Eswood ES-220 Technical Document

EQUIPMENT MANUAL

FOR

ES-220

RACK CONVEYOR DISHWASHER

JUNE

2011

ES-220 RACK CONVEYOR DISHWASHER – JUNE 2011 2

T

ABLE OF CONTENTS

1. Installation

1.1. Important: Prior to Installation 3

1.2. Service & Spare parts 4

1.3. Installation 5

1.4. Initial Start-up Procedure 6

2. Washin Operation 7

3. Shutdown and Maintenance 8

4. Trouble Shootin 9,10,11

5. Dia rams 12-13

ES-220 RACK CONVEYOR DISHWASHER – JUNE 2011 3

I

MPORTANT

:

PRIOR TO INSTALLATION

1.1

Installation must be carried out accordin to local re ulations by

qualified trade persons. Isolatin switch(es), shut-off valves etc must

be within easy reach of the machine for future service and

maintenance requirements. If in doubt call ESWOOD AUSTRALIA or

their representative for further information. No responsibility will be

accepted for defects or dama es by improper installation, for

chan es to the product not authorised by ESWOOD AUSTRALIA, or

for operation outside the technical specifications.

ESWOOD AUSTRALIA warrants their products to be free from

defects in material and workmanship under "normal use and

service". This does not include normal wear and tear of parts.

ESWOOD AUSTRALIA will repair or replace any parts, which in

ESWOOD AUSTRALIA's sole jud ement are defective in material or

workmanship, in accordance with the warranty offered.

This undertakin covers the provision of labour and parts for 12

months from the date of delivery to the purchaser. This undertakin

applies only to state capitals. Remote areas are not covered by this

commitment and special enquires should be made. (No e: Travel

ime no covered by warran y)

In no event will ESWOOD AUSTRALIA be liable for loss of facilities

or other property and such thin s as, but not limited to, additional

labour costs, loss of revenue or anticipated profits, and other

dama es of any kind whether direct, indirect, incidental or

consequential.

Labour under warranty is supplied free of char e durin normal

workin hours, Monday to Friday. Should warranty work be

requested outside or our normal workin hours a labour char e will

be applied equivalent to a normal hour rate without out of hours

penalty rates. (Refer to next pa e (1.2) of this manual for your

closest branch for Warranty repair services)

No e: It is the responsibility of the owner to ensure the water feed to

Eswood Dish and Glass washers is of a quality that will not form

excessive build up of calcium and other dissolved minerals on the

heatin elements. Premature failure of heatin elements that exhibit

this cause of failure will not be covered under warranty.

ES-220 RACK CONVEYOR DISHWASHER – JUNE 2011 4

E

SWOOD AUSTRALIA BRANCHES

1.2

For inquiries and access o 24/7 service backup, please call our Toll-Free

Number: (Applicable to landline only char es apply for calls made from a

Mobile Phone)

1800 013 123

This number will automatically access your nearest State office, or the

technician on duty if after hours. After hours char es apply.

ES-220 RACK CONVEYOR DISHWASHER – JUNE 2011 5

I

NSTALLATION

1.3

1. Remove the packin materials from the machine, includin inside

the chambers.

2. Remove the lower panels, position the machine and level by

screwin the adjustable feet.

3. Connect the 2” B.S.P. ravity drains via 2” traps to the drain outlets.

4. Connect the hot water to the

1

/

2

” B.S.P. inlet valve, located under the

main wash tank, via an isolatin valve (supplied by others). The hot

water supply must be at least 60

O

C and between 200 to 400kPa. A

pressure reducin valve must be fitted for pressure above 400kPa.

The pressure reducin valve is to be supplied by others.

Note that all plumbin work is to be done in accordance with local

plumbin codes.

5. Ensure that the rotary switch is “OFF”, open the top of the control

panel and connect the 3-phase power to L1, L2 and L3. Then

connect neutral to “N” on the terminal block and connect the earth

wire to the earth terminal. An isolatin switch is also required beside

the machine.

Note that all electrical work is to be done accordin to the ratin

plate on the ri ht hand side of the Control Box.

6. Connect the benchin to either end of the machine so that there is a

fall back towards the machine to allow the water to drain back

ES-220 RACK CONVEYOR DISHWASHER – JUNE 2011 6

I

NITIAL START

-

UP PROCEDURE

1.4

1. Check that all the curtains are in position

2. Check that the drains are closed. To open, lift the T-bar (found

inside the inspection doors) and twist it 90

°

DEG. To close the drain,

twist the T-bar until it drops into place.

3. Close the inspection doors and turn the rotary switch to “FILL”. The

pilot li ht will illuminate until the cycle is complete.

4. Check the direction of rotation of all pumps accordin to the

arrows on the motor housin s. If the pumps are runnin in the

wron direction, reverse two of the phases at the power supply

in the control box.

5. Select “L. Speed” with the rotary switch to enter the washin mode,

and press the reen start button to be in. The pilot li ht will

illuminate.

6. Pass a number of empty racks throu h the machine until water

comes out of the rinse jets at the exit end of the machine.

All thermostats have been factory set. Durin the operation check

that the wash thermometer is readin between 65°and 70°C and

that the rinse thermometer is readin between 80° and 90°C.

The rinse will function automatically as the racks pass the trip

lever.

7. When washin is complete, turn the rotary switch “OFF”, open

the doors and check for leaks.

8. Replace the lower panels.

9. The machine is now ready for use. To interrupt the washin

operation press the red button. This will stop the conveyer and

pumps. To completely stop the machine turn the rotary switch

“OFF”.

ES-220 RACK CONVEYOR DISHWASHER – JUNE 2011 7

W

ASHING OPERATION

2

1. Check that the strainers are clean and in position. They are

located in the pre-wash, wash and rinse tanks. Close the drains

by twistin the T-bars until they drop into place.

2. Check the levels of the deter ent and rinse aid containers

(supplied and fitted by others)

3. Place the dirty items in an appropriate rack and push the rack

into the entry of the machine. The rack will then automatically

proceed to the exit.

4. Durin washin check that the water temperature in the tanks are:

Wash 65°-70°C

Pre-Rinse 75°-80°C

Rinse 80°-90°C

5. Periodically remove the pre-wash strainers and empty the contents

into a rubbish bin. Rinse the strainers under a tap and refit them.

ES-220 RACK CONVEYOR DISHWASHER – JUNE 2011 8

S

HUTDOWN AND MAINTENANCE

3

1. When washin is complete turn the rotary switch "OFF".

2. Open the inspection doors and drain the tanks, by liftin and twistin

the T-bar lever.

3. Remove the curtains and wash them in warm water

4. Remove the strainer pans and clean them under a tap. Hose the

inside of the machine and make sure that all of the water drains out

of the tanks. Then remove the strainers from the pump intakes,(in

bottom of wash tanks-one per tank-) clean them under a tap, replace

them immediately then replace the strainer pans.

5. Check that the jets and arms are free of forei n matter

and, if necessary, remove the end caps to clean them.

6. Clean the exterior of the machine with a damp spon e. Do

not pass water over the electrical controls and do not use

abrasive or stron deter ents.

7. Leave the inspection doors open to allow the machine to air.

ES-220 RACK CONVEYOR DISHWASHER – JUNE 2011 9

T

ROUBLE SHOOTING

4

PROBLEM POSSIBLE CAUSE AND REMEDY

When machine is (a) Check that main isolatin switch is

turned on, white pilot turned on and fuses are okay.

li ht does not

illuminate (b) Pilot li ht may be burnt out. If so,

replace it (this will not stop machine

from operatin thou h).

(c) Check control circuit fuse in control

box. If blown, check for cause and

then replace fuse.

Machine will not start (a) Check if main motor

contactor has been tripped out. Reset

if necessary and check draw current of

motor.

(b) Check water level in wash tank.

(c) Check pressure switch, and check

that tube from pressure switch to air

chamber is not leakin .

Machine not fillin (a) Check if pressure switch of the

correctly and/or fillin relevant wash tank is functionin .

continuously Replace or adjust if necessary. Also

check air tube to the pressure switch

for air leaks.

(b) Check if water isolatin valve is

fully open, and check for obstructions

in the water supply line.

(c) Check if overflow pipes are seated

correctly in wash tanks, and check for

forei n matter under the O-rin s of the

pipes.

ES-220 RACK CONVEYOR DISHWASHER – JUNE 2011 10

PROBLEM POSSIBLE CAUSE AND REMEDY

As above (d) Check for obstruction in the

water supply solenoid valve and

clean if necessary. Check

diaphra m and replace if

punctured.

Racks not advancin (a) Check for obstruction within

properly throu h machine machine that could cause

conveyor to stop.

(b) Check clutch adjustment on

motor reduction unit. If necessary,

ti hten sli htly, but do not over-

ti hten.

(c) Check that the overload relay of

the conveyor motor has not tripped

out. If it needs to be reset check

draw current of motor.

(d) Check bench switch is workin

correctly-if fitted to your machine-.

Insufficient wash (a) Check that deter ent feeder to

machine is operatin correctly.

(b) Check for forei n matter in pre-

wash and wash arm jets. Clean if

necessary.

(c) Check that items to be washed

are correctly placed in racks.

(d) Check temperature of tanks. If

incorrect check thermostat settin s,

heatin elements and contactors.

(e) Check that all pumps are

functionin . If not, check overload

relays. Reset if necessary and check

current.

(f) Check pump rotation direction

(usin the arrows). If incorrect,

ES-220 RACK CONVEYOR DISHWASHER – JUNE 2011 11

reverse wirin of 2 phases at the

power supply.

PROBLEM POSSIBLE CAUSE AND REMEDY

Incorrect temperature of (a) Check thermostat settin .

wash tanks

(b) Check heatin elements.

(c) Check contactors.

Insufficient rinse (a) Check that water pressure to

machine is not less than 200 kPa. If

so, ensure that the water isolatin

valve is fully open.

(b) Check rinse jets for forei n

matter and clean if necessary.

(c) Check that the water supply

solenoid valve is functionin

correctly.

(d) Check that the line strainer is

not partially blocked. If so, remove

and clean filter.

Insufficient rinse (a) Check that thermometer readin

Temperature is correct and thermometer is not

faulty.

(b) Ensure that temperature of

incomin water supply is between

60° and 65°C.

(c) Check that boiler thermostat is

set correctly and functionin .

(d) Check element controls as

appropriate.

ES-220 RACK CONVEYOR DISHWASHER – JUNE 2011 12

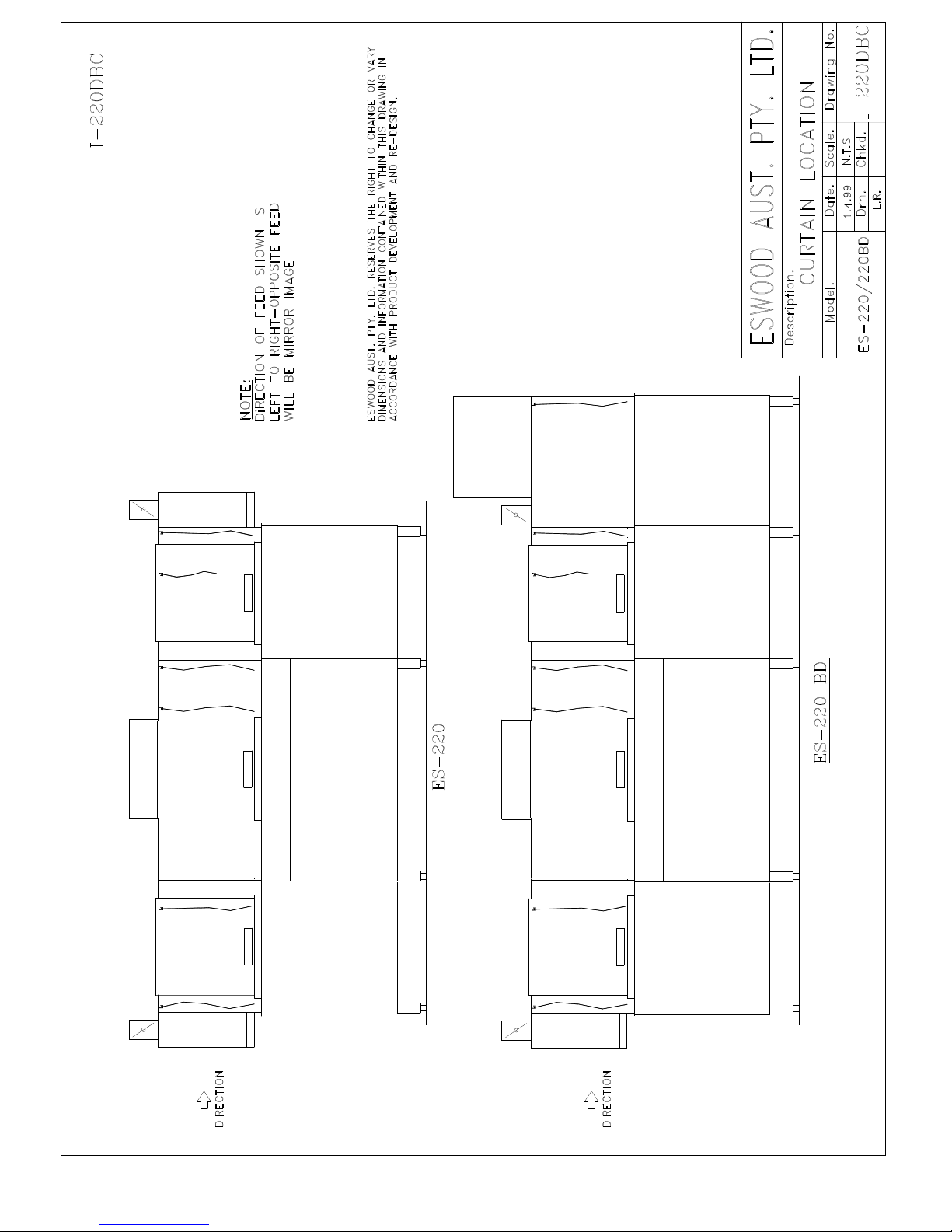

D

IAGRAMS

5

DRAWING No.

A. CURTAIN LOCATION

ES-220/ES-220 BD I-220DBC

ES-220 RACK CONVEYOR DISHWASHER – JUNE 2011 13

Table of contents

Other Eswood Dishwasher manuals