DOSEURO®

XMPE0TMA125SST014 2014 EDITION

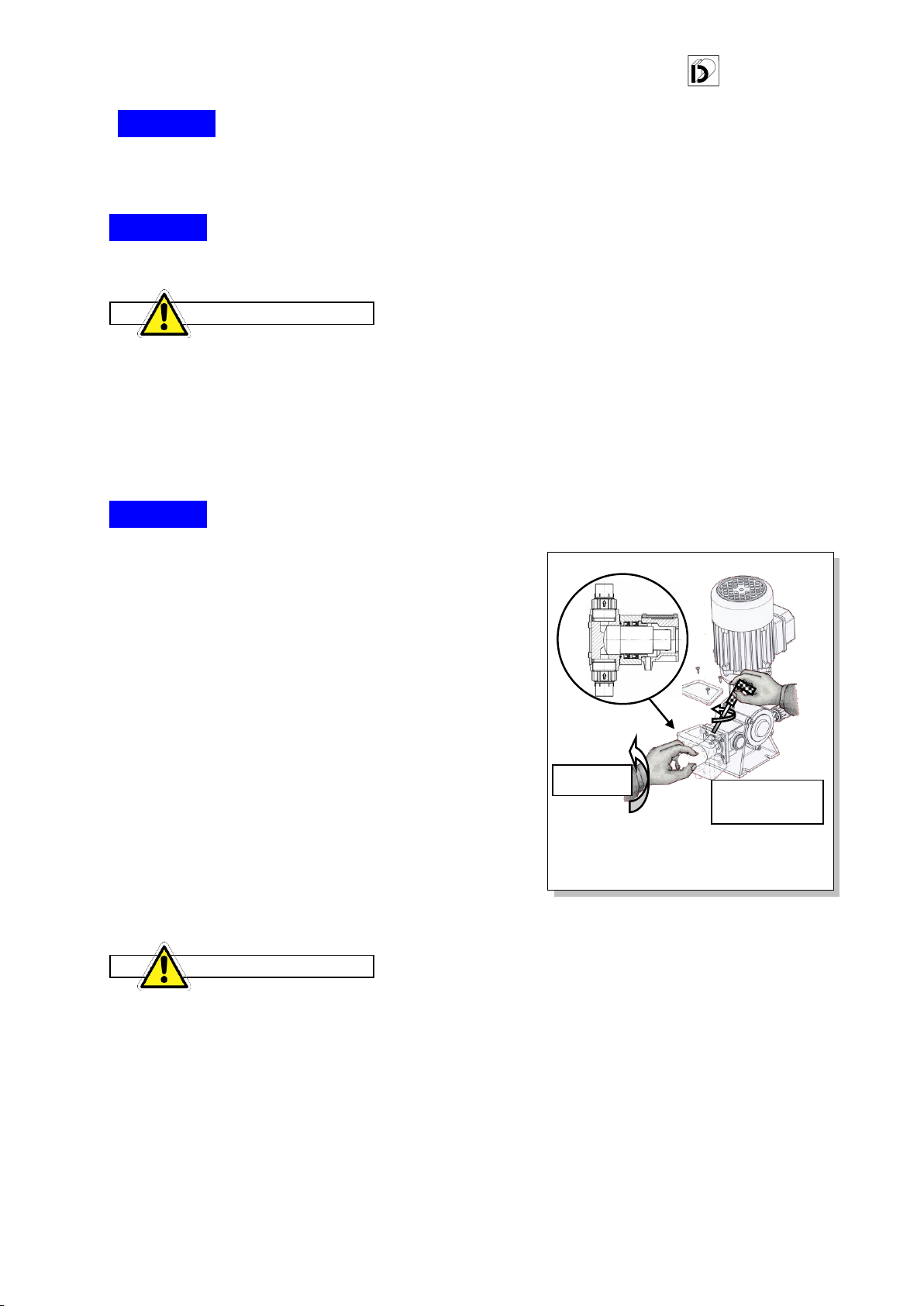

"PTFE" GASKET REPLACEMENT AND ADJUSTMENT

Replacement of gasket pack (execution head 21)

After maintenance, proceed as follows:

Disconnect the pumping head 1from the system and

from the lantern on the metering pump.

Wash the pumping head so that the operator can safely

handle the component.

Loosen the locking ring 11 until completely removed.

Check the plunger for wear 2, and replace it if

scratched or worn. Do this by loosening the dowels 15.

Extract the ruined gasket pack 3, insert the new one

inside the pumping head paying attention to the

orientation direction of the gaskets.

Tighten the locking ring 11 until the gaskets touch,

without tightening further.

Insert the pumping head 1on the plunger, push it up to

the lantern and fix it with the screws 4.

Adjustment and compression of the "PTFE" gaskets

Work as follows to make any adjustments:

Connect the metering pump to the system piping and bring the pressure up to speed.

Acting on locking ring 11, gradually fasten to compress the gaskets making sure there is no

liquid leaking.

The gasket pack control and adjustment operations must be performed periodically. In

executing the adjustment operation, the operator must not excessively fasten the locking ring

in order to preserve the integrity of the gaskets.

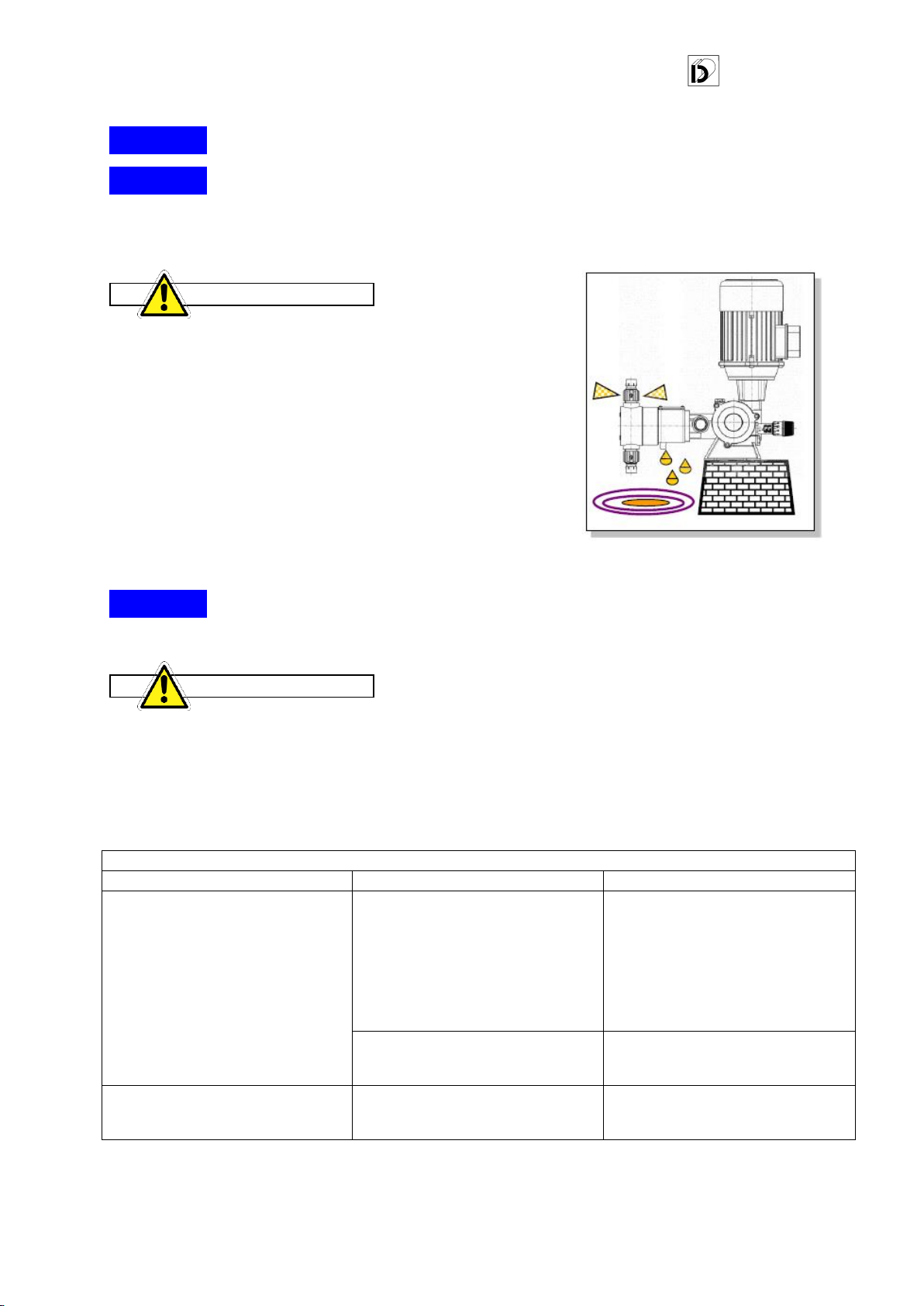

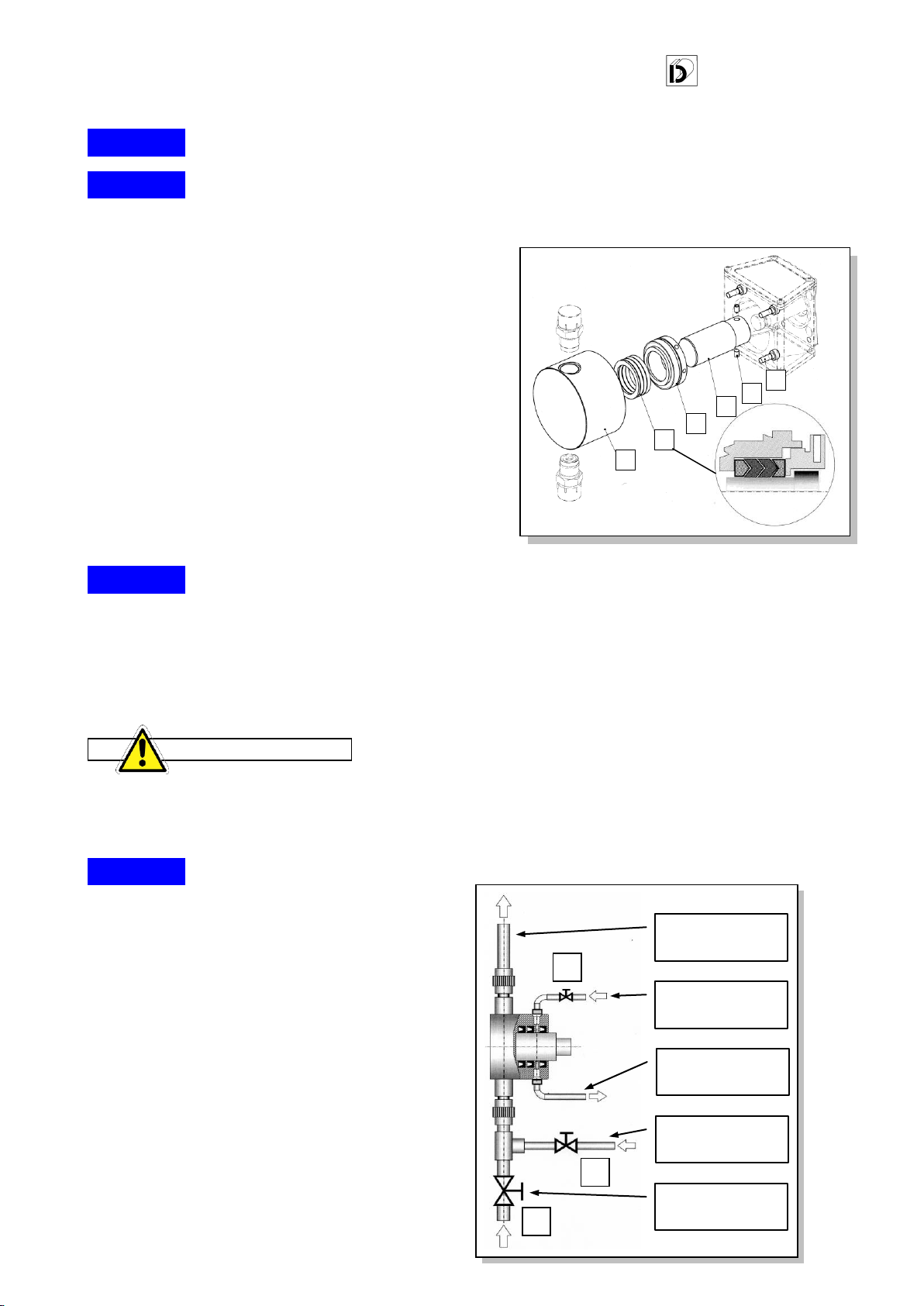

HEAD WITH WASHING

This type of head, that provides for the washing of the

internal parts, is used when the liquid to be dosed can

create abrasion or solidification.

Typical representation of the system to execute

washing.

Washing the seal gaskets

Let the water continuously flow through the area

containing the seal gaskets, with a flow rate of 40/50

l/h, at a pressure of 0.5/1 bar.

It is essential to continuously wash the gaskets as it

helps remove any fouling and stops the product from

solidifying and damaging the seal profiles.

FROM THE WATER

MAINS FOR HEAD

WASHING

FROM THE WATER

MAINS FOR GASKET

WASHING

PIPING FOR

DRAINING

WASHING

DELIVERY PIPING TO

SYSTEM