- 2 -

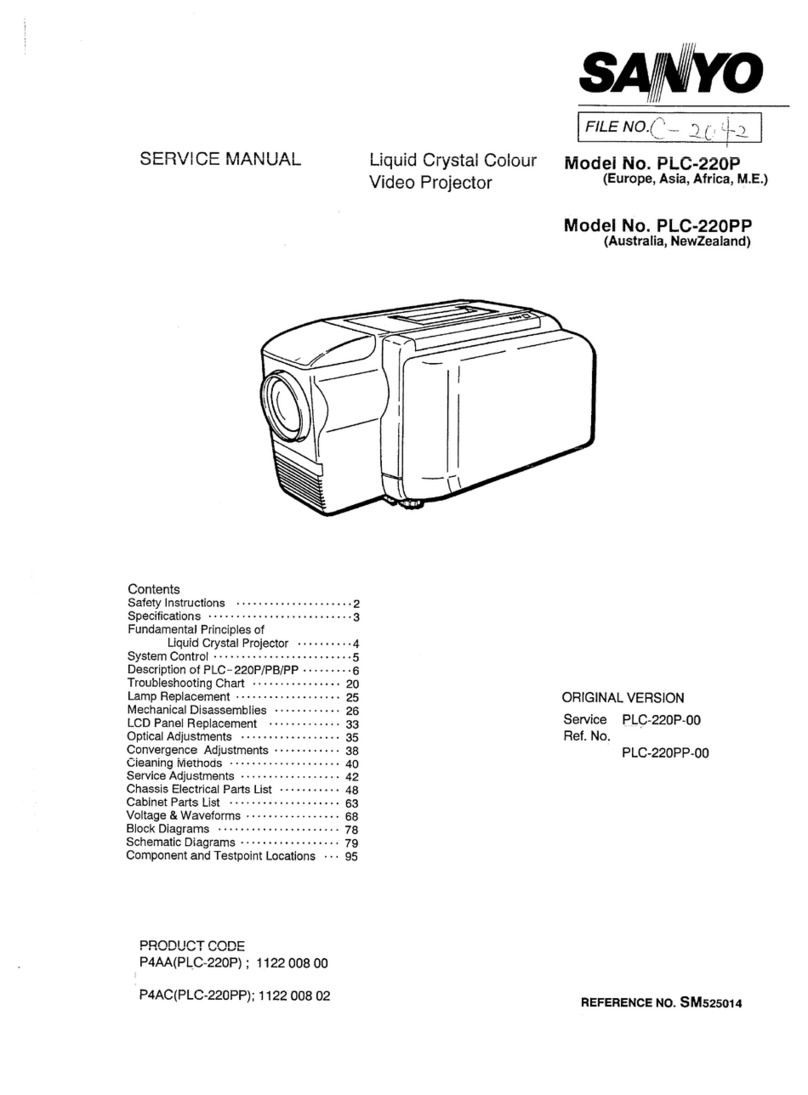

Contents

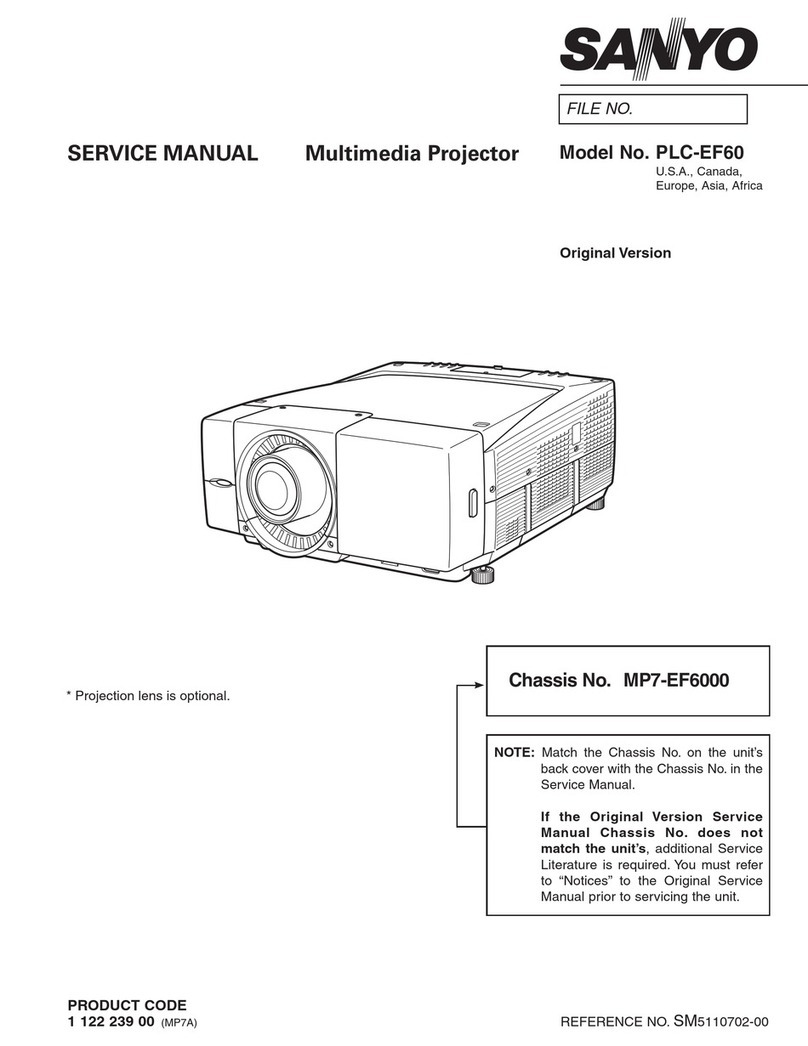

SERVICE MANUAL ................................................... 1

Contents ........................................................................ 2

Safety Instructions ......................................................... 3

SAFETY PRECAUTIONS........................................... 3

PRODUCT SAFETY NOTICE .................................... 3

SERVICE PERSONNEL WARNING .......................... 3

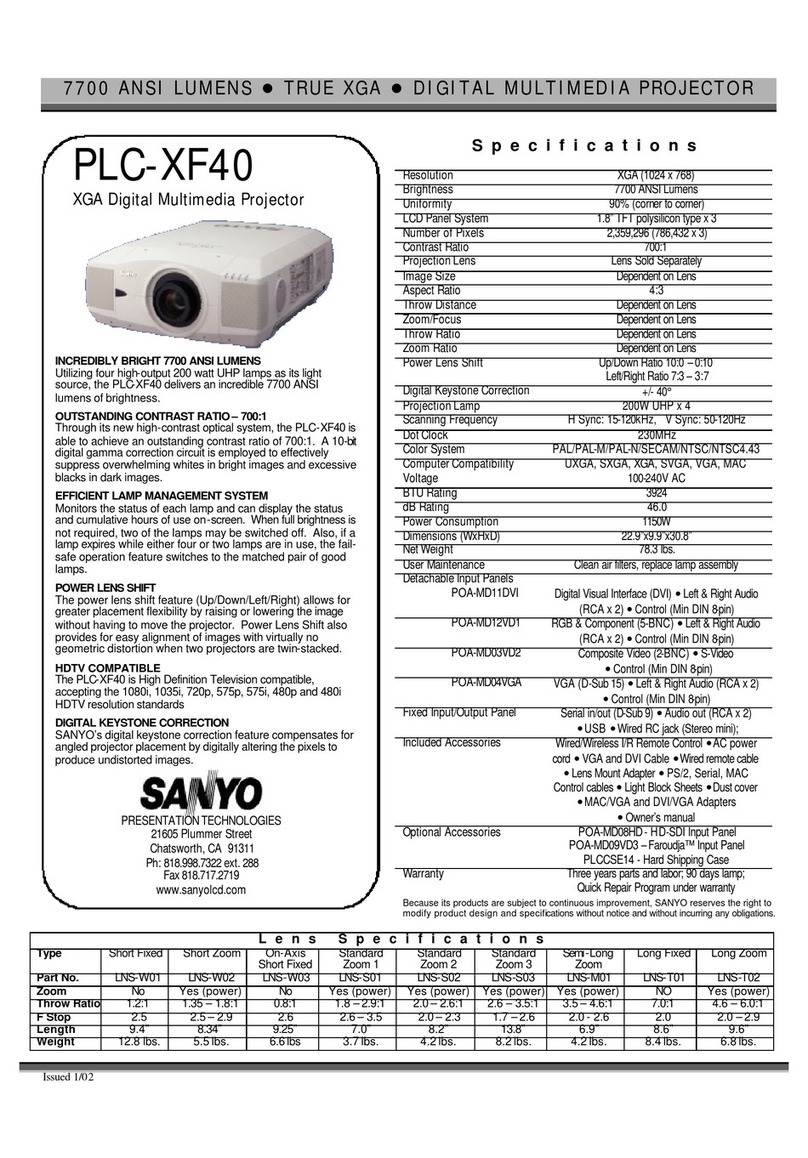

Specifications ................................................................ 4

Circuit Protections ......................................................... 5

Fuse............................................................................ 5

Thermal switch ........................................................... 5

Lamp cover switch...................................................... 6

Door switches for automatic slide shutter................... 6

Warning temperature and power failure protection .... 6

Maintenance and Cleaning............................................ 7

Cleaning the RGB panels .......................................... 8

Warning Indicator ..................................................... 10

Cleaning the Air Filters ............................................. 11

Resetting the Filter Counter...................................... 12

Cleaning the Projection Lens.................................... 12

Cleaning the Projector Cabinet................................. 12

Lamp Replacement ..................................................... 13

Lamp Replacement Counter..................................... 14

Service Port ................................................................. 16

Mechanical disassemblies........................................... 17

Optical disassemblies.................................................. 34

Adjustments................................................................. 44

Adjustments after Parts Replacement ...................... 44

Optical Adjustment ...................................................... 45

Electrical Adjustment ................................................... 47

Service Adjustment Menu Operation........................ 47

Circuit Adjustment .................................................... 48

Location of Test Points ............................................. 52

Service Adjustment Data Table ................................ 53

Chassis Block Diagram ............................................... 72

Chassis Overview ..................................................... 72

Video signal processing circuit and LCD panel driving

circuit ........................................................................ 73

System Controls ....................................................... 74

Motor driving circuit .................................................. 76

Fan control circuit ..................................................... 78

Power supply circuit and Protection circuit ............... 80

Troubleshooting........................................................... 82

Indicators and Projector Condition ........................... 83

No Power.................................................................. 84

No Picture................................................................. 86

Control Port Functions................................................. 88

Electrical Parts List...................................................... 90

Electrical Parts Location ........................................... 91

Mechanical parts List................................................. 109

Cabinet Parts Location ........................................... 109

Optical Parts Location ............................................ 111

Diagrams & Drawings..................................................A1

Parts description and reading in schematic diagram...A2

Schematic Diagrams ...................................................A3

Printed Wiring Board Diagrams...................................A9

Pin description of diode, transistor and IC.................A13

Note on Soldering......................................................A14