ET Solar ETM53670 Guide

1

Installation and Assembly Instructions

for Solar Modules

1. Company Introduction

ET Solar Group is a vertically integrated solar energy equipment manufacturer and

turnkey solutions provider. With local sales and marketing subsidiaries and offices

throughout Asia, Europe, and North America, we provide high quality photovoltaic

modules, world leading solar tracking systems and smart turnkey solutions to our

customers in more than 50 countries and areas. Our products have been delivering strong

operating performance in a large number of residential and utility scaled solar PV

projects around the world.

2. Structure of module

ET modules are made by layering low-iron-tempered glass, an EVA sticky membrane,

high conversion-efficient solar cells and a behind-the-membrane multi-layer backsheet.

These elements are laminated into a plate by being heated in a vacuum. After installing

the aluminum alloy frame and wiring compartment, a module is born (see Fig. 1)

.

WARNING!

The photovoltaic module produces electricity when exposed to the sun or

other light sources. For your safety and the safety of others, please read

the entire Installation and Assembly Instruction manual carefully prior to

installation. Please carefully read the following installation and safety

instructions. Non-compliance with these instructions may void the module

warranty.

2

Fig.1: Front and back sides of ET-M572170 module

3. Installation of modules

3.1 Installation

When installing the modules, the face of the units should be placed where they are highly

exposed to the sun. It is recommended that the modules usually face the equator; thus, in

the Northern Hemisphere the surface should be oriented towards the south, and in the

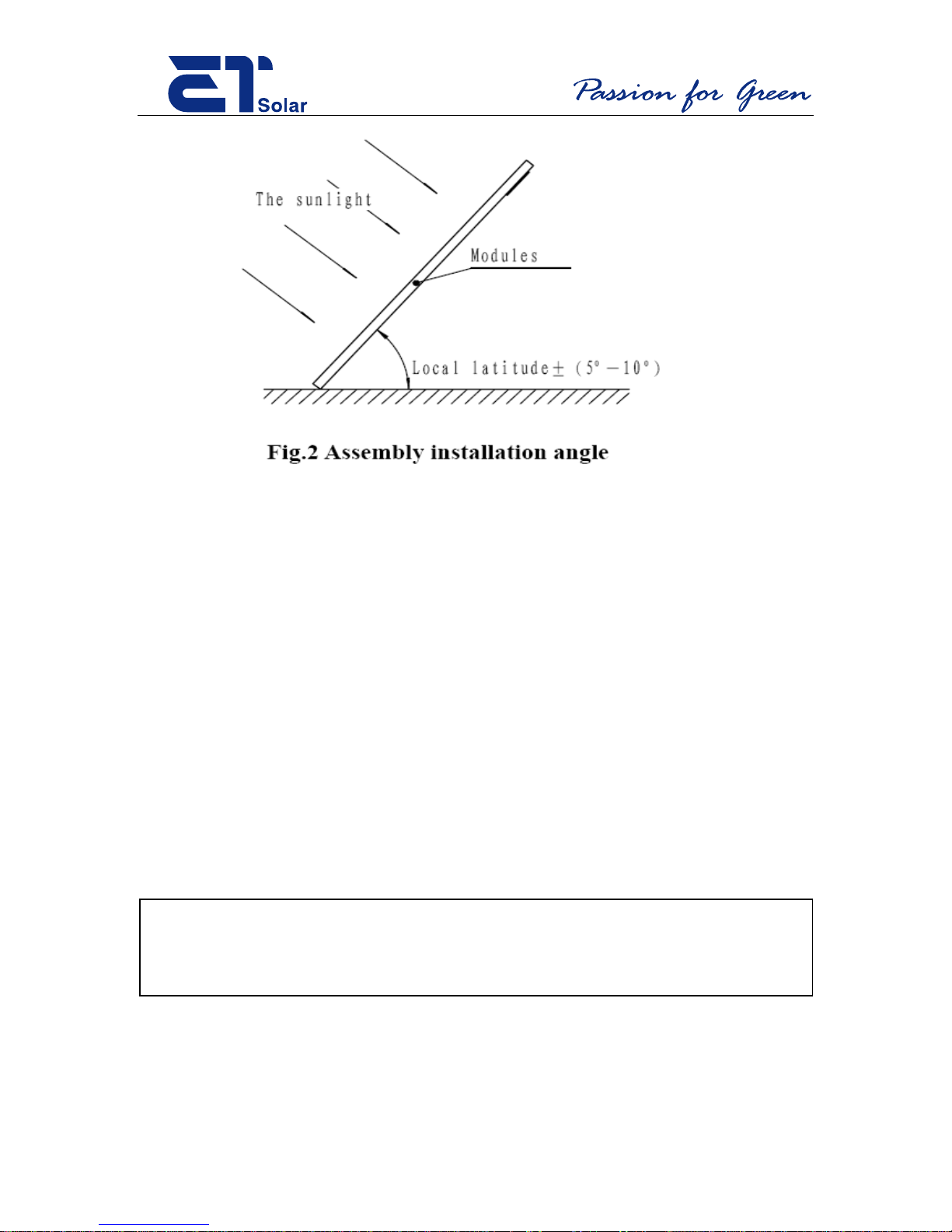

Southern Hemisphere, towards the north. Usually the angle between modules and the

ground should be local latitude ± (5°~10°) as show in Fig.2.

WARNING!

Do not attempt to clean a module with a broken glass cover or a

perforated backsheet. Such a module can present a serious shock

hazard.

3

The recommended standoff height is 5 in. (127mm), if other mounting means are

employed this may affect the UL Listing.

The specific angle depends on the sunlight condition, local climate and the actual

application requirements. The appropriate angle of evaluation has a very important

relationship to the output power of the modules and the cost of the construction. The

surface of the modules should avoid shadows and be kept clean from foreign materials

such as dirt.

The assembly is to be mounted over a fire resistant roof covering material when roof

mounting is intended for the modules, the fire resistance of roof covering or wall should

be rated for the application.

A torsion and corrosion-resistant anodized aluminum frame ensures dependable

performance, even under harsh weather conditions. Eight pre-drilled mounting holes,

WARNING!

The local shadowing of modules may cause serious hot-spots and

damage the modules.

4

located on the aluminum alloy frame, are provided for ease of installation. They are

designed to be used with metric M6×1(Torque 12 Lb-in) stainless steel screws.

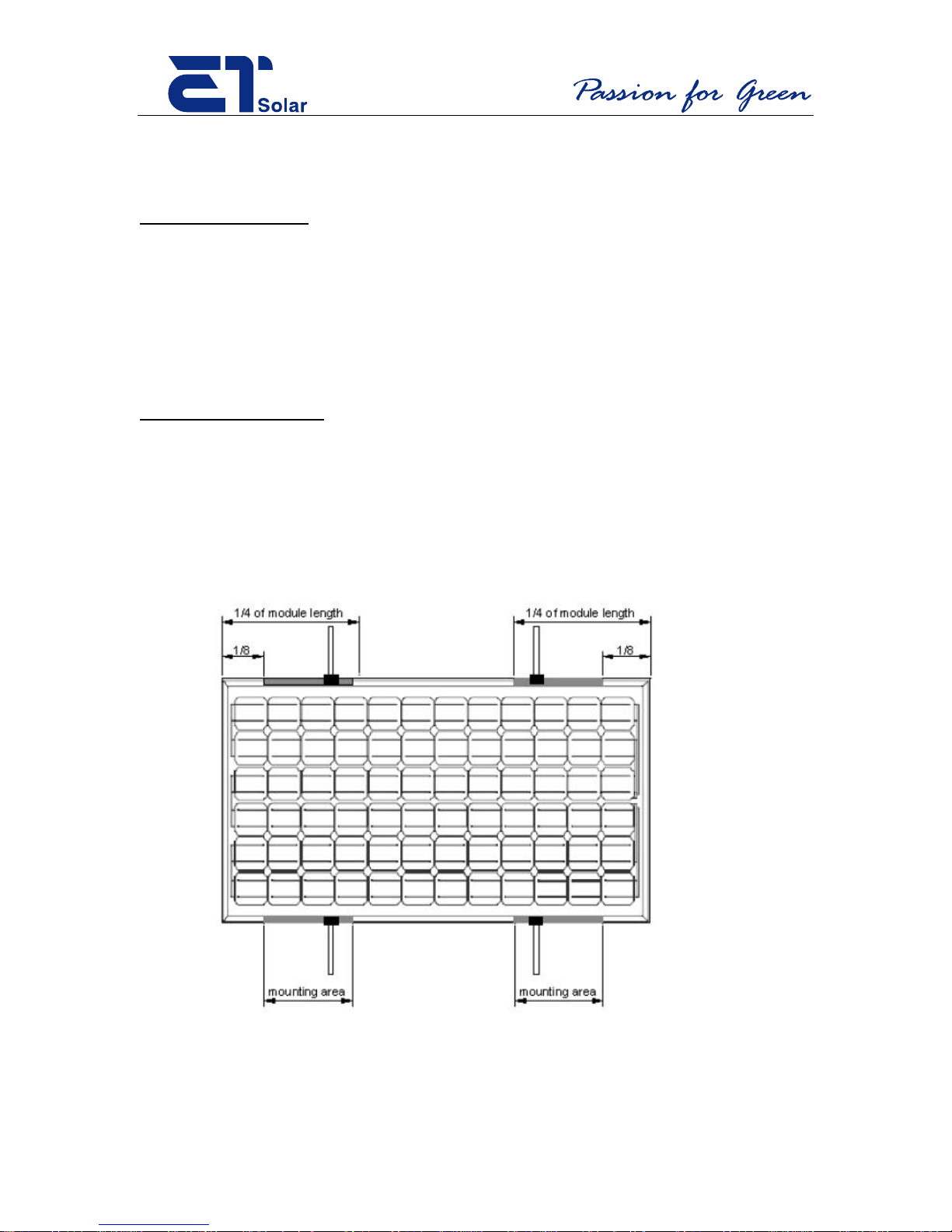

Mounting with Bolts

• The module must be attached and supported by at least four bolts through the

indicated mounting holes.

• Most installations will use the four inner mounting holes on the module frame.

• Depending on the local wind and snow loads, additional mounting points may be

required.

Mounting with Clamps

• If module clamps are used to secure the module, the torque on the clamp bolt

should be around 8–10 Nm.

• A minimum of four module clamps should be used, two on each long frame side,

in the general clamping areas denoted by the wide arrows on the drawing.

• Depending on the local wind and snow loads, additional module clamps may be

required.

5

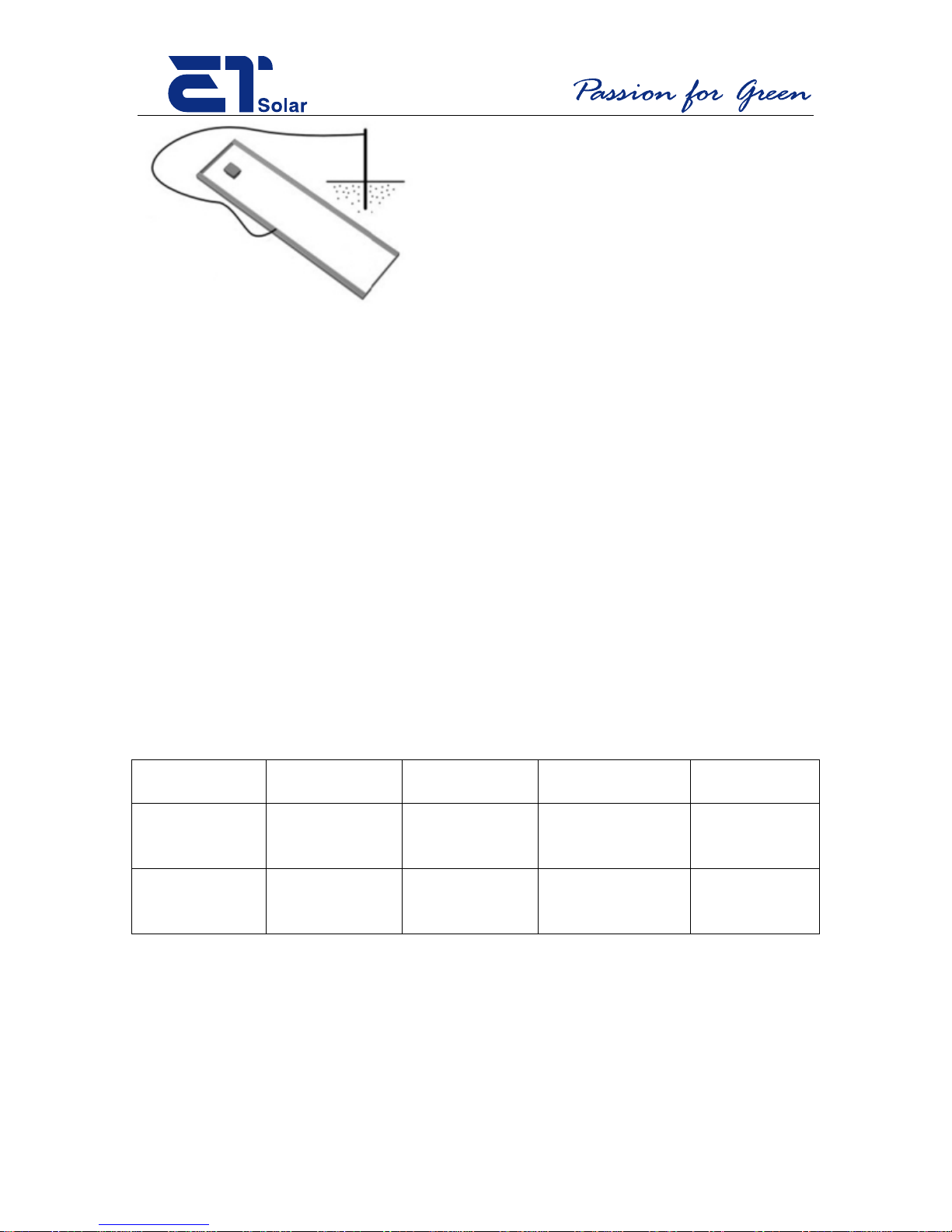

Grounding:All permanently mounted modules have to be provided with appropriate

grounding. The grounding lug should be suitable for outdoor use with aluminum. The

grounding method of the frame of arrays shall comply with the NEC, article 250 and also

meet UL 1703 standard. Lay-in-Lug ground part with 32 threads per inch (e.g., the lay-

in-lug with UL file number E34440, part # GBL-4DB), with size #10-32 ½ inch stainless

steel thread cutting screw, and using a 20 lb*inch torque, should be mounted to one of the

4 mm diameter grounding holes marked as grounding hole on the frame. When the

module system is used, it should be connected to the ground reliably. The ground wire

should be a naked copper wire with surface coating only and with no insulation jacket.

The area of cross-section of wire should be sized in accordance with the prime current

carrying conductor. The area of cross-section of wire should meet the NEC, article 250.

Installation in Canada shall be in accordance with CSA C22.1, Safety Standard for

Electrical Installations, Canadian Electrical Code, Part 1 ( refer Figure 3)

Fig 3. PV module grounding with lay in lug (φ4mm grounding holes)

WARNING!

The Fire Rating of this module series is Class “C”.

6

Fig 4. Module to grounding rod

3.2 Junction box

The junction box should be fixed on the top end of the module during assembly so as to

prevent the seepage of rain.

ET Solar provides a wiring type box. When the integrated J-box is adopted, no tool is

necessary for wiring. Just connect the modules in series according to “+” or “-”. You

can complete complex series and parallel connection easily and quickly using different

electric connectors provided by your supplier.

Connectors provided by different suppliers will not mutually match up. Different

connectors provided by one supplier will not match up either. Only one type of the same

connector from one supplier should be used to ensure the reliability of the electrical

connection.

Module

Male connector

Female

connector

Manufacturer

Notes

ETP672series

ETP654 series

ETP660 series

1394461-2

1394462-4

Tyco Electronics

Amp GMBH

12AWG wire

ETM572 series

ETM53680

Series

PV-KBT3

PV-KST3

Multi-Contact

USA

12AWG wire

There are other options in addition to using a wiring type junction box only consisting of

two terminals marked with "+" and "-" to represent the positive and negative terminals of

the power supply. Some junction boxes include three or more terminals. Only those

terminals indicated with "+" and "-" should be connected to the load. The others are

designed for the bypass diodes to reduce the damage to modules caused by hot spots and

7

to ensure undisrupted electrical energy output from the array. The hex nut in the exit

position on the junction box is used to hold a rubber ring to seal the box.

When disconnecting the connectors of a photovoltaic module in a module array that is

exposed to sunlight, electric arcs may result. Such arcs may cause burns and fires.

Therefore, PV system commissioning and maintenance must be performed by a qualified

electrician in accordance with the NEC. Before disconnecting a module in a solar array,

disconnect the string of module from the DC Disconnect at the inverter side, and then

fully cover the module with an opaque material. Do not short the positive and the

negative connectors of a module exposed to sunlight.

The specification of wire for the electric coupler that ET Solar provided is 1 x 4.0mm2.

Equivalent wire should be used if the user prefers to use his own wire. When the

module’s rated current is lower, 12AWG wire is recommended for use, and the strength

of the wire should be taken into consideration. ET Solar does not provide any output

wiring for module installation.

ET Solar modules are designed to use copper wire only. The working temperature of wire

and J-box is –40℃- 90℃. The wiring box interior is not intended for field access, and no

serviceable parts are inside.

The installation in Canada shall be in accordance with CSA C22.1, Safety standard for

electrical installations, Canadian Electrical Code, Part 1.

3.3 Output Voltage, Current and Maximum Power

The open-circuit voltage (Voc), short-circuit current (Isc) and maximal power (Pmax) are

printed on the PET label on the backside of the module. The electrical characteristics are

within ±10 percent of the indicated values of Isc, Voc and Pmax under standard test

WARNING!

Wiring must only be completed by a qualified engineer with

suitable tools.

8

conditions (irradiance of 100 mW/cm2, AM1.5 spectrum, and a cell temperature of 25oC

(77oF)).

Under normal conditions, a photovoltaic module is likely to experience conditions that

produce more current and/or voltage than reported at standard test conditions.

Accordingly, the values of Isc and Voc marked on this module should be multiplied by a

factor of 1.25 when determining component voltage ratings, conductor capacities, fuse

sizes, and size of controls connected to the PV output. If modules are to be installed in

parallel (electrically), each module (or series string of modules so connected) shall be

provided with the maximum series fuse as specified.

The modules will generate electrical energy under sunlight and other light sources.

Refer to Section 690-8 of the National Electrical Code for an additional multiplying

factor of 125 percent (80 percent derating) which may be applicable.

4. Characteristics of Modules

The array consists of modules in series and parallel and has a similar electrical curve to

that of a single module. In order to output maximum electrical power to the load, try to

make the impedance of the load match the electric performance of the module or array. In

order to maintain the stability of the system, also pay attention to the changes in the

WARNING!

In order to avoid electric shock and scalding, it is necessary to

cover the surface of the module with a suitable material to prevent

incidental light contacting the modules during the connection

process.

WARNING!

The product is designed as a plain plate type that should not

be irradiated directly under concentrated light.

9

electric curve of modules, especially under weak light. In more complex control circuits,

the controller supplier may have already adopted microprocessors for the tracking of

maximum power output. For the best impedance matching and the best tracking of

maximum power output, please refer to other relevant documents regarding these issues.

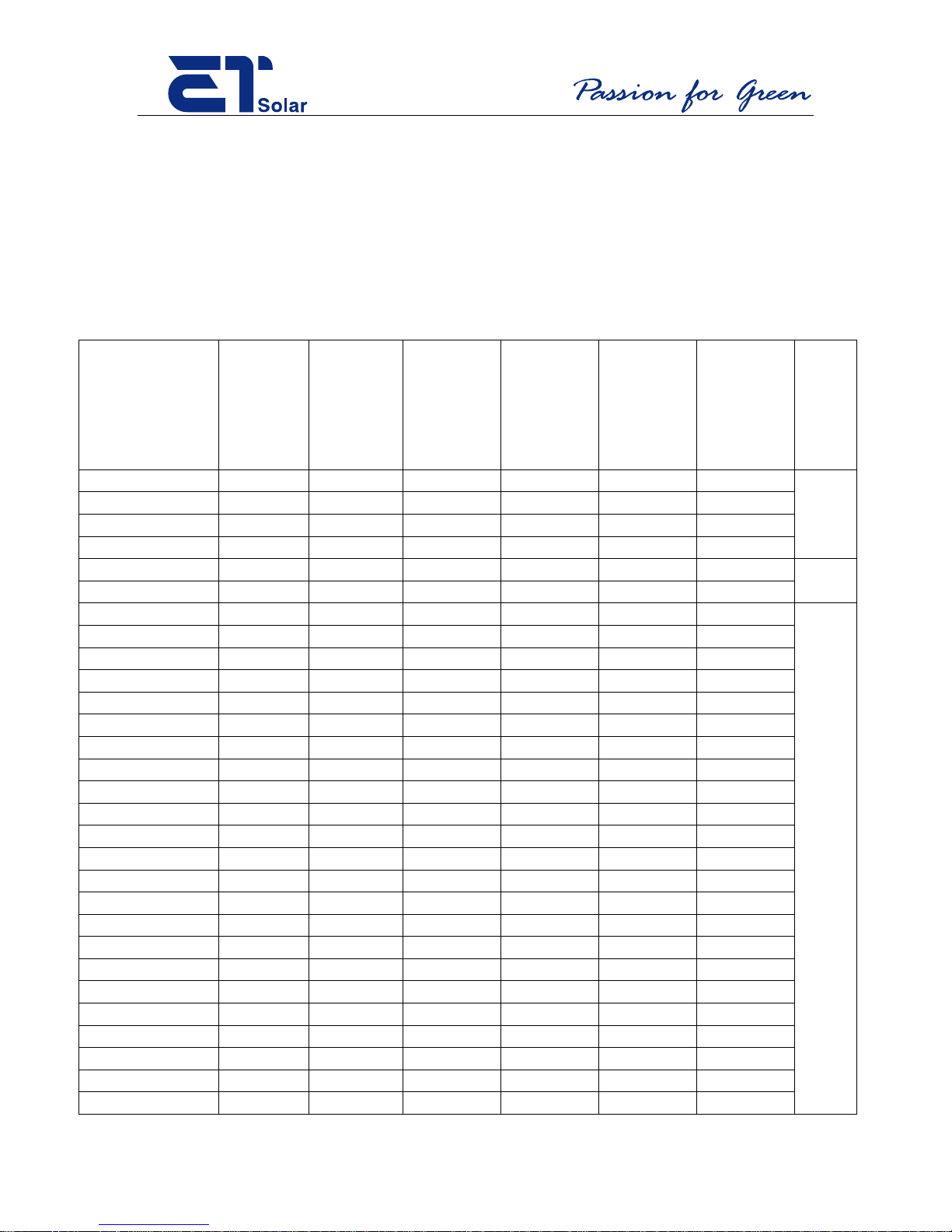

Electrical ratings of ET Solar modules are as follows. The detailed specs should refer to

module datasheet.

Model

Open

circuit

voltage

at

STC(Vd

c)

Rated

Voltage

at

STC(Vdc

)

Maximu

m system

voltage(V

dc)

Rated

current at

STC(A

dc)

Short

circuit

current at

STC(Adc)

Rated

maximum

power at

STC(watt

s)

Maxi

mum

series

fuse(

A)

ETM53670

21.45

16.9

600

4.14

4.45

70

7

ETM53675

21.73

17.4

600

4.31

4.72

75

ETM53680

21.88

17.64

600

4.54

4.98

80

ETM53685

21.94

18.05

600

4.71

5.29

85

ETM572155

43.30

35.20

600

4.40

4.98

155

12

ETM572160

43.90

35.26

600

4.49

5.07

160

ETM572165

44.12

35.68

600

4.60

5.19

165

15

ETM572170

44.16

36.13

600

4.71

5.3

170

ETM572175

44.25

36.24

600

4.83

5.50

175

ETM572180

44.60

36.30

600

4.95

5.61

180

ETM572185

44.60

36.30

600

5.09

5.80

185

ET-P654180

32.35

26.45

600

6.81

7.6

180

ET-P654185

32.3

26.45

600

6.99

7.7

185

ET-P654190

32.5

26.78

600

7.1

7.72

190

ET-P654195

32.75

27

600

7.22

7.98

195

ET-P654200

33.2

25.8

600

7.75

8.26

200

ET-P654205

32.8

27.3

600

7.5

8.1

205

ET-P654210

32.83

27.54

600

7.63

8.3

210

ET-P654215

33.2

27.54

600

7.81

8.5

215

ET-P654220

33.2

27.54

600

7.81

8.5

215

ET-P672230

43.56

34.2

600

6.75

7.32

230

ET-P672235

43.56

34.2

600

6.87

7.45

235

ET-P672240

43.85

34.95

600

6.88

7.63

240

ET-P672245

43.85

34.95

600

7.01

7.7

245

ET-P672250

43.88

35.2

600

7.12

7.81

250

ET-P672255

43.88

35.2

600

7.24

7.85

255

ET-P672260

43.49

34.8

600

7.47

8.18

260

ET-P672265

43.63

36.4

600

7.28

7.9

265

ET-P672270

43.63

36.4

600

7.43

7.9

270

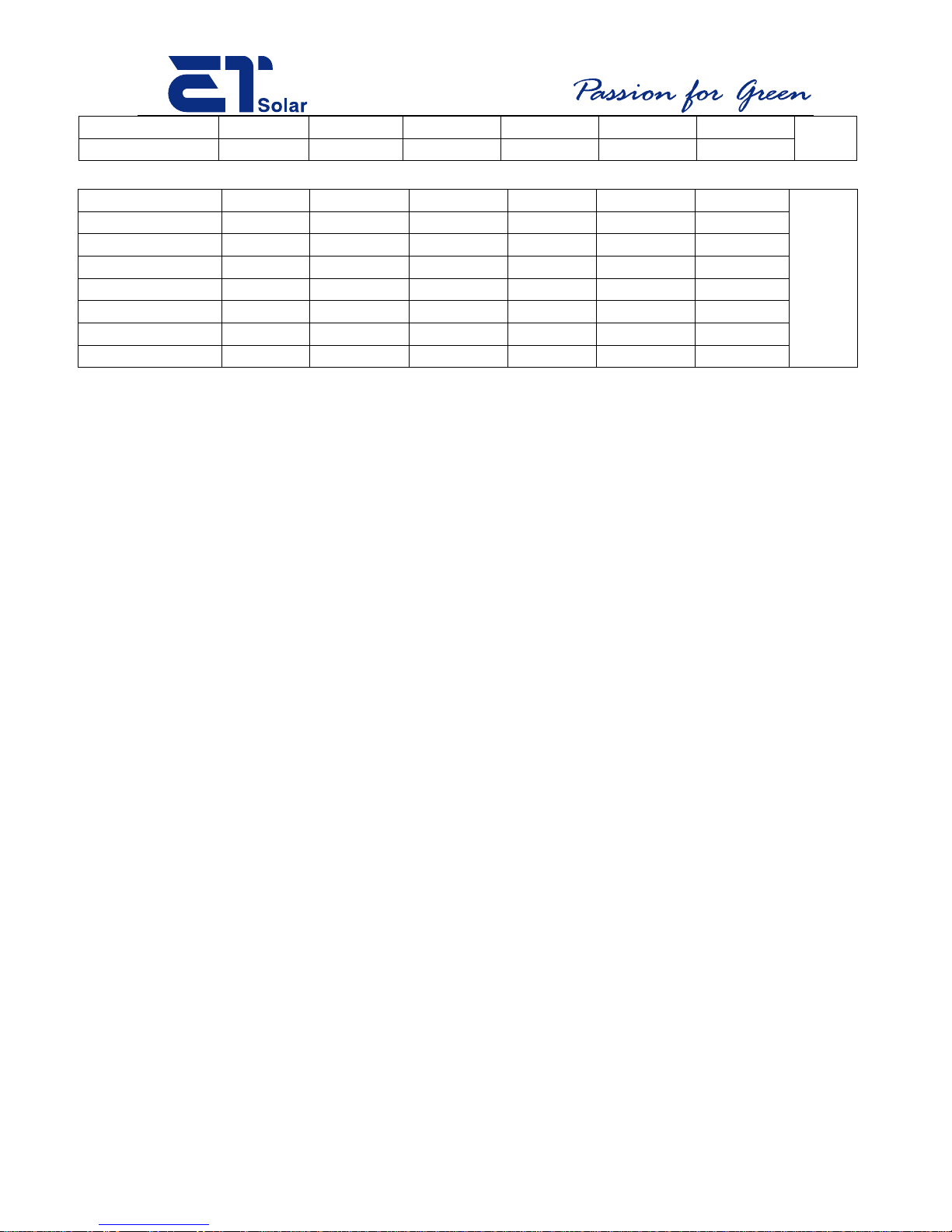

10

ET-P672275

43.78

36.72

600

7.49

7.96

275

ET-P672280

43.78

36.72

600

7.63

7.98

280

ET-P660200

36

28.75

600

7.7

7.71

200

15

ET-P660205

36

28.75

600

7.13

7.8

205

ET-P660210

36

28.75

600

7.3

7.99

210

ET-P660215

36

29

600

7.41

8.1

215

ET-P660220

36.3

29

600

7.58

8.1

220

ET-P660225

36.3

29

600

7.75

8.1

225

ET-P660230

36.5

29.4

600

7.82

8.3

230

ET-P660235

36.5

29.4

600

7.99

8.3

235

Usually the load of the modules is a group of batteries. To prevent the modules from

being charged by batteries under the circumstance of no sunlight, it is important to add a

shut-off diode in series. Also, please consider the voltage decrease of PN junction of

about 0.7V when connecting the shut-off diode. The modules can withstand for a

maximum positive or negative design loading of 45 lbs / ft2.

The environmental temperature may also affect the modules’ output power. If the

environmental temperature goes up, the short-circuit current will increase a little, while

open-circuit voltage will decrease, which will result in a decrease in the module’s output

power. Therefore, a lower environmental temperature is most appropriate for the module.

5. Operation and Maintenance

ET Solar module users should rinse the array seasonally or as needed in dry, dirty areas

to improve the performance of their solar electrical systems. Heavily soiled modules will

have a decrease in performance due to reduced light on the photovoltaic cells. Studies by

the PVUSA in Davis, CA estimate that during a dry year module soiling may affect

performance by as much as 7% annually with no cleaning. Seasonal rains often clean the

modules, however, during the long dry summer, it is helpful to rinse the modules as

needed.

ET solar modules may be rinsed with clean water to remove dirt. Normal pressure from a

standard residential hose and nozzle is recommended. Early morning and late afternoons

are favorable times to clean to avoid a sudden change in temperature. Care must be taken

since modules produce energy any time light is present. Modules are not to be touched or

walked on except by a licensed professional.

11

Disclaimer of liability

Because the use of this manual and the conditions or methods of installation, operation, use

and maintenance of photovoltaic products are beyond ET Solar's control, ET Solar does not

accept responsibility and expressly disclaims liability for loss, damage, or expense arising

out of or in any way connected with such installation, operation, use or maintenance. No

responsibility is assumed by ET Solar for any infringement of patents or other rights of third

parties, which may result from use of the PV product. No license is granted by implication or

otherwise under any patent or patent rights.

The information in this manual is based on ET Solar's knowledge and experience and is

believed to be reliable, but such information including product specification (without

limitations) and suggestions does not constitute a warranty, expressed or implied. ET Solar

reserves the right to change the manual, the product, the specifications, or product

information sheets without prior notice.

Contact information of manufacturer:

ET Solar Group Limited

24F, A2 World Trade Center Mansion,

67 Shanxi RD, Nanjing 210009, China

Tel: 86 25 86898096 86898098

Fax: 86 25 86898097

E-mail: [email protected]

www.etsolar.com

You may contact our regional branches for questions and services:

ET Solar Europe (Europe),

Munich City Tower Landsbergerstr. 110-114, 9 Fl. D-80339

Munich, Germany

Tel: +49 89 5009405-0

Fax: +49 89 5009405-99

Email:Sales @etsolar.de

ET Solar USA (America & Canada )

4900 Hopyard Road, Suite 290, Pleasanton, CA 94588, USA

Tel: +1 925 4609 898

Fax: +1 925 4609 929

Email: sales @etsolar.us

12

Please consult your dealer or the manufacturer concerning the warranty of your

modules. 2010 © ET Solar Group.

This manual suits for next models

38

Other ET Solar Solar Panel manuals

Popular Solar Panel manuals by other brands

Astronergy

Astronergy CHSM60M(DG)/F-B installation manual

PROMETHEUS SOLAR

PROMETHEUS SOLAR Plug & Play Solar Kits GT user manual

ENN Solar Energy

ENN Solar Energy EST-110 installation manual

Simplicity

Simplicity 1691373 Operator's manual

ACOPOWER

ACOPOWER KIT-HYS100MB user manual

Xantrex

Xantrex 783-0100-01 owner's guide