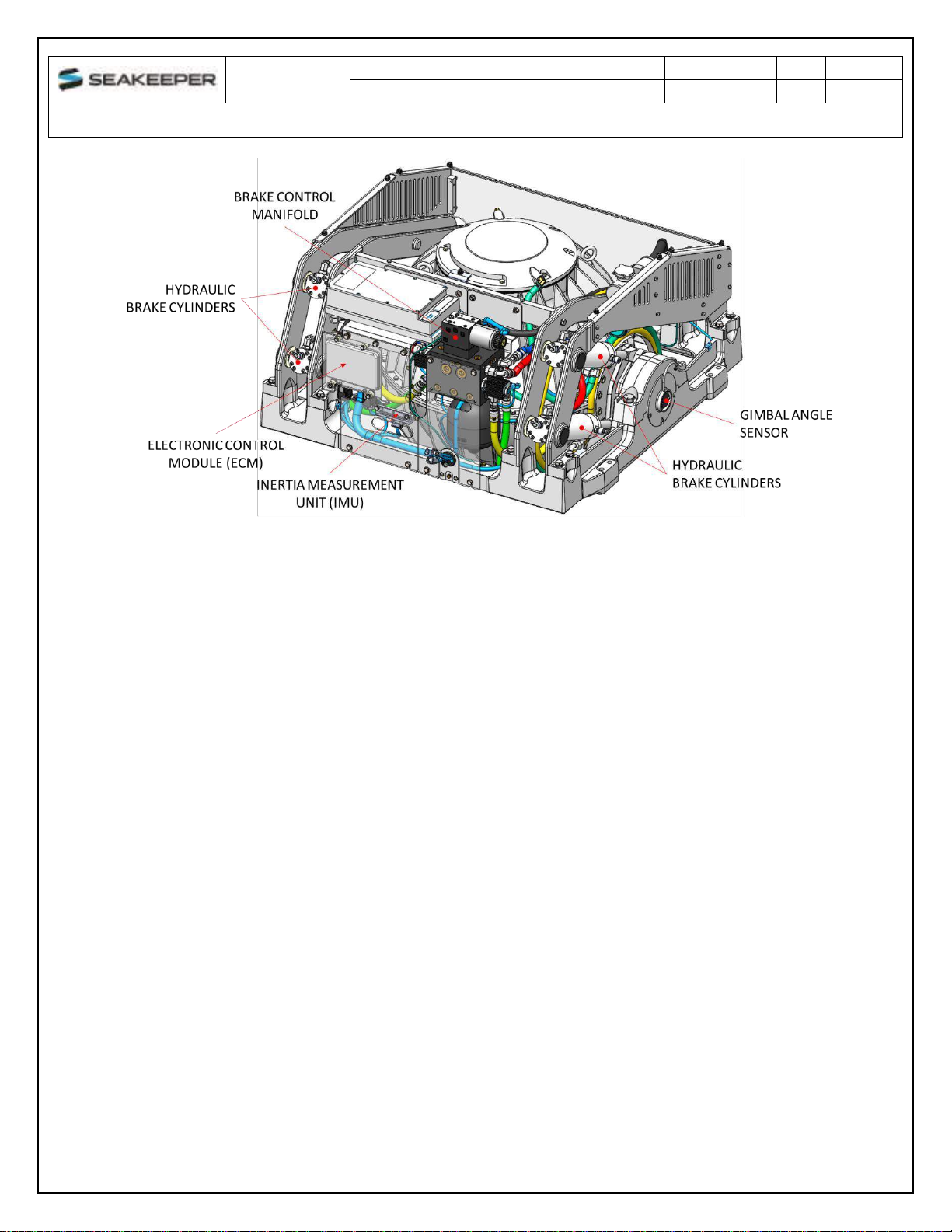

1.4 Electronic Control Module

The Electronic Control Module (ECM) monitors all the system sensors and automatically regulates

operation of the Seakeeper.

The controller commands the motor speed and regulates the Seakeeper’s precession rate and

gimbal angle. This is accomplished by commands to a high response flow control valve in the

hydraulic brake circuit that increases or decreases the brake pressure.

1.5 Inertia Measurement Unit (IMU)

The motion sensor suite in the IMU measures the angular movements of the vessel and the

vertical and lateral boat movement. These signals are communicated to the ECM through the

Seakeeper’s wiring harness.

1.6 Brake

The brake mechanism consists of four hydraulic cylinders that attach to crank arms on the

Seakeeper gimbal shafts. The Seakeeper controller modulates how fast the oil can flow through

a control valve thus controlling the precession rate of the Seakeeper.

The brake hydraulic circuit is a pre-charged closed loop system –that is, there is no pump, motor

or reservoir in the circuit. An accumulator is installed in the circuit, so the pre-charge pressure

does not increase as the fluid temperature rises due to the braking action. Locking solenoid

valves are installed in the circuit to lock the Seakeeper, so it cannot precess if there are any

alarms or a mechanical problem with the Seakeeper.