ET Hydrogen L/160 Troubleshooting guide

1

2

OPEN PACKAGE AND PLACE ALL ITEMS ON A WORKING BENCH TABLE.

The package contains: burner tips; user manual; quick start guide; DVD guide; USB tutorial guide; spare

fuse; plastic funnel; torch(es); fire proof plastic hose; power cord.

For a better understanding, Elettronica Todescato recommends to take vision of our DVD and/or USB Key

guide, and to simultaneously consult the present manual.

Step 1 Make sure that the switch is turn on “O” (OFF). Then, plug the power cord / cable into the

machine and into the electrical outlet make sure the voltage is make sure that the switch is

on the off position, “O”.

(3 POSITION SWITCH)

Step 2 PREPARE THE ELECTROLYTE SOLUTION

Carefully read Section 4.2 in the USER MANUAL and follow the instructions properly to

prepare the electrolyte solution. Make sure to understand the necessary pre-cautionary

procedures explained under the “DANGER“ symbol, in section 4.2 in the USER

MANUAL to avoid hazardous complications and mistakes.

NOTE: -2,6 liters of distilled or demineralized water needed to fill the tank.

-Mix with 1080 grams of KOH (Potassium Hydroxide).

-Let the chemical components cool down for 10 to 15 minutes or more.

-In appendix 1, there are Conversion Tables that can assist you in the amounts

needed for different units of measure.

ATTENTION!

Always use clean objects for

preparing the electrolyte solution.

If some of the tools used are not clean

wash it with tap water a few times

until it becomes clean and after

dry it with a rag.

DO NOT USE CLEANINGS

OR LIQUID SOAPS.

ATTENTION!

It is important to use protective

gloves and glasses

due to the corrosive

nature of the solution.

3

Step 3 UNSCREW THE SAFETY CAP ON TOP OF THE MACHINE.

( SAFETY CAP )

Step 4

Turn the switch into the down position ( “=” ) to refill, this will enable the operator to check

the level of demineralized water.

(3 POSITION SWITCH)

Notice:

a. Green light is “on”, indicating the machine is connected to the electricity (pic 1).

b. Yellow light is “on”, initially indicating the internal tank level is empty and needs to be

filled, or the water level is below normal during daily usage and there is need to add

more water. (see picture below).

c. Red light is, “off”, indicating that the internal tank needs to be filled.

4

Step 5 POUR ELECTROLYTE SOLUTION

IMPORTANT NOTICE:

The electrolyte solution’s lifetime is of one year.

It must be poured when:

1- Using unit for the first time.

2- When solution has previously been poured through contaminated or dirty funnel.

3- When unnecessary or contaminated liquids have been poured inside the internal tank, such

as deoxidizer, etc.

After the electrolyte solution has cooled off, pour the solution into the internal tank (slowly) using a

funnel, until the Red-light indicator comes on, (pic. 2) indicating the internal tank is properly filled. At

the same time, the Yellow light will turn “off”, indicating that the tank is being filled and has reached

above the minimum level required. Stop pouring the solution, as soon as the red light comes on.

When the red light comes on, stop pouring the demineralized water, in order to avoid over filling the

tank.

(This is IMPORTANT: DO NOT OVERFILL). Then close the cap tightly safe.

Notice: The booster tank initially is disconnected.

Step 6 PREPARE THE DEOXIDIZER

FLUX (deoxidizer) Methyl Alcohol ( 1 liter ) + Boric Acid ( 15 –20 grams )

sec . 4.5 in the USER MANUAL),

contains the procedure and safety precautions to follow.

5

Step 7 BOOSTER TANK FILLING

Take the un-attached booster tank in hand, start pouring the deoxidizer in the booster tank by

placing your index on the hole in the center of the booster tank to avoid filing the interior chamber.

Fill to the maximum level indicated on the outside of the booster tank.

(DO NOT OVER-FILL)

EXAMPLE OF

HERMETIC SEAL

6

STEP 8.

BOOSTER TANK INSTALLATION

To mount the booster tank after having it filled with the flux (deoxidized), tighten the handle

knob making sure to not over screwing in order to preserve the gaskets and the internal

thread of the booster tank.

(BOOSTER TANK KNOB)

NOTE: For daily use and refill, refer to the section called “Attention “(page 14).

7

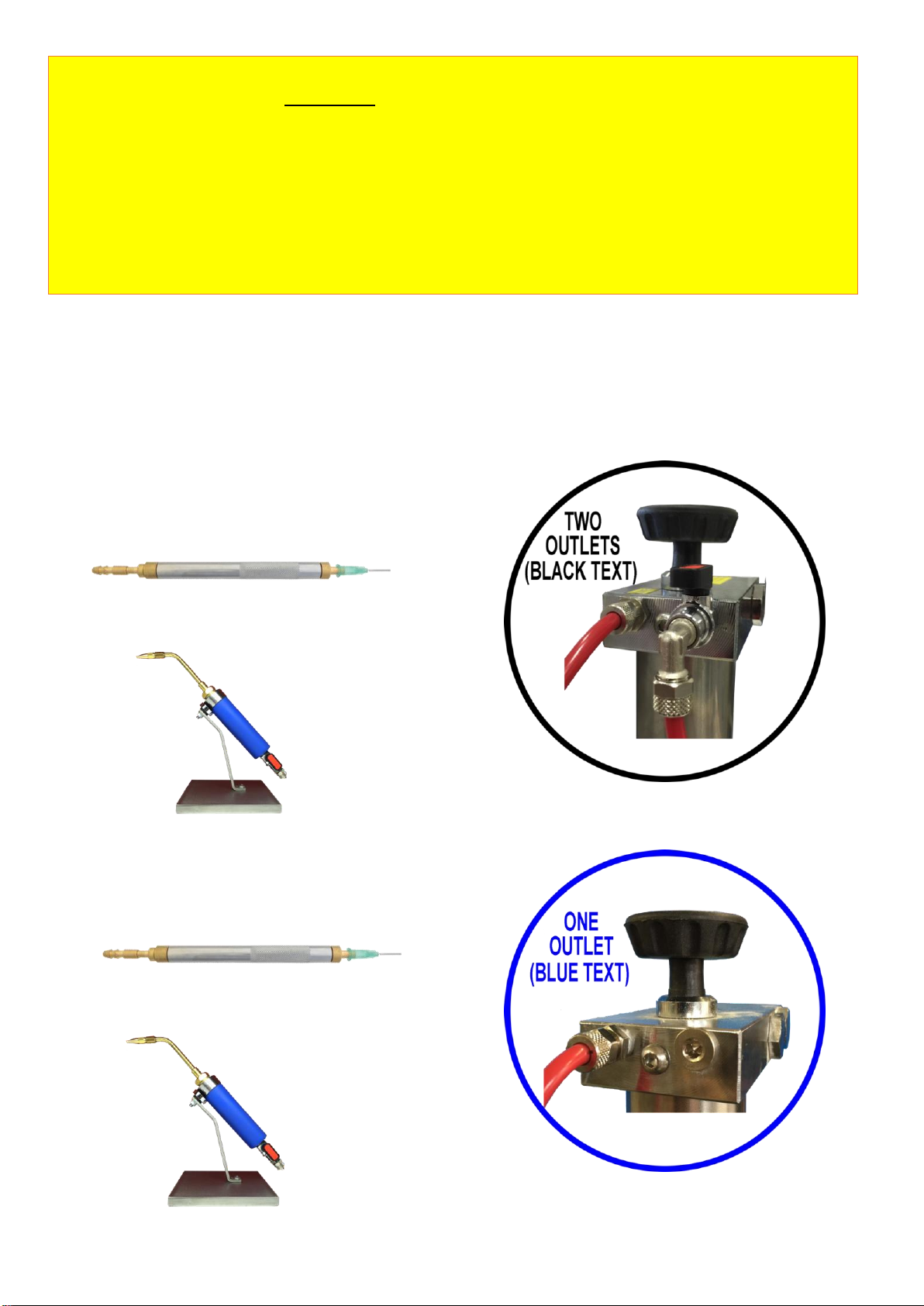

In the following steps, you must choose to operate with one or two outlets according to your

working needs.

Two outlets system is on the left side of the manual, starting from the next pages.

(highlighted in BLACK);

One outlet system is on the right side of the manual, starting from the next pages.

With the L/160 model, you can choose different working options:

SETTING THE MACHINE WITH TWO OUTLETS

YOU CAN WORK WITH:

•1, 2, 3 OR 4 STANDARD TORCHES.

•OR 1, 2, OR 3 SPECIAL TORCHES.

SETTING THE MACHINE WITH ONE OUTLET

YOU CAN WORK WITH:

•1 STARDARD TORCH (SUGGESTED).

•OR 1 SPECIAL TORCH (SUGGESTED).

! WARNING !

REMEMBER TO SHUT OFF ALL THE FLAMES BEFORE

DOING THE FOLLOWING OPERATIONS:

•OPENING THE TANK OR THE BOOSTER TANK FOR REFILLING OR POURING THE CHEMICALS.

•CHANGING OR ADDING MORE TORCHES, HOSES OR BURNER TIPS AND/OR NOZZLES.

•TURNING OFF THE MACHINE.

FAILURE TO FOLLOW THE UPPER ACTIONS WITHOUT SHUTTING OFF THE FLAME

MAY CAUSE THE BURNER TIP FUSING AND/OR BACKFLAME.

PROCEDURE FOR TWO

OUTLET SYSTEMS

Step 9.

With the model L/160 with two outlets, you

can use between one and four torches with

the following procedures:

NOTE: to connect the hoses properly, see

picture BELOW.

ONE TORCH:

Connect the hose to LINE 1 fitting (closest to

the machine), with the shut-off gas valve of

LINE 2 in the “off” position, then select the

green burner tip (refer to Table 2 –STEP 13)

and light the flame.

TWO TORCHES:

You must use the default LINE 1.

Connect the hose with the two split torches

to LINE 1 fitting (closest to the machine), with

the shut-off gas valve of LINE 2 in the “off”

position, then select the green burner tips

(refer to Table 2 –STEP 13) and light the

flames.

THREE TORCHES:

USE of LINE 1: Connect the hose with the

two split torches to LINE 1 fitting (closest to

the machine).

USE of LINE 2: Connect the hose with one

single hose and torch to LINE 2 by opening

the gas valve in the “on” position, then select

the green burner tips (refer to Table 2 –

STEP 13) and light the flames.

FOUR TORCHES:

USE of LINE 1: Connect the hose with the

two split torches to LINE 1 fitting (closest to

the machine).

USE of LINE 2: Connect the hose with the

two split torches to LINE 2 fitting by opening

the gas valve in the “on” position, then select

the green burner tips (refer to Table 2 –

STEP 13) and light the flames.

NOTE:

TO CONNECT THE HOSES TO THE

FITTINGS, UNSCREW THE FERRULE.

See Picture Below.

Then insert the plastic hose to the fitting,

tightening the ferrule to ensure a proper

and secure connection.

PROCEDURE FOR ONE

OUTLET SYSTEMS

Step 9 a.

NOTE: to connect the hoses properly, see picture

BELOW.

Prepare the special torch making sure the hose is

fitted (#16) to its fitting and the nozzle or burner tip

(refer to Table 2 or Table 2A) is selected and fitted

(#11).

SPECIAL TORCH

Step 9 b.

One Special Torch or Standard Torch (optional).

Connect the hose to the GAS OUTLET fitting, then

select the nozzle or burner tip (refer to Table2 or

Table 2A).

NOTE:

TO CONNECT HE HOSES TO THE FITTINGS, UNSCREW

THE FERRULE.

See Picture Below.

Then insert the plastic hose to the fitting, tightening

the ferrule to ensure a proper and secure connection.

TWO OUTLETS SYSTEM ONE OUTLET SYSTEM

9

STEP 10.

IMPORTANT: Before turning on the machine

set the power control knob to zero (see

picture below).

Step 11.

After mounting the booster tank, select the

green burner tip (0.8 mm).

Refer to TABLE 2, (Step 13).

WARNING: Failing to follow the values of

power regulation indicated in TABLE 2,

may cause the burner tip fuse and/or back

flame.

Step 12.

Turn “on” the machine by pushing the 3

position switch to the TOP position, where

the “-”is indicated. After a couple of minutes

this will start the gas emission.

(see picture below).

(3 POSITION SWITCH)

Step 10.

IMPORTANT: Before turning on the machine set the

power control knob to zero (see picture below).

Step 11.

After mounting the booster tank, select the burner tip

or nozzle (refer to table 2 or table 2A).

WARNING: When using burner tips, failing to follow

the values of power regulation indicated in TABLE 2 or

TABLE 2A, may cause the burner tip fuse and/or back

flame.

Step 12.

TURN ON THE MACHINE

Turn “on” the machine by pushing the 3 position switch

to the TOP position, where the “-”is indicated. After a

couple of minutes this will start the gas emission.

(see picture below).

(3 POSITION SWITCH)

TWO OUTLETS SYSTEM ONE OUTLET SYSTEM

10

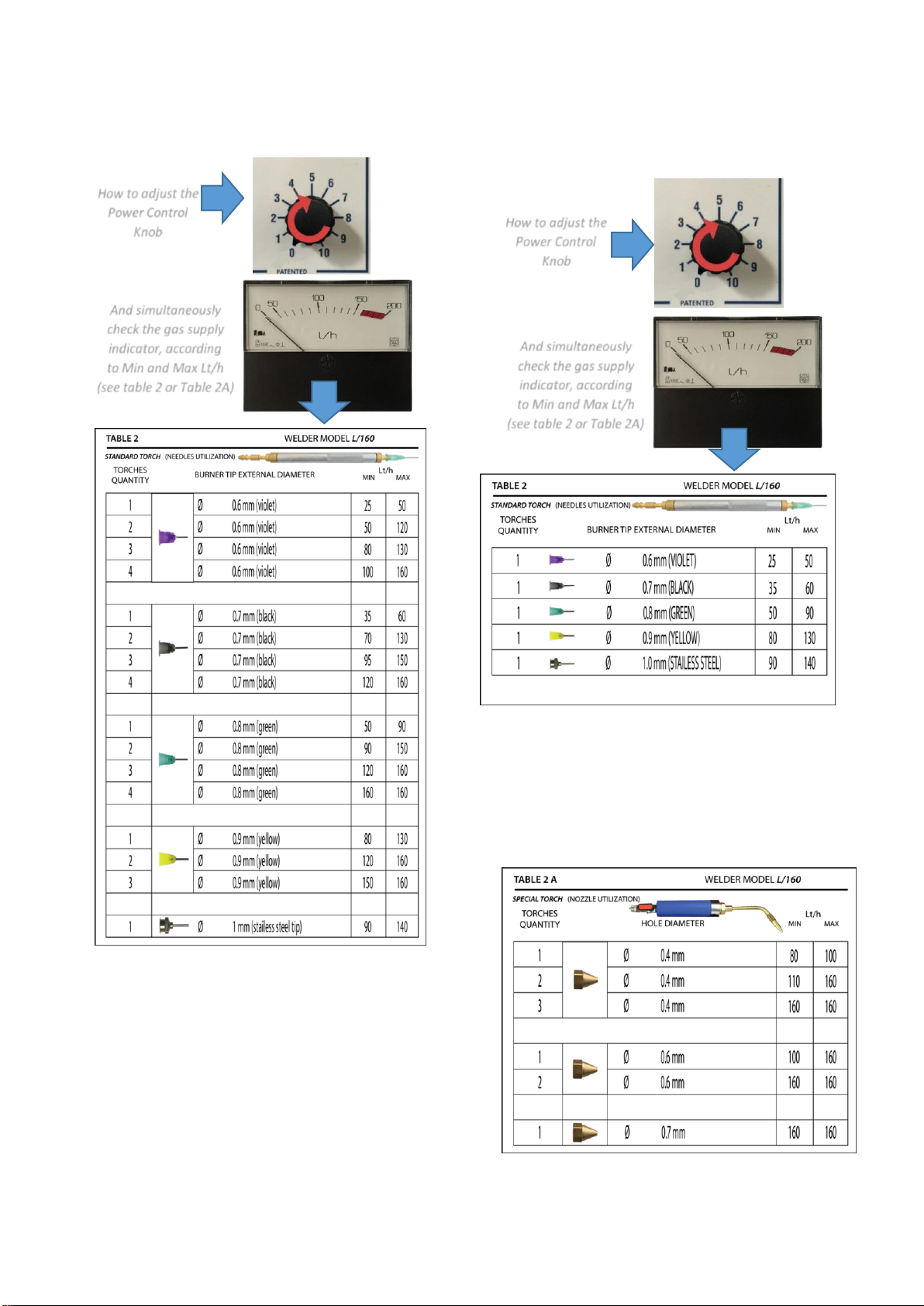

STEP 13.

HOW TO ADJUST THE POWER

ACCORDING TO BURNER TIP TIP SIZE.

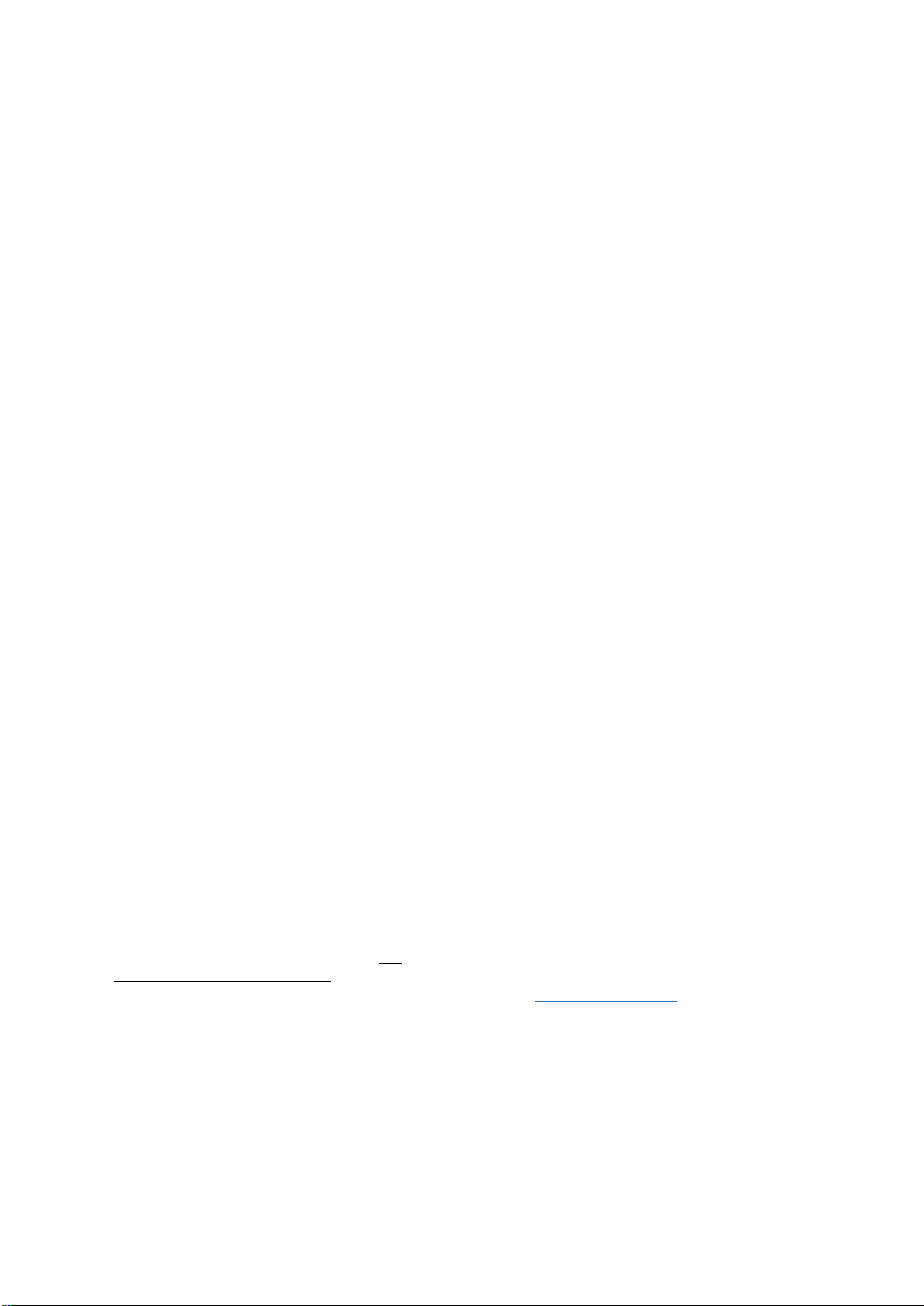

STEP 13.

HOW TO ADJUST THE POWER

ACCORDING TO NEEDLE OR

NOZZLE TIP SIZE.

Adjust the power control knob using the gas supply

indicator according to the Min/Max values using

Table 2 or Table 2A.

NOTE:

Remember to not regulate the power under the

minimum value, indicated in Table 2. This may

cause the burner tip to fuse and burn excessively

or back flame.

How to adjust the

Power Control

Knob

And simultaneously

check the gas supply

indicator, according

to Min and Max Lt/h

(see table 2 or Table 2A)

How to adjust the

Power Control

Knob

And simultaneously

check the gas supply

indicator, according

to Min and Max Lt/h

(see table 2 or Table 2A)

TWO OUTLETS SYSTEM ONE OUTLET SYSTEM

11

Adjust the power control knob using the gas

supply indicator according to the Min/Max

values using Table 2 or Table 2A.

NOTE:

In order to insert the burner tip correctly, push

and rotate this item simultaneously at the

extremity of the torch, to make sure the burner

tip (picture A) is properly fitted. According to the

number of torches desired to use, and to the

diameter of the burner tip, remember not to

regulate the power under the minimum value,

indicated in Table 2. This may cause the burner

tip to fuse and burn excessively or back flame.

(picture A)

Adjust the power control knob using the gas

supply indicator according to the Min/Max

values using Table 2 or Table 2A.

NOTE:

In order to insert the burner tip correctly, push

and rotate this item simultaneously at the

extremity of the torch, so as to make sure the

burner tip (picture A) is properly fitted. According

to the number of the torches desired to use, and

with respect to the diameter of the burner tip,

remember not to regulate the power under the

minimum value, indicated in Table 2. This may

cause the burner tip to, fuse and burn

excessively.

(picture A)

TWO OUTLETS SYSTEM ONE OUTLET SYSTEM

12

Step 14.

Wait to the gas to exit from the burner tip

(approximately two/three minutes or more),

then light the flame with a lighter or

electronic igniter.

If the flame is too weak move on to the next

burner tip on table two (2).

(TORCH AND FLAME)

Step 15.

To turn off the machine switch the flame off

by pushing the base of the torch (as you do

with a pen), then ultimate the procedure by

turning the switch to “0”.

Always shut the flame OFF, before turning

machine off.

Do not turn the machine “off” while the flame

is lit.

Always, turn OFF the flame from the torch,

before shutting down the machine, always.

See picture below.

STEP 14.

NOTE 1 (REFERED FOR SPECIAL TORCH)

The operator will have to use the Gas Supply

Indicator –Power Control Knob/(Burner

Tip/Nozzle), with the min/max values, all

simultaneously in order to achieve the correct

flame desired, without burning the tips, before

lighting the flame. (See picture A,B,C).

NOTE 2 (REFERED FOR STANDARD TORCH)

After selecting the burner, screw the tip

(picture D) in place at the end of the torch, then

turn on the machine, while simultaneously using

the “Gas Supply Indicator” (picture C) for

gauging purposes. Then from Table 2/Table 2A

make sure the selected tip, does not go below

the Min/Max Lt/h value permitted, while also

using the Power Control Knob for adjusting

purposes. (Picture A).

Failure to follow the suggested Min/Max setting

will result in melted or fused burner tip/s.

(picture A)

(picture B)

(picture C)

(picture D)

TWO OUTLETS SYSTEM ONE OUTLET SYSTEM

13

Step 15.

Wait for the gas to be produced and exiting from

the torch, (approximately 2 or 3 minutes or

more) then light the flame with a lighter or

electronic igniter.

If the flame is unsatisfactory, move to the next

burner tip from Table 2/Table 2A.

(see picture below).

Step 16.

To turn the machine “OFF”, shut the flame off the torch

by pushing the torch hose fitting, if you use a standard

torch (picture 1), closing the shut off valve, if you use a

special torch (picture 2). Then push the (3-position

switch) to then central initial position, “O”.

Always shut the flame OFF, before turning machine off.

Do not turn the machine “off” while the flame is lit.

Always, turn “OFF” the flame from the torch, before

shutting down machine, always.

See picture below.

(PICTURE 1) (PICTURE 2)

HOW TO USE THE SPECIAL TORCH:

To turn on the flame, it is sufficient to open the

Valve at the base of the torch (“OPEN” position)

To turn OFF the flame, rotate the valve (quickly),

From “open” to “close” and then to “open” again.

(see step 16).

IMPORTANT NOTE:

IMPORTANT NOTICE:

The electrolyte solution’s lifetime is of one

year. It must be poured when:

1- Using unit for the first time.

2- When solution has previously

been poured through

contaminated or dirty funnel.

3- When unnecessary or

contaminated liquids have been

poured inside the internal tank,

such as deoxidizer, etc.

IMPORTANT NOTE:

For the first startup of our ET systems, or

for the yearly maintenance (once every

year), the machine must be filled or re-

filled with electrolyte solution.

For the daily re-fill it is mandatory to pour

only demineralized (or distilled) water

inside the electrolyte tank.

Pouring daily electrolyte solution will

cause a crystallization inside the tank and

consequent obstructions of machine’s

hoses, potentially causing a general

malfunction.

TWO OUTLETS SYSTEM ONE OUTLET SYSTEM

14

GOOD DAILY HABITS FOR

MAINTAINING THE MACHINE

AT OPTIMAL PERFORMANCE

A T T E N T I O N

1. Do not unscrew “booster tank” nor the

“safety cap”, while the flame is on.

2. Do not leave the machine on for more than

30 minutes, while the flame is “off”.

3. RE-Fill WATER IN THE INTERNAL TANK by

DEPRESSURIZING THE Booster Tank (first)

Whenever water or electrolyte solution needs

to be added to the (internal tank) it is

IMPORTANT to (Depressurize) the booster

tank (first) by simply unscrewing the handle-

knob (see photo in Step # 8). This will keep

the flux (deoxidizer) from contaminating the

electrolyte solution.

A) (unscrew safety cap) and add water or

electrolyte solution until the Red lamp comes

“on “, indicating its full.

B) afterwards re-tighten the safety cap and the

booster handle knob. Taking care not to over

tighten, or over-screw, or de-thread the

internal chamber. This will become a daily,

on-going standard operation, as water will

probably be constantly added to the (internal

tank), before starting the working day.

4. Do not turn the machine “off” while the flame

is lit. Always, turn off the flame from the

torch, before shutting down machine, always

do this as a pre-cautionary procedure.

5. Shut off the flame before refilling any liquid

flux (deoxidizer) or demineralized water) With

the tanks full, the machine will operate

approximately 6-8 hours.

6. If only the booster tank needs refilling, DO

NOT OPEN THE SAFETY CAP on top of the

machine. Just remove the booster tank and

fill accordingly to the max level position using

a finger in the center to avoid spilling fluid in

the improper location. Reattach the booster

tank when done filling.

GOOD DAILY HABITS FOR MAINTAINING

THE MACHINE

AT OPTIMAL PERFORMANCE

A T T E N T I O N

1. Do not unscrew “booster tank” nor the “safety

cap”, while the flame is on.

2. Do not leave the machine on for more than 30

minutes, while the flame is “off”.

3. RE-Fill WATER IN THE INTERNAL TANK by

DEPRESSURIZING THE Booster Tank (first)

Whenever water or electrolyte solution needs

to be added to the (internal tank)

it is IMPORTANT to (Depressurize) the booster

tank (first) by simply unscrewing

the handle-knob (see photo in Step # 8). This

will keep the flux (deoxidizer) from

contaminating the electrolyte solution. Then,

unscrew safety cap and add water or

electrolyte solution until the Red lamp comes

“on “, indicating its full. Then afterwards re-

tighten the safety cap and the booster handle

knob. Taking care not to over tighten, nor over-

screw, nor de-thread the internal chamber.

This will become a daily, on-going standard

operation, as water will probably be constantly

added to the

(internal tank), before starting the working

day.

4. Do not turn the machine “off” while the flame

is lit. Always, turn off the flame from the

torch, before shutting down machine, always

do this as a pre-cautionary procedure.

5. Shut off the flame before refilling any liquid

Flux (deoxidizer) or demineralized water

With the tanks full, the machine will operate

approximately 6-8 hours.

6. If only the booster tank needs refilling, DO NOT

OPEN THE SAFETY CAP on top of the machine.

Just remove the booster tank and fill

accordingly to the max level position using a

finger in the center to avoid spilling fluid in the

improper location. Reattach the booster tank

when done filling.

TWO OUTLETS SYSTEM ONE OUTLET SYSTEM

15

7. If both tanks need re-filling, first depressurize

the booster tank by removing it, then remove

the Safety Cap on top of the machine. Then

pour water in the Internal Tank until the Red

light comes on (indicting its filled). Re-insert

safety-cap back on top, then add the flux

(deoxidizer) to the booster tank and tighten.

8. Whenever the machine has been refilled, it

must be pressurized. Do not refill and let sit

over night without turning on to pressurize.

9. When pushing the (3-point switch) to the

down position, (fill-refill “= “), you will be able

to check the level of the demineralized water,

located in the internal tank.

a. If the Red light is off, then water is needed

in the internal tank, fill until the red light

comes, “on”.

b. If the yellow light indicator is “on”, then it’s

below the acceptable usage level and

water must be added.

c. If both the (Red & Yellow) lights are off,

then the water level is somewhere in

the middle of the tank.

10. If you use the machine once or twice a week,

every 15-20 days, turn –ON the welder

at least 3 minutes at max power without

lighting the flame, to avoid that the check

valve does not become blocked. After that,

turn, OFF the machine.

and DO NOT DEPRESSURIZE THE

INTERNAL TANK BY UNSCREWING THE

SAFETY CAP.

11. If two torches are selected, and during

operation, one of the two operators desires

to leave, shut off both torches; then

disconnect the hoses and then reconnect

one single torch. In this case the power

control knob must be readjusted for one

torch power.

If on the other hand, one of the two

operators chooses to stop using the torch

and turns the flame off, this can only be

done for 15-20 minutes since the gas will

be omitted into the environment. If the

period exceeds twenty minutes, just use

the default line nearest the machine with

one torch only.

7. If both tanks need re-filling first, depressurize the

booster tank by removing it, then remove the

Safety Cap on top of the machine.

Then pour water in the Internal Tank until the

Red light comes on (indicting its filled).

Re-insert safety-cap back on top, then add the

flux (deoxidizer) to the booster tank and tighten.

8. Whenever the machine has been refilled, it

must be pressurized. Do not refill and let sit

over night without turning on to pressurize.

9. When pushing the (3 point switch) to the down

position, (fill-refill “=”), you will be able to

check the level of the demineralized water,

located in the internal tank.

a. If the Red light is off, then water is needed in

the internal tank, fill until the

red light comes, “on”.

b. If the yellow light indicator is “on”, then it’s

below the acceptable usage level and water

must be added.

c. If both the (Red & Yellow) lights are off, then

the water level is somewhere in the middle

of the tank.

10. If you use the machine once or twice a week,

every 15-20 days, turn –ON the welder at least

3 minutes at max power without lighting the

flame, to avoid that the check valve does not

become blocked. After that, turn, OFF the

machine.

and DO NOT DEPRESSURIZE THE INTERNAL

TANK BY UNSCREWING THE SAFETY CAP.

11. If one (1) torch is selected for use, follow the

instructions at the beginning of the quick start

guide, (step 9). Essentially the L/160 will then

have one torch, and the operator will use the

machine accordingly.

TWO OUTLETS SYSTEM ONE OUTLET SYSTEM

16

12. Do not light the flame until the gas flows

out from the burner tip and at same time

the power control knob (MUST) be in the

correct position according to the Table 2

settings, before lighting the flame/s.

13. Clean the orifice (Fig. 1 # 11) with a thin

steal wire or other similar safe object, in

order to avoid causing personal harm or

damage to the burner tip. You can also

clean the burner tip in lukewarm water for

approximately twenty minutes.

12. If two torches are selected, and during

operation, one operator desires to shut off one

torch; then turn off the flame and then close

the valve. If, on the other hand, the operator

chooses to stop using the torch (nearest to the

machine) and turns the flame off, this can only

be done for 15-20 minutes since the gas will be

omitted into the environment.

14. Do not light the flame until the gas flows out

from the burner tip and at same time the

power control knob MUST be in the correct

position according to the settings in Table 2,

before lighting the flame/s.

15. Clean the orifice of the burner tip (fig.1 # 11)

with a thin steel wire daily before starting the

machine.

17

APPENDIX 1

INFORMATION ON CHEMICALS USED IN OUR HYDROGEN GENERATORS.

•ELECTROLYTE SOLUTION (LIQUID):

GO TO STEP 2 IN THE QUICK START GUIDE.

Electrolytic solution ready for use

COUNTRY

WELDER MODEL

QUANTITY OF ELECTROLYTE (LIQUID)

EU

L/160

EU LT 3

USA

L/160

US gal 0.792

UK

L/160

UK gal 0.659

•ELECTROLYTE SOLUTION IN DRY BAG:

GO TO STEP 2 IN THE QUICK START GUIDE.

How to prepare the electrolytic solution with dry bag.

COUNTRY

WELDER MODEL

QUANTITY OF

DEMINERALIZED

WATER

QUANTITY OF POTASSIUM

HYDROXIDE (KOH in FLAKES or

POWDER with 90% of PURITY)

EU

L/160

LT 2,6

grams 1080

USA

L/160

US gal 0.687

ounces 38.09

UK

L/160

UK gal 0.572

ounces 38.09

•FLUX (DEOXIDIZER) COMPOSITION:

GO TO SECTION 4.5 IN THE USER MANUAL.

The deoxidizer is a liquid with particular compounds(methyl alcohol + boric acid) in order to obtain

a clean flow solder. Useful for avoiding oxidation and porosity during the soldering / brazing

process.

The following table illustrate proportions and quantities to take in consideration in order to obtain

the correct deoxidizer and enable the machine function properly without obstructions.

FLUX (DEOXIDIZER) STANDARD COMPOSITION

(EU UNIT OF MEASURE)

1 Lt of Methyl Alcohol + (15 to 20) grams of Boric

Acid

FLUX (DEOXIDIZER) STANDARD COMPOSITION

(USA UNIT OF MEASURE)

US gal 0.264 of Methyl Alcohol + (0.529 to 0.705)

ounces of Boric Acid

FLUX (DEOXIDIZER) STANDARD COMPOSITION

(UK UNIT OF MEASURE)

UK gal 0.219 of Methyl Alcohol + (0.529 to 0.705)

ounces of Boric Acid

18

DANGER

! ATTENTION!

DO NOT TURN/UNSCREW THE

SAFETY CAP AND/OR THE HANDLE

WHILE THE FLAME/FLAMES ARE LIT

NEVER LEAVE THE MACHINE ON

WITH THE TORCH OFF.

AVOID DISPERDING GAS INTO THE ENVIROMENT.

DO NOT TURN THE MACHINE OFF

WHEN THE FLAMES ARE LIT.

19

DO NOT PLACE THE FLAME NEAR THE MACHINE,

IN PARTICULAR, ON THE BOOSTER TANK,

SAFETY CAP, THE FILLING NECK,

THE BOOSTER HANDLE KNOB

OR THE GAS HOSES.

DO NOT CUT THE GAS HOSES WHILE FLAMES ARE LIT.

NEVER LIGHT THE FLAME IF

BOOSTER TANK IS EMPTY.

NEVER LIGHT THE FLAME WHEN

THERE ARE NO BURNER TIPS OR

NOZZLES MOUNTED

ON THE TORCH.

20

ATTENTION: the flame reaches a very high temperature of (3200°C / 6100°F).

DO NOT COME IN CONTACT WITHIN THE VICINITY OF THE FLAME,

(WITH A MINIMUM OF 50 CM / 20 INCHES). THE FLAME IS VERY

DANGEROUS, AND MAY CAUSE, SEVERE ENJURIES IF THE OPERATOR

DOES NOT FOLLOW THESE RULES.

KEEP THE MACHINE AND ITS ATTACHED AND UNATTACHED

ACCESSORIES AWAY FROM CHILDREN.

Do not allow gas to enter the environment for more than 15-20

minutes.

Alternatively, it is best to turn off the machine completely.

ATTENTION!

ONCE A YEAR

For optimal performance of equipment, a yearly maintenance is

required, with instruction located in sec. 5.3 of the technical

user manual.

Table of contents

Other ET Hydrogen Welding System manuals