ET Solar ET SOLAR Series User manual

INSTALLATION

MANUAL (IEC)

ET SOLAR SERIES MODULE

Installation | Safety instructions | Maintenance

INFORMATION ABOUT MANUFACTURER:

ET SOLAR CHINA

Please consult your dealer or the manufacturer concerning the warrantyof

your modules. If you have any further questions, your dealer andET Solar will

gladly assist you.

Tel: 86 25 86897287

E-mail: [email protected]

www.etsolar.com

Building 3 No.1, Yaojia Road Jiulong Town,

Hailing District, Taizhou, China

This guide contains information regarding the installation and safe handling of ET

Solar photovoltaic modules (hereafter referred to as "modules"). All instructions should

be read and understood before attempting installation. If there are any questions,

please contact your dealer or ET Solar for further information. The installer should

conform to all safety precautions in the guide when installing modules. Before

installing a solar photovoltaic system, the installer should become familiar with the

mechanical and electrical requirements for photovoltaic systems. Keep this guide in

a safe place for future reference. If not otherwise specified, it is recommended that

the requirements of the U.S. National Electrical Code (NEC) or respective European

Code be followed.

Non-compliance with this installation instruction may result in property damage

and/or physical injury. ET Solar will not be liable for compensation of any loss or injury

caused by this type of non-compliance.

www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group 1

1

2

2.1

2.2

3

3.1

3.2

4

4.1

4.2

4.3

5

5.1

5.2

5.3

5.4

6

7

8

TABLE OF CONTENTS 1. PURPOSE OF THIS GUIDE

Installing solar photovoltaic systems requires specialized skills and knowledge. The

installer assumes all risk of injury, including risk of electric shock. Module installation

should be performed only by qualified persons.

All modules come with a permanently attached junction box and #12 AWG (4 mm²)

wire terminated in Multi Contact PV connectors. Your dealer can provide additional

extension cables to simplify module wiring.

Each individual module can generate DC voltages greater than 30 volts (V) when

exposed to direct sunlight. Contact with a DC voltage of 30 V or more is potentially

hazardous. Exercise caution when wiring or handling modules exposed to sunlight.

When disconnecting wires connected to a photovoltaic module that is exposed to

sunlight, an electric arc may occur. Arcs can cause burns, start fires or otherwise

create safety problems. Exercise caution when disconnecting wiring on modules

exposed to sunlight.

2. GENERAL

www.etsolar.com

Purpose of this guide

General

Safety precautions for installing a solar photovoltaic system

General installation notes

Mechanical Installation

Selecting the location

Selecting the proper mounting structure and hardware

Mounting methods

Mounting with bolts

Mounting with clamping hardware

Anti-salt module mounting procedure

Electrical Installation

Grounding

Wire

General electrical installation

Electrical ratings of the concerned modules

Testing, debugging and troubleshooting

Maintenance

Disclaimer of liability

1

1

2

3

4

4

4

4

5

5

6

9

9

10

11

12

12

13

14

www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group

2 3

Photovoltaic solar modules convert light energy to direct-current electrical

energy, and are designed for outdoor use. Proper design of support structures is

the responsibility of the system designer and installer.

Modules may be ground mounted, pole mounted, or mounted on rooftops.

Do not apply paint or adhesive to the module.

When installing modules, observe all applicable local, regional and national

codes and regulations. Obtain a building and/or electrical permit where required.

Storage Temperature: -10 C ~40 C, Storage Humidity: ≤70%RH;

Modules should operate at environmental temperature of between -40 to +85℃. If

modules are to be installed in areas where the temperature may go outside the

above range, please consult with ET Solar before installation.

Observe the instructions and safety precautions for all other components used in

the system, including wiring and cables, connectors, DC-breakers, mounting

hardware, inverters, etc.

Use only equipment, connectors, wiring and mounting hardware suitable for use in

a photovoltaic system.

Always use the same type of module within a particular photovoltaic system.

Under normal operating conditions, PV modules will produce currents and

voltages that are different from those listed in the date sheets. The values in the

module data sheets are collected under very specific circumstances known as

Standard Test Conditions.

Short-circuit current and open-circuit voltages should be multiplied by a factor of

1.25 when determining component voltage ratings, conductor ampacity, fuse

sizes and size of controls connected to the module or system output. An

additional multiplying factor of 125 percent (80 percent de-rating) may be

applicable.

Drainage holes must not be covered with parts of the mounting system. The

junction box has a breather port which must be mounted facing downward and

cannot be exposed to the rain. The junction box should be on the higher side of

the module when it is mounted in order to orient the breather port correctly.

Do not lift the module by grasping the module's junction box or electrical leads.

Do not stand or step on module.

Do not drop the module or allow objects to fall on the module.

Do not place any heavy objects on the module.

Do not scratch the anodized coating of the frame (except for grounding

connection).

Do not scratch the glass surface.

Prior to installation, do not store modules outdoors or in a damp environment.

Inappropriate transport and installation may damage the module glass or frame.

Solar modules produce electrical energy when exposed to sunlight. DC voltages

may exceed 30V on a single exposed module.

Only connect modules with the same rated output current in series. If modules are

connected in series, the total voltage is equal to the sum of the individual module

voltages.

Only connect modules or series combinations of modules with the same voltage in

parallel. If modules are connected in parallel, the total current is equal to the sum

of individual module or series combination currents.

Bypass diodes are preassembled in each module. Do not remove these diodes.

Keep children well away from the system while transporting and installing

mechanical and electrical components.

Completely cover all modules with an opaque material during installation to

prevent electricity from being generated.

Do not attempt to disassemble the module, and do not remove any attached

nameplates or components. Doing so will void the warranty.

Do not use mirrors or other hardware to artificially concentrate sunlight on the module.

Use appropriate safety equipment (insulated tools, insulating gloves, etc)

approved for use on electrical installations.

2.1 Safety precautions for installing a solar photovoltaic system

Do not wear metallic rings, watchbands, ear, nose, or lip rings or other metallic

devices while installing or troubleshooting photovoltaic systems.

www.etsolar.com

2.2 General installation notes

www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group

4 5

Select a suitable location for installation of the module.

For optimum performance, the module must be facing true south in northern

latitudes and true north in southern latitudes.

For detailed information on optimal module orientation, refer to standard solar

photovoltaic installation guides or a reputable solar installer or systems integrator.

Shading on the module will reduce electricity production.

Do not install the module near equipment or in locations where flammable gases

can be generated or collected.

Observe all instructions and safety precautions included with the mounting system

to be used with the module.

Do not drill holes in the glass surface of the module. Doing so will void the

warranty.

Do not drill additional mounting holes in the module frame. Doing so will void the

warranty.

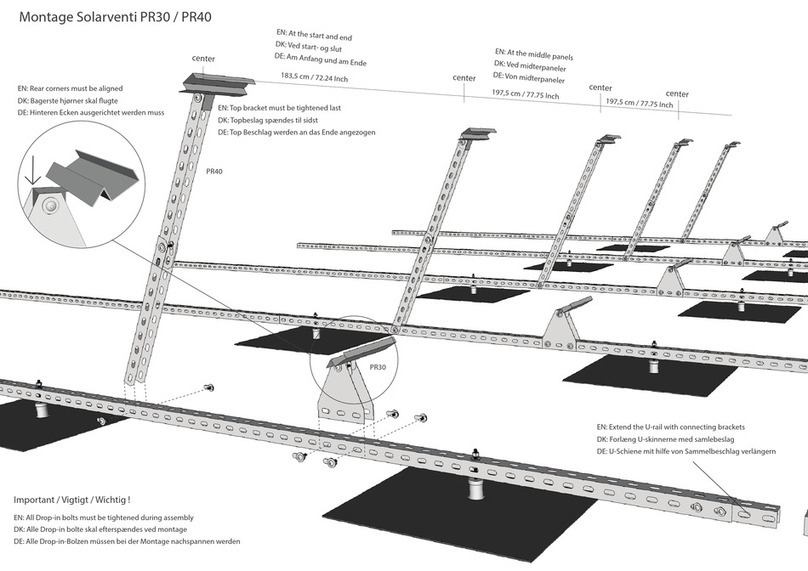

Modules must be securely attached to the mounting structure using four mounting

points for normal installation. If heavy wind or snow loads are anticipated,

additional mounting points should also be used. Please see the drawing below.

Load calculations are the responsibility of the system designer or installer.

The mounting structure and hardware must be made of durable, anti-corrosion

and UV-resistant material.

4.1 Mounting with bolts

A minimum of four module clamps should be used, two on each long/short frame

side, in the general clamping areas denoted by the wide arrows on the drawing.

Other mounting methods are acceptable as long as the minimum requirements

as described under term 4.2 mounting with clamping hardware are met.

If module clamps are used to secure the module, The torque should refer to

mechanical design standard, we recommend the following torque for bolt:

M6------9 N.m

M8------16~20 N.m

3. MECHANICAL INSTALLATION

4. MOUNTING METHODS

www.etsolar.com

3.1 Selecting the location

3.2 Selecting the proper mounting structure and hardware

4.2 Mounting with clamping hardware

The module must be attached and supported by at least four bolts through the

indicated mounting holes.

Most installations will use the four inner mounting holes on the module frame.

Depending on the local wind and snow loads, additional mounting points may be

required.

Four or Eight pre-drilled mounting holes, located on the aluminum alloy frame, are

provided for ease of installation. They are designed to be used with metric M8

stainless steel screws. We recommend to use a tighten torque of 16~20 N.m

Mounting hole installation

Use four mounting holes

snow load 2400Pa/wind load 2400Pa

Use four mounting holes

snow load 5400Pa/wind load 2400Pa

www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group

6 7

4.3 Anti-salt module mounting procedure

For photovoltaic systems to be installed near the coastline, we recommend using ET

SOLAR Anti-salt modules with the following installation action items.

www.etsolar.com

Mainstream Grounding Methods:

Grounding System Installation Steps:

Recommended mounting methods

Grounding bolt

Grounding wire

Fluorocarbon paint

Fluorocarbon paint

Grounding wire ring

Grounding wire

Option 2

Before the installation of each module, clean the frame installation area (35mm by

100mm surrounding the grounding hole) and keep it dry.

Choose either one of the two options described in the diagrams above to properly

ground the module.

Spray varnish on the yellow portion of the diagram covering the entire grounding

area. We recommend fluorocarbon varnish.

For mounting system with bolts, refer to picture 1 and 2.

Hexagonal screw

Plain washer

Elastic washer

Insulation gasket

Picture1 Picture 2

1)

2)

3)

Clamping installation

Use four clamps on short frame

snow load 5400Pa/wind load 2400Pa

Permissble position of clamps

Use four clamps on long frame

snow load 2400Pa/wind load 2400Pa

Permissble position of clamps

1/4 L ±50mm 1/4 L ±50mm

1/4 L ±50mm 1/4 L ±50mm

Use four clamps on long frame

snow load 5400Pa/wind load 2400Pa

Permissble position of clamps

1/4 of module lenth 1/4 of module lenth

1/4 of module lenth 1/4 of module lenth

5. ELECTRICAL INSTALLATION

www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group

8 9

For mounting system with clamps, refer to picture 3 and 4.

To ensure optimum modules performance at project sites near the coastline, we

recommend the following maintenance services once every 3 months:

Inspect the frames, mounting systems, grounding holes and other easily corrodible

areas.

Clean the frames, mounting systems, grounding holes and other areas subject to dust

and salt accumulations.

To maintain and repair installation sites that are rusty and corroded:

Clean up the dust and salt accumulations around the rusty areas.

Spray fluorocarbon varnish on all installations and rusty areas. Make sure that no area

is missed.

For other operation and maintenance guidance, please refer to near-coast

installation standard.

www.etsolar.com

Maintenance

Attentions

5.1 Grounding

Aside from components that are parts of the grounding circuit, all other components

should be insulated from the module frames using non-conductive gaskets.

For fluorocarbon varnish or other chemicals, please follow the instructions strictly,

personal protective equipment (such as goggle, mask, gloves etc) may be needed

during the operation.

No photovoltaic module should be installed within 50 meters from the edge of the

coastline.

In areas between 50 meters and 500 meters from the edge of the nearest coastline,

we recommend ET SOLAR Anti-salt Modules to be used in photovoltaic energy systems

installations.

In areas greater than 500 meters from the edge of the nearest coastline, we

recommend conventional modules to be used in photovoltaic energy systems

installations.

Picture

3 Picture 4

Briquetting

Nut

Plain washer

Bolt

Insulation gasket

All module frames must be properly grounded.

Observe all local electric codes and regulations.

A bonding or toothed washer is required to make proper and reliable electrical

grounding connection with the anodized aluminum frame.

Devices listed and identified for grounding metallic frames of PV modules are

permitted to ground the exposed metallic frames of the module to grounded

mounting structures.

Consider using a lay-in lug, rated for outdoor use, if the module grounding conductor

is to be larger than #10 AWG.

When using lay-in lugs, the grounding conductor should be inserted into the opening

indicated in the figure, and secured using the set screw.

1)

2)

1)

2)

3)

www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group

10 11

www.etsolar.com

5.2 Wire

5.3 General electrical installation

When connecting parallel modules strings to the distribution box, use proper

third-party PV system connectors with suitable length PVF type cable which are

qualified for EN50521 and 2PFG1169. All field wiring cables must have large enough

cross-sectional areas approved for use at the maximum short-circuit current of the PV

module. ET Solar recommends that installers use only sunlight resistant cables (PVF1

type) for direct current (DC) wiring in PV systems. The recommended minimum wire

size should be 4 mm² and must be subject to the local national codes and regulations.

The connecting cables must not cross each other and must be kept away from direct

sunlight, heat source and any static pool of water. The cables should be secured by

the modules mounting structure and should maintain a distance of at least 25 mm

from one another with no possibility of coming into contact.

The connectors should be kept dry and clean. Do not attempt to make electrical

connections between wet, soiled, or otherwise faulty connectors. Faulty connections

can result in electrical shocks and arcs.

Expect for equipment grounding, ET Solar recommends the negative pole of PV

module array is connected to earth during all PV system installations. That will keep

optimal performance of PV Power Plants, which are located in a hot, high humidity

climate and high Maximum System Voltage.

The junction box on each PV module has two wires that terminate in a male and a

female connector. When the modules are to be connected in series, the male

connector should be plugged into the female connector of the neighboring module

while the female connector should be plugged into the male connector of the other

neighboring module.

Do not use modules of different configurations in the same system.

This module is supplied with Multi Contact connectors for electrical connections.

Refer to local code to determine appropriate types and temperature ratings of

conductors. Wiring should be #12 AWG, 4 mm² (minimum) and must be temperature

rated at 90 °C (minimum).

Completely cover system modules with an opaque material to prevent electricity from

being generated while disconnecting conductors.

Refer to local code to determine over current, conductor ampacity and size

requirements.

Installation shall be in accordance with local code.

PV module grounding with lay in lug (φ4mm grounding holes)

6. TESTING, DEBUGGING AND TROUBLESHOOTING

7. MAINTENANCE

www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group

12 13

www.etsolar.com

5.4 Electrical ratings of the concerned modules

Troubleshooting for low voltage

For best performance, ensure that positive and negative DC wires run closely together

to avoid loops.

Blocking diode can be used in PV system to prevent reverse current from the battery if

there is no photovoltaic current in the module. If charge controllers are not used, then

it is recommended to use blocking diodes. For more details on charge controllers,

please consult with professionals.

In cases where two or more modules are connected serially in a system, if part of the

modules are occluded and the other part are exposed to the sun, the high reverse

current will flow partially or completely through the module, causing the modules to

overheat and even damaging the modules. Bypass diode used in modules can

protect modules from such impact of excessive reverse current..The bypass diodes

have been integrated in the junction box.

Operators should protect themselves from electrical shock during debugging or

maintenance of solar systems.

There are two causes of low open circuit voltage, environmental change or circuit

fault. The drop of irradiance or increase of environmental temperature reduces the

open circuit voltage, which is normal. The troubleshooting here refers to the low

voltage caused by circuit faults, which is usually due to incorrect connection of

terminals or damage of bypass diodes.

First, check all wiring connections, and ensure they are well-connected into the PV

system. Then check the modules one by one as below:

Measure the open circuit voltage of a module.

Cover the module completely with opaque material.

Disconnect the module from the system.

Remove the opaque material from the module, and measure its open circuit voltage.

If the measured voltage is one third or two thirds of the rated value, it indicates that

bypass diodes don’t work well, and should be replaced.

WARNING!

Electrical shock hazard!

Do not touch bare conductors or other potentially energized parts.

Please refer to ET module datasheets. Datasheets can be downloaded from website:

www.etsolar.com

Use digital multimeter to check the total open circuit voltage of the serially

connected modules. The results should be equal to the sum of the open circuit

voltage of individual modules, which can be found from the label on the modules. If

the total open circuit voltage is much lower than expected, please follow the

following procedure in this instruction.

Test procedure for modules serial connected before connect them to the PV system.

ET Solar recommends the following maintenance items to ensure optimal performance

of the module:

Clean the glass surface of the module as necessary. It is recommended to clean the

glass surface with pressured running water compliance with local drinking standards,

e.g. low mineral content, near neutral PH value. The maximum water pressure

recommended is 1 MPa and the water jet is at least 50cm away from the glass

surface. Do not use dishwasher detergent. Do not have water staying on the glass

surfaces of PV modules for a long time.

If a module power decreases abnormally, and its glass surface is found covered by

dust, please contact your module installer, retailer or ET solar immediately for technical

support.

Do not attempt to clean a module if the front glass is broken or the backsheet is

perforated.

Shutting down the system

8. DISCLAIMER OF LIABILITY

www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group www.etsolar.com Subject to technical modifications without notice. 2016 © ET Solar Group

14 15

www.etsolar.com

Electrical and mechanical connections should be checked periodically by qualified

personnel to verify that they are clean, secure and undamaged.

Check the electrical and mechanical connections periodically to verify that they are

clean, secure and undamaged.

Problems should only be investigated by qualified personnel.

Observe the maintenance instructions for all other components used in the system.

Completely cover system modules with an opaque material to prevent electricity from

being generated while disconnecting conductors.

Disconnect system from all power sources in accordance with instructions for all other

components used in the system.

The system should now be out of operation and can be dismantled. In doing so,

observe the all safety instructions as applicable to installation.

Because the use of this manual and the conditions or methods of installation, operation,

use and maintenance of photovoltaic products are beyond ET Solar's control, ET Solar

does not accept responsibility and expressly disclaims liability for loss, damage, or

expense arising from or in any way connected with improper installation, operation, use or

maintenance . Improper installation, operation, use or maintenance means that

installation, operation, use or maintenance does not strictly follow this manual and/or the

local, regional and national codes and regulations.

ET Solar shall not be any way responsible or liable for natural causes, including but not

limited to normal wear and tear of photovoltaic products, the natural effects of exposure

to weather conditions over time and the outdoor dust build-up.

ET Solar shall not be in any way responsible or liable for the end user Customer or any

third-party arising out of any non-performance or delay in performance of any terms

and conditions of sale, including this manual, due to fire, flood, blizzard, hurricane,

thunder, acts of God, changes of public policies, terrorism, war, riots, strikes,

unavailability of suitable and sufficient labor or materials and other events which are

out of control of ET Solar.

No responsibility is assumed by ET Solar for any infringement of patents or other rights

of third parties, which may result from use of the PV product. No license is granted by

implication or otherwise under any patent or patent rights.

The information in this manual is based on ET Solar's knowledge and experience and

is believed to be reliable, but such information including product specification

(without limitations) and suggestions does not constitute a warranty, expressed or

implied. ET Solar reserves the right to change the manual, the product, the

specifications, or product information sheets without prior notice.

This manual suits for next models

1

Table of contents

Other ET Solar Solar Panel manuals

Popular Solar Panel manuals by other brands

Viessmann

Viessmann VITOSOL 100-F Technical data manual

Hunter

Hunter Solar Panel Plus SP150 user manual

Viessmann

Viessmann Vitosol-F Type SV installation instructions

Wagan

Wagan 8212 user manual

Viessmann

Viessmann Vitosol-F Series installation instructions

Solar Technology International

Solar Technology International PV Logic Flexi user manual