Herzog A Series Manual

Other Herzog Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

OEM Tools

OEM Tools 87032 Operating instructions and parts manual

Power Fist

Power Fist 8873341 quick start guide

Flofab

Flofab FFWP Series Operation, maintenance & installation manual

Atronix

Atronix 9885110 user manual

PSS

PSS RoadQuake 2 Product guide

EGAmaster

EGAmaster ROSCAMATIC 100-4 operating instructions

Heinzmann

Heinzmann PRIAMOS I Series manual

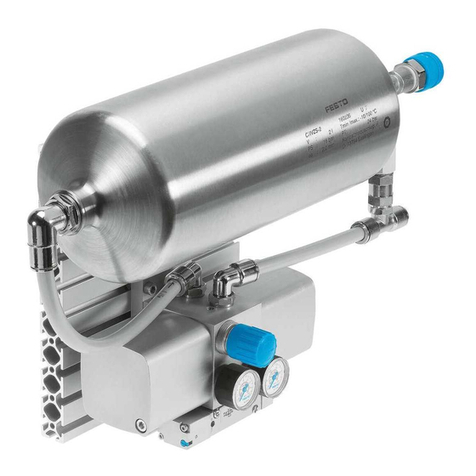

Festo

Festo DPA-***-10-***-CRVZS Series operating instructions

Wilo

Wilo Helix V Installation and operating instructions

Kenet

Kenet R-PRO 25 user manual

Grunbeck

Grunbeck GENO-OSMO-AVRO 125 RU Operation manual

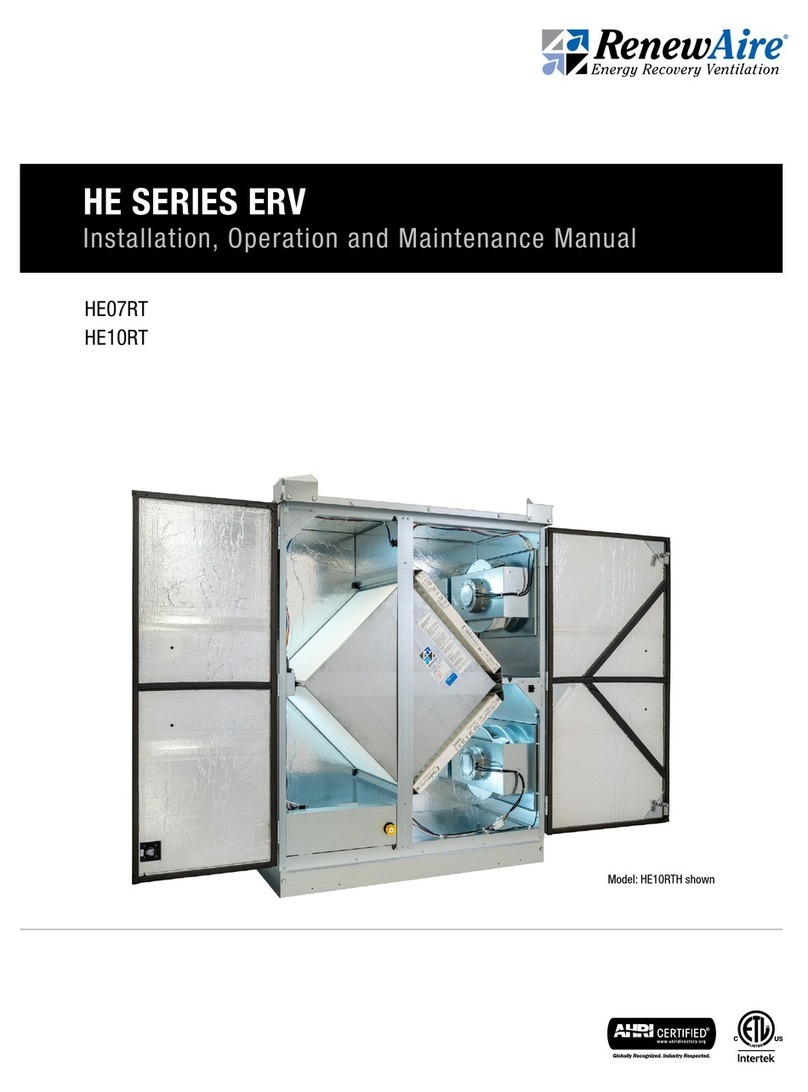

RenewAire

RenewAire HE Series Installation, operation and maintenance manual