6/9

8. Notice

1) Bias and scale factor drift

Surrounding temperature variation might affect sensor output (bias, scale factor). Sensor should

be mounted where temperature does not vary significantly.

When canceling bias drift, please refer to the following examples.

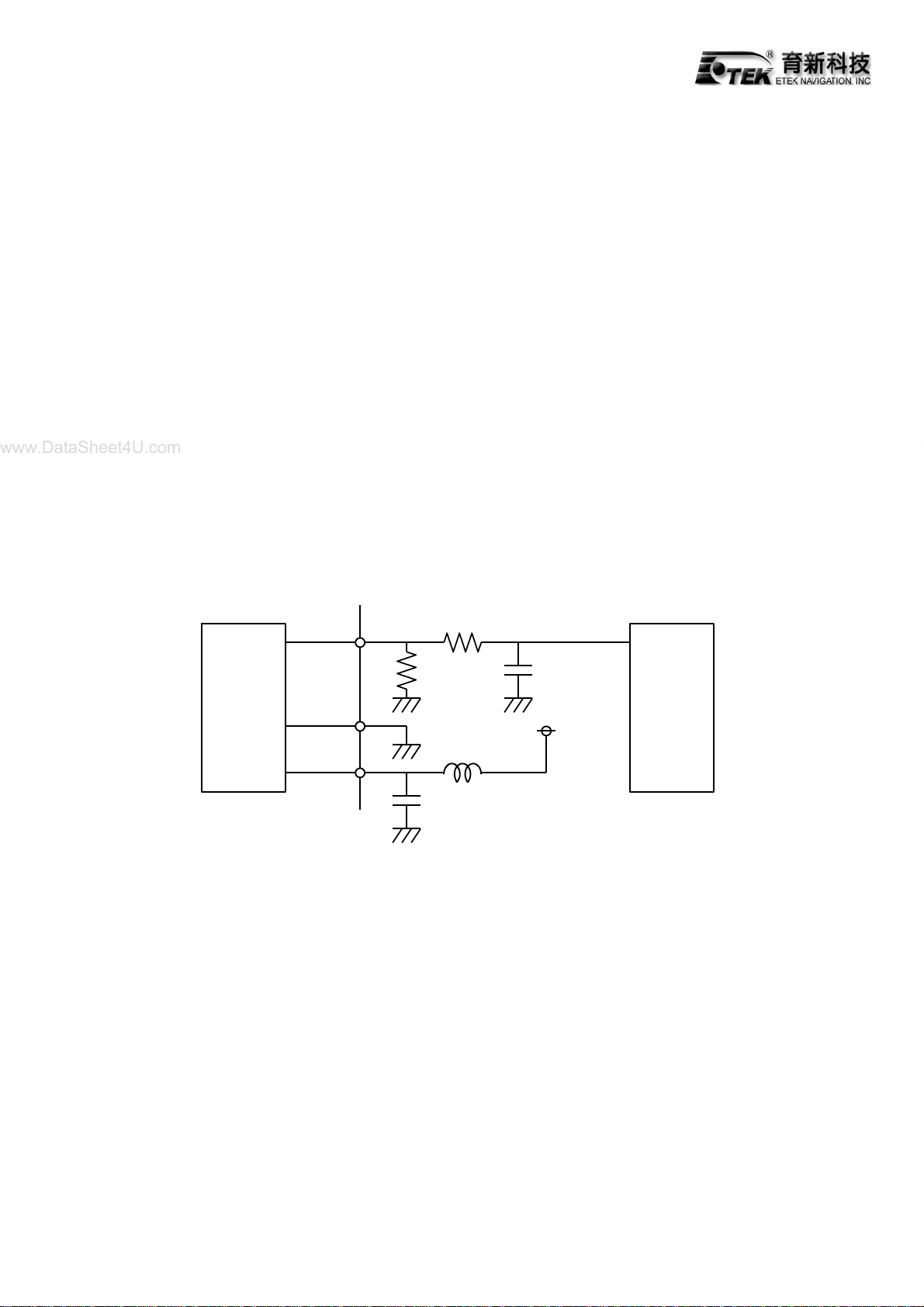

- Cut DC level of output using HPF (Hi-Pass-Filter) with low cut-off frequency on sensor output.

- If bias voltage can be detected just before measurement, replace former bias with it.

( refer to page 8)

2) Gyrostar detects angular velocity. It is possible to derive relative angle variation from integrating

output voltage.

9. Handling

1) Incorrect handling may affect sensor characteristics. Please note the following precautions;

A. Do not subject the sensor to shocks that exceed the rated limit.

B. Do not subject the sensor to a magnetic field exceeding 5000µT (50 G).

C. Do not install or store the sensor in a location in which condensation is likely to form on it.

D. Do not install or store the sensor in a location in which water may splash directly on it.

E. Do not install or store the sensor in a location in which it is likely to be exposed to salt water or

corrosive vapor.

2) Precision electronic parts, such as ICs, are used for the sensor; therefore, it is necessary to take

anti-static measures when handling.

3) Do not wash the sensor, It is not water resistant.

4) Do not remove label.

5) Do not disassemble.