Contents 3

Contents

1Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

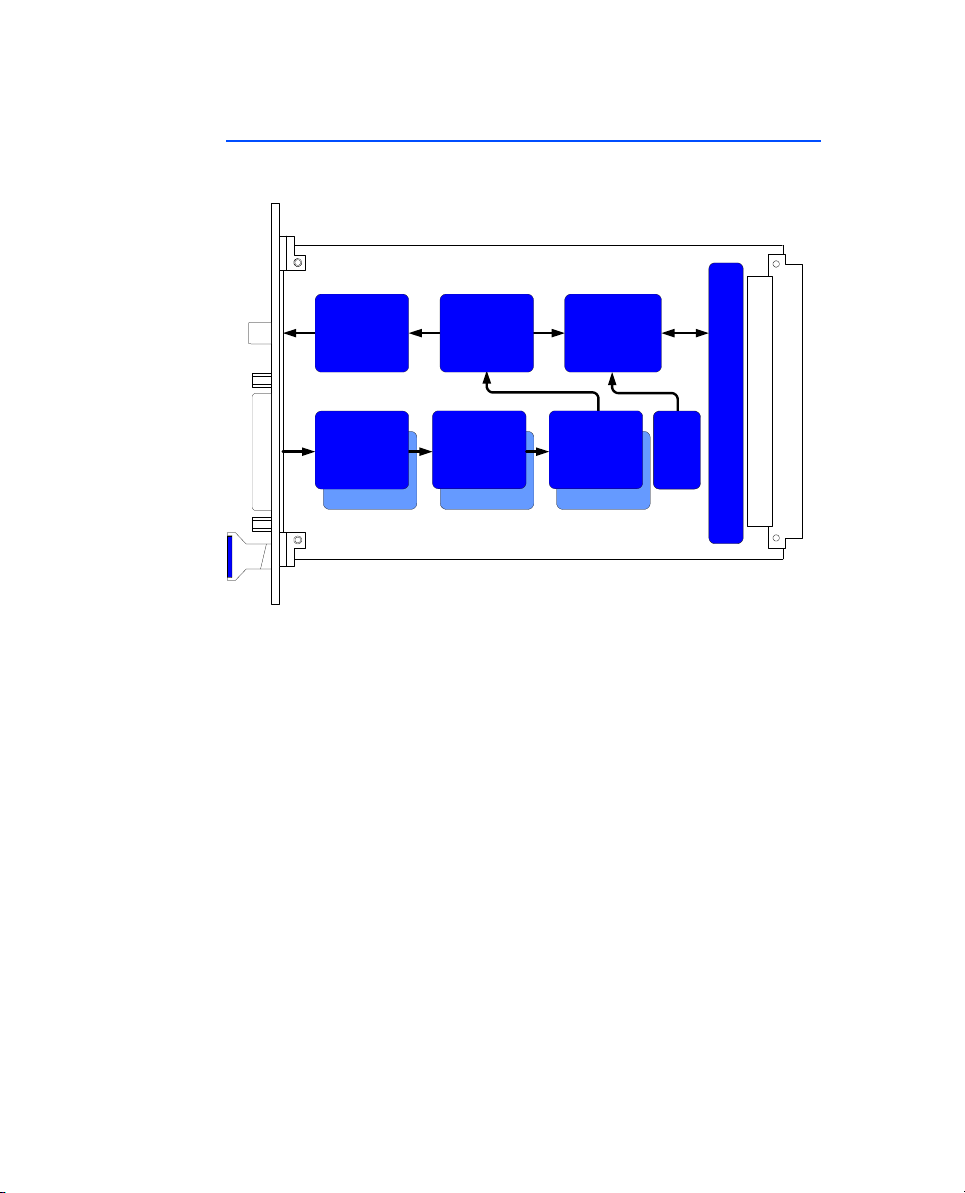

1.3 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Taking the Product Back and Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Signal Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.1 Input Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.2 Electrical Strength and Impedance Converter . . . . . . . . . . . . . . 11

2.1.3 Threshold Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1.4 Ground and Shielding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Synchronization Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3 Angle Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4 Diagnostic Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5 Measurement Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.6 Start of Angle Measuring after Initialization . . . . . . . . . . . . . . . . . . . . . . . 17

3Pin Assignment and Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 “Input 0-19” Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 “DIAG 0-7” Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20