PRODUCT

P 1/ 9

Model No.

Description

CONCEPT AND MAIN APPLICATIONS

BJS100, BJS101

Cordless Metal Shears 1.0mm (20Ga)

Specification

Standard equipment

Optional accessories

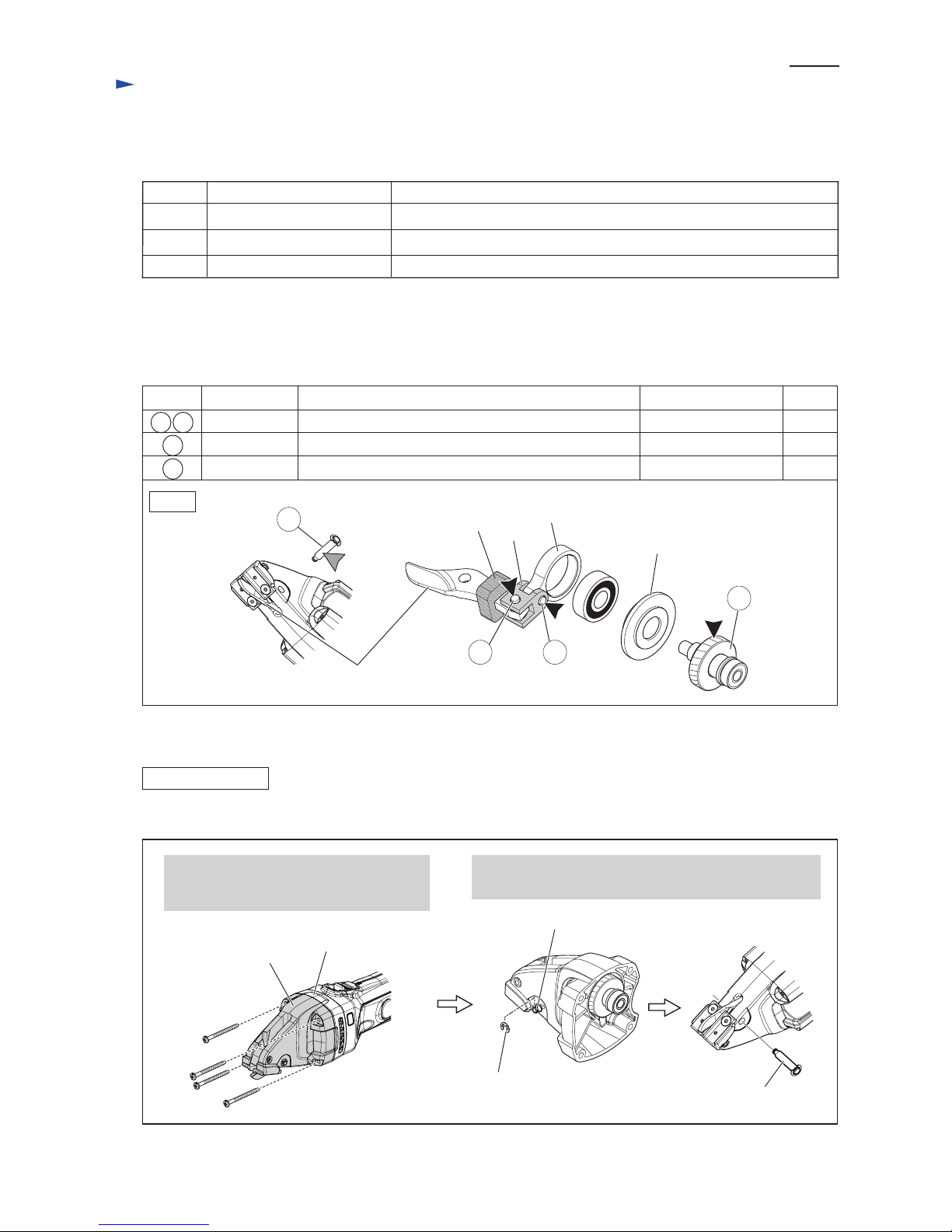

Center blade

Side blade (L)

Side blade (R)

Charger DC18SD

Charger DC18SE (for automobile cigarette lighter socket)

Charger DC24SC

Battery BL1430 (for BJS100 only)

Battery BL1830 (for BJS101 only)

Fast charger DC18RA

Note: The standard equipment for the tool shown above may vary by country.

Hex wrench 3 .................................... 1

These products are available in the following variations.

All models also include the accessories listed below in "Standard equipment".

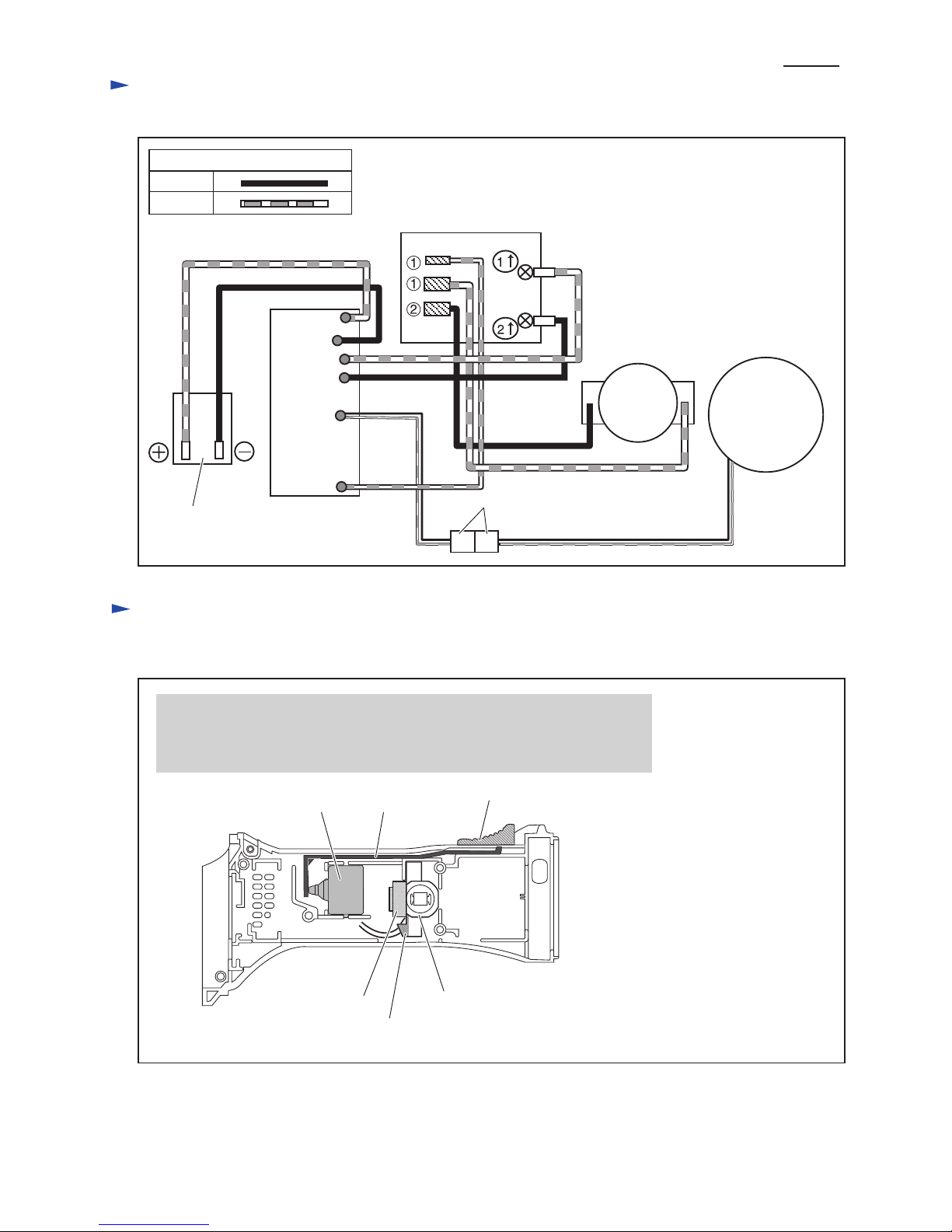

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 364 (14-3/8)

78 (3-1/16)

103 (4-1/16) 118 (4-5/8)

BJS100 BJS101

BJS101

Models BJS100 and BJS101 have been developed as sister models of

cordless straight shears BJS160 and BJS161.

BJS100 is powered by 14.4V/3.0Ah Li-ion battery BL1430, and BJS101

is powered by 18V/3.0Ah Li-ion battery BL1830.

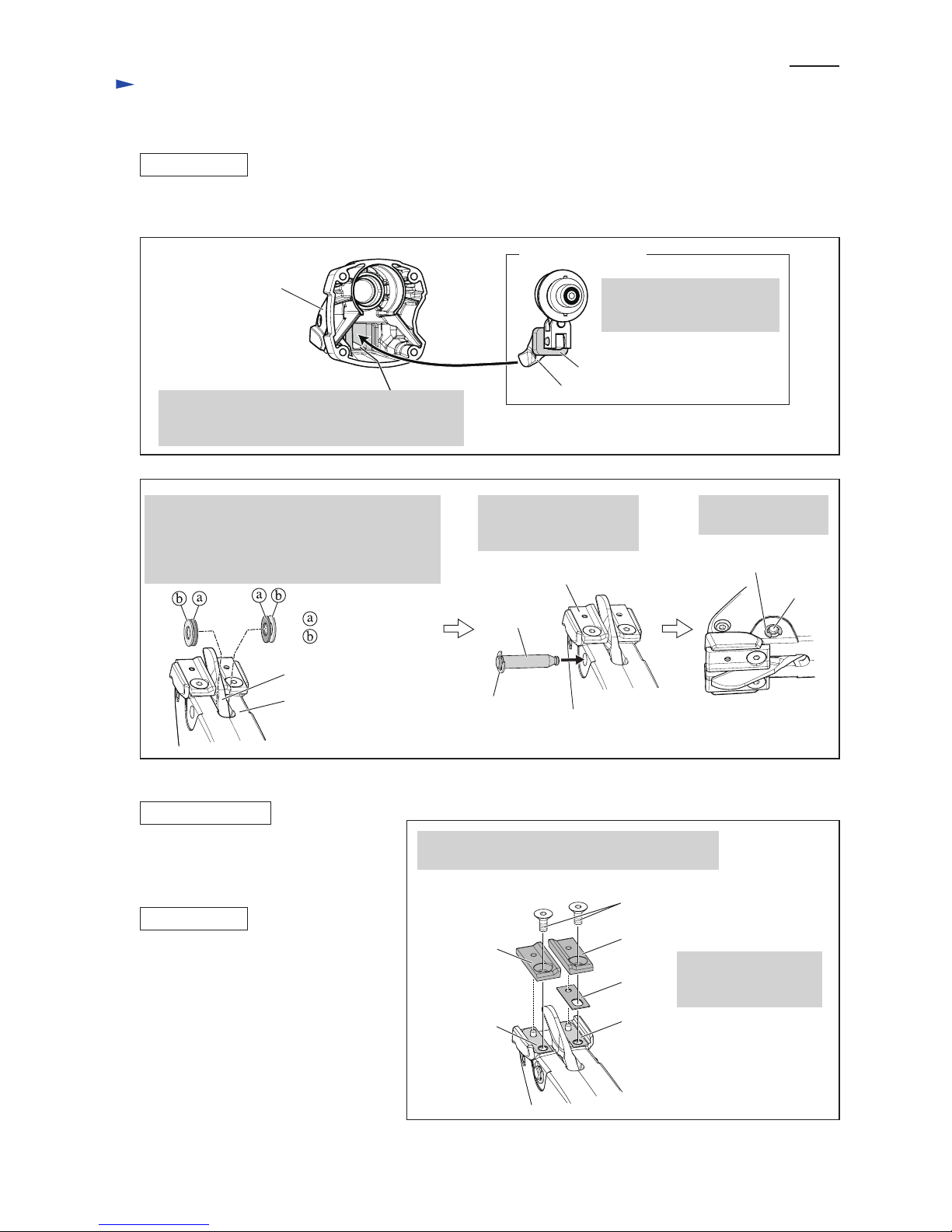

Ability to cut curves with minimum cutting radius of 30mm (1-3/16”) is

obtained by mounting the blades of Model JS1670 on BJS160/ BJS161.

Note: 1.3Ah Li-ion battery BL1415/ BL1815 cannot be used for BJS100/ BJS101.

*Weight according to EPTA-Procedure 01/2003, including battery

Battery

Max cutting capacities:

mm (Ga)

Steel with tensile strength

up to 600N/mm2

Cell

Voltage: V

Capacity: Ah

Li-ion

14.4 18

3.0

Net weight*: kg (lbs) 1.9 (4.2) 2.0 (4.4)

0.7 (23)

Aluminum with tensile

strength up to 200N/mm22.5 (12)

Steel with tensile strength

up to 400N/mm21.0 (20)

No load speed: min-1=spm (strokes per minute) 4,300

Max output (W)

Minimum cutting radius: mm (") 30 (1-3/16)

Overload protection by current limiter Yes

280 350

Specification Model BJS100 BJS101

22 with DC18RACharging time (approx.): min.

BJS100RFE

BJS100Z

BJS100

Model No. Offered to

All countries

Mexico, Panama

All countries except the two listed above

BL1430

(Li-ion 3.0Ah) DC18RA

No No No

type quantity Charger

Yes

No

Plastic

carrying case

2 1

Battery Battery

cover

BJS101RFE

BJS101Z

BJS101

Model No. Offered to

All countries

Mexico, Panama

All countries except the two listed above

BL1830

(Li-ion 3.0Ah) DC18RA

No No No

type quantity Charger

Yes

No

Plastic

carrying case

2 1

Battery Battery

cover

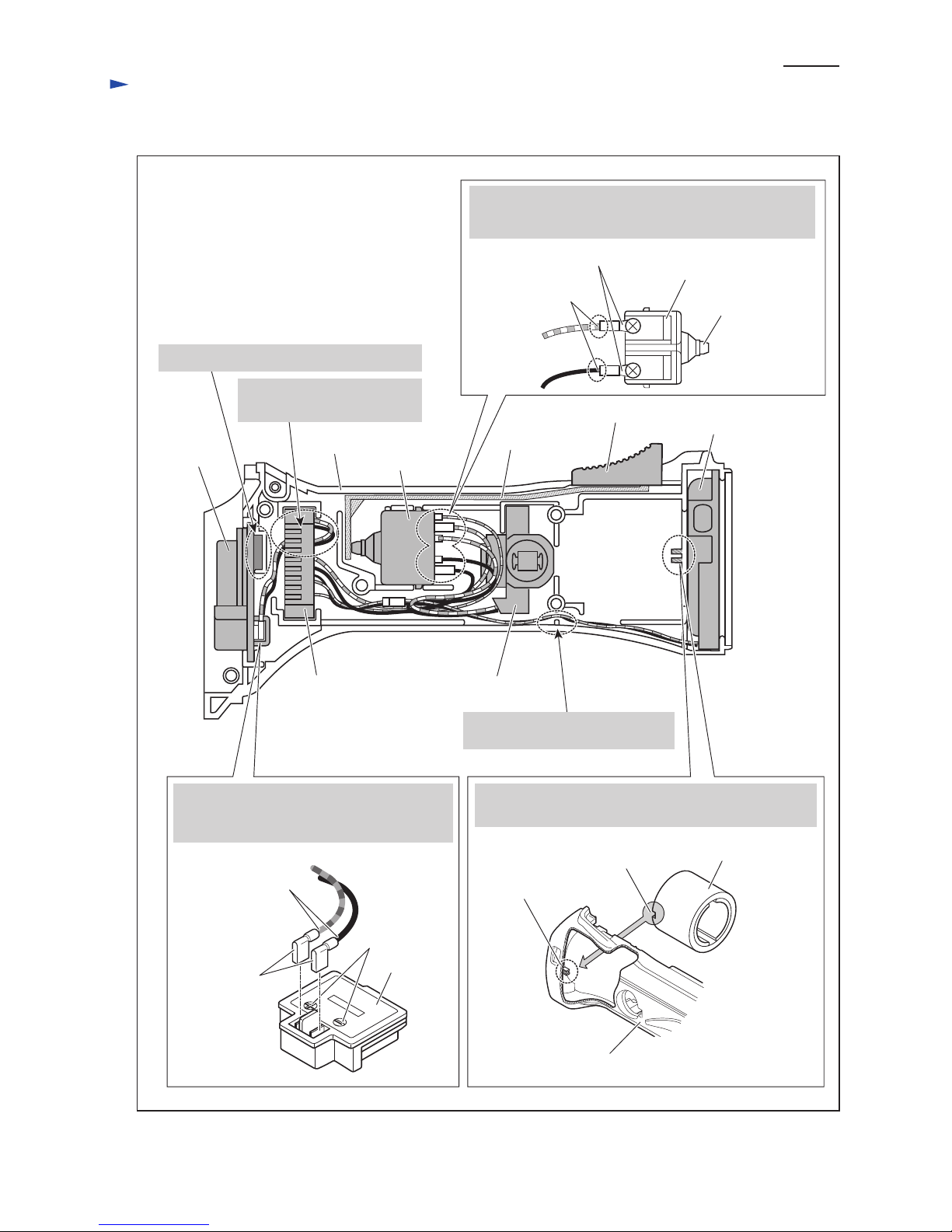

BJS100

BJS101

T

ECHNICAL INFORMATION

L

H

W

BJS100