ESY Sunhome ESYSUNHOME 5KWH+ Instruction Manual

ESYSUNHOME ESS BATTERY SYSTEM

ESY SUNHOME CO., LTD

ESY SUNHOME CO., LTD

User Guide & Installation Manual

Made in China

Website﹕ www.esysunhome.com

Phone: +86 (0)755 8522 9087

Address: 101, Building 6, No. 5-2, Inner Ring Road, Shanxia Community,

Pinghu Street, Longgang District, Shenzhen, China.

8 Batte Maintenance

8.1 Staup and Shutdown Procedure

8.2 BMS-STM8S-TI

8.2.1 BMS-STM8S-TI software connection

8.2.2 BMS-STM8S-TI functions operation

8.3 Maintenance Instructions

9 After-sales Seice

19

19

19

20

20

22

22

Table of Contents

Mission:

To provide safe and high quality new energy products (batteries and power supplies) for eve

family.

Vision:

Take the sun home.

1 Precautions

1.1 General Statement

1.2 Requirements for Installation and

Maintenance Personnel

1.3ImpoantSafetyInformation

2 SafetyPrecautionsforUse

3SafeTranspoationandStorage

3.1BatteTranspoation

3.2BatteStorage

4 Appearance

4.1OutlineDimensions

4.2NameplateIdentication

4.3PoDescription

4.4NoACconnectiononbatte

4.5 Batte Isolation Device Description

5 Product Parameters

5.1 Parameters of the Batte

5.2ModuleParameters

6 Circuit Structure Schematic

7 Preparation Before Installation

7.1PackingListofBatte

7.2BaseofBatte

7.3PreparationbeforeInstallations

7.3.1PreparationofInstallationTools

7.3.2SelectionoftheInstallationEnvironment

7.3.3 Installation Safety Precautions

7.3.4SelectionofInstallationLocations

7.4Installation

7.4.1Location

7.4.2Drilling

7.4.3BracketInstallation

7.4.4OneBatteInstallation

7.4.5StackingofMultipleBatteries

7.4.6Batte Eahing

7.5DCConnectionInstructions

7.6BatteandInveerCommunication

7.7HowtoSetUpBatteMonitoring

01

01

01

02

02

03

03

03

03

03

04

05

07

07

07

07

07

08

09

09

09

10

10

11

12

13

14

14

15

15

16

17

17

18

18

19

Core Values:

Unity and hard work;

Pragmatic and far-reaching;

Innovative research and development;

Scientic and intelligent manufacturing;

Creating value for customers;

Creating oppounities;

Contributing to society.

ESY SUNHOME staed out as a lithium batte business, powered by cutting-edge batte protection

systems and a procient Research & Development team. The founder, Mr. Lee, recognized the absence

of energy storage choices available to households worldwide and was enthusiastic about combining

photovoltaic energy storage solutions with lithium batteries. With this vision in mind, the team

embarked on the development and testing of PV home energy storage products, forming an ecient,

highly qualied team of Research & Development, manufacturing, and quality control professionals

with distinguished backgrounds in various elds of technology. After two years of intensive eo, the

team successfully developed and tested PV home energy storage products, resulting in the ocial

launch of the HM6 series storage system products on Janua 14th, 2023. ESY SUNHOME now has

branches in Sydney, Australia and Munich, Germany, with a long-term objective of becoming a

global brand.

2 Safety Precautions for Use

Before conducting any work, carefully read all safety instructions and always adhere to them

when handling or using the batte. Failure to comply with the preventive measures described

in this section may result in severe personal inju or propey damage.

02

声明

01

1 Precautions

NOTE

Professionals: Professionals refer to individuals who have received training or have experience

in equipment operation and possess professional knowledge of potential hazards and their

severity in equipment installation, operation, and maintenance.

Trained personnel: refer to the personnel who have received technical training or have the

necessa experience, and are aware of possible hazards in some operations and able to take

protective measures to minimize hazards to themselves and others.

Operators: refer to the personnel who have access to devices except trained personnel and

professionals.

1.1 General Statement

Statement

This manual applies to the ESYSUNHOME ESS Batte Models:

ESYSUNHOME 5KWH+

ESYSUNHOME 10KWH+

ESYSUNHOME 15KWH+

ESYSUNHOME 20KWH+

ESYSUNHOME 25KWH+

ESYSUNHOME 30KWH+

Please read this manual carefully and strictly adhere to all safety instructions during installation,

operation, and maintenance. ESY SUNHOME will not be liable for any consequences arising from

noncompliance with the general safety requirements or safety standards of design, production

and use.

It is crucial to use this product under the specied design conditions, as any damage to pas,

personal inju, or propey loss resulting from improper usage will not be covered by the warranty.

In addition, during installation, usage, and maintenance, all local laws and regulations must be

obseed. The safety instructions in this manual are supplementa to local laws and regulations.

During the installation and debugging of the batte, please use dedicated charging and

discharging equipment.

ESY SUNHOME reserves the right not to assume any responsibility for consequences arising

from the following:

Damage caused during transpoation;

User does not meet the national standards to install, ret or use our device;

Noncompliance with the installation and use instructions outlined in this manual;

Operation under harsh conditions that are not specied in this manual;

Failure or damage caused by installation, repair, modication, or disassembly by non-authorized seice personnel;

Energy storage system failure or damage caused by the use of non-standard components or software or those that

are not provided by our company;

Noncompliance with relevant international standards for design, installation and use;

Device damage caused by abnormal natural conditions (force majeure such as lightning strikes eahquakes, re

and storms).

Expiation of free warranty of the product and its pas;

The personnel to be dispatched for installing or maintaining ESY SUNHOME’s devices are fully trained and

knowledgeable of all safety precautions and capable of peorming all operations correctly.

Safety facilities must be dismantled and inspected by professionals.

Only professionals or authorized personnel are allowed to replace equipment or components (including device

software).

Device installation, operation and maintenance must be carried out by professionals or trained personnel.

1.2 Requirements for Installation and Maintenance Personnel

1.3 Important Safety Information

Before device installation, operation and maintenance, please read this manual carefully.

Make sure that the product is eectively grounded before operation. The grounding resistance

should be less than 0.1Ω.

Batte installation must be carried out according to this instruction manual. During operation, comply with the

relevant signs and symbols on the equipment.

The batte terminals may be live during operation. If the batte is not connected, cover it with insulating material

inside a protective cover for protection.

If the energy storage system, consisting of the batte, needs to be connected to the grid for power supply, it must

obtain approval from the local power depament or comply with the relevant regulations of the user's count and

local laws. Grid connection should be peormed by qualied personnel.

Use a d powder extinguisher in case of re. Do not use a liquid extinguisher.

When installing the batte, installation personnel must strictly adhere to the installation standards specied in

AS/NZS 5139.

Fire hazard!

Do not place the batte near heat sources, such as direct sunlight, replace, non-insulated walls

exposed to sunlight, hot water, or heaters. Keep ignition sources like sparks, ames, and smoking

materials away from the batte.

Electric shock hazard!

Do not dismantle the batte.

Do not handle the batte or use wet tools.

Do not immerse the batte in water or expose it to moisture or liquid.

Keep the batte out of reach of children and animals.

Wear appropriate clothing, protective equipment, and gloves to prevent direct contact with DC voltage.

Use insulated tools when working with the batte.

Remove metal jewel before dealing with the DC circuit.

Gas hazard!

Damaged batteries may release hazardous substances and ammable gas mixtures. Even if you are a

qualied electrician, do not attempt to repair the batte.

Explosion hazard!

Do not apply any excessive force to the batte.

Do not subject the batte to mechanical damage (such as puncturing, deforming, stripping, etc.).

Do not heat the batte or expose it to re.

Do not install the batte in potentially explosive environments.

Do not submerge the batte in water or other liquids.

3.2 Battery Storage

If the batte is not installed immediately, it needs to be stored properly. When storing the equipment,

use the original packaging and store it in a cool, d, and well-ventilated area to prevent equipment

damage due to moisture.

This product should be stored at an ambient temperature of -10°C to 35°C for no more than 6 months.

The relative humidity during storage should be between 0% to 95% Rh. Store the batte in a clean and

d place, avoiding exposure to direct sunlight and rain. The storage location must be free from harmful

gases, ammable/explosive products, and corrosive chemicals. Avoid mechanical impact, high voltage,

high-intensity magnetic elds, and direct sunlight on the batte. Pay attention to harsh environments

such as sudden cooling/heating and collisions to prevent damage to the batte.

Packaged batte modules should not be stacked more than 5 layers high, and direct stacking of

unpackaged batteries is strictly prohibited.

If the batte is stored for more than 3 months under specied conditions, it needs to be charged

once until the system SOC reaches 50% to 80%. Please use our rechargeable products for charging.

Failures and hazards caused by charging and discharging with other equipment are not covered

under our warranty. For storage with SOC at 50%, a charge-discharge maintenance should be

peormed within 6 months to prevent irreversible capacity loss. If storage with SOC at 50% exceeds

9 months without charge-discharge maintenance, any capacity loss or other defects caused to the

batte will be considered as a waiver of warranty by our company.

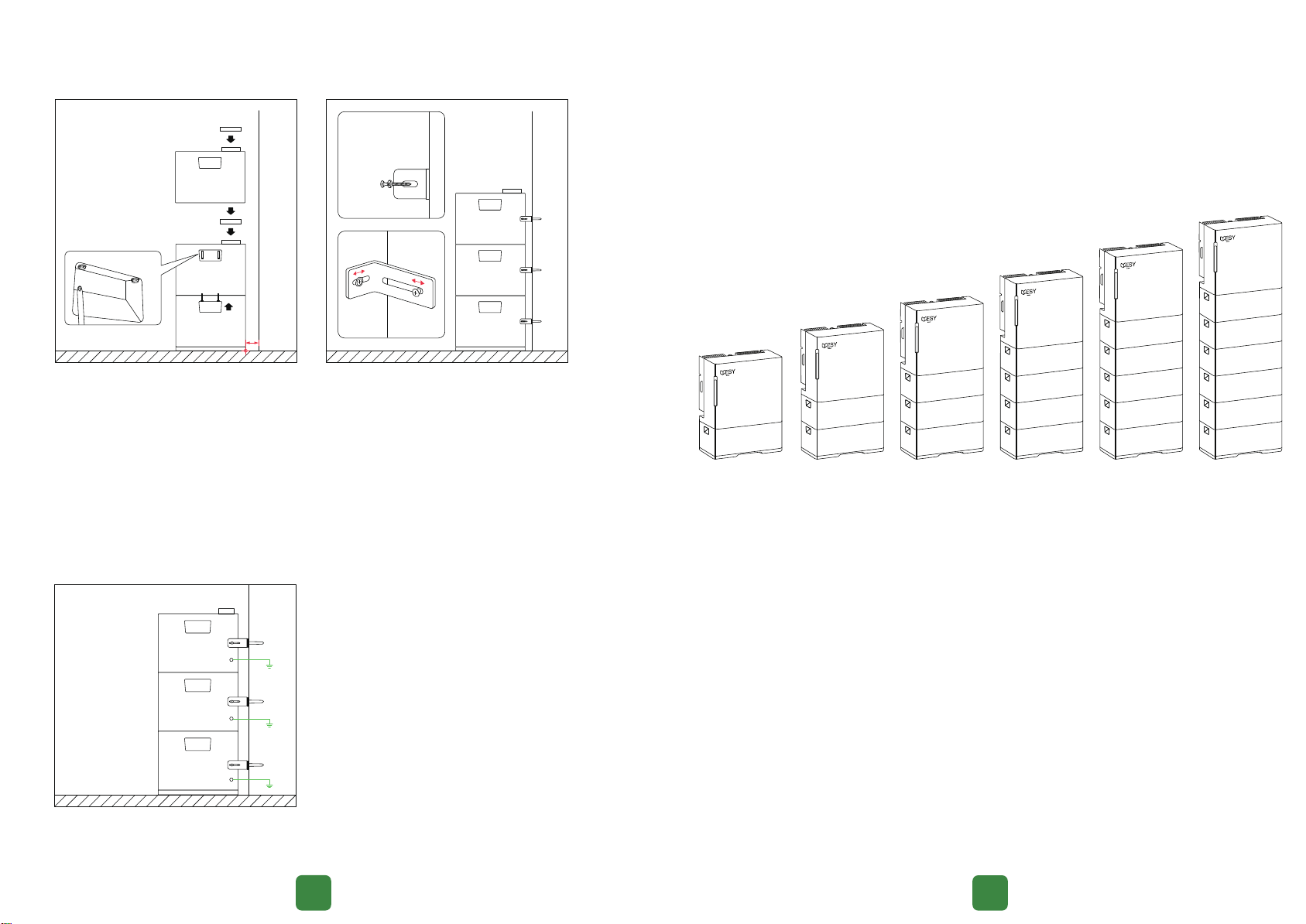

4 Appearance

4.1 Outline Dimensions

Battery Dimensions

305±0.5 mm

220±0.5 mm

600±0.5 mm

Base Dimensions

4.2 Nameplate Identification

03 04

3 Safe Transpoation and Storage

3.1 Battery Transportation

When transpoing the batte, it must be packed in the original packaging to ensure the safety

of the equipment during transpoation.

Upon receiving the goods, please inspect the external packaging of the batte and then open

the box for a comprehensive inspection.

If any damage to the batte occurs during transpoation, please notify the shipping company.

The shipping company is responsible for any equipment damage caused during transpoation.

If necessa, seek assistance from the installer or manufacturer.

When handling batte weighing 50 kg or more, please use appropriate equipment or work

together with multiple people.

When storing the equipment, please use the original packaging and store it in a cool, d, and

well-ventilated area to prevent damage caused by moisture.

Pay attention to safety.

Pay attention to high suace temperature.

Be cautious of electric shock.

Compliant with CE safety ceication standards.

This product is in compliance with IEC 62040 ceication

standards.

This product is in compliance with RCM ceication standards.

Professional recycling is required.

Please read this manual before using the product.

Prior to attempting any repair, electrical installation or accessing

any live pas, make sure that the power supply is cut o and wait

for 5 min until internal capacitors are discharged to a safe voltage.

ESYSUNHOME: brand

5KWH+: model, indicating that the batte specication is

5KWh

305±0.5 mm

28±0.5 mm

600±0.5 mm

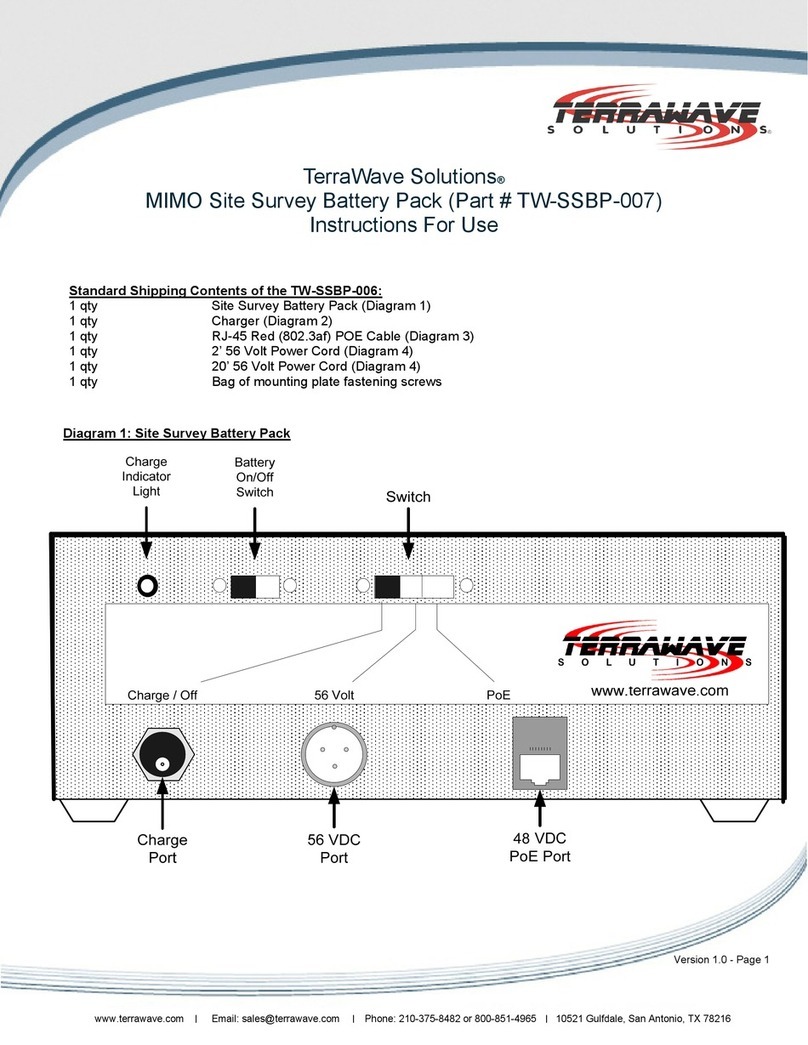

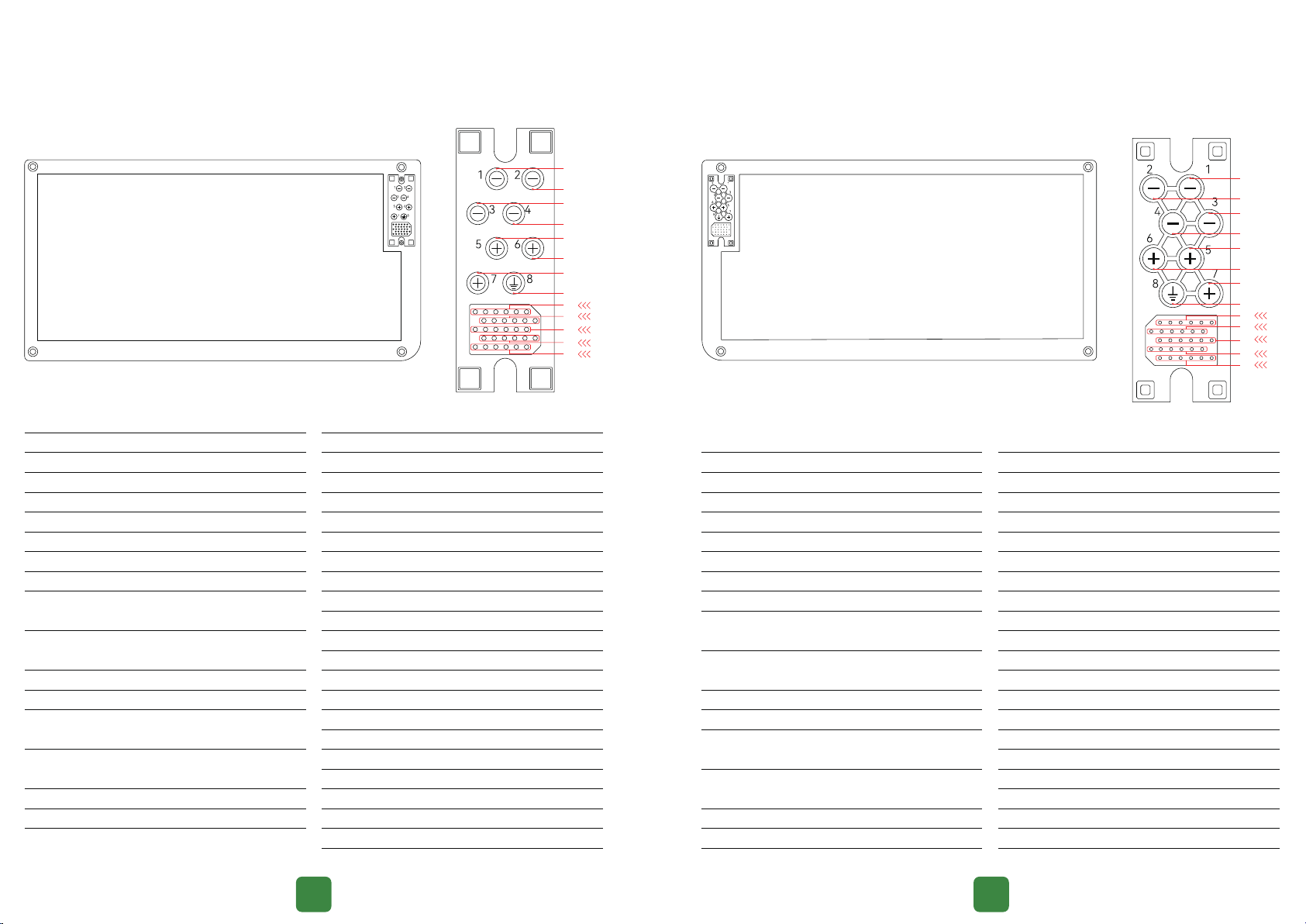

4.3

Po Description

Schematic diagram of top port arrangement for battery Schematic diagram of bottom port arrangement for battery

05 06

S/N

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

Mark

PACK-

PACK-

PACK-

PACK-

PACK+

PACK+

PACK+

Ground wire

RS485-B2

RS485-A2

GND

GND

SW-air switch

SW-air switch

NC

NC

NC

Purpose

Batte cathode

Batte cathode

Batte cathode

Batte cathode

Batte anode

Batte anode

Batte anode

Ground wire of the chassis

Batte and power supply

communication po

Batte and power supply

communication po

Ground wire

Ground wire

Signal cable for enabling

batte discharge

Signal cable for enabling

batte discharge

Reseed inteace

Reseed inteace

Reseed inteace

Purpose

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

Reseed inteace

S/N

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

Mark

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

S/N

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

Mark

PACK-

PACK-

PACK-

PACK-

PACK+

PACK+

PACK+

Ground wire

RS485-B2

RS485-A2

GND

GND

SW-air switch

SW-air switch

RS485-A2

RS485-B2

Purpose

Batte cathode

Batte cathode

Batte cathode

Batte cathode

Batte anode

Batte anode

Batte anode

Ground wire of the chassis

Batte and power supply

communication po

Batte and power supply

communication po

Ground wire

Ground wire

Signal cable for enabling

batte discharge

Signal cable for enabling

batte discharge

Batte and power supply

communication po

Batte and power supply

communication po

Purpose

Reseed inteace

Ground wire

Communication Inteace

Communication Inteace

Communication Inteace

Communication Inteace

Reseed inteace

Reseed inteace

Reseed inteace

Ground wire

Communication Inteace

Communication Inteace

Communication Inteace

Communication Inteace

Reseed inteace

Reseed inteace

12V+

12V+

Reseed inteace

Reseed inteace

Ground wire

Ground wire

S/N

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

Mark

NC

GND

CAN-H2

CAN-H2

CAN-L2

CAN-L2

NC

NC

NC

GND

CAN-H1

CAN-H1

CAN-L1

CAN-L1

NC

NC

12V+

12V+

NC

NC

GND

GND

04

02

08

06

05

07

01

03

14 09

20 15

26 21

32 27

38 33

01

02

03

04

05

06

07

08

09 14

15 20

21 26

27 32

33 38

4

20.48

19.456

4.864

400

﹙600±2)x﹙305±2)x﹙908±2)

207±1

4864

95

4864

95

(16S)4P

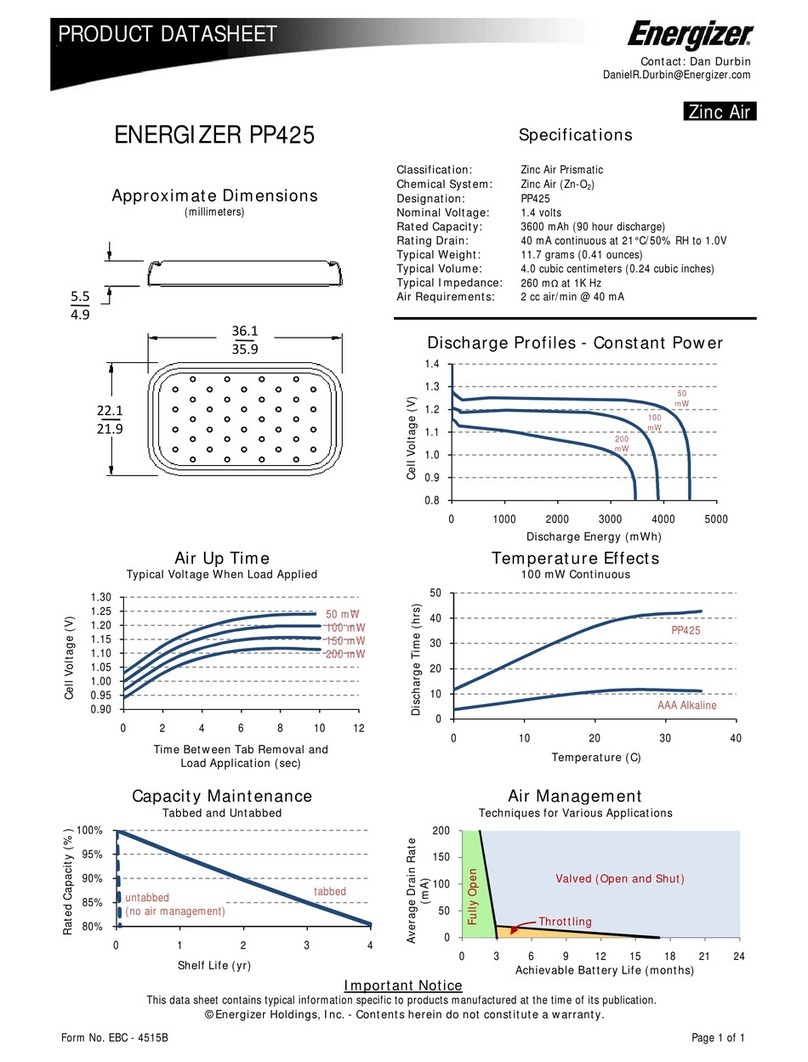

5 Product Parameters

07 08

6 Circuit Structure Schematic

Batte

Voltage I2C

Control signal

Temperature

Balancing

Power circuit

MCU

AFE

Communication inteace

Discharge enable control switch

Multifunctional button

Load/charger detection

B- P-/C-

P+/C+

Current and sho circuit

sensing circuit

Discharge MOSFET

switch

Charging MOSFET

switch

MOS driver circuit

Pre-discharge

control

Charging current

limiting circuit

4.4 No AC connection on battery

The batte does not possess an alternating current (AC) inteace; it has a direct current (DC) inteace. There are three

terminals labeled PACK+ and four terminals labeled PACK-. On the top and bottom of the batte, there are dedicated

GP38 connectors that are directly connected. Please refer to the batte po diagram.

The connection between the batte and the inveer is in the form of direct current (DC). The inveer's AC inteace is

linked to the grid and the backup power source.

4.5 Battery Isolation Device Description

The positive output terminal P+ of the batte is controlled by the discharge control terminal SW. When there are no

external connections, P+ does not output any power. Power output from the batte only occurs when the external

control box or inveer is installed, and the batte switch is turned on.

Both batte terminals, P+ and P-, are isolated and covered with silicone sleeves. The protective sleeves are removed

during installation, and there is no voltage output during the installation or removal process.

Batteries are intended to be installed with ESYSUNHOME HM6 which has an integrated circuit breaker for isolating the

batte.

ESYSUNHOME ESS Battery Models

51.2

IFpP

40.8~57.6

56.8

57.6

40.8

95 %

3~55

-20~58

IEC 62619﹐ ISO 13849, IEC/EN 62040-1, CEC+RCM

IEC 61000-6-1, IEC/EN 61000-6-3

IP66

Ⅰ

120 months

China

5.1 Parameters of the ESYSUNHOME ESS Battery Models

Model

Nominal Voltage (Vd.c.)

Batte Type

Voltage Range (V)

Charging Voltage Declared by Manufacturer (V)

Upper limit Charging Voltage (V)

Discharging Cut o Voltage (V)

Depth of Discharge

Standard Temperature Range for Charging (℃)

Standard Temperature Range for Discharging (℃)

Standards

EMC Standards

Ingress Protection Rating

Protection Class

Warranty

Count of Manufacture

5.2 Module Parameters

Number of Batteries

Batte Capacity (kWh)

Usable Capacity (kWh)

Rate DC Power ﹙kW﹚

Rated Capacity ﹙Ah)

Size (LxWxH mm)

Weight (kg)

Max. Continuous Charging Power ﹙W﹚

Max. Continuous Charging Current (A)

Max. Continuous Discharging Power ﹙W﹚

Max. Continuous Discharging Current (A)

Conguration

Model ESYSUNHOME 5KWH+ ESYSUNHOME 10KWH+

1

5.12

4.864

4.864

100

﹙600±2﹚x﹙305±2﹚x﹙248±2﹚

57±1

4864

95

4864

95

16S

2

10.24

9.728

4.864

200

﹙600±2﹚x﹙305±2﹚x﹙468±2﹚

107±1

4864

95

4864

95

(16S)2P

3

15.36

14.592

4.864

300

﹙600±2﹚x﹙305±2﹚x﹙688±2﹚

157±1

4864

95

4864

95

(16S)3P

ESYSUNHOME 15KWH+

Number of Batteries

Batte Capacity (kWh)

Usable Capacity (kWh)

Rate DC Power ﹙kW﹚

Rated Capacity ﹙Ah)

Size (LxWxH mm)

Weight (kg)

Max. Continuous Charging Power ﹙W﹚

Max. Continuous Charging Current (A)

Max. Continuous Discharging Power ﹙W﹚

Max. Continuous Discharging Current (A)

Conguration

Model

5

25.6

24.32

4.864

500

﹙600±2)x﹙305±2)x﹙1128±2)

257±1

4864

95

4864

95

(16S)5P

6

30.72

29.184

4.864

600

﹙600±2)x﹙305±2)x﹙1348±2)

307±1

4864

95

4864

95

(16S)6P

ESYSUNHOME 20KWH+ ESYSUNHOME 25KWH+ ESYSUNHOME 30KWH+

09 10

2Expansion screw gaskets

Inner diameter: 5mm;

outer diameter: 12mm;

SUS304 gasket

7.2 Base of Battery

600 mmx305 mmx44.1 mm

Silicone, black, matte,

110 mmx39.9 mmx9 mm

(installed on the base)

PM4*8mm

1

1

4

Waterproof

connector cover

Bracket

Bracket

mounting

screws

Name Specifications Quantity Schematic Diagram

7 Preparation Before Installation

7.1 Packing List of Battery

1

2

1

2

4

2

Battery

Fixing angle iron screws

Waterproof connector cover

Corner angle irons

Handlebar screws

Expansion tubes with screws

Name Specifications Quantity Schematic Diagram

M4x8 mm

5KWH+ residential

energy storage battery

Silicone, black, matte,

110 mmx39.9 mmx9 mm

L60.5x32x25 mm

M4x30 mm flange hex screws

6 mmx40 mm

7.3 Preparation before Installation

7.3.1 Preparation of Installation Tools

Tools and Descriptions

Spirit level Marker

Electric drill with φ6

Hammer

Screwdriver

Phillips

PH1

Allen

M2

Slotted

SL2.5

Diagonal pliers

Utility knife Crimping pliers

Network cable

crimping pliers

Installation

Type

Safety

Safety gloves Dust mask Goggles

Ruler

Stripping pliers

Open-end wrench

S=7mm

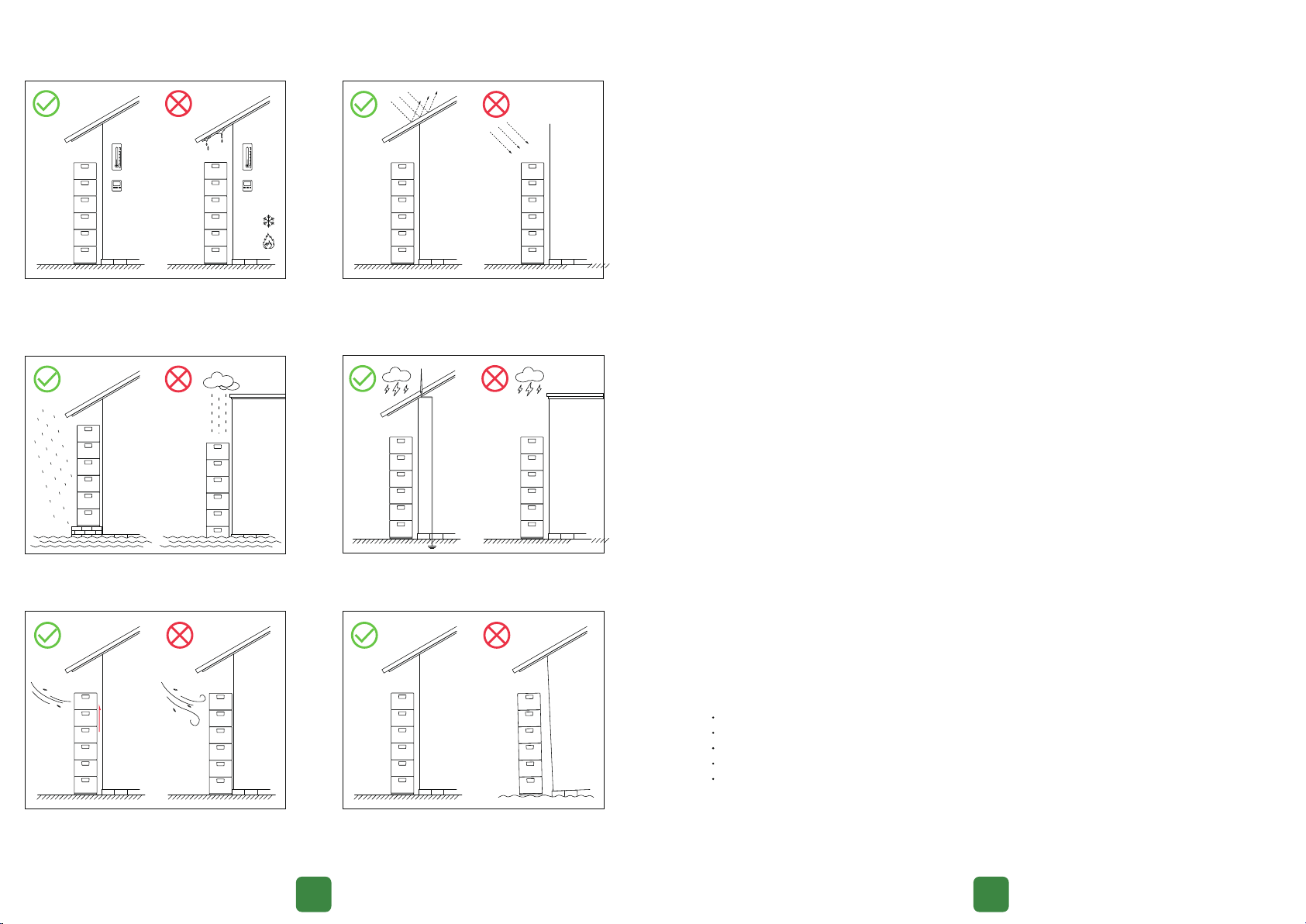

7.3.2 Selection of the Installation Environment

Please select the site according to the relevant requirements.

Do not install it in a wet place or in water. Do not install it in areas prone to lightning

strikes.

This product is self-cooled. To ensure proper

heatdissipation, please install it in a

well-ventilated place.

For stability, the product should be installed

on solid and at ground, with the wall being

perpendicular to the ground.

The ambient temperature should be -20 ℃ to

58 ℃and the relative humidity should be 0%

to 100% (no condensation).

-20℃

≤100%

58℃

≤-20℃

≥100%

≥58℃

It can be installed outdoors, but must not be

directly exposed to sunlight.

11 12

7.3.3 Installation Safety Precautions

The installation and use environment of lithium batteries must comply with relevant international,

national, and local standards, as well as local laws and regulations.

Ensure that the battery is not accessible to children and is kept away from areas of daily work or

living, including but not limited to: offices, bedrooms, living rooms, music rooms, kitchens, studies,

game rooms, home theaters, sunrooms, bathrooms, laundry rooms, and attics.

When installing the battery in a garage, keep it away from the driveway. It is recommended to

install the battery on a wall higher than the bumper to prevent collisions.

For basement installations, maintain good ventilation. Do not place flammable or explosive

materials around the battery. It is recommended to install the battery on a wall to avoid contact

with water.

Install the battery in a dry and well-ventilated environment and secure it on a solid and flat

surface.

Install the battery in a concealed location or install a canopy above it to protect it from direct

sunlight or rain.

Install the battery in a clean environment without strong infrared radiation, organic solvents, and

corrosive gases.

For areas prone to natural disasters such as floods, earthquakes, and typhoons/hurricanes,

appropriate installation precautions should be taken.

Keep the battery away from ignition sources. Do not place any flammable or explosive materials

around the battery.

Keep the battery away from water sources such as faucets, drains, sprinklers, etc., to prevent water

ingress.

Do not install the battery in easily accessible locations, as the enclosure and heat sink temperature

can be high when the battery is in operation.

To prevent overheating, ensure that the vents and cooling system are not blocked when the

battery is in operation.

Do not expose the battery to flammable or explosive gases or smoke. Do not perform any

operations on the battery in such environments.

Do not install the battery on a moving object such as a boat, train, or car.

Do not install the battery in outdoor areas affected by salt, as it may corrode. This area refers to

a distance of up to 500 meters from the coast or areas susceptible to sea breeze influence. Areas

susceptible to sea breeze influence may vary due to weather conditions such as typhoons and

monsoons, or terrain features such as dams and hills.

In the case of backup power, do not use the battery in the following situations:

Vital medical equipment for human life.

Control equipment for trains, elevators, etc.

Computer systems with social and public impoance.

Locations near medical equipment.

Other devices similar to those described above.

7.3.4 Selection of Installation Locations

Veical installation, without forward or backward tilting.

The clearances around the power supply must not be less than the following:

Top

≥800 mm

Front

≥1000 mm

Rear

=45 mm

Left

≥300 mm

Right (door side)

≥600 mm

Front

≥1000 mm

Rear

=45 mm

Top

≥800 mm

Left

≥300 mm

Right (door side)

≥600 mm

7.4 Installation

7.4.1 Location

13 14

Tools: spirit level, marker, ruler

Mark and designate the left and right boundaries of

the selected equipment, with a distance of 600 mm

between points A and B. Secure a spirit level veically

on each side of the equipment to draw marking lines

A and B, ensuring that the lines are perpendicular to

the ground.

AB

600 mm

Perpendicular to marking line A, use a ruler and a

laser Level to measure and draw marking line C. The

distance between line C and the ground is 165 mm.

Mark screw hole positions on the outer side, 18 mm

away from the intersection of A, B, and C, and use

a bubble Level to check if the two hole positions

are in a straight line.

165 mm

A B

C

18 mm

18 mm

For each additional batte, add 220 mm to the

existing base and make corresponding markings.

165 mm

165 mm

220 mm

220 mm

220 mm

220 mm

220 mm

385 mm

605 mm

825 mm

1045 mm

1265 mm

A B

C1

C2

C3

C4

C5

C6

7.4.2 Drilling

7.4.3 Bracket Installation

When installing a single batte, the output terminal P+ is in a closed state. It is necessa to externally connect

the batte control box or inveer and then turn on the control switch to engage the discharge control terminal.

Only then will the batte have voltage output to power the equipment.

7.4.4 One Battery Installation

15 16

NOTE

Tools: electric drill (bit size: φ6 mm), hammer, expansion tube (6x40 mm) with screws

165 mm

A B

C

18 mm

18 mm

Drill three holes using the electric drill with φ6 mm

bit as indicated in the gure.

Drill a hole with depth of 40mm. Hammer the

expansion tubes into the holes.

>40 mm

It is recommended to place the batte upside

down on a soft suace to avoid scratches. Align

the bracket’s fool-proof po with the batte (Do

not remove the waterproof connector cover on the

bracket), and fasten the bracket with the batte.

Before installation, remove the dust cover on the top

and bottom to avoid damage during installation.

Tools: screwdriver, screws﹙M4x8 mm﹚

Secure four screws using the screwdriver

Bracket mounting screws

M4x8 mm

Once the installation location has been determined,

tighten all screws. Ensure the bracket is properly

tted with the batte.

Bracket mounting screws

M4x8 mm

Tools: ruler, screwdriver, screws (M4x8 mm), angle iron (L79.5x32x25 mm), expansion tubes (M6x40 mm)

with screws, gasket (SUS304)

Make a mark of 45mm from the wall, and align the

batte(including the bracket) with the mark, xed

the angle iron to the batte, align the other end

with the hole in the wall(Do not tighten the screws).

Secure the

screws only.

Do not tighten it.

45 mm

After adjusting the position of the angle iron, pass

the expansion screw through the gasket and angle

iron, x it on the wall﹐ after the angle iron is adjusted,

then tighten the screws respectively.

Screws

M4x8 mm

Expansion tubes

with screws,

expansion screw

gasket

7.4.5 Stacking of Multiple Batteries

7.4.6 Battery Earthing

Please refer to the following illustration for batte eahing. Compatible inveer model for the

batte: ESYSUNHOME HM6.

18

17

When multiple batteries are connected together to form a system, the output terminal P+ remains in a closed state.

It is necessa to externally connect the batte control box or inveer and then turn on the control switch to engage

the discharge control terminal. Only then will the batte have voltage output to power the equipment.

Tools: ruler, screwdriver, open end wrench (7 mm), angle iron screws (M4x10 mm), angle iron (L79.5x32x25 mm),

expansion tube (M6x40 mm) with screw, handlebar screws (M4x30 mm), waterproof connector cover,

gasket (SUS304)

Make a mark 45 mm from the wall, align the batte

with the mark. Intall the waterproof connector

cover, and then stack the next batte. Once a

batte is installed, secure its two sides with

handlebar screws, and stack them as required.

After stack all the batteries, install the angle iron

on the batte, and then x the expansion screws

through the gasket and angle iron onto the wall.

Fix each batte rst, adjust the angle iron position,

and then tighten the screws separately.

Waterproof

connector cover

Waterproof

connector cover

45 mm

Expansion tubes

with screws,

expansion screw

gasket

Angle

irons

Connect the batteries and lock the angle irons onto

the concrete wall. The batte has independent

eahing terminal, please eah the batteries as

shown in the diagram above.

Tools: screwdriver

7.6 Batte and Inveer Communication

After the connection of ESYSUNHOME HM6 inveer and ESYSUNHOME batte system, please turn on the batte switch

on the inveer which allows connection to the grid, photovoltaic system, and household devices. Once the power is on,

the inveer will act as the main unit and initiate communication with the batte.

7.5 DC Connection Instructions

The batte has three PACK+ pos and four PACK- pos. There are dedicated GP38 connectors on the top and bottom

of the batte for direct connection. When connecting the ESYSUNHOME HM6 inveer to the batte system, align and

position the inveer above the batte system. Ensure the correct direction and position.

To prevent accidental discharge of the batte during transpoation or installation, avoiding potential harm to

individuals or propey, the batte pack is equipped with a discharge control po. This po is located on the connector

of batte system. Only when the batte is connected to ESYSUNHOME HM6 via stack installation, and the batte

switch on the inveer is activated, can the batte discharge externally. Otherwise, the batte's external discharge

function will be deactivated.

20

19

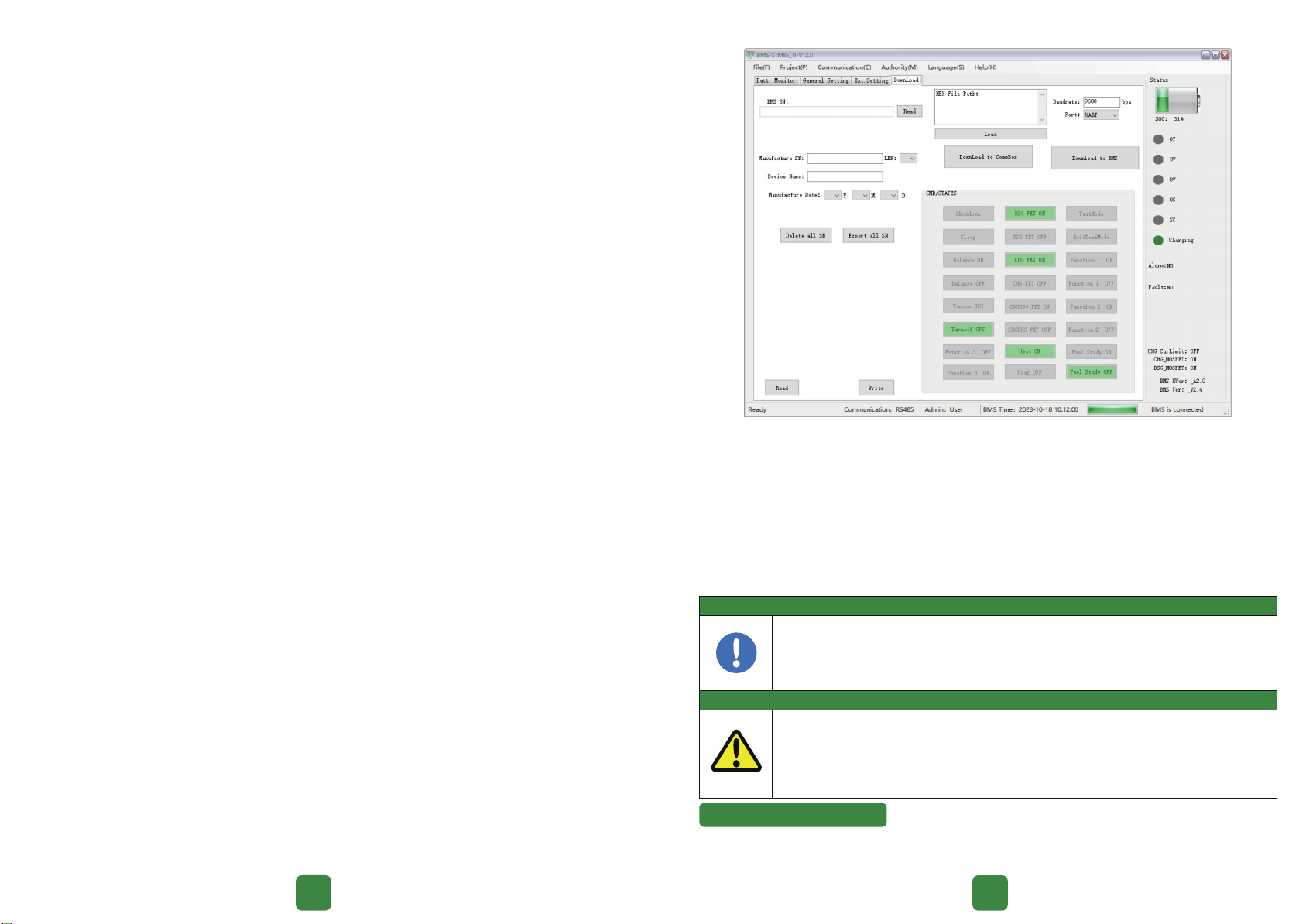

8.2.2 BMS-STM8S-TI functions operation

① Batte monitor: review the real-time data of the batte about Voltage, current, temperature,

software version, batte status, etc.

CAN

(Yellow)

RS485

(Grey)

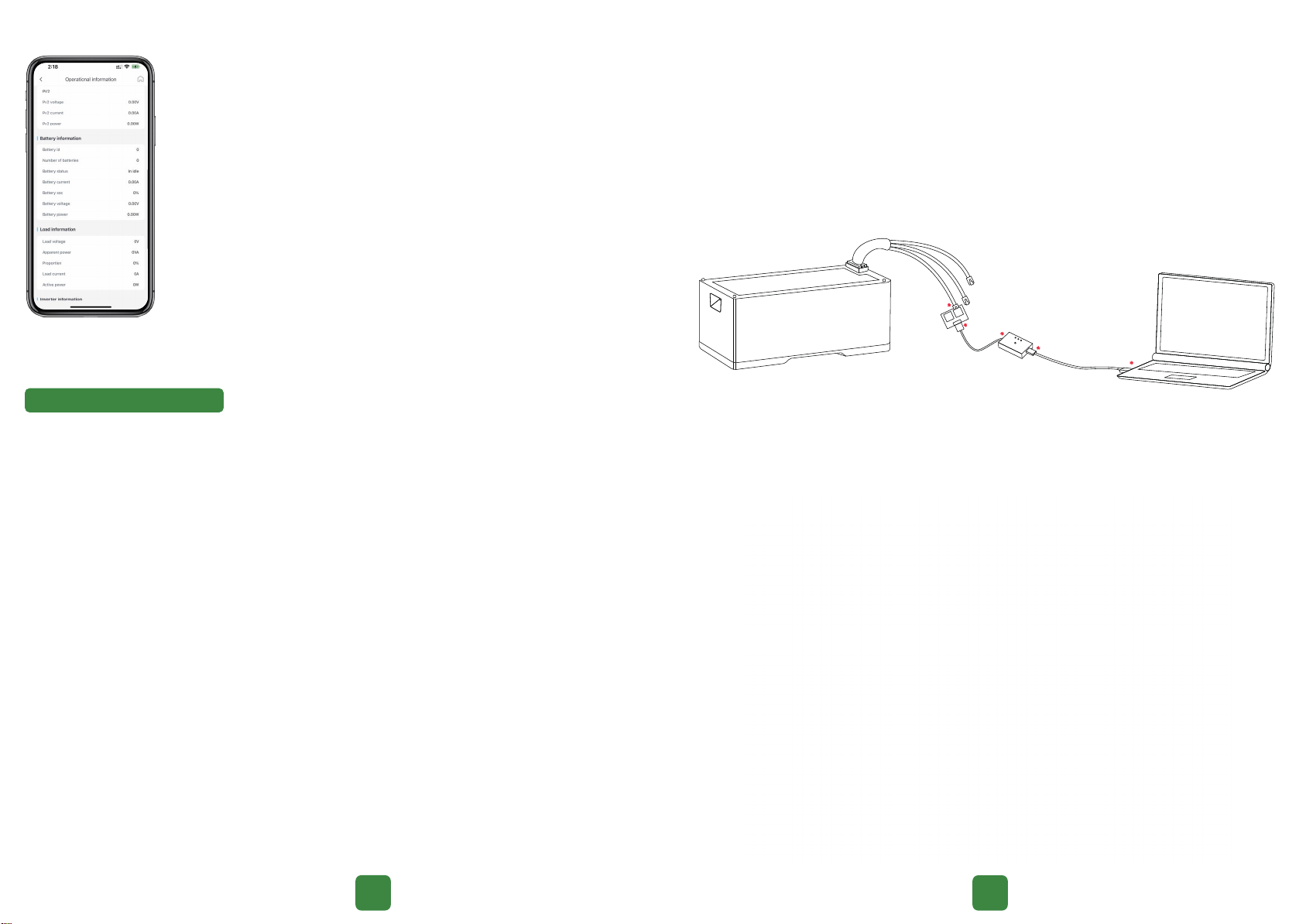

8.2.1 BMS-STM8S-TI software connection

Connect the batte and PC host software through GP 38 wire, connect the USB inteace of the

adapter to the computer. Use the BMS-STM8S-TI software provided with the batte to operate.

Communication through RS485 or CAN.

User permissions:

Read only: User or inspector. These settings can be able to be viewed by the user/inspector.

Read and editing: Batte manufacturers or authorized maintenance personnel. These settings can

be edited by the authorized persons. The authorized persons need to enter the correct password

to enable editing permission.

7.7 How to Set Up Batte Monitoring

Batte monitoring is set up through an app. When you want to view batte-related

information, connect your phone to the app.

You can then access information such as the number of connected batteries, batte

voltage, batte current, batte power, remaining batte capacity, and batte

operating status.

8 Batte Maintenance

8.1 Staup and Shutdown Procedure

Battery startup procedure:

1. Connect the inveer to the batte;

2. Turn on the batte circuit breaker on the inveer;

3. A beeping sound indicates that the batte has been staed up.

Battery shutdown procedure:

1. Dismantle all of the AC and DC cables from HM6 inveer;

2. Turn o the batte circuit breaker on the inveer;

3. Wait for the HM6 inveer lights to go out;

4. Disconnect HM6 inveer from the batte;

5. Batte will stop outputting;

6. Batte will be in dormant mode after 48 hours.

8.2 BMS-STM8S-TI

BMS-STM8S-TI is a PC host software designed for ESYSUNHOME ESS Batte Models:

ESYSUNHOME 5KWH+

ESYSUNHOME 10KWH+

ESYSUNHOME 15KWH+

ESYSUNHOME 20KWH+

ESYSUNHOME 25KWH+

ESYSUNHOME 30KWH+

It includes functions such as batte parameter viewing, batte settings modication, fault alarm

viewing, batte status viewing, etc.

22

21

② General setting: set the parameters for the batte.

9 After-sales Seice

Seice email: suppo@esysunhome.com

Or, Please contact the local installer.

Warning

Attention

The batte should be kept clean, and the terminal and connectors should be cleaned regularly.

Dierent types and capacities of batteries should not be mixed. It is recommended to use batteries

of the same model.

When installing or replacing the batte, remove any metal objects such as watches and rings from

your hands to avoid the risk of sho circuit and burns.

Batte maintenance should be peormed or supeised by personnel with knowledge of batteries

and with necessa precautions.

Batteries can present a risk of electric shock and high sho-circuit current.

Do not throw batteries into re. They may explode.

Do not open or damage batteries. The released electrolyte can be harmful to the skin and eyes, and

may be toxic.

8.3 Maintenance Instructions (Electrical Connection Maintenance and ESD Cleaning)

The surroundings of the batte enclosure should be kept clean, and any debris, dust, or accumulated water on the

suace of the enclosure should be cleaned.

The oor of the batte installation area should be kept d, and any accumulated water should be cleaned to prevent

water damage.

The batte installation area should have proper ventilation, and any objects obstructing ailow should be moved.

High-temperature or heat-emitting objects should not be placed around the batte to avoid aecting its normal

operation.

There is a ground wire inside the batte connecting to the enclosure, which is also connected to the inveer. Regularly

check if the external grounding of the inveer is secure.

③ Download: update the software of batte, do some impoant conguration

This manual suits for next models

5

Table of contents

Other ESY Sunhome Batteries Pack manuals