Before pressing/switching any button/switch always confirm that the button/switch is the correct one and never touch

a switch accidentally. Malfunction and potential danger might result.

Do not operate when wearing gloves or loose clothing. Malfunction and potential danger might result.

Do not touch switches with wet hands, an electric shock could occur.

If a work requires two or more operators, the cooperation among each operator must be well organized, every step of

each operator should be clarified to avoid potential danger.

Tools should be consisting with the machine's specifications, such as dimensions,weight and types.Grip workpieces

carefully to minimize movement and vibration between workpieces.Too much movement/vibration might result in

injuries of personnel, or damage the machine or workpiece.

Stop the machine before replacing workpiece, and reserve sufficient distance between workpiece and machine.Safety

for the electrical connection/disconnection

Electrical connection:

A cable with four wires is supplied to connect your machine into the 3 phase power supply.The exact power source

voltage, frequency, and number of phase shall be checked according to the installation diagram and circuit diagram.

The correct direction of main motor should be checked after connecting.

Electrical disconnection:

Be sure to disconnect this machine from power source, when you want to stop the job for maintenance or adjustment.

Grounding

The grounding of this model is carried out by connecting the yellow/green terminal of supply cable to the grounding

terminal of power source. Be sure to ground your machine before connecting machine to power source in any

situation.

Warning!

Do not disconnect grounding terminal before disconnecting power source.

Description for the safety function of this machine

The following safety functions are equipped with this machine. Be sure to check and

ensure the correct function before you start to operate your machine:

The emergency stop device:

The machine is designed to be immediately stopped under emergency situation. As soon

as this device is actuated, any movement will be stopped in a short time after the actuation of emergency stop switch

(E-stop).

Be sure to check that machine action will stop immediately after this button is pressed and will not cause any action

when this button is disengaged.

V. Machine adjustment

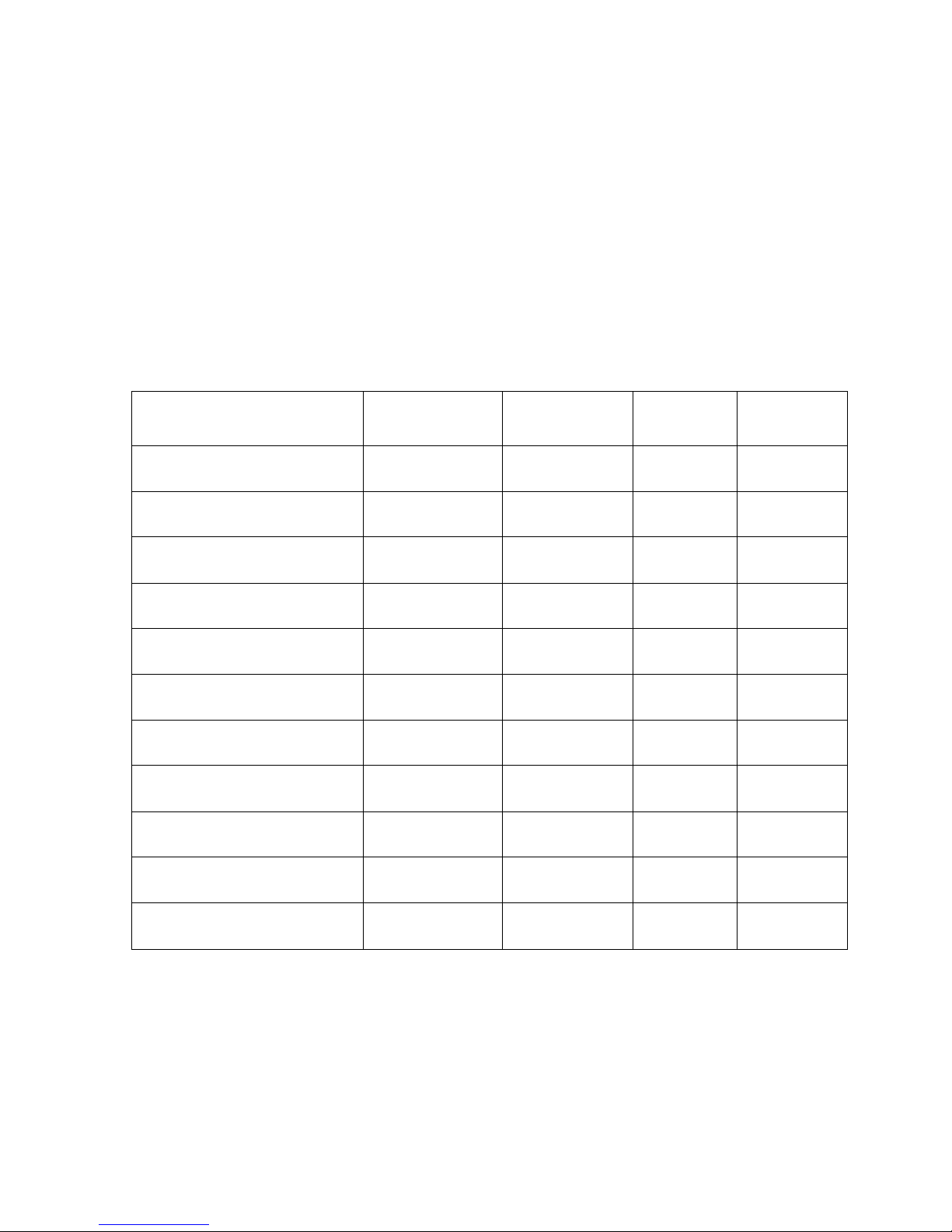

CLEARANCE CHART

Before operation, please use the following formula to calculate & adjust the gap between the punch & die according to

the thickness of the work piece

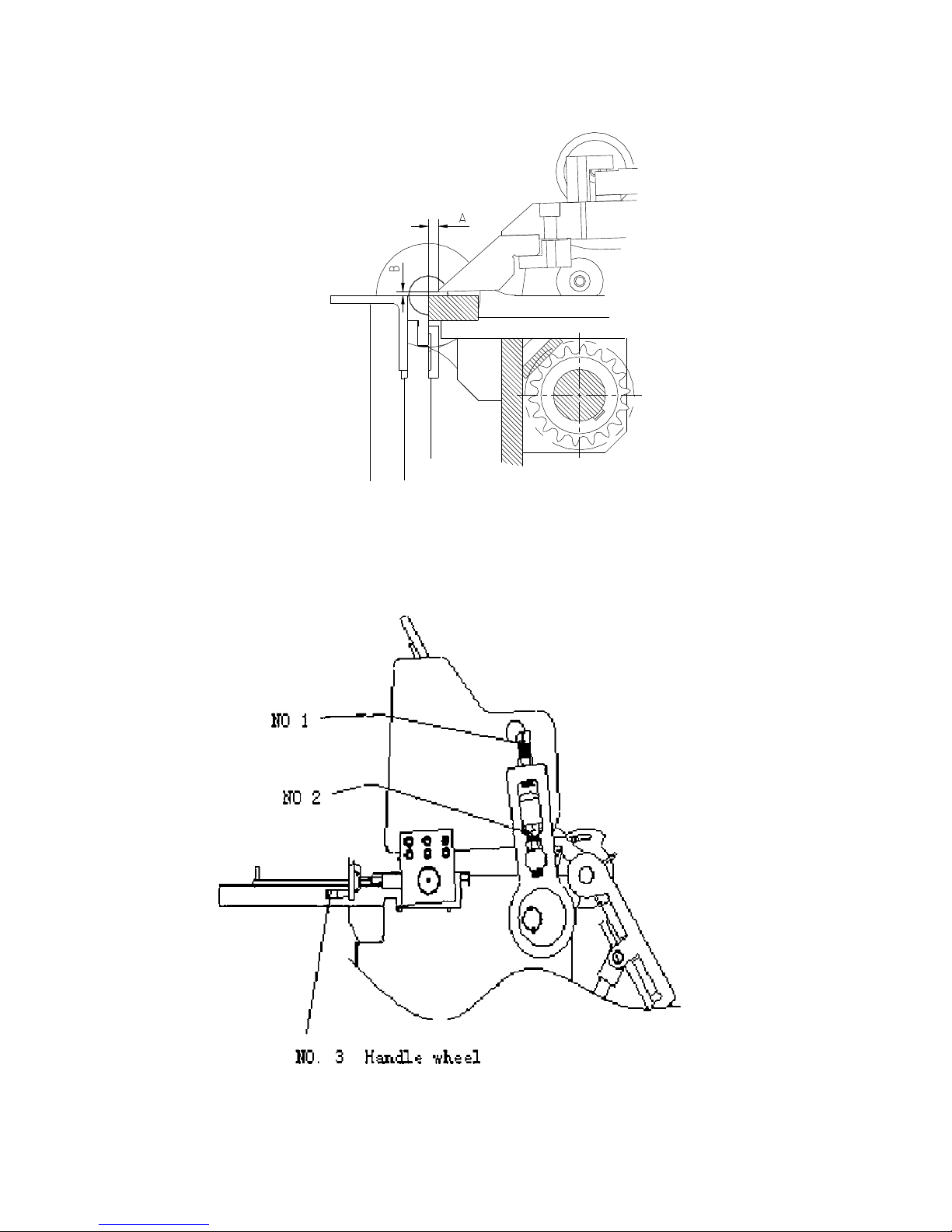

For the following,A=material X2,for example,if you want to process 10Ga. thickness material,the

A=0.137X2=0.274inch

B=thickness of material -0.5~2mm. For example,if the thickness of the material is 2.0mm,the B=1.0mm. If the

thickness of the material is 10Ga, B=0.098” ( 12Ga.)