX4 0302 31

Interior lighting cab1 AUX5 0310 31

Interior lighting cab2 AUX6 0318 31

Red cab1 AUX7 0326 31

Cab-control panel cab1 and 2 AUX8 0334 31

Brake lights AUX9 0342 15

Red cab2 AUX10 0350 31

The value 0 in the following CV‘s will disable the

lights completely:

Description

(*für CNet,TGOJ,CFL)

Decoder

output

Index

CV 32 CV Value

Lower right cab1 Light forward [1] 0259 1

Lower right cab1 (blinking) Light forward [2] 0355 12

Lower right cab2 Light rear [1] 0267 1

Lower right cab2 (blinking) Light rear [2] 0363 12

Lower left cab1 AUX1[1] 0275 1

Lower left cab1 (blinking) AUX1[2] 0371 1

Lower left cab2 AUX2[1] 0283 1

Lower left cab2 (blinking) AUX2[2] 0379

Upper cab1 AUX3 0291 1

Upper cab2 AUX4 0299 1

Interior lighting cab1 AUX5 0307 1

Interior lighting cab2 AUX6 0315 1

Red cab1 AUX7 0323 1

Cab-control panel cab1 and 2 AUX8 0331 1

Brake lights AUX9 0339 3

Red cab2 AUX10 0347 1

5.10. Smoke generator

You may also adjust the smoke generator as you

desire.

5.10.1. Blower of the smoke generator

The revs of the blower can be set with CV 138 (de-

fault value: 128). A higher value results in higher

revs and thus in more smoke. However, this also

means higher consumption of the distillate and a

somewhat “thinner” smoke plume.

5.10.2. Heating temperature

The temperature of the heating element can be ad-

justed with CV 139 (default value: 128). Only inc-

rease this value slightly in order to avoid excessive

wear and tear of the smoke generator. The settings

in CVs 138 and 139 are dependent of each other

and should be adjusted together.

6. Maintenance

6.1. Removing the housing

Put the model on its roof. You will find four Phillips

screws at the bottom of the chassis located between

the bogies and the fuel tank. Remove these screws

and put the model back on its wheels. Now you can

easily remove the housing. The yellow circles point

to the screws to be removed in order to take off the

housing.

6.2. Lubrication

We have equipped the class 66/77 with durable

mechanical components. All moving parts have

been permanently lubricated with durable grease

and oil. Additional lubrication of these individual

components is therefore not required.

6.3. Replacing wheel sets

Exchanging wheel sets: If installed, first remove the

centre pick-up by pulling it off with the tool provi-

ded (also refer to chapter 3.2.2). Remove the three

Phillips screws at the bottom of the bogie (marked

Screw locationFigure 7:

18

Maintenance

6.4. Replacing traction tires

Traction tires do age and must be replaced after

wearing. ESU supplies suitable traction tires with

each locomotive. For exchanging the traction tires

you must remove the side parts of the bogies (also

refer to chapter 6.3.).

Please make sure that the traction tires are put onto

the wheels uniformly and without any tension in

order to avoid out-of-round running characteristics

of the model. It has proven quite useful to place

the traction tires prior to mounting into some low

surface tension water (a drop of dishwashing liquid

is sufficient).

6.5. Installing a coupler

A standard coupler is mounted ex works at the cab

2 end of the locomotive. At the other end the de-

flector is closed and prototypical hoses have been

mounted. Installing a model train coupler takes

about two minutes. You will find the required parts

in the packaging. The only tool you may need is

either a pair of flat nose pliers or tweezers and a

thin screw driver.

Remove the coupler shaft and the coupler from the

accessory bag.

Removal of bogie side partsFigure 9:

Installation of bogie side partsFigure 12:

Installed contract bracketsFigure 11:

Removal of wheel setFigure 10:

Screw location on bogieFigure 8:

with a yellow circle) and lift off the gear cover.

Remove the released bogie side part.

The contact bracket for the turnout sensor is loca-

ted above the first and the sixth axle. These bra-

ckets remain in place when exchanging the wheel

sets. Slightly lift the wheel set and pull it towards

the centre of the locomotive.

Insert the new wheel set and make sure the current

pick-up strips touch the inside of the wheels.

When replacing and screwing down the bogie side

part please make sure that the contact brackets can

be seen through the elongated slots.

19

En g i n E E r i n g Ed i t i o n

Model

Maintenance

The sprung socket for holding the coupler shaft is

located between front deflector and the front of

the bogie.

Pull off the hoses and the prototype coupler using

the tweezers or the flat nose pliers and then press

the deflector inwards.

Since the latter may sit quite firmly in its position

push a thin screw driver next to the retaining clip

between deflector and insert.

Accessory partsFigure 13:

Sprung socketFigure 14:

Removal of small partsFigure 15:

Place the coupler shaft onto the sprung socket that

the front faces left in “driving direction”.

Then press the shaft downwards and turn it by 90

degrees until it projects through the deflector at the

front.

Now insert the coupler.

Removal of deflectorFigure 16:

Installation of coupler shaftFigure 17:

Installed coupler shaftFigure 18:

Insert the couplerFigure 19:

20

Maintenance

9. Spare parts

Due to the large number of parts built into class

66/77 we have divided the spare parts in to compo-

nent groups. Some parts belonging to large parts

groups are also included in smaller groups.

Please bear in mind that only the spare parts lis-

ted in the supplied spare part list are available ex

works as spare parts. Enquiries for individual parts

are pointless.

Should you require a spare part you must first

identify the spare part group containing the nee-

ded part. For rarely needed parts you may have to

purchase a larger component group. You must sta-

te the listed ESU part number when ordering spare

parts from your hobby shop

Both arresting positionsFigure 20:

The first arresting position of the coupler may be

needed in order to avoid the buffers of the locomo-

tive and the first car missing each other in curves

(Particularly S curves) when ever heavy trains are

pushed through such curves. Generally you would

push the coupler into its proper position.

7. Accessories supplied with the model

ESU is fully aware of the “challenges” of model

train operations. Often enough small detail parts

break off and “disappear”. Since the class 66/77

has quite a few details and we want to make sure

that can enjoy your class 66/77 for a very long time

we have put a little plastic bag with small parts that

could easily break or get lost. Make sure you keep

these parts for the time when you may need them.

8. Technical support

Should you have questions regarding your class

66/77 to which you have not found the right ans-

wer in this manual please first contact your hobby

shop. The people there are your competent contact

for all questions relating to model trains.

Should you not be able to get an answer to your

question look up our homepage in the internet. We

continuously publish topical questions and answers

as well as the latest versions of manuals. Of course

you will also find our postal address as well as our

phone number on our site.

www.esu.eu

This manual suits for next models

1

Table of contents

Other Esu Toy manuals

Popular Toy manuals by other brands

Eduard

Eduard 36 456 manual

Fleischmann

Fleischmann 6454 operating instructions

MGA Entertainment

MGA Entertainment Little Tikes MERMAID ISLAND WAVEMAKER quick start guide

Forpost Arena

Forpost Arena LaserPro user manual

LEGO

LEGO CITY 4430 Building instructions

Mega Bloks

Mega Bloks NANO Rescue Cutter 5952 Assembly instructions