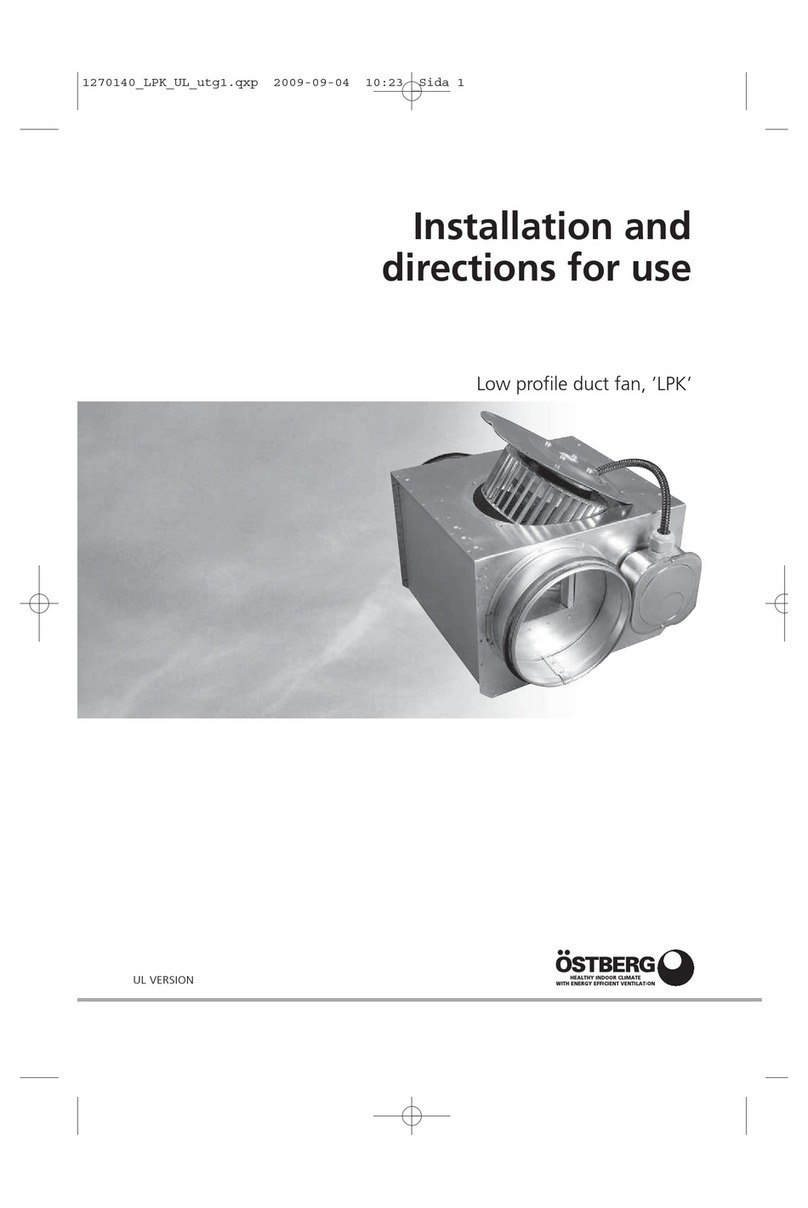

Euramco RAFMAN TurboForce WF390 User manual

1

WF390 Owner’s Manual | REV B/0 | Euramco Group

Preface

Thank you for purchasing the RAMFAN WF390 Positive Pressure Ventilator manufactured by Euramco Group.

For more than 30 years Euramco Group has been on the cutting edge of industrial, fire, and marine ventilation

products. Each and every one of our blower/exhausters, smoke ejectors, PPV & LSV fans and accessories

represent the finest technologies available. Every product is constructed to demanding and exact specifications for

quality, performance, and reliability.

When human life depends on having a fan that can deliver clean, safe air, you have only one choice you can trust:

RAMFAN.

Explore our website and online catalog at www.Euramco.com and discover how RAMFAN can make a difference

in the field!

This manual covers operation and maintenance procedures for the RAMFAN WF390 Positive Pressure

Ventilator.

All product information in the publication is based on the most current information available at the time of

printing. Euramco Group reserves the right to make changes at anytime without notice.

READ MANUAL BEFORE STARTING FAN FOR FIRST TIME!

2

WF390 Owner’s Manual | REV B/0 | Euramco Group

Table of Contents

1 | Warning Labels ......................................................................................................................................... 3

2 | Features & Benefits ................................................................................................................................. 4

3 | Safety Precautions.................................................................................................................................... 5

4 | Preparation ................................................................................................................................................ 5

5 | Operation ................................................................................................................................................... 5

5.1 | Control Features ......................................................................................................................... 6

5.2 | Run Procedure............................................................................................................................ 7

5.2.1 | Start Up....................................................................................................................... 7

5.2.2 | Shut Down................................................................................................................... 7

6 | Maintenance .............................................................................................................................................. 7

7 | Storage....................................................................................................................................................... 8

8 | Troubleshooting........................................................................................................................................ 8

9 | Spare Parts ................................................................................................................................................ 8

10 | Supplements............................................................................................................................................ 8

10.1 | Setback Distances .................................................................................................................... 8

10.2 | Shared Operation Zone .......................................................................................................... 10

3

WF390 Owner’s Manual | REV B/0 | Euramco Group

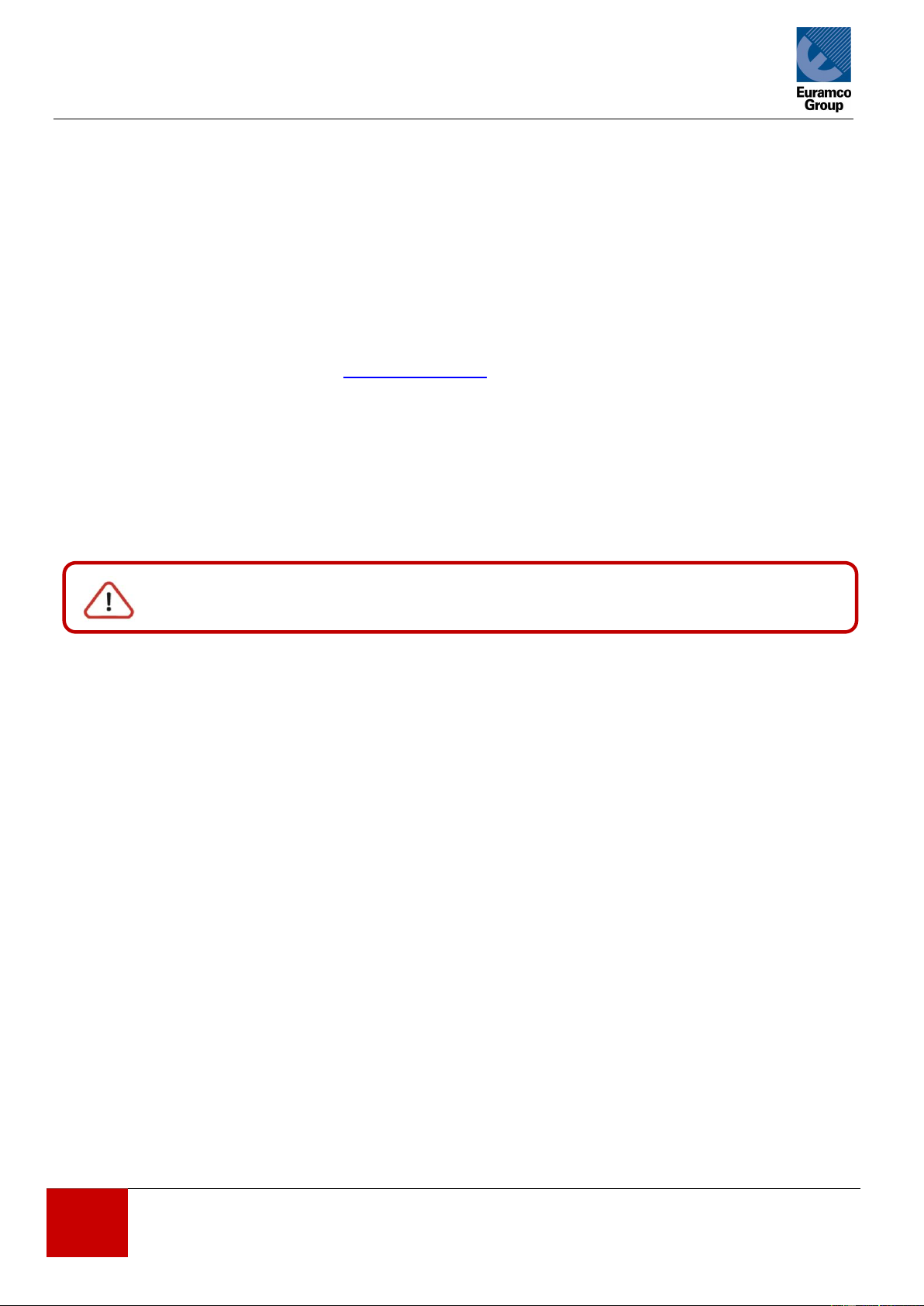

1 | Warning Labels

Ventilator Cautions, Warnings & Specs:

NOTE: This fan is NOT for use in Explosive Atmospheres!

4

WF390 Owner’s Manual | REV B/0 | Euramco Group

2 | Features & Benefits

WF390 | 16”/40 cm

Water-Powered Turboventilator with TurboForce™ Technology

Fan output is only half the story in PPV. RAMFAN fans are more penetrating, high velocity airflow means

faster cooling and clearance of dangerous smoke and toxic gases. TurboForce Technology accelerates the

airflow and literally cuts into the dangerous heat and smoke layer to quickly clear and cool the way for

advancing firefighters.

The NO COMPROMISE Leader

RAMFAN® is the brand leader in quality portable ventilation as a result of Euramco Group’s “No

Compromise” approach to user safety, product design and performance. RAMFAN fans are built using

premium components and tested to meet high standards in performance and safety.

NO COMPROMISE Design and Performance

•TurboForce® Fans accelerate the airflow up to 20% greater than conventional propeller style fans

•7-Blade Polymer TurboForce™ Impeller for increased shatter resistance and enhanced PPV

performance

•Outlet for water recycling (closed circuit) to conserve water supply

•Compact, for easy storage in typical engine compartments

•Wide range tilt adjustment

•Powder coated steel frame

•Full-width retractable handle and heavy-duty wheels for upright, push-pull operation

•4 soft rubber feet - fan will never walk back while performing PPV

5

WF390 Owner’s Manual | REV B/0 | Euramco Group

3 | Safety Precautions

DO NOT START fan if there are any signs of shipping damage, particularly to blade, guards, or

housing. If ANY damage is suspected, STOP and call your dealer immediately.

Use safe lifting practices.

Keep fingers, hair, debris, food or any loose objects away from intake of fan.

Wear eye and ear protection.

Start ONLY if fan is sitting in a stable and upright position.

DO NOT move fan while in operation.

•Keep fan guard securely in place. Do NOT operate with damaged or missing fan guards.

•Keep area clear of rocks and debris.

•Operate the fan on a level surface whenever possible, NOT to exceed 20°.

•Do not stand directly in front of the fan.

•Turn fan OFF if you hear unusual noises.

•Exercise care during deployment and storage to prevent physical damage.

•Allow fan to cool before storing.

•Blower should be operated and repaired by trained personnel ONLY.

4 | Preparation for Use

•Use only with properly tested and certified hose to make inlet and discharge connections.

•Connect inlet hose to proper connection. Observe the inlet labeling.

5 | Operation

•STOP the blower if mechanical noise, vibration, or other abnormal condition occurs. Any noise other than

turbine type pitch is not normal.

•Remove protective end caps from inlet and discharge swivels. Connect the inlet and discharge water

hoses to the fan. Run both hoses to provide as straight a path as possible. MAX PRESSURE IS 250 psi/

1.75MPa

•Visually check for leaks or excessive strain from the hose. Leakage should be controlled if the presence of

water could be detrimental to the surrounding area.

5.1 Control Features

6

WF390 Owner’s Manual | REV B/0 | Euramco Group

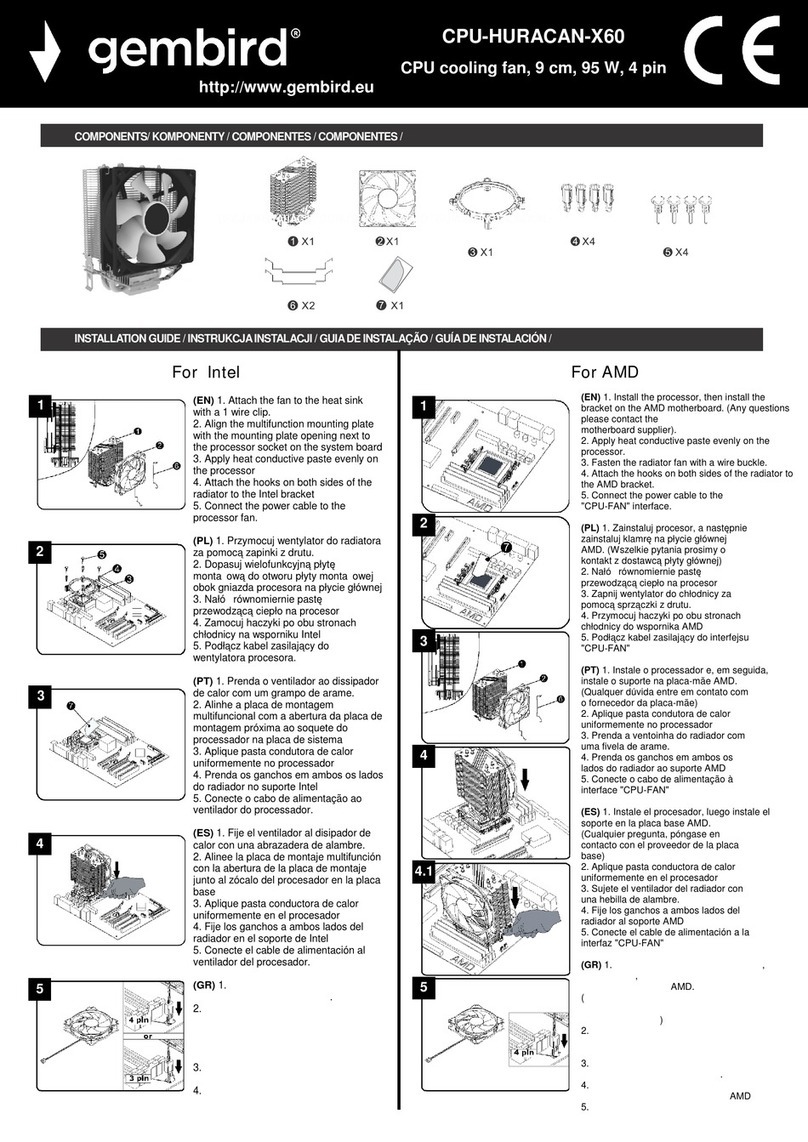

Refer to Figure 1 below for location of WF390 controls and features.

Figure 1- WF390

Water Outlet

Water Inlet

7

WF390 Owner’s Manual | REV B/0 | Euramco Group

MAX PRESSURE is 250 psi / 1.75 MPa

Figure 1 –WF390 Control Functions & Features

1

Water Inlet

Connect water supply hose

2

Water Outlet

Connect water discharge hose

3

Push/Pull Handle

Retractable handle for easy maneuvering

4

Tilt Mechanism

Adjust tilt from 0to 20

5

Rubber Feet

Rubber feet and wide footprint reduces vibration, lengthens service life.

6

Semi-Pneumatic Tires

Easily roll over wet grass or mud

5.2 | Run Procedure

5.2.1 | Start-Up

1 Read the Owner's Manual completely before starting fan.

2 Wear both eye and ear protection.

3 Complete checks as indicated in Section 4, Preparation for Use.

4 Position the fan on a level surface at your desired setback distance.

5 Using the Tilt Mechanism, adjust fan to the desired angle.

6 Remove protective end caps from inlet and discharge swivels. Connect the inlet and discharge

water hoses to the fan. Run both hoses to provide as straight a path as possible.

5.2.2 | Shut-Down

1 Secure water supply and disconnect from blower.

2 Disconnect discharge hose and allow blower to drain.

3 Flush internal water passages of unit with clean, fresh water after each use.

4 Allow unit to dry. Using compressed air or a blower can reduce drying time.

5 Install end caps on swivels and recover the tilt to 0before storage.

6 | Maintenance

•There are no user serviceable parts. Contact factory for replacement part applicability.

•NEVER operate fan with damaged or missing finger guards.

•Inspect the fan for loose fasteners at least once every 6 months. Tighten any loose fasteners

immediately. Do NOT overtighten.

8

WF390 Owner’s Manual | REV B/0 | Euramco Group

•Inspect impeller blade for cracks and pitting prior to each use. Never operate fan with a broken impeller.

Contact factory for parts and installation instructions.

•Clean with commercially available biodegradable cleaning solutions. DO NOT use solvents containing

chlorinated hydrocarbons (i.e., MEK, Acetone)

•Check rubber feet on frame for excessive wear or breakage.

•Inspect and clean strainer if necessary. Reinstall strainer and strainer adapter on inlet swivel. Tighten

only enough to prevent leakage. Do NOT overtighten. Excessive force can result in damage to threads.

•Flush internal water passages of unit with fresh water after each use.

•Grounding connection on blower should be maintained tight and free of corrosion.

7 | Storage

•Drain water.

•Make sure all parts of the fan are dry.

•Store in the upright position ONLY.

8 | Troubleshooting

•Fan does not tilt down

- Fan is already at the down limit. Tilt fan up.

•Fan does not tilt up

- Fan is already at the upper limit. Tilt fan down.

•Limited Performance

- Increase water pressure.

- Increase outlet hose diameter.

- Check debris filter on inlet.

9 | Spare Parts

10 | Supplements

10.1 Setback Distances

Setback distance, is the term used to describe how far back from the structure’s ingress point to setup the

ventilator. As any front line responder will tell you, techniques are based on the situation at the scene and

should not be dictated by a manufacturer's design limitations.

RAMFAN

Rubber Feet

Part # FZ-TPRRF6

For other spare parts, contact

theteam@euramcosafety.com

RAMFAN

Inlet Strainer

Part # WA2300

RAMFAN

Inlet Adapter

Part # WB2810

RAMFAN

Outlet Adapter

Part # WA2203

9

WF390 Owner’s Manual | REV B/0 | Euramco Group

Here's a bit of insider information: with certain designs, the fan can produce some amazing airflow

numbers set pretty far back, which is great for marketing big numbers, but when positioned at more

realistic distances (closer in to the entry point) the performance of most ventilators is pretty much the

same, because most countries use standard door sizes in the construction of buildings. All our equipment

is rated at several different door sizes to guide your proper selection and to provide a better understanding

of the ventilators capabilities.

Every structure is different, every fire is dynamic, and every piece of rescue equipment must be ready for

anything. Therefore, the topic of "setback distance" needs to be addressed. The setback distance is simply

a general range of acceptable setback distances, that will provide the desired result of ventilating the

structure.

Sometimes structural entries have large approaches, where the ventilator can be setback farther, at

distances of 4 meters or more.

Sometimes a short approach, with stairs or a turn or in a hallway, confines the useable setback distance to

3 meters or less.

The point is, you don't always know, and in this line of work you have to be prepared for anything.

When selecting any equipment for your brigade, you should already know the typical structure types and

sizes in your response area. A ventilators size and performance should be chosen based upon the

following criteria:

1. What is the average size structure in your response area?

If mixed, for example, between small residential/commercial and a few larger industrial buildings,

several smaller fans may be a more realistic choice than a single giant fan that will take up

valuable space and is difficult to maneuver. Several smaller fans, used together, can produce

very impressive air movements and easily fit within the compact compartments of most modern

fire apparatus.

2. How big are your truck's compartments?

Saving space, and minimizing weight, are increasingly becoming concerns of brigades when

deciding which equipment to choose. Furthermore, budget cuts may force fire brigades to use

their current apparatus, more efficiently. That means, packing as much equipment as possible

into your existing truck. To do this, equipment must be lightweight and as compact as possible,

while still providing the performance needed to get the job done.

3. What do you expect from your ventilator?

While there are certain factors that can affect the airflow performance of a ventilator, considering

the challenging realities faced by first responders, there really are more important things to

consider when selecting equipment than which one has the highest airflow performance in a

controlled test environment.

- Reliability:Which ventilator will keep on working after running the gauntlet on fire scene

operations for the next 3 years or more?

- Durability: Which ventilator is tough enough to start right up after the new rookie drops it

out of the rear compartment?

- Performance: Which ventilator will provide superior performance at every ventilation-

required scene in your response area?

10.2 Shared Operation Zone

10

WF390 Owner’s Manual | REV B/0 | Euramco Group

Every fire and rescue scene has an area in which all responders, their equipment, and their vehicles must

share. How this area is shared and how efficiently it is used and managed will determine the quality of the

response itself. We call this the Shared Operation Zone (SOZ).

When selecting the tools, equipment, and vehicles needed to respond to any situation, the best Fire

Fighting leaders will choose the equipment that allows them to manage their response operations the most

efficiently and effectively as possible.

Euramco Group knows this, and designs special characteristics into each product to ensure the SOZ at

your next response can be used effectively.

Any structure fire has limited ingress/egress

opportunities, as determined by the location of

the fire within the structure, the building design,

and the overall mission.

Often, personnel, along with vehicles,

equipment and hoses must be strategically

located around a single ingress point of the

structure. This obviously places restrictions on

the specifications of everything from the

vehicles, equipment & hoses to personnel and

strategy.

Vehicle placement happens first, as first

responders arrive. This immediately places

further restrictions on potential placement of

equipment. Is your equipment designed to

accommodate these restrictions? Or will you be

wishing your procurement officer paid attention

to what really matters when purchasing

equipment, now that you are facing a life &

death situation?

In an average high-rise response situation, the

SOZ gives the responders less than 500 square

meters of area to place equipment and

personnel in front of the main ingress/ egress

point. Many factors come into play.

•How to lay your hand lines?

•Where to place your main pumper,

command vehicle, and rescue truck?

•Where to stage spare SCBAs?

•Where to place your ventilator to

eliminate smoke in the ingress/egress

route? The stairwell?

Consider this carefully, through smart

equipment selection and proper fire fighter

training, develop equipment specifications and

SOPs that meet the actual challenges that you face every day, and the challenges that you will face

tomorrow. Seek the opinions and guidance of those more experienced than yourself. Make sure you are

ready!

Table of contents

Other Euramco Fan manuals

Popular Fan manuals by other brands

Hunter

Hunter 59245 installation manual

Holmes

Holmes HAWF-1013 owner's guide

Mitsubishi Electric

Mitsubishi Electric EF-35UDT2-GL Installation instructions manual

Gallet

Gallet VEN 11T Lestre instruction manual

Progress Lighting

Progress Lighting AirPro P250102 installation manual

Gaggenau

Gaggenau VL 040 714 use and care manual