Eumig Automatic P8 User manual

eUumid

Pê

automatic

CONTENTS

If

is

always

a

great

event.

Ee

EE

Ee

N

Ee se eN

ee

6

Before

connecting

your

projector

ta

the

mains

ss

7

Automatic

threading

of

the

film

.

.

ii EE

EE EE EE

SE

Es EE

N

Ee

10

Threading

by

hand

.

.

isi

Ek

EER

FEE HER

WEN

WEE

WEN

EES

Gee

ge

TE

Projéelior!

ew

EER VEN

REK

;

EE

EER

HER

RE

HOE

Ed WO

EVER,

BEE WER EES

13

Visible

reverse

projeelien

.

.

sie

Es Ee

Eg

EE

Ke

ei oa WE

EGE

BEK EER

14

Es

AE

N

N

DE

EE

T4

Rewiridig

Gie

EE

EE

ls

HER

GR

GEE

WE

WER

WE

NEG

ORE

SR

GER WEE

HE

15

Care

and

maintenance

of

the

P

BAUTOMATIC

. .

ie

Es

ER

GE

Ee

de

ei

Té

The

Birthplace

of

the

EUMIG

P 8

AUTOMATIC

.

.

ie

Ee

ESE

EG

Ke

18

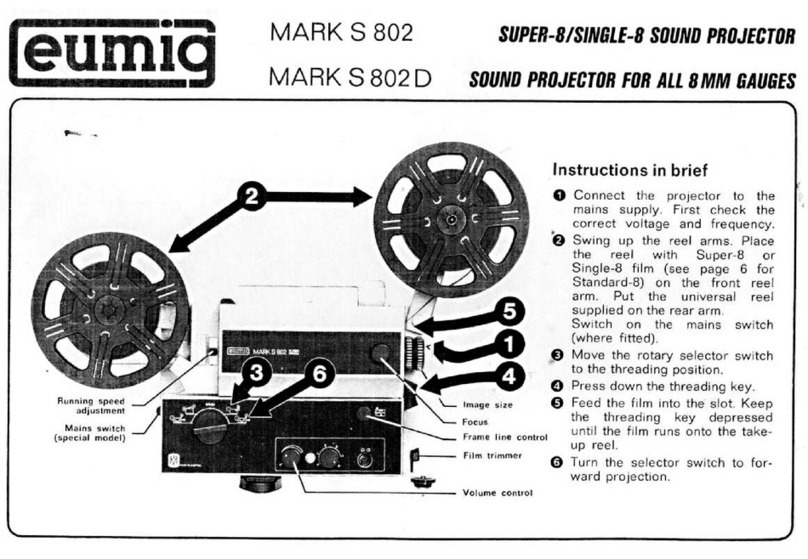

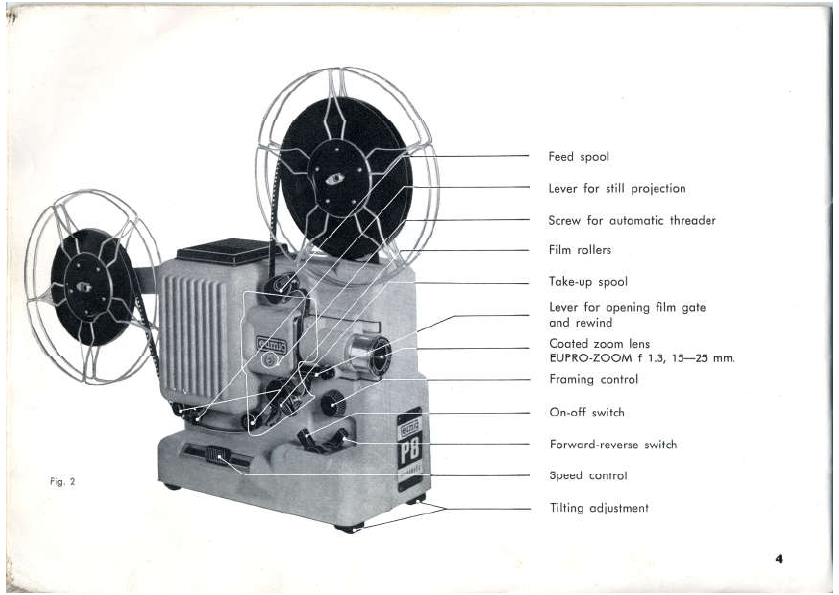

Feed

spool

Lever

for

still

projectien

Screw

for

nutomatic

threader

Film

rollers

Take-up

spool

Lever

for

opening

film

gate

and

rewind

Coated

zoom

lens

EUPRO-ZOOM

f

1.3,

15—25

mm.

Framing

control

On-off

switch

Forward-reverse

switch

Speed

control

Tilting

adjustment

Lamp

house

Feed

spool

arm

Take-up

spool

arm

Carryina

handle

Locking

serew

Voltage

selector

Knob

for

manual

operation

of

projector

mechanism

Mains

connection

Socket

for

table

lamp

Earth

sorket

lt is

always

a

great

event

for

you,

your

family

and

your

guests

when

you

show

your

films

and

bring

He

happy

past

back

ta

life

on

the

screen.

You

are

now

fhe

fortumate

owner

of

a

EUMIG

P B

AUTOMATIC,

the

ideal

projector

for

the

job,

as

it

has

everything

necessary

for

the

perfect

proiection

of

your

valuable

films,

and

possesses

many

eX-

cellent

features.

The

EUMIG

P 8

AUTOMATIC

has

a

special

automatic

threading

mechanism.

Threading

Hhe

film

in

the

projector

is

therefore

completely

trouble-free,

necessitating

only

a

few

simple

mavements.

The

EUMIG

P

8

AUTOMATIC

uses

a

low-voltage

lamp

and

gives

exceedingly

bright

illumination

—

in

the

same

way

os

a car

headlamp.

EUMIG

was

the

first

firm

to

use

this

principle

in

8

mm.

projectors

and

it

has

proved

its

value

a.

thousand

times

over,

The

EUMIG

P

8

AUTOMATIC

is

eguipped

with

a

spe-

cially

designed

optical

system,

which,

in

combina-

tion

with

the

superior

all-caated

zoom

lens

EUPRO-

ZOOM

$

13,

15—?25

mm,

transmits

exctraordinarily

large

and

vividly

brilliant

pictures.

With

this

lens,

the

size

of

He

sereen

picture

can

be

changed

at

will.

Thanks

to

its

high-preeisien

film

transport

medha-

nism,

the

EUMIG

P 8

AUTOMATIC

gives

outstand-

ing

freedom

from

flicdker

and

maximum

protection

for

your

films.

In

spite

of

its

small

size,

the

EUMIG

P B

AUTO-

MATIC

can

take

400

#t.

spools

without

having

to

be

mounted

on a

special

base.

The

EUMIG

P 8

AUTOMATIC

is

simple

and

almost

fool-proof

in

operation.

Even

if

the

controls

are

wrongly

actuated,

it

is

almost

impossible

to

damage

the

proiector,

but

we

would

ask

you

to

read

the

follawing

instructions

carefully

all

the

same.

Yaur

EUMIG

P

8

AUTOMATIC

will

repay

this

study

with

trouble-free

running.

Fig.

4

Fig.

3

Before

connecting

your

projector

to

the

mains

please

refer

to

your

electricity

meter

to

check

up

on

your

mains

supply.

The

EUMIG

P B

AUTOMATIC

will

operate

only

on

10—220

volt

(T10—240

volt)

A.C.

(50—&0

eydles).

The

voltage

selector

A

(Fig.

4)

above

the

mains

socket

is

nor

mally

set

to

220

volts.

If

you

da

not

have

220

volt

current,

vou

must

adjust

the

voltage

selector

by

turning

if

until

the

correct

voltage

is

opposite

the

white

dot.

Before

you

raset

the

vol-

tage

selector,

vou

must

disconnect

the

mains

lead.

Now

swing

out

he

two

spool

arms

(Fig.5)

—

the

drive

belts

al-

ways

remain

in

position.

You

tan

now

connect

the

P

B

AUTOMATIC

to

the

mains

by

inserting

the

female

plug

of

the

mains

lead

supplied

inte

socket

B

(Fig.4|.

Please

notice

the

connection

for

room

lighting

(C,

Fig.

4).

We

suggest

that

you

tonmmert

a

table

lamp

or

small

standard

lamp

to

sorket

€.

The

lamp

gees

out

automatically

when

the

projector

is

switched

on

and

comes

on

again

when

the projector

is

switdhed

off.

FT

Fig.

$

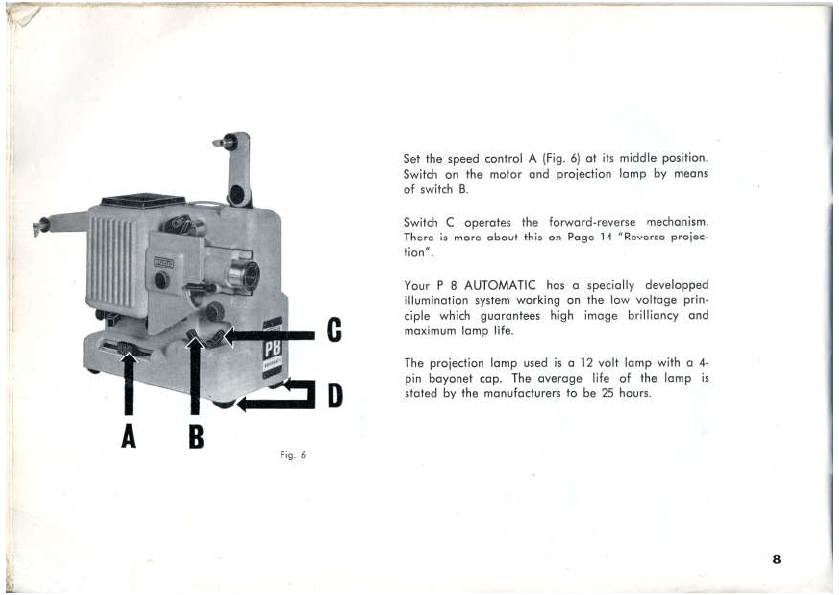

Set

the

speed

control

A

(Fig.

8)

at

its

middle

position.

Switch

on

the

metor

and

proiectien

lamp

by

means

of

switch

B.

Switch

C

operates

the

forward-reverse

mechanism.

There

is

more

about

fhis

on

Page

14 "Reverse

proiee-

ton”.

Your

P B

AUTOMATIC

has

a

sperially

developped

illumination

system

working

on

the

law

voltage

prin-

ciple

which guarantees

high

image

brillianey

and

maximum

lamp

life.

The

projection

lamp

used

is

a 12

volt

lamp

with

a

4-

pin

bayonet

tap.

The

average

life

of

the

lamp

is

stated

by

the

manufacturers

ta

be

25

hours.

To

replace

the

lamp,

open

the

lamp

house

as

shown

in

Fig.

7,

turn

the

lamp

slightly,

and

pull

it

out.

CAUTION:

The

lamp

will

be

hof

after

projiection!

Insert

the

new

lamp

by

pressing

down

slightly

and

turning

in

a

clockwise

diree-

tion.

Replace

the

lid

of

fhe

lamp

house

(Fig.

B).

It

is

not

necessary

to

centre

Hhe

projection

lamp, as

these

special

lamps

are

pre-centred,

that

is,

the

position

of

the

light

point

in

relation

to

the

cap

has

already

been

set

with

great

accuracy

by

Hhe

makers.

The

two

serew

feet

D

(Fig.

é)

are

for

tiling

the

projeetor.

In

order

to

comply

wifh

regulations

in

various

countries

regarding

the

earthing

of

electrical

appliances,

the

P 8

AUTOMATIC

is

provided

with

an

earth

sodel

(Page

5,

Fig.

3.

Fig.

7

Fig.

B

Fig.%

Fin.

10

Automatic

threading

of

the

film

Having

trained

your

P

8

AUTOMATIC

on

the

screen

and

set

the

projector

to

the

correct

height,

you tan

proceed

to

thread

the

film.

An

error-free

functioning

of

the

automatic

fhreader

is

only

then

guaranteed

when

the

film

end

has

been

properly

prepared,

that

is,

trimmed

in

the

correct

way.

Fig.

9

shows

how

the

correctly

trimmed

film

end

should

look

like.

Take

goed

care

that

the

perforatien

A

is

not

damaged

by

the

trimming.

NOTE:

For

the

preservation

of

yeur

valuable

film

we

recommend

the

splicing

on

of

a long

leader.

As, for

a

perfect

functioning

of

the

automatic

Hhreader

it is

essential

to

have

an

absolutely

straight

end

to

the

film,

creased

or

half-tarn

film

ends

must

be

cut

off

or

made

perfectly

smooth.

After

having

put

the

feed

spool

on

the

front

arm

—

with

the

per-

foratfions

on

the

right,

laaking

towards

the

sereen

from

behind

the

projector

—

set

lever

€

on

point

D

and

the

speed

control

to

its

middle

position.

Switdh

on

fhe

projecter

by

means

of switch

E

(switch

F

must

be

set

to

"forward"

and

the

lever

for

still

projection

should

NOT

be

on

“still

projecfien”,

sea

Fig.

10).

With

the

meter

running,

he

end

of

the

film

is

slid

between

the

stamped

rib

and

the

feed

sprocket.

From

this

moment

onward,

the

automatic

threader

takes

charge

of

all

further

film

manipulation.

In

case

if

was

for-

goten

to

set

lever

C

to

the

correct

pasitian

and

fhe

film

has

al-

ready

engaged

in

Hhe

automatic

threader,

all

that

is

necessary

is

to

switch

fo

“reverse”

(see

“Reverse

projection"”

on

Page

14).

The

film

then

disengages

from

the

automatic

mechanism.

After

having

set

lever

C

to

point

D,

the

film

may

be

re-inserted

in

Hhe

automatic

thraader,

10

11

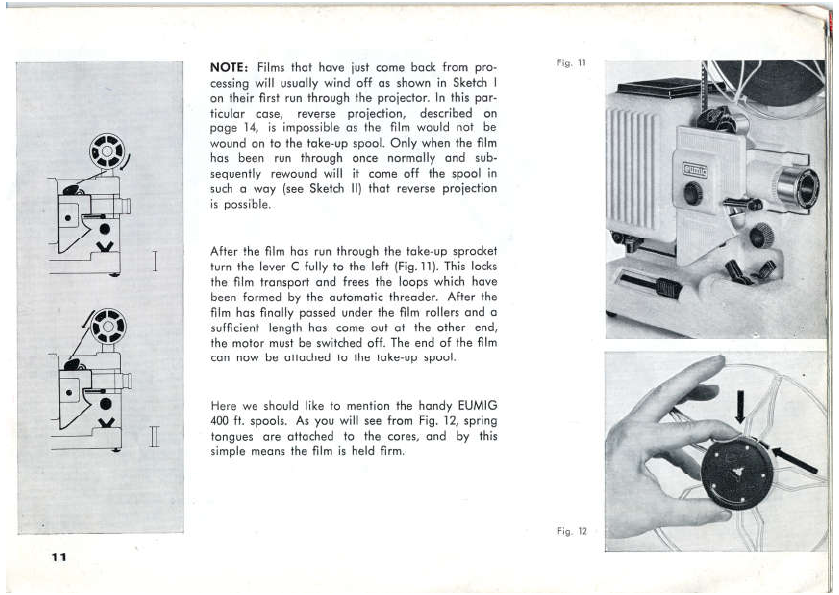

NOTE:

Films

Hhat

have

just

come

back

from

pro-

cessing

will

usually

wind

off

as

shown

in

Sketch

|

on

their

first

run

through

the

projector.

In

this

par-

ticular

case,

reverse

prajection,

described

on

page

14,

is

impossible

as

the

film

would

not

be

wound

on

to

the

take-up

spool.

Only

when

the

film

has

been

run

through

ance

normally

and

sub-

seguently

rewound

will

it

come

off the

spool

in

suck

a

way

[see

Sketch

|I)

that

reverse

projectien

is

possible,

After

!he

film

has

run

through

the

take-up

spracket

turn

the

lever

C

fully

to

the

leff

(Fig.

T1).

This

lacks

the

film

transport

and

frees

the

laops

which

have

been

formed

by

the

autamatic

threader.

After

the

film

has

finally

passed

under

the

film

rollers

and

a

sufficient

length

has

come

out

at

the

ofher

end,

the

motor

must

be

switched

off.

The

end

of

the

film

can

now

be

attached

to

the

take-up

spool.

Here

we

should

like

to

mention

the

handy

EUMIG

400

H.

spools.

As

vou

will

ses

from

Fig.

12,

spring

tongues

are

aftached

to

the

cores,

and

by

this

simple

means

the

film

is

held

firm.

Fig.

Threading

by

hand

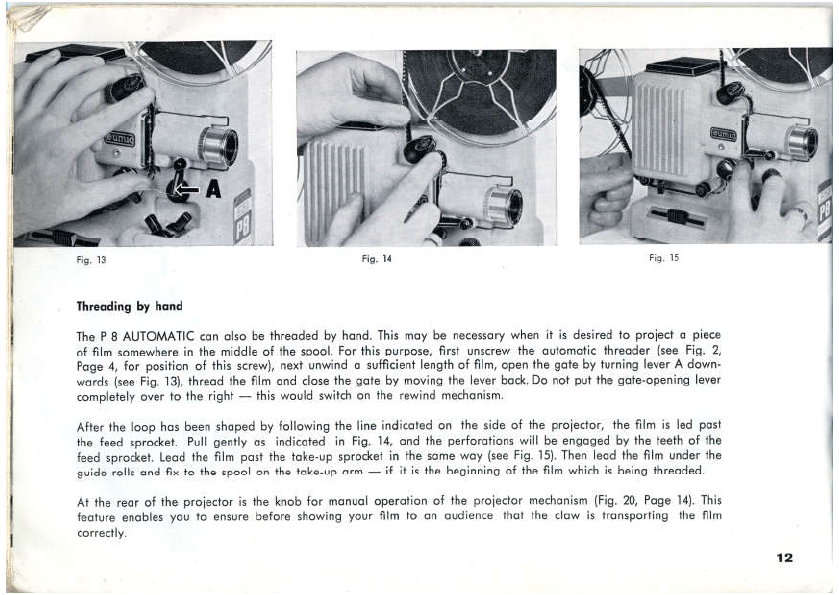

The

P B

AUTOMATIC

can

olso

be

fhreaded

by hand.

This

may

be

necessary

when

it

is

desired

to

project

a

piece

of

film

somewhere

in

the

middle

of

the

spool.

For

this

purpose,

first

unscrew

the

automatic

threader

[see

Fig.

2,

Page

d,

for

position

of

this

serew),

next

unwind

a

sufficient

length

of

film,

open

the

gate

by

turning

lever

A

down-

wards

(see

Fig.

13),

thread

the

film

and

close

the

gate

by

moving

the

lever

back,

Do

not

put

fhe

gate-opening

lever

completely

over

to

the

right

—

this

would

switch

on

the

rewind

mechanism.

After

the

loop has

been

shaped

by

following

fhe

line

indicated

on

the

side

of

He

projector,

the

film

is

led

past

the

feed

sprocket.

Pull

gently

as

indicated

in

Fig.

14,

and

the

perforations

will

be

engaged

by

the

teeth

of

ihe

feed

sprocket,

Lead

the

film

past

the

take-up

sprodket

in

he

same

woy

(see

Fig,

15),

Then

lead

the

film

under

the

guide

rolls

and

fix

to

the

spool

on

the

take-up

arm

—

if

it

is

the

beginning

of

the

film

which

is

being

fhreaded.

At

the

rear

of

the

proiector

is

the

knob

tor

manual

operation

of

the

proiectar

mechanism.

(Fig.

20,

Page

14).

This

feature

enables

you

to

ensure

before

showing

your

film

te

an

audience

that

fhe

claw

is

transporting

the

film

correctly.

12

13

Projection

The

P 8

AUTOMATIC

is

now

ready

for

proieetion.

Switch

on by

means

of

switch

E,

as

deseribed

in

"Autematie

threading ef

the

film”

en Page

10.

The

table

lamp

connarted

to

the

projiecter

will

immediately

go

out.

First

determine

the

desired

sereen

picture

size

by

holding

the

lens

by

its

front

rim

and

pulling

it

in

or

out,

hen

focus

by

rofating

the

lens

to

the

right

or

left.

Picture

size

and

focus

are,

of

course,

also

adjustable

during

projection.

Adijust

the

running

speed

if

necessary

with

the

speed

control

A

(Fig.

16)

until

all

fliker

disappears.

NOTE:

During

the

short

time

taken

by

the

aufa-

matic threading

of

the

film,

the

projector

noise

is

slightly

louder

than

during

the actual

projerfion.

In

order

to

proteet

the

film,

a

special

geld-glass

heat

ubsorbing

filter

is

autematically

interposed

between

the

lamp

and

the

film

when

the

projecter

is

switched

on,

remaining

in

position

until

the

nor-

mal

speed

has

been

reached.

This

filter

is

also

inter-

posed

as

soon

as

the

speed

drops

to

belaw

10

fra-

mes

per

second,

If

parts

of

two

frames

are

shown

on

the

screen,

turn

knob

B

until

this

Fault

disappears.

widih

of

picture

im

feet

Fig,

IT

O 3 6 2

seraan

distance

in

feet

2

TS

Fig.

14

Fig.

IS

Fig.

2

If

you

are

expecting

guests,

if

is

advisable

to

have

a

trial

run

to

make

any

necessary

adjustments

far

picture

size,

focus,

speed

and

framing.

Then

all

you

have

to

do

is

to

switch

on

the

projiector.

Af

the

end

of

he

performance

vou

just

switch

off

the

projiector,

and

the

table

lamp

will

automatically

come

on

again.

Fig.

17

shows

the

relationship

between

picture

size

and

screen

distance

when

using

tha

focal

lengths

range

of

the

EUPRO-ZOOM

(15—25

mm.).

Visible

reverse

proiection

The

P

B

AUTOMATIC

also

permits

reverse

projection.

To

switch

over

From

forward

to

reverse,

simply

move

switch

A

(Fig.

18).

There

is

no

need

to

switch

off

the

projecter

beforehand.

During

the

short

time

the

film

slows

down,

stops,

ond

begins

to

run

backwards,

a

shutter

automatically

cuts

off

the

light

to

protect

the

film

from

damage.

This

moves

out

of

the

optical

path

again

once

the

film

has

reached

the

reauired

running

speed,

After

switdhing

from

forward

to

reverse

proiection

or

vice

versa,

it

may

be

necessary

to

reediust

the

framing.

Still

projection

Still

proiection

sarves

far

observing

individual

frames

of a

film.

In

fhis

case,

pull

back

switch

B

as

shown

in

Fig.

19.

This

outomatically

introduces

Hhe

special

goldglass

heat

filter

into

the

optical

system,

noticeable

by

the

drop

in

the

pro-

jected

image

brilliance.

On

switching

to

still

projection,

the

rotafing

projector

shutter

may

eccasionally

stop

in

front

of

the

film

gate

and

so

obscure

the

pic-

ture.

In

that

case,

turn

knob

C

(Fig.

ZO)

at

the

rear

of

the projector

until

the

reguired

frame

appears

on

the

screen.

This

knob

also

serves

to

move

Ihe

film

farward

or

back,

frame

by

frame,

For

selecting

any

particular

single

frame.

14

Fig,

21

Fig.

22

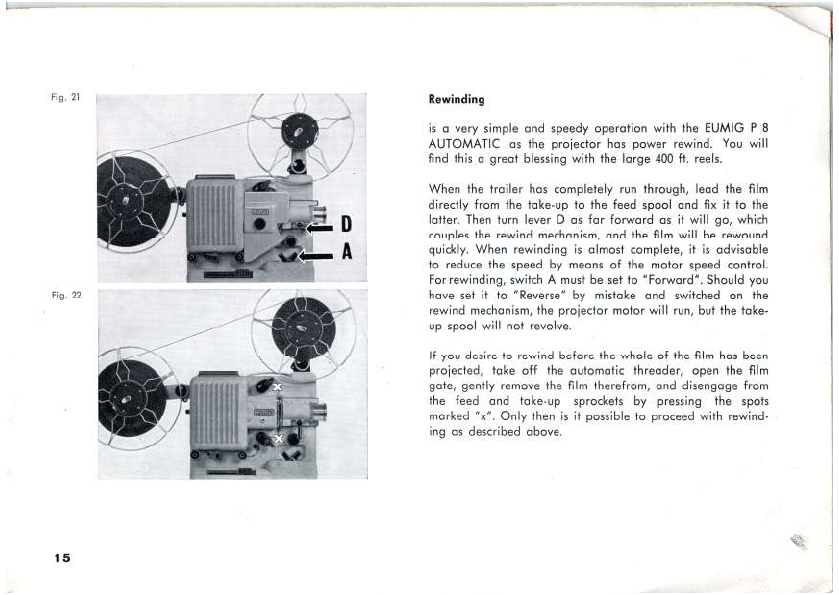

Rewinding

is

a

very

simple

and

speedy

operation

with

the

EUMIG

P

8

AUTOMATIC

as

the

projector

has

power

rewind.

You

will

find

this

a

great

blessing

with

the

large

400

ft.

reels.

When

the

trailer

has

compleiely

run

through, lead

the

film

directly

from

the

take-up

to

fhe

feed

spool

and

fix

it

to

the

latter.

Then

turn

lever

D

as

far

Forward

as

it

will

ga,

which

couples

the

rewind

mechanism,

and

the

film

will

be

rewound

auickly.

When

rewinding

is

almost

complete,

it is

advisable

to

reduce

the

speed

by

means

af

the

motor

speed

control.

For

rewinding,

switch

A

must

be

set to

“Forward",

Should

vyau

have

set

it

to

"Reverse"

by

mistake

and

switched

on

the

rewind

mechanism,

the

projectar

matar

will

run,

but

the

take-

up

spool

will

not

revolve,

If

you

desire

to

rewind

before

the

whole

af

the

film

has

been

projecled,

take

off

the

automatic

threader,

open

the

film

gate,

gently

remove

the

film

therefrom,

ond

disengage

from

the

feed

and

take-up

sprorkets

by

pressing

the

spots

marked

"x”,

Only

fhen

is

it

possible

to

proceed

with

rewind-

ing

as

described

above,

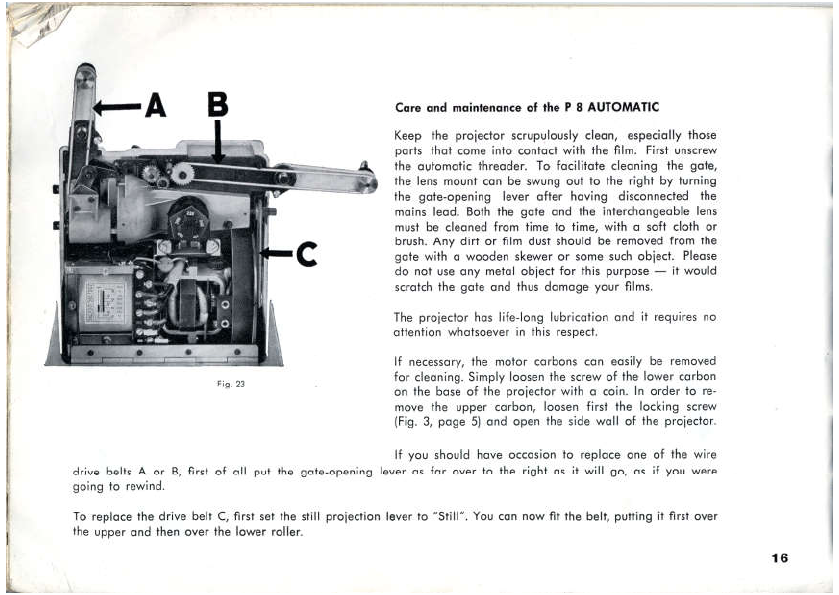

Care

and

maintenance

of

the

P 8

AUTOMATIC

Keep

the

projiector

scrupulously

clean,

especially

fhose

parts

that

come

inta

contact

with

fhe

film.

First

unserew

the

automatic

#hreader.

To

facilitate

cleaning

the

gate,

the

lens

mount

can

be

swung

out

to

the

right

by

turning

the

gate-opening

lever

after

having

disconnected

the

mains

lead.

Both

Hhe

gate

and

the

interdwangeable

lens

must

be

cleaned

from

time

to

time,

with

a

soft

cdlath

or

brush.

Any

dirt

or

film

dust

should

be

removed

from

the

gate

with

a

wooden

skewer

or

some

such

object.

Please

do

nat use

any

metal

object

for

this

purpose

—

it

would

scratch

the

gate

ond

thus

damage

your

films,

The

proiector

has

life-lang

lubrication

and

it

reguires

no

attention

whatsoever

in this

respect.

If

necessary,

the

motor

carbons

can

easily

be

removed

for

cleaning.

Simply

loosen

fhe

seraw

of

the

lawer

carbon

on

the

base

of

the

prajector

with

a

coin.

In

order

ta

re-

move

the

upper

carbon,

loosen

first

the

locking

sErew

(Fig.

3,

page

5)

and

open

the

side

wall

of

the

prajectar

If

vou

should

have

pecasion

to

replace

one

of

the

wire

drive

belis

A

or

B,

first

of

all

put the

gofe-opening

lever

as

far

aver

to

the

right

as

it

will

ge,

as

if

vou

were

going

ta

rewind.

To

replace

the

drive

belt

C;

first

set

the

still

projection

lever

to

“Still”,

You

can

now

fit

the

belt,

putting

it

first

over

he

upper

and

then

over

the

lower

roller.

16

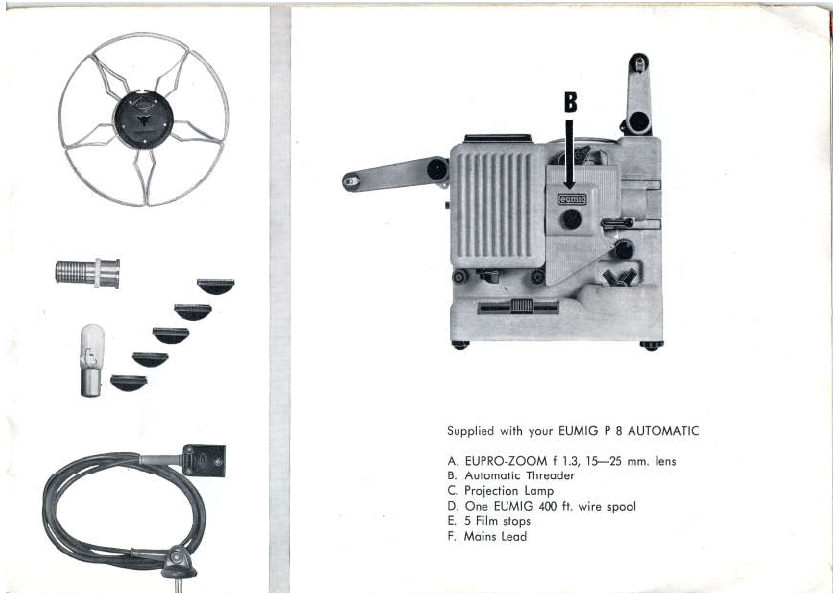

Supplied

with

your

EUMIG

P

8

AUTOMATIC

A.

EUPRO-ZOOM

f

1.3,

15—28

mm.

lens

B.

Automatic

Threader

C.

Projection

Lamp

D.

One

ELMIG

400

H.

wire

spoel

E.

$

Film

stops

F,

Mains

Lead

Td

The

Birthplace

of

the

EUMIG

P 8

AUTOMATIC

The Vienna

Works

Part

of

the

Kirchdarf

Works,

Upper

Austria

18

Other manuals for Automatic P8

1

Table of contents

Other Eumig Projector manuals