4

Product Features:

Product functions:

1.Convenience resistance:

1)Material lightweight, convenient for handheld.

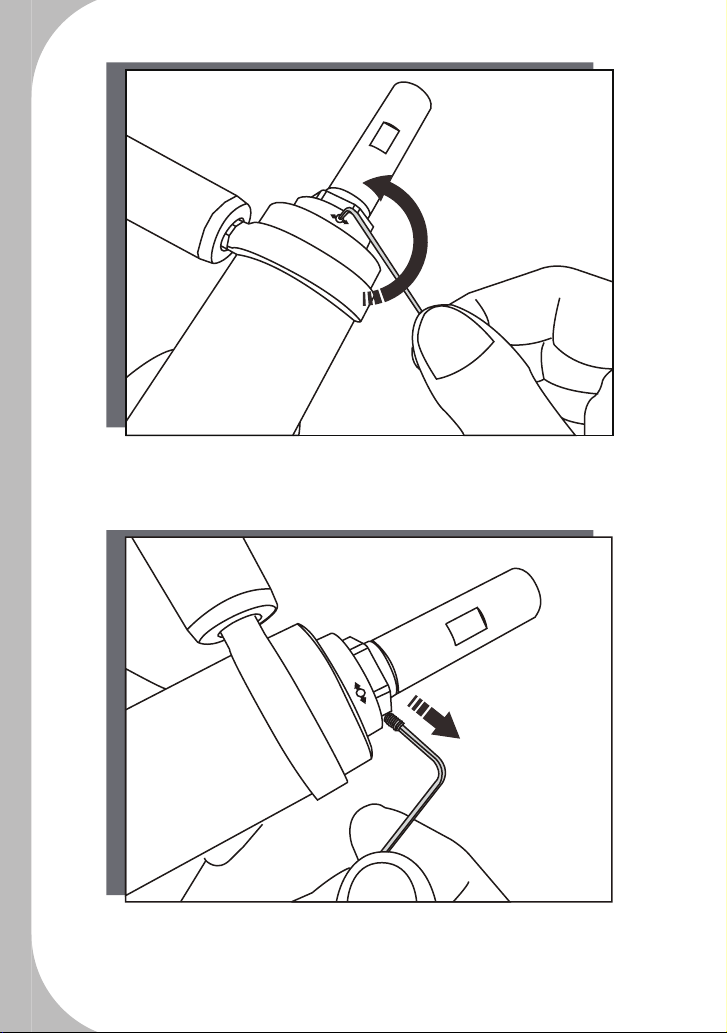

2)Auxiliary handle can be rotated 360 degrees.

2.Economy attribute:

1)Not electrical kind motor consumable part, lower cost.

2)Consumption replacement parts only or fixed collet maintenance.

3)the adding of pneumatic lubricants depends to the working environment conditions.

3.Safety devices:

1)Adjustable torque can be reduced to the minimum --- 5 N / m.

2)Maximum torque can be increased to 125 --- N / m. adjustable

3)Floating design --- wire-tapping exits to prevent repeated tapping.

4)Not leakage, do not cause high temperature; Chemical Factory available.

1)Fuselage with knobs, adjustable air pressure and air volume size.

2)Separation type of rotary, reverse rotary button.

3)Auxiliary handle can be adjusted steeples 360 degrees.

4)Adjust torque output is divided into 12 sections, precise positioning. (5 to 85 N / m)

5)Tapping exit, drive shaft Heart flexible, avoid duplication tapping.

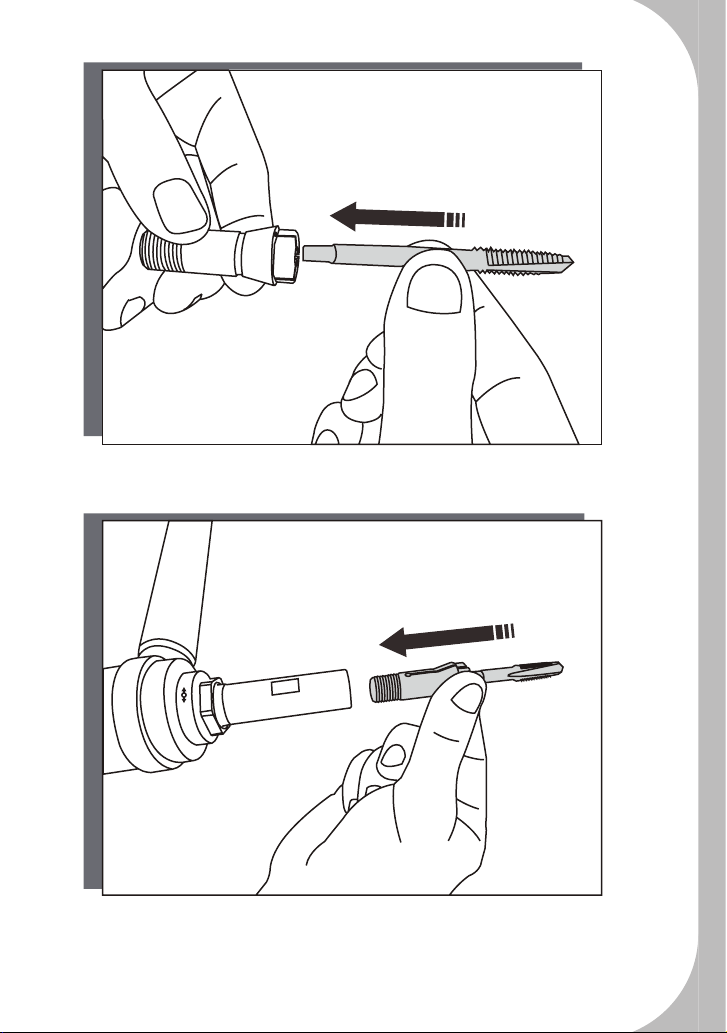

6)Collet chuck can be replaced independently, saving Consumption costs.

Product components:

1)Tapping machine body ------------ 1 set.

2)Auxiliary handle --------------- 1 set.

3)Tapping Collet chuck --------------- 7 (T4 to T8.5).

4)Torque regulator ------------ 1.

5)An open-head wrench. ---------------1(14 mm)

6)An open-head wrench. ---------------1(17 mm)

7)Hex spanner --------------- 1. (1.27 mm)

8)Optional accessories --------------- tapping M3 to M12.