eTORK QuadTork Torque User manual

INSTRUCTIONS

QuadTork Torque Wrenches

with Electronic Digital Display

www.etork.com

TM

R

eTORK

READ BEFORE YOU USE

1. This torque wrench is a precision instrument

intended to be used only to tighten screws, bolts and

nuts to a desired torque. Do not use it as a "nut

breaker", pry bar, or in lieu of a regular ratchet.

2. Do not apply torque in excess of the maximum

capacity of the wrench .

3. Apply load to the grip only , and do not use any

handle extension bars. Any such misuse will result in

inaccurate readings, and it may damage the wrench.

4. Make sure that you adjust the wrench to the exact

torque units your specifications call for, or you will

severely under-torque or over-torque, causing severe

damage to the equipment you are working on.

5. Do not disassemble the wrench for any reason.

Highly stressed internal components may cause

severe injury when released in an unintended manner.

6. The wrench should be re-calibrated periodically . The

calibration of the wrench should be checked at least

once a year, after any abnormal handling or

overloading, or after 10,000 uses.

-2-

7. This torque wrench indicates when the preset torque

has been reached by releasing for a few degrees of free

travel, which is usually accompanied by an audible

"click" signal.

-3-

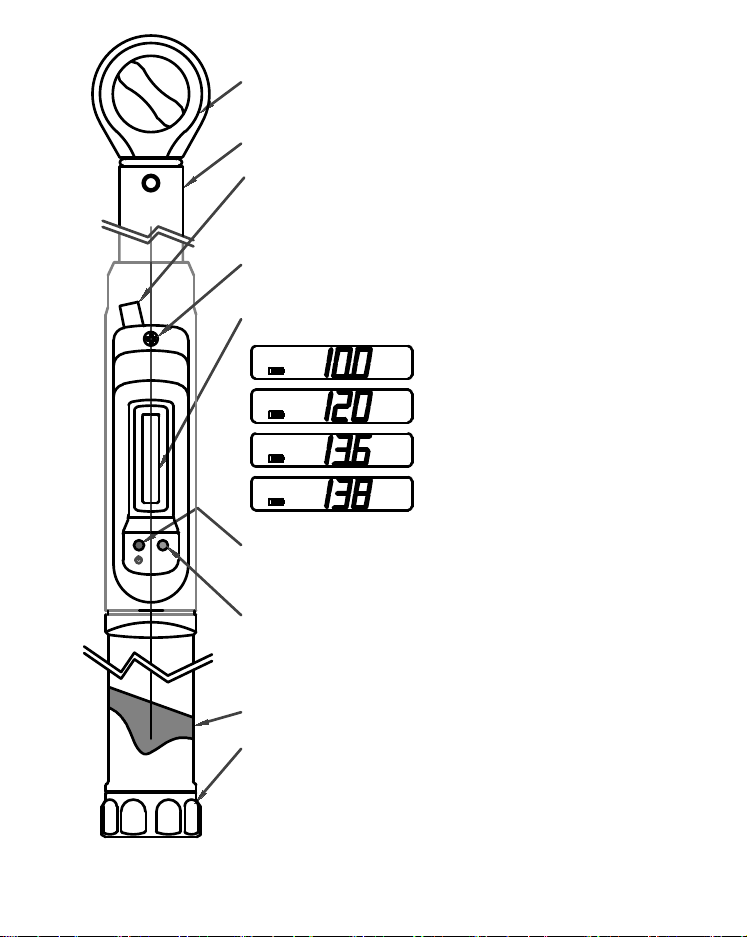

Hardened alloy steel housing

45-tooth reversible ratchet: wrench

torques in both clockwise and

counterclockwise direction

EASY TO READ SCALES:

Ergonomic grip

Torque adjusting knob: Pull out to

unlock, turn clockwise to increase

torque, counterclockwise to decrease

torque. Push back in to lock.

TARGET

ft.lb

TARGET

in.lb

TARGET

N.m

TARGET

kg.cm

Battery compartment (2 X LR44)

Foot Pounds

Inch Pounds

Newton Meters

Kilogram Centimeters

Red Key: Press once to turn ON, press and

hold to turn OFF. Auto Off in 10 minutes.

Green Key. Press to change torque

units, press and hold to turn backlight

ON

Battery isolation plastic tab: Pull out and

discard to engage the battery (New

wrenches only!)

PULL

UNITS

LIGHT

SETTING TORQUE

1. Pull the adjusting knob out.

2. Turn the knob in the clockwise direction to increase

the torque, and in the counterclockwise to decrease it.

WARNING: Be sure that the torque units you have

selected are exactly the same as the torque units

specified by the manufacturer of the equipment you

are working on.

4. Push the adjusting knob in to lock the selected

reading.

-4-

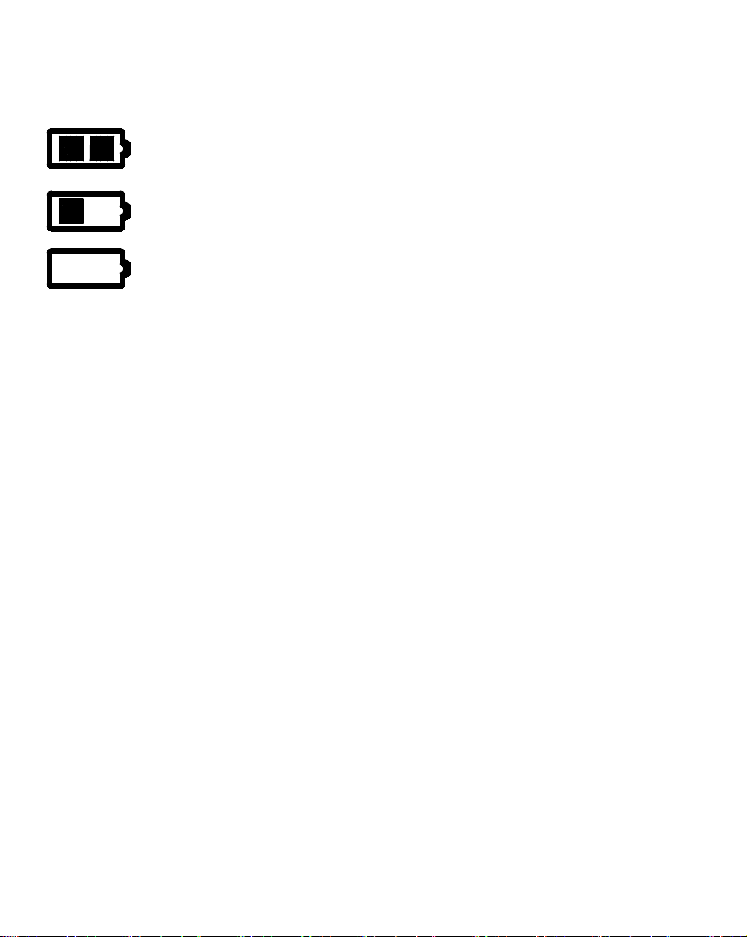

New battery, about 30 hours remaining.

About 10 hours remaining.

Wrench can not operate.Insert two new LR44 or

equivalent (AG13,357,SR44,A76,LR1154)

batteries. Make sure the "-" ends are toward the

spring. To optimize battery life, do not use

backlight, and remove batteries when the wrench

is not used for prolonged periods.

BATTERY STRENGTH INDICATOR

-5-

L

E

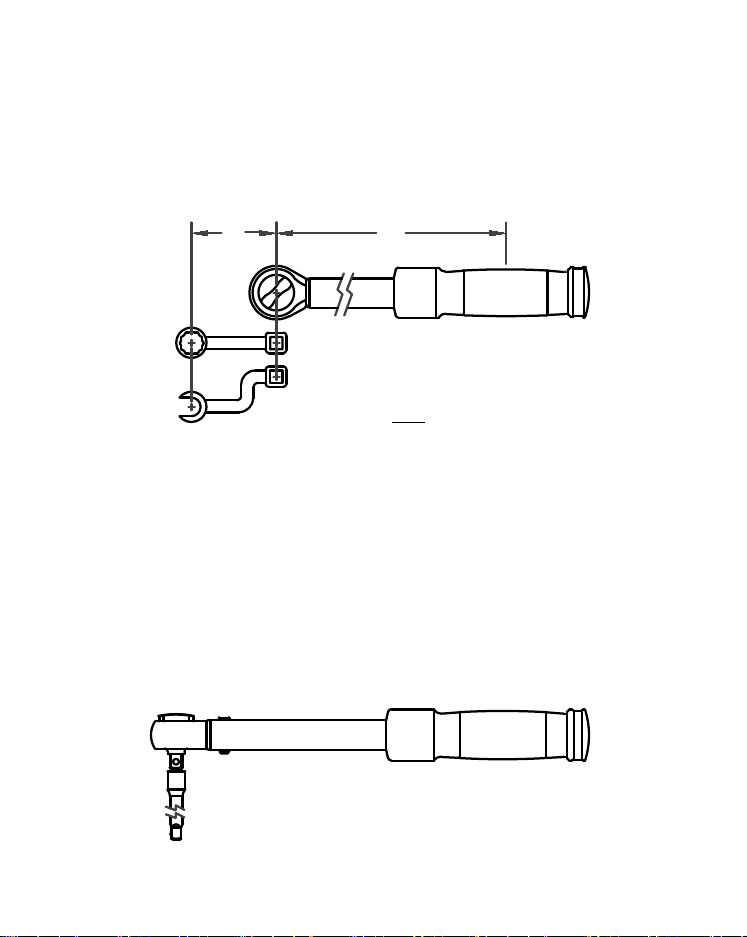

T(E) - Torque applied by

attachment (desired torque)

T(W) - Torque set on the

wrench

T(W) = T(E) L

L+E

USE OF ATTACHMENTS

1. Attachments that put the center of the fastener being

tightened away from the centerline of the ratchet drive, result in

the effective torque being different from the one shown on the

wrench. Consequently, the torque set on the wrench must be

corrected using the formula shown.

2. An attachment as shown below, is a drive extension

which does not affect the torque and no correction is

required. However, be careful when using a long

extension to assure that the extension stays in line with

the drive. You may support a long extension with your

free hand with no measurable affects on the accuracy.

Avoid using universal joints when torqueing unless the

angle of mis-alignment is less than 5 degrees.

APPLYING TORQUE

1. Insert an appropriate socket or drive attachment

onto the square drive of the ratchet and onto the

fastener you want to tighten.

2. Apply hand pressure to the grip, and ONLY TO THE

GRIP. You may support the wrench at the ratchet head

with the other hand to steady it, especially when using

long socket extensions, without appreciably affecting

the accuracy of the wrench.

3. If, due to the required effort, you need to use both

hands, put the other hand on the top of the first hand,

never on any other part of the wrench.

4. Apply slow and steady pull or push until the wrench

momentarily releases, with or without a distinct "click"

sound. Release the pressure right at this point. DO

NOT OVERTORQUE!

SAFETY WARNING

Overtorqued or defective fasteners, sockets, as well as

the wrench itself, may suddenly break causing you to

lose balance, fall, or to suffer other trauma. Be sure

that you have firm footing, are properly balanced, and

if necessary are using appropriate harness, back

support, or other safety device.

-6-

MAINTANANCE

1. When not in use, adjust the wrench to its lowest

reading and store it in the provided case.

2. With the exception of the ratchet mechanism, do not

lubricate the wrench. The ratchet mechanism may be

lubricated as needed with a few drops of light machine

oil.

4. Do not use acetone or other solvents to clean the

wrench, use window cleaners or denatured alcohol

applied with a clean cloth instead.

5. With the exception of the ratchet mechanism, there

are no user-serviceable parts. For repair and/or

re-calibration information, call 1-678-439-8782

LIFETIME WARRANTY

The manufacturer warrants this product against

defects in material and workmanship except for

re-calibration and for damage resulting from

over-torquing and other abuse. Calibration is

guaranteed for a period of one year from the date of

purchase. This warranty excludes incidental and

consequential damages, except as might be

specifically required by law in some states. For

warranty work, contact us at www.etork.com

-7-

-8-

OWNER'S INFORMATION

Date Purchased: ___________________________

Place Purchased: ___________________________

Serial Number: ___________________________

NOTES and SERVICE RECORD:

CERTIFICATION

This torque wrench is certified to have been calibrated

prior to shipment to the accuracy of +/- 3% in the

clockwise direction, and +/- 6% in the counterclockwise

direction

Copyright 2019-05-07

Table of contents