Et 400 Series Manual

Erhardt + Leimer Inc.

350 Tucapau Road

Duncan, SC 29334 USA

Telephone 864/486-3000

Telefax 864/486-3011

BULLETIN 25

WEB GUIDING SYSTEMS

B-25

Rev. 1/97

NOTICE TO PERSONNEL

Safety must be a primary concern for all personnel who operate, maintain, or service any of our

machinery or its component parts.

While we have tried hard to design our equipment to be as free from hazard as we feel we can

reasonably make it, moving webs and automated equipment present safety hazards, which

cannot always be completely eliminated through design. Everyone must stay alert and exercise

constant caution in any area where the web guide and other machinery are running.

Be careful to avoid contact with the edge of the moving web

Do not allow fingers, jewelry, or clothing to get caught between the web and idler roll

Always remember to turn off or electrically disconnect the power to any machine prior to

opening any enclosures or working on it

Avoid contact with moving parts in general.

Please read this manual and become familiar with the operation and care of your guide before

using it.

Suggestions on how to further enhance safety to operating personnel are always welcome and

encouraged. If you have any questions about how to safely operate any machine, please ask

your foreman or supervisor for directions and/or a demonstration, or contact one of our offices

below.

Main office and plant

Duncan, South Carolina 864/486-3000

Canadian offices

Burlington, Ontario 905/632-8181

Montreal, Quebec 514/635-4311

Mexico office 011-52-5-55-669-3122

Bulletin 025

Web Guiding Systems

TABLE OF CONTENTS

SUBJECT PAGE

I. SECTION DESCRIPTION AND OPERATION .................................................. 1-3

ACTUATING DEVICES ....................................................................... 1

ACUTATION POWER ......................................................................... 1

WEBALIGNER POWER UNITS .......................................................... 1

SENSING DEVICES............................................................................ 2

CONTROL OPTIONS .......................................................................... 2

DETAILED DESCRIPTION AND OPERATING INFORMATION......2-3

II. SECTION INSTALLATION ...............................................................................3-4

COMPONENT INSTALLATION........................................................... 3

HYDRAULIC AND PNEUMATIC INTERCONNECTIONS................... 3

CONTROL OPTION INTERCONNECTIONS ...................................... 4

III. SECTION CHECKOUT ........................................................................................ 5

IV. SECTION OPERATING INSTRUCTIONS ........................................................... 5

V. SECTION MAINTENANCE AND REPAIR........................................................... 5

VI. SECTION TROUBLESHOOTING ...................................................................6-11

….E+L Bulletin 025, Web Guiding Systems

SECTION I: DESCRIPTION AND OPERATION

Whether simple or sophisticated, all web guiding systems contain the same basic components.

They are listed below, by category, and are described in brief detail. Today's guiding systems

find guiding components combined in many unusual and even unique ways, but they all have

the same purpose, they control the web so that the web and the process retain the right

relationship to one another.

ACTUATING DEVICES

Actuating devices are those devices, which act directly upon the web to control the web

position.

They can be traditional units such as Steering Rollers, which urge the web into the right path by

force or adaptor bases, which make it possible to move an unwind roll, a rewind roll, or a scray

so its position compensates for web wander. Or they can be modern long-correction-span

Tracking Rollers, which gently, but positively, place the web back into position with almost no

induced stress or strain by displacement.

Modern systems also find the process following the web in some cases. Examples of this are

tenter frames, trim knives, and movable coaters or trackers. In such systems, the purpose is to

chase the web rather than to reposition it.

ACTUATION POWER

A quick-acting, accurate, and controllable mechanism must be used to power the actuating

devices. For most applications, E+L uses a precision, double acting hydraulic cylinder, properly

sized for the task at hand. In other applications, an electric actuator is more suitable.

WEBALIGNER POWER UNITS

E+L uses one of a series of Web Aligner pneumatic-hydraulic power units in most of its

systems.

The power unit is much more than just an energy source, however, because it furnishes

modulated power to the actuating devices. Therefore, it is an amplifier of control signals as

well as a power source.

In addition to providing hydraulic power for the actuating system, the power unit produces

pneumatic power for the sensors. Sensor supply pressure must remain constant; the E+L

constant pressure generator produces constant pressure at a given head without the use of a

pressure regulator. Water, oil, scale and graphite contamination and other compressed air

problems are thus avoided.

1

….E+L Bulletin 025, Web Guiding Systems

SENSING DEVICES

Web guiding relies upon an integrated feedback control system; that is, the sensing device

continuously senses web location and sends appropriate corrective signals to the actuating

device. The control signal strength is dependent upon the position of the web and is, therefore,

proportional.

Traditional sensing relies on pneumatics. The edge of the web passes between two "fingers"

which contain the opposing out breathing jets of air. The position of the edge modulates the

effects of the jets on one another, causing a pressure fluctuation in the air supply of one of the

jets. It is this pressure fluctuation, which provides the corrective signal that controls the power

unit output. E+L can supply a special porous sensor, which guides on a row of holes, or one,

which senses the edge of scrim material with openings as large as half of an inch.

Photoelectric sensing is desirable in many instances where the edge is relatively unimportant to

the process, but where following a printed line or pattern is the key "edge".

Erhardt + Leimer produces a photoelectric sensing system. This system is designed so that it is

integrated with traditional pneumatic-hydraulic power and actuation devices. It can, therefore,

be retrofitted to existing systems, or combined with them to provide alternate guiding

techniques.

E+L also manufactures special sensing devices to meet the requirements of specific

applications. An example of this is the Tuft Aligner, a pneumatic sensor that is widely used in

the carpet industry. This device guides on a row of tufts on the face of the carpet. Another

example is a special electronic sensor, which senses the hidden steel outer cord in a rubber

web on a tire cord calender.

CONTROL OPTIONS

E+L provides a number of control options that provide specific "behavior" characteristics on the

web guiding system on which they are imposed. Many of these control options have been

designed to meet standard requirements in given industries. Others have been developed to

give greater versatility to systems to suit them in a wide range of applications.

All E+L control options function by controlling either the output of the hydraulic power supply or

by controlling the source, magnitude and application of the sensing signal. In some systems,

the control option functions entirely manually, that is, the operator opens and closes valves to

achieve the desired result.

In most cases, however, the sophistication of the control system requires important interlock

features difficult to achieve with a mechanical system. In such cases, the control option is

imposed by means of solenoids, and activated by selector switches, timers, and push buttons.

DETAILED DESCRITPION AND OPERATING INFORMATION

Each major component (and many significant variations) is described in detail in the following

bulletins. Refer to each of these for the information that will describe your system fully.

Because a web guiding system is complex and comprises many variables, the equipment and

its function must be explained on a component-by-component basis. Where these components

interface, that interface is defined, often in two bulletins. While this leads to some redundancy,

it also makes possible a complete set of instructions.

2

….E+L Bulletin 025, Web Guiding Systems

In other instances, notably in bulletins covering control options, you will be referred from one

bulletin to another.

In some cases, your web guiding system will be specially designed, and the accompanying

instructions will be only generally applicable. In such cases, specific details will appear on the

engineering drawings that accompany your order.

SECTION II: INSTALLATION

COMPONENT INSTALLATION

Each major component in your system is handled as a separate entity, and a suitable bulletin in

this instruction manual describes its installation. Its interrelationship with other components is

also described in the appropriate installation section. It is wise to install all components before

proceeding with any checkout procedure because most checkout procedures involve some

interaction between components. General procedures covering some key interrelationships are

also covered below.

HYDRAULIC AND PNEUMATIC INTERCONNECTIONS

The basic interconnection between power unit, pneumatic sensor, and hydraulic servo cylinder

is shown in Figure 1. Certain sensors and other servo-mechanisms may vary from this basic

scheme. Where such variance is necessary, it will be spelled out in detail in the component

bulletin.

The following rules of thumb apply to all hydraulic and pneumatic connections. Where

variances are permissible, they will be explained in the component or option bulletin.

1. Be sure the I.D.s of all hydraulic and pneumatic lines, fittings, and connectors are

clean and free from contaminants. When opening ports in any component, use care

to prevent contamination from entering.

2. Use hydraulic components designed for hydraulic systems only. Use 1/4-inch Nylon

tubing on 400B units and 3/8-inch tubing on all other sizes. Be sure the tubing is rated

for your system pressure. Do not use reinforced hydraulic hose.

3. Do not use pipe dope on fittings. Fittings are normally supplied wrapped with Teflon

pipe thread tape. If your fittings are not wrapped, wrap them with tape. Leave 1-!/2

threads clean on the inner end to avoid extrusion of tape particles into the system.

4. Be sure the tubing passes entirely through the ferrule on the fitting to insure adequate

grip on the tube.

3

….E+L Bulletin 025, Web Guiding Systems

Chasing

Applications

Guiding Applications

Figure 1. System Interconnection

5. Run all tubing so that it will not kink or be pinched during operation, and so that it will

not become entangled in the web or protrude into adjacent aisles. Pneumatic Tygon

tubing must be run in gentle curves; kinks and sharp bends will degrade the accuracy

of the sensing signal.

6. Pneumatic tubing should not exceed 8-10 feet in length or system performance will

suffer.

7. If double pneumatic tubing is used, slit the connecting rib far enough to spread the

hoses sufficiently to fit over pneumatic fittings without inducing kinks or sharp bends.

A protruding rib on one of the joined, lines "identifies" the line from end to end.

8. Half-inch I.D. metal tubing may be used to replace all or part of the Tygon tubing.

Tubing bend radii should not be less than six inches nominal.

CONTROL OPTION INTERCONNECTIONS

If your system is equipped with a control option, check the enclosed 700 Series Bulletin(s) for

option installation instructions.

4

….E+L Bulletin 025, Web Guiding Systems

SECTION III: CHECKOUT

Checkout can be performed essentially on a component-by-component basis. Where system

interconnection is involved, component checkout procedures define the interrelationship

sufficiently to prove system operation. Because of the component interactions involved in a

web guiding system, it is wise to complete all installation before proceeding with checkout.

SECTION IV: OPERATING INSTRUCTIONS

Operating instructions are handled on a component-by-component basis. Where component

interaction is involved, component operating procedures, backed up by control option operating

procedures, are sufficiently detailed to insure proper system operation.

SECTION V: MAINTENANCE AND REPAIR

Maintenance and repair instructions are handled on a component-by-component basis.

Components comprising control options are covered in the applicable control option bulletin.

5

….E+L Bulletin 025, Web Guiding Systems

SECTION VI: TROUBLESHOOTING

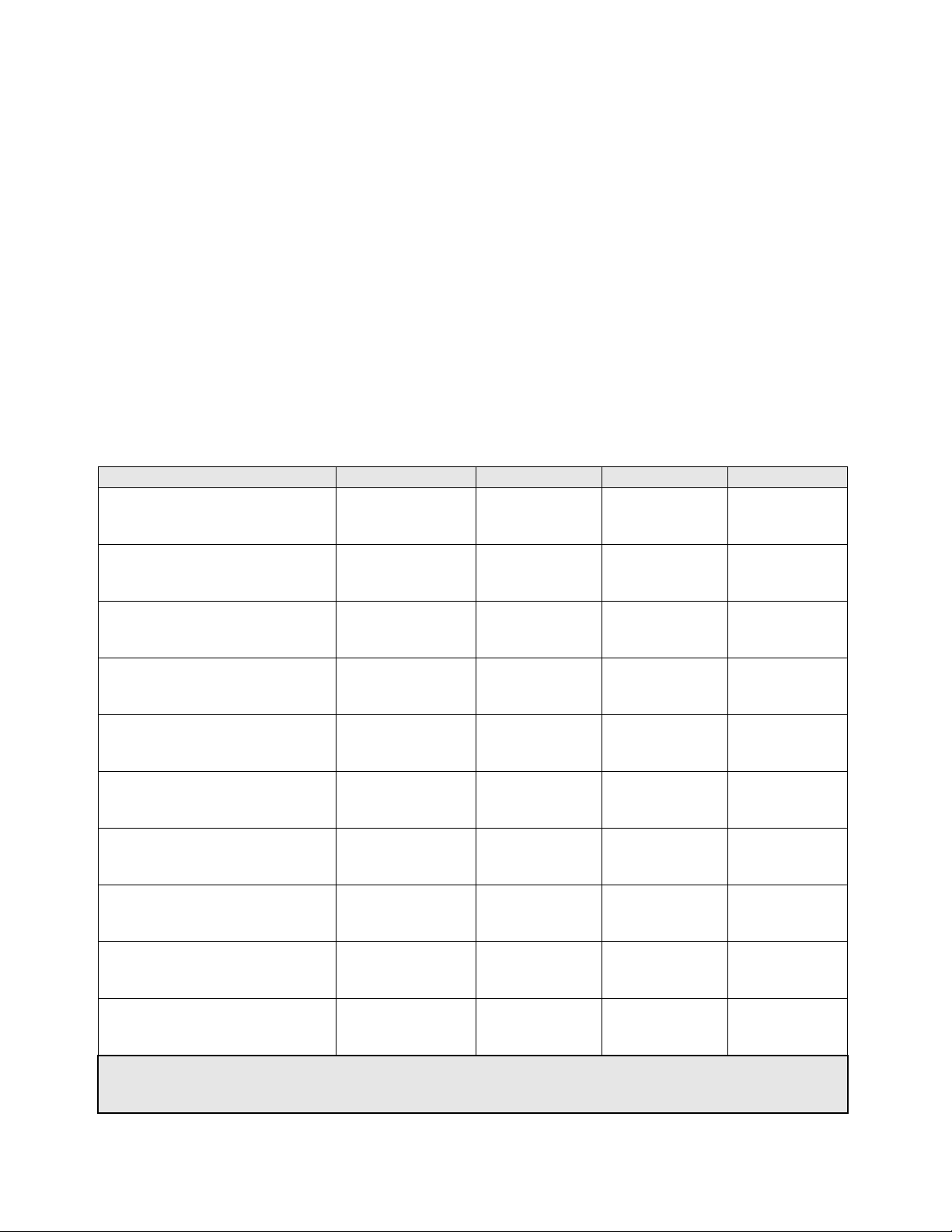

Most problems with web guiding equipment reveal themselves as system malfunctions.

Consequently, all basic trouble-shooting is handled in the table below. Where specific

maintenance or repair procedures must be followed, reference is made to the applicable

bulletin.

In the case of specialized "system-type" equipment, namely, centerline resolving and control

options, additional trouble-shooting procedures will be found in the applicable bulletin. Those

trouble-shooting procedures pertain only to the equipment covered by the specific bulletin.

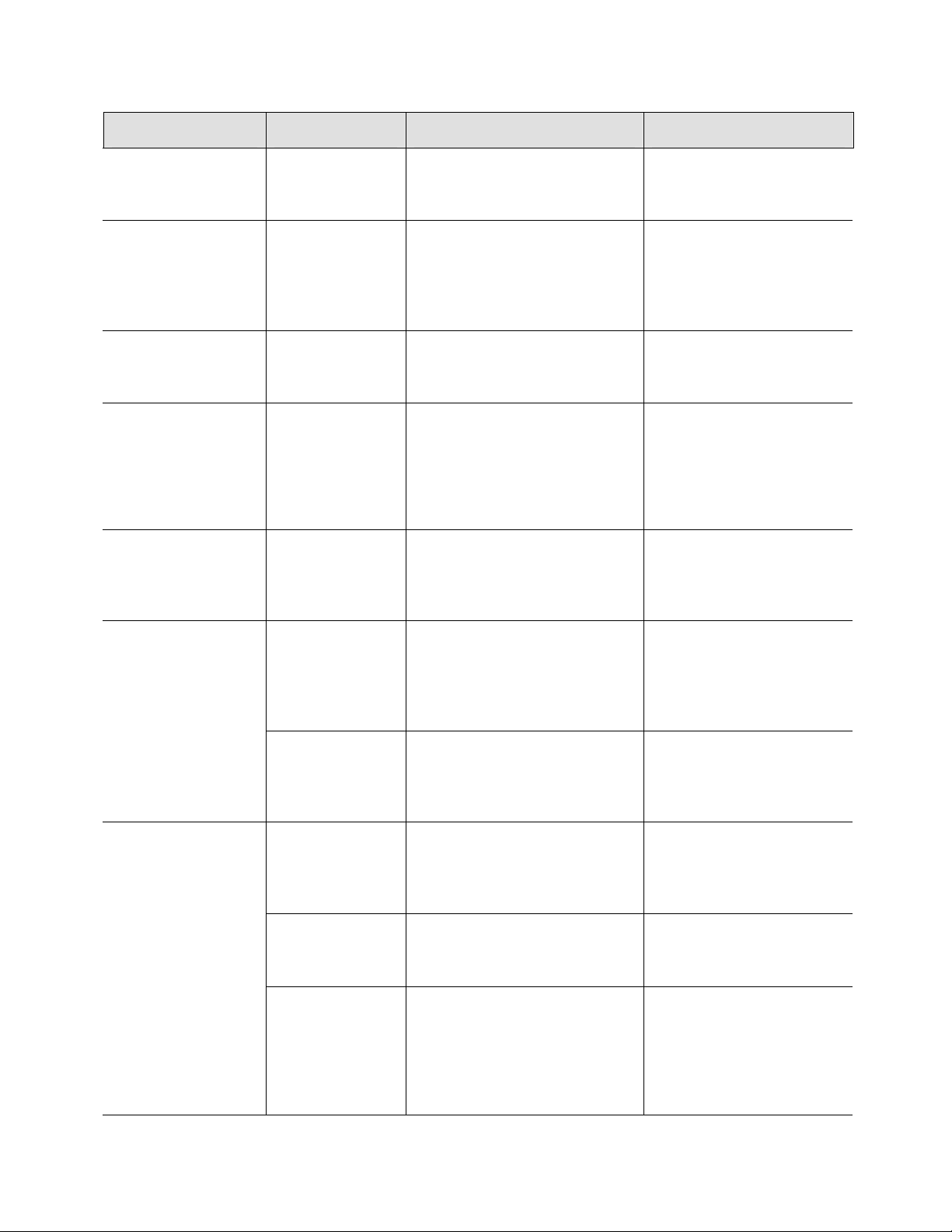

SYMPTOM CAUSES ISOLATING PROCEDURE REPAIR PROCEDURE

Power unit will not

start

No power to

motor

Check continuity on power

leads before starter

Connect power

Heater trip Visually inspect Reset heater and

determine cause

Contactors do

not close

Visually inspect: if physically

malfunctioning, then…

If no apparent malfunction,

then…

replace contactors

replace coil

Blown capacitor Check continuity to ground

before and after capacitor

Replace capacitor

Open or

shorted motor

winding

Check continuity at motor Replace or repair motor;

see Bulletin No. 100

Power unit cycles

ON and OFF

(single phase with

internal thermal

overloads)

Motor over

heating

If motor is too hot to touch, let

it cool and try again. Check

for proper voltage.

Rewire motor to proper

voltage if necessary.

Power unit motor

shuts down

automatically (3-

phase only)

Motor

overheating,

causing a

heater trip

Visually inspect; check for

proper heater size

Reset heater and

determine cause; Replace

undersized heater with

one of proper size; see

Bulletin No. 100

6

….E+L Bulletin 025, Web Guiding Systems

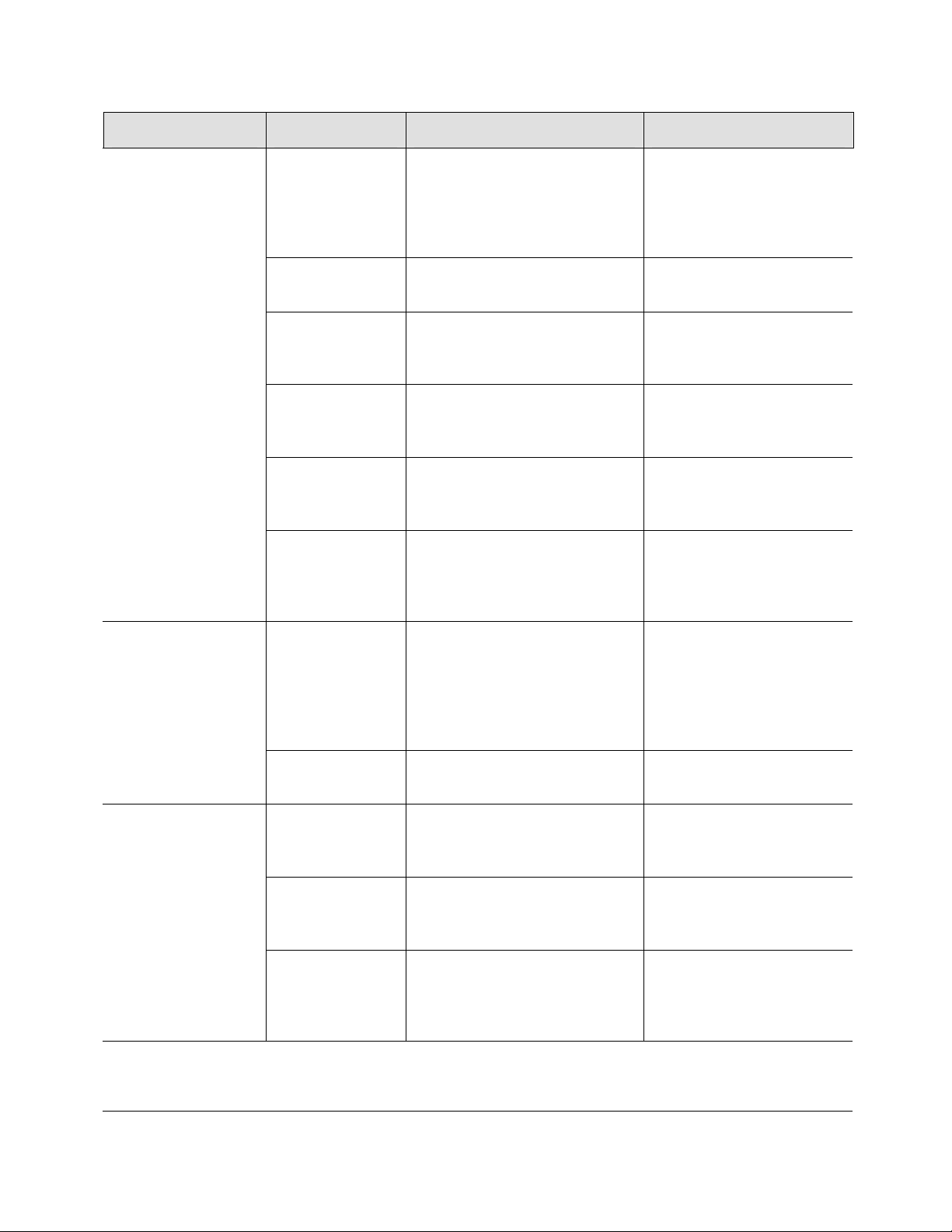

SYMPTOM CAUSES ISOLATING PROCEDURE REPAIR PROCEDURE

Oil under power

unit

Hymod, oil

pump, or fittings

are leaking

Visually inspect unit to

determine source of oil;

Disregard Spillage

Replace leaking Hymod

or oil pump; see Bulletin

No. 100

Power unit noisy Wrong motor

voltage

Visually inspect wiring to see

that it is properly connected

for the available power

Rewire motor to proper

voltage if necessary;

Wiring diagram is beneath

connector cover or on

name plate

Blower bearing

has failed

Observe operating blower Replace blower; see

Bulletin No. 100

Timing belt

loose

Check to see if it displaces

more than ¼” with moderate

finger pressure

Reset tension; see

Bulletin No. 100

Motor pump

coupling loose

Check for wear on pump

housing

Raise and tighten per

Bulletin No. 100

Power unit

operating hot

Motor cooling

intakes clogged

Visually inspect Clean out intakes

Ambient

temperature too

high

Check to see if ambient

temperature exceeds 100º F

Reduce ambient

temperature, relocate

power unit to cooler

location, or cool unit with

a fan during operation

Low oil level Check oil level Top up as necessary

Flexible motor

pump coupling

swells

Coupling has

been soaked

with oil

Visually determine; Also

locate source of oil

Replace coupling and

eliminate oil leak; see

Bulletin No. 100

TRA or adapter

base binds

Bearing insert

has failed

Visually check to see if the

bearing cage is contacting the

support bar

Replace bearing; see

Bulletin No. 400

Bearing support

bar bent

Check with straight edge

(Arcuate bars have regular

radius in plane of travel)

Replace bar; see Bulletin

No. 400

Corner support or

rigidity fails on TRA

or adapter base

Bearing loose Visually inspect Tighten retaining bolt; If

threads are stripped,

replace bearing

Bearing support

bar loose

Visually inspect Tighten retaining bolt

7

….E+L Bulletin 025, Web Guiding Systems

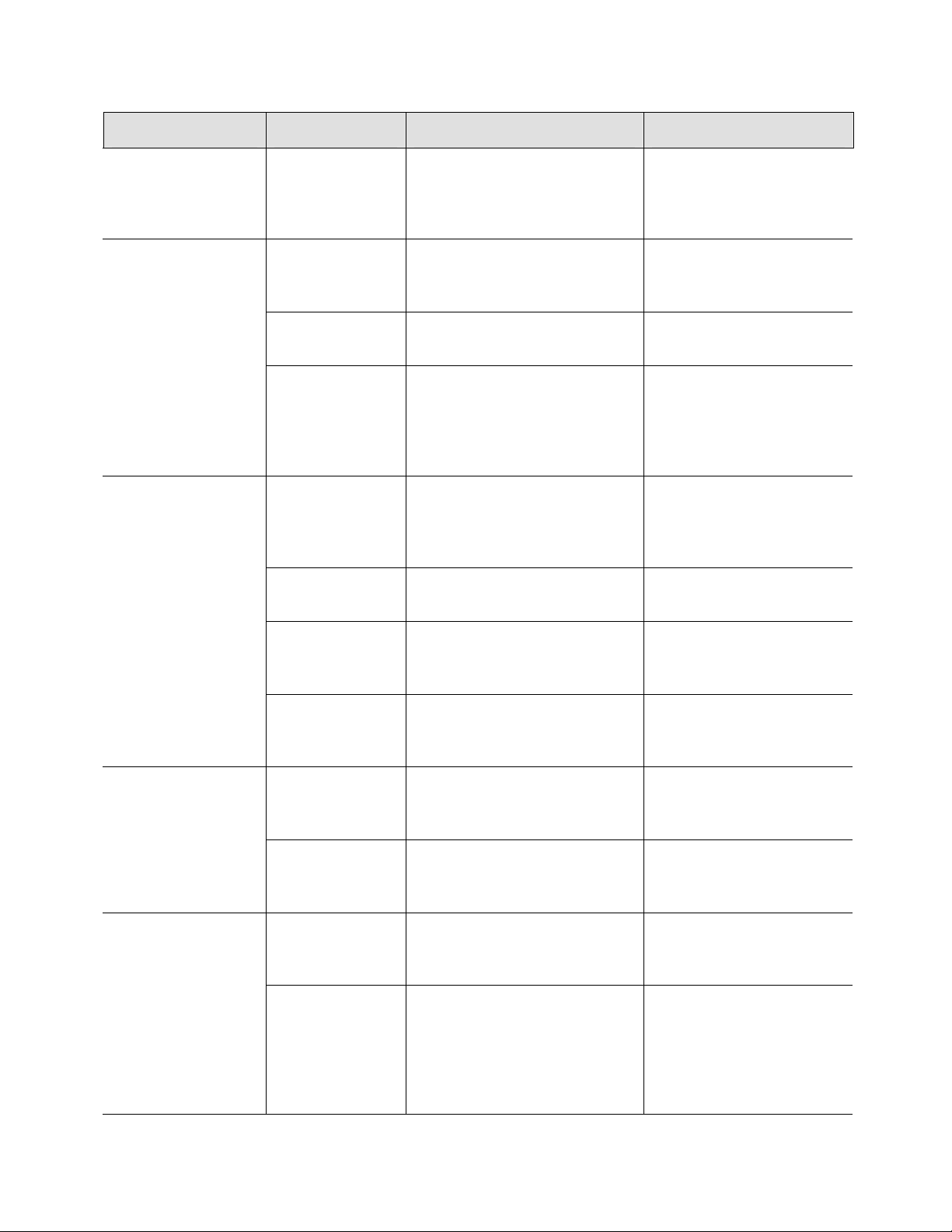

SYMPTOM CAUSES ISOLATING PROCEDURE REPAIR PROCEDURE

Noisy TRA or

adapter base

Bearing insert

has failed

Check bar for rapid wear Replace bearing and

support bar; see Bulletin

No. 400

Supporting knuckle

of arcuate motion

generator becomes

loose and flops out

of position

Arcuate motion

generator cable

broken

Shut down line; Move knuckle

by hand to see if it moves

without inducing motion in

other end of unit

Repair cable

Idler bracket rocks Bracket

retaining bolt

loose

Visually inspect Tighten bolt

Oil leaking from

cylinder

Leaking seal or

pitted rod

Extend cylinder and wipe

clean; Watch for oil as rod is

moved;

Stationary leakage only

Moving leakage only

see Bulletin No. 200 for

replacement procedures

Replace seal

Replace rod

Web contains

continuous wrinkle

or appears tight on

one side of TRA

Idler roller out

of tram

Check parallelism according

to Bulletin No. 400

Retram if necessary

Wrinkle into rewind

or out of unwind on

adapter base

Not enough

span between

base idler (or

roll) and last

process idler

Visually inspect, span should

generally be at LEAST half

the web width. Less flexible

webs require more span

Span must be lengthened;

Contact your E+L

representative for further

information

Misplaced edge

sensor

Visually inspect; Sensor

should be as close as

possible to adapter base to

avoid correction lag

Relocate sensor

System controls

inaccurately by

overreacting or

overshooting

Dipstick fiber

filter soaked

with oil

Visually inspect Replace filter; see

Bulletin No. 100

Sensor too far

from guiding

device

Check relationship; Should be

much closer to moving idler

than to next fixed idler

Reposition sensor as

close as possible to

guiding device

Improperly bled

cylinder

Remove breather cap and

look for foam on top of Hymod

oil. Feel oil pressure line

(base to top of Hymod on side

away from C1 and C2 ports)

for hard, rapid vibration

Bleed cylinder according

to the instructions in

Bulletin No. 100

8

….E+L Bulletin 025, Web Guiding Systems

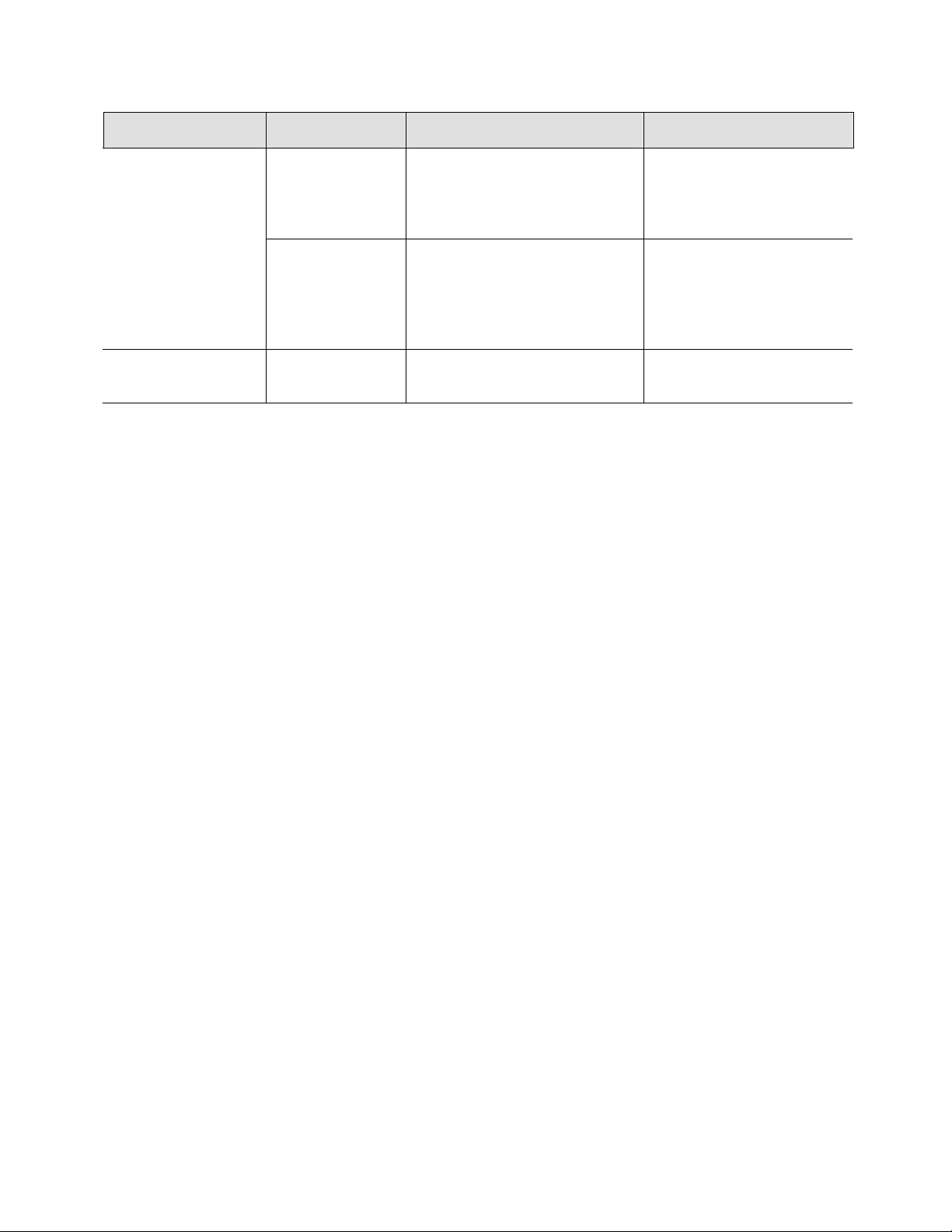

SYMPTOM CAUSES ISOLATING PROCEDURE REPAIR PROCEDURE

System controls

inaccurately by

overreacting or

overshooting

(continued)

Light web

material curls

under S1

pressure

Observe web edge within

sensor

Install sole plate on

sensor

Servo cylinder

mounting loose

Visually inspect Tighten retaining nuts

Cylinder

mounting too

flexible

Observe cylinder mounting for

deflection

Mounts must be

strengthened; Contact

your E+L rep.

Cylinder stroke

too short for

error present

Observe cylinder to see if

cylinder is traveling full stroke

Replace with longer-

stroke cylinder; contact

your E+L rep.

Idler Roller

bearings loose

Inspect idlers for end play Replace with new idlers or

bearings; see Bulletin

No. 500

System

undersized for

load imposed

Check tension and/or weight,

error rate, and web speed

against original design

parameters

Most systems can be

upgraded by substitution

of only components;

Contact your E+L rep.

Guiding device

moves to end of

travel and won’t

return

Valve stuck in

Hymod

Remove cap in center of

Hymod and remove magnetic

disc or plastic cap; Check

valve stem for freedom of

movement

Shock system

pneumatically according

to Step 4 of the Check-

Out Procedure in Bulletin

No. 100, then replace

Hymod

Signal hose

disconnected

Visually inspect Reconnect hose

Guiding device

won’t move or only

moves sluggishly

No or low oil in

Hymod

Check level with dipstick Fill or top up according to

Bulletin No. 100

Control option

lock valves

closed

Refer to appropriate 700

series bulletins for control

option troubleshooting

Signal lines too

long or pinched

Visually inspect; Lines should

be 8 feet long

Short lines (12 feet

absolute max.); If this

cannot be done, contact

E+L

9

….E+L Bulletin 025, Web Guiding Systems

SYMPTOM CAUSES ISOLATING PROCEDURE REPAIR PROCEDURE

Guiding device

won’t move or only

moves sluggishly

(continued)

10 Micron outlet

filter clogged

Loosen oil fittings slightly on

top of Hymod and watch for

oil leakage; No oil clogged

filter

Replace Hymod; see

Bulletin No. 100

Guiding device

drifts in one

direction

No or low oil in

Hymod

Check level with dipstick Fill or top up according to

Bulletin No. 100

Pump inlet

strainer clogged

Listen for signs of cavitation,

such as noise, vibration, relief

Replace Hymod; see

Bulletin No. 100

Oil pump shaft

is binding

Following pump repair

procedure in Bulletin No.

100, disassemble pump far

enough to determine if pump

is free turning

Replace pump and

inspect spider for wear or

damage

Guiding device

moves fast in one

direction and slow

in the other

S1 signal line

cut or

disconnected

Visually inspect Replace or connect line

S1 sensor

orifice clogged

Visually inspect Clean orifice

Blower filter

clogged

Remove belt guard at blower

end of power unit; Visually

inspect

Clean or replace filter

Bias knob

adjustment

incorrect

(if all above are O.K.) Pop cap and adjust

knurled knob slowly to

even out speed

Sensor and web

move toward one

another

Standard

sensor S2

orifice clogged

Visually inspect Clean orifice

Three-leg

sensor shop air

orifice clogged

Visually inspect Clean orifice

Sensor and web

move apart

suddenly

S2 signal line

cut or

disconnected

Visually inspect Replace or connect line

Timing belt

failed OR

generator signal

hose

disconnected

Remove S1 signal line and

check for air pressure. If

none, remove belt guard on

blower end of power unit and

check belt and generator

signal line

Replace belt or reconnect

hose

10

….E+L Bulletin 025, Web Guiding Systems

11

SYMPTOM CAUSES ISOLATING PROCEDURE REPAIR PROCEDURE

Sensor and web

move apart

suddenly

(continued)

Blower filter

clogged

Remove belt guard at blower

end of power unit; Visually

inspect

Clean or replace filter

Tuft Aligner

installations:

Tuft Aligner

spring

deformed

Visually inspect spring Replace spring

System generally

unstable

Signal lines too

short or pinched

Visually inspect; Lines should

be 8 feet

Install lines of proper

length

Erhardt + Leimer Inc.

350 Tucapau Road

Duncan, SC 29334 USA

Telephone 864/486-3000

Telefax 864/486-3011

BULLETIN 100

WEBALIGNER 400 SERIES POWER UNIT

B-100

Rev. 1/97

NOTICE TO PERSONNEL

Safety must be a primary concern for all personnel who operate, maintain, or service any of our

machinery or its component parts.

While we have tried hard to design our equipment to be as free from hazard as we feel we can

reasonably make it, moving webs and automated equipment present safety hazards, which

cannot always be completely eliminated through design. Everyone must stay alert and exercise

constant caution in any area where the web guide and other machinery are running.

Be careful to avoid contact with the edge of the moving web

Do not allow fingers, jewelry, or clothing to get caught between the web and idler roll

Always remember to turn off or electrically disconnect the power to any machine prior to

opening any enclosures or working on it

Avoid contact with moving parts in general.

Please read this manual and become familiar with the operation and care of your guide before

using it.

Suggestions on how to further enhance safety to operating personnel are always welcome and

encouraged. If you have any questions about how to safely operate any machine, please ask

your foreman or supervisor for directions and/or a demonstration, or contact one of our offices

below.

Main office and plant

Duncan, South Carolina 864/486-3000

Canadian offices

Burlington, Ontario 905/632-8181

Montreal, Quebec 514/635-4311

Mexico office 011-52-5-55-669-3122

Bulletin 100

WebAligner Power Unit

TABLE OF CONTENTS

SUBJECT PAGE

I. SECTION DESCRIPTION AND OPERATION .................................................. 1-3

DESCRIPTION .................................................................................... 1

OPERATION........................................................................................ 2

CONTROL OPTIONS .......................................................................... 3

II. SECTION INSTALLATION ...............................................................................5-9

HANDLING .......................................................................................... 5

MOUNTING LOCATION...................................................................... 5

CLEARANCES .................................................................................... 5

ATTACHMENT .................................................................................... 6

CONTROL AND DETECTOR OPTIONS............................................. 6

POWER CONNECTION ...................................................................... 7

General Instructions.................................................................... 7

Motor Rotation ............................................................................ 7

Single Phase Units ..................................................................... 7

Three Phase Units ...................................................................... 7

Starters ....................................................................................... 8

HYDRAULIC CONNECTION............................................................... 8

PNEUMATIC CONNECTIONS .........................................................8-9

CONTROL OPTIONS AND DETECTOR VARIATIONS...................... 9

III. SECTION CHECKOUT .................................................................................10-11

IV. SECTION OPERATING INSTRUCTIONS ......................................................... 12

V. SECTION MAINTENANCE ...........................................................................12-13

HYDRAULIC OIL ............................................................................... 12

BREATHER/DIPSTICK...................................................................... 13

BLOWER FILTER.............................................................................. 13

GENERAL CLEANLINESS................................................................ 13

CONTROL OPTIONS ........................................................................ 13

VI. SECTION REPAIR ........................................................................................14-17

REPLACING THE HYMOD ............................................................... 14

REPLACING THE BLOWER ............................................................. 14

REPLACING THE MOTOR ASSEMBLY ........................................... 15

REPLACING THE MOTOR ............................................................... 15

REPLACING THE HYDRAULIC PUMP ASSEMBLY ...................15-16

REPLACING THE TIMING BELT ...................................................... 16

REPLACING MISCELLANEOUS PARTS ......................................... 16

CONTROL OPTION REPAIR ............................................................ 16

SPARE PARTS (Breakdown of Parts) .................................................................................. 17

Table of Figures

Figure 1. WebAligner Power Unit, 400 Series

Figure 2. Principles of Power Unit Operation

Figure 3. Installation Clearances

Figure 4. System Interconnection

Figure 5. Exploded View of Power Unit

Table of Tables

Table 1. WebAligner Power Unit, 400 Series

Table 2. Power Unit Installation Clearances

Table 3. Approved Hydraulic Fluids

….E+L Bulletin 100, WebAligner Power Units

SECTION I: DESCRIPTION AND OPERATION

DESCRIPTION

The 400 Series WebAligner is a hydraulic power unit used in web guiding systems. Because it

converts a pneumatic sensor signal directly into hydraulic output power, it acts as a pneumatic-

hydraulic transducer-amplifier. Four models of the WebAligner exist. They provide varying

working capacities and pressures to suit the needs of a wide range of applications. Specific

details of the various models are provided in Table I.

Figure 1. WebAligner Power Unit, 400 Series

1

….E+L Bulletin 100, WebAligner Power Units

The WebAligner Power unit is a self-contained device consisting of a number of integrated

modules. These modules are: an electric motor, a pneumatic constant pressure generator, a

hydraulic pump, and a hydraulic reservoir and pneumo-hydraulic servo valve. The pneumatic

circuit is protected by an intake filter. The hydraulic circuit contains a pressure relief valve and

is protected by an inlet strainer located in the reservoir. The pneumatic-hydraulic servo valve is

protected by a 10-micron filter located at the output of the pump.

OPERATION

The 400 Series WebAligner operates in conjunction with a pneumatic (fluidic) edge detector or

similar device (described elsewhere in this instruction manual), which provides a proportional

signal that varies in the range of 0.5 to 4.5 inches of water pressure. Signal pressure is varied

by the position of the web being guided. The power unit operates in conjunction with a

hydraulic servo-cylinder or servo-motor, which in turn, actuates the guiding device to position

the web correctly.

TABLE I. WEBALIGNER POWER UNIT, 400 SERIES

Characteristic 400- B 400-BM 400-BH 400-BHX

Weight (Pounds) * 80 80 110 110

Length (Inches) 17 ¼ 17 ¼ 22 22

Width (Inches) 10 ¼ 10 ¼ 12 12

Height (Inches) 15 ¾ 15 ¾ 16 ¾ 16 ¾

Motor H.P. ** 1/3 ½ ¾ 1

60 Cy. RPM ** 1725 1725 1725 1725

50 Cy. RPM ** 1450 1450 1450 1450

Hydraulic Flow (GPM) 0.49 0.82 1.41 1.41

Working Pressure (PSI) 300 300 400 400

Reservoir Capacity (Qt) 5 5 20 20

*Add 10 lbs. For explosion proof version.

**Standard and explosion proof motors are available in all standard voltages in both 50

and 60 cycle versions, to suit all normally encountered U.S. and foreign installations.

2

This manual suits for next models

4

Table of contents

Popular Industrial Equipment manuals by other brands

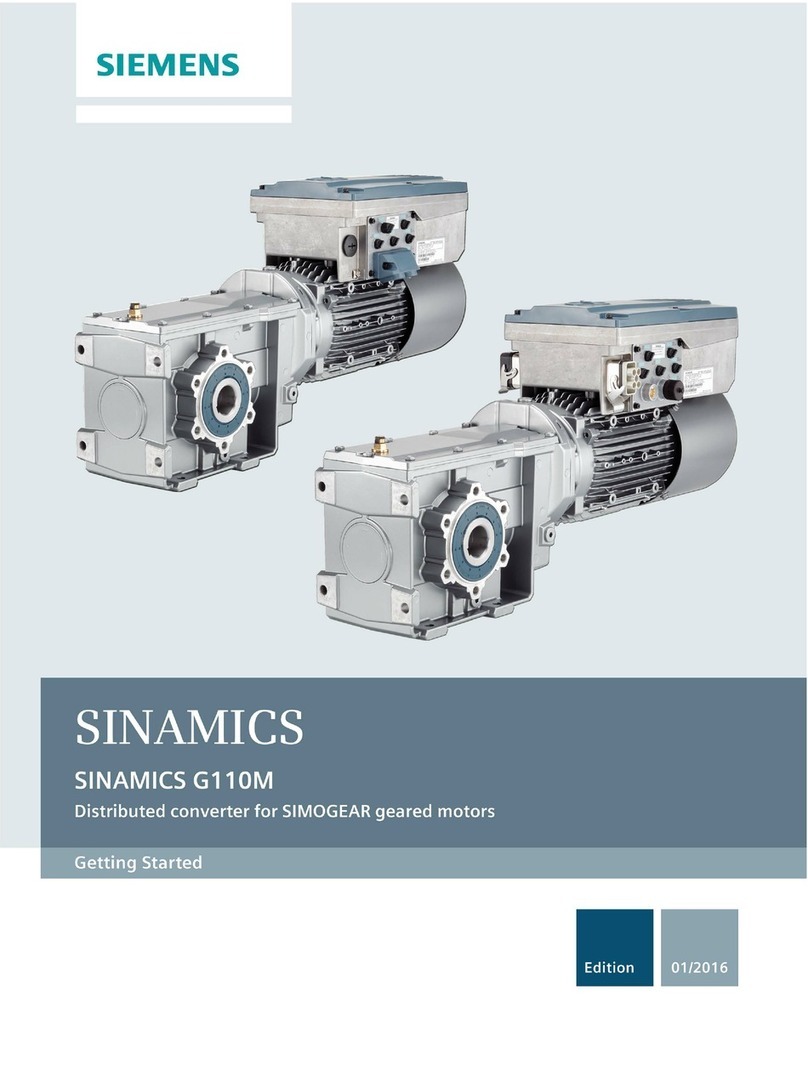

Siemens

Siemens SINAMICS G110M Getting started

Aerotech

Aerotech HexGen HEX300-230HL Hardware manual

Sulzer

Sulzer J 205 Assembly and installation instruction

MIYAWAKI

MIYAWAKI RE2 Series Operation manual

Labconco

Labconco RapidVap Vacuum user manual

Keysight Technologies

Keysight Technologies N5245BU-619 Installation note

Steenbeck

Steenbeck ST 2520 user manual

Nederman

Nederman 591 Series user manual

Herzog

Herzog A Series Installation and service instruction

Dover

Dover WILDEN PSG Equalizer SD Series Engineering, operation & maintenance

Eaton

Eaton NZM2-XUHIV20 Series Instruction leaflet

Rohm

Rohm FORTO-HT 37/70 Translation of the original operating manual