Euramco RAMFAN FlowPath UB20 Series Manual

SM-EFATEX Rev F1 - Page 1 of 16

FlowPath™ Control

Euramco Group | 2746 Via Orange Way, Spring Valley CA 91978 USA

Ph: +1-619-670-9590 | www.euramco.com

TECHNICAL INFORMATION AND ORIGINAL INSTALLATION

INSTRUCTIONS

SM-EFATEX REV F2

Portable Ventilators for

Hazardous Locations UB20xx EFi120xx

EFi75xx EFi150xx

Applicable Models:

The Portable Ventilators described herein are intended

for use in Explosive Atmospheres in accordance

with the limitations of the rating. It is the user’s

responsibility to determine the suitability of equipment

for the intended purpose.

II 2 G Ex db eb IIC T6 Gb

II 2 G Ex h IIB T6 Gb

0539 Demko 09 ATEX 0926969X

IECEx UL 13.0062X

0539

SM-EFATEX Rev F2 - Page 1 of 16 SM-EFATEX Rev F2 - Page 2 of 16

WARNING!

These units are intended for Explosive Atmosphere use in accordance with ATEX Directive

2014/34/EU. It is the user’s responsibility to determine the suitability of this equipment for

the intended purpose.

CAUTION! THESE FANS ARE NOT INTENDED FOR USE IN MINES SUSCEPTIBLE TO FIRE-

DAMP.

Explosion Proof Fan Rated:

II 2 G Ex db eb IIB T6 Gb

II 2 G Ex h IIB T6 Gb

Euramco Safety hereby declares that the equipment listed in this manual conforms to the

relevant Essential Health and Safety Requirements of the European Machinery Directive

and standards listed below.

Council of European Communities Directive:

Directive 2014/34/EU.

Standards to which conformity is declared:

See “Declaration of Conformity”

Category, Group and Zone Classications

According to ATEX Directive (2014/34/EU)

II 2 G Ex db eb IIB T6 Gb

II 2 G Ex h IIB T6 Gb

0539 Demko 09 ATEX 0926969X

IECEx UL 13.0062X

Design of fans working in potentially explosive atmospheres EN 14986

The letter “X” at the end of the ATEX, IECEx, and INMETRO certicate

numbers indicate a special condition for safe use. This special condition

of safe use refers to the fact that the Hazardous Location Fans referenced

herein may be purchased with or without an AC power plug termination for

the power cable.

Classication: Ex de

According to IEC 60079-1 / 60079-1 / ABNT NBR IEC 60079-1

Flame Proof Enclosures with Increased Safety Components

IEC 60079-7 / EN 60079-7 / ABNT NBR IEC 60079-7

RAMFAN SAFETY VENTILATORS ELECTRICAL RATING

Model No. Euramco Part

No.

Input Voltage Frequency Current

UB20xx EF7002

EF8002

115 VAC

230 VAC

50/60 HZ

50/60 HZ

2.3 A

1.2 A

EFi75xx EB7201XX

EB7201XX-230

115 VAC

230 VAC

50/60 HZ

50/60 HZ

8.8 A

4.4 A

EFi120xx EA8120XX-110

EA8120XX

110 VAC

240 VAC

50 HZ

50 HZ

10.8 A

5.5 A

EFi150xx EG8200XX

EG8200XX-230

115 VAC

230 VAC

50/60 HZ

50/60 HZ

15 A

8.1 A

Special Conditions for Safe Use:

If fans are purchased with unterminated power cables, (ying leads), then it becomes the

responsibility, of the end user to select a compliant power plug in accordance with stan-

dard, IEC/EN/ABNT NBR IEC 60079-14 and to install the plug in accordance with the plug

manufacturers instructions. Color code for ying lead power cables is brown “hot”, blue

“neutral”, & yellow/green “ground” for plug connections.

T6 Temperature Classication:

85°C T6 - According to IEC 60079-0 / EN 60079-0 / ABNT NBR IEC 60079-0.

To ensure that there is no risk of ignition due to hot surfaces, the equipment is classied

with regard to the maximum surface temperature of any part of the equipment while in

operation based on the ambient temperature of 40°C. Equipment must be selected with a

suitable temperature classication for the gases and vapors present where the equipment

is to be installed. Ensure that the maximum surface temperature of any parts of the equip-

ment are below the ignition temperature of the explosive atmosphere concerned.

This equipment is intended for use in ambient temperatures ranging between -20°C and

+40°C.

SM-EFATEX Rev F2 - Page 4 of 16SM-EFATEX Rev F2 - Page 3 of 16

Description of Apparatus

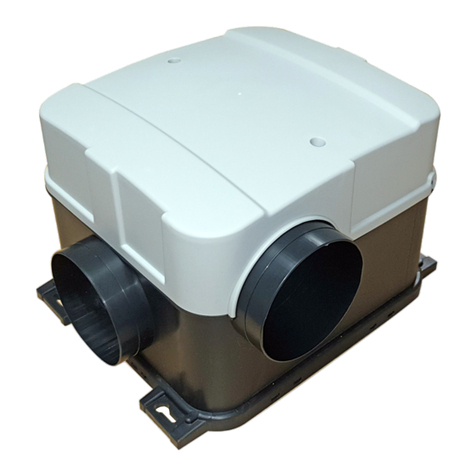

The Portable Ventilator assemblies represented herein consist of an Approved Explosion

Proof Electric Motor Rated: Ex d IIB as listed below.

RAMFAN SAFETY VENTILATORS MOTOR

Model No. Part No. Input Voltage/

Frequency

Impeller Motor part No.

UB20xx EF7002

EF8002

115 VAC, 50/60 HZ

230 VAC, 50/60 HZ

Plastic 1933007415

1933007419

EFi75xx EB7201XX

EB7201XX-230

115 VAC, 50/60 HZ

230 VAC, 50/60 HZ

Metal 1133007405

EFi120xx EA8120XX-110

EA8120XX

110 VAC, 50 HZ

240 VAC, 50 HZ

Plastic 1223007401

EFi150xx EG8200XX

EG8200XX-230

115 VAC, 50/60 HZ

230 VAC, 50/60 HZ

Plastic 1133007417

The Flame Proof Electric Motor Power

Requirements: See chart above.

Ambient Temperature Range: -20°C<Tamb<+40°C

Maximum Inlet Temperature: 40°C

Maximum Temperature Conveyed to Atmosphere: 2°C above air inlet temperature

Maximum Fan Casing Pressure: 12” / 305mm w.g.

Ingress Protection to IEC 529: IP55

Marked: Electric Motor for Hazardous Locations.

Flame Proof Enclosure: Ex d IIB

The electric motor consists of one ameproof enclosure, which contains less than 6%

magnesium by weight. The on/o switch is housed within the motor enclosure, and is

operated by a shaft, extending out from the rear end bell to a lever. The lever is accessible

via an attached push rod.

Motor connections are made through a non-detachable cable, secured to the motor with

an approved Flame Proof cable gland from the company Hawke, model 501/421/0/M20

and complies with International Standards EN 60079-0, EN 60079-1, and EN 60079-7.

The electric motor drives an aluminum or plastic fan blade which is enclosed in a plastic,

statically conductive housing with a conductivity rating of <1 giga ohms. Connection to

the motor is facilitated by a Terminal Block mounted in an Increased Safety/Flame Proof

Enclosure rated II 2 G Ex e II T6, from the company Rose Industries, Part Number 05080806,

and covered under ATEX Certicate No. PTB 00ATEX1063. This box was designed to

conform to International Standards EN 60079-0, EN 60079-1, EN 60079- 7, IEC/EN 60079-31.

The enclosure features stainless steel grounding lugs, with a high heat silicon gasket.

The Flame Proof enclosure has attached, approved, explosion proof cable glands, as

described below.

Rated: II G Ex e II

Type: Polyamide Ex metric conforms to International Standards EN 60079-0, EN 60079-1,

EN 60079-7, IEC/EN 60079-31.

Material: Polyamide Color: Black/Blue

Grommet: NBR Protection Classication: IP68

Temperature Range: -4°F to +212°F Approval: PTB 00 ATEX 1063

If the fan power cables are not terminated with power plugs see Special Conditions for safe

use.

The fans are assembled with both Inlet and Outlet Safety Guards that conform to the safety

standards to prevent danger zones being reached by upper limbs in the BS EN ISO 12100

Safety Machinery – Guards Standard.

Installation and Start-Up

• During the installation and start-up of the RAMFAN blowers in areas where there is a

risk of explosion:

• Design of the electrical installations must be in accordance with EN/IEC/ABNT NBR IEC

60079-14.

• Ensure power source is providing an electrical ground.

• Blowers must be integrated into a system in a way to support accessibility for regular

maintenance.

• Blowers are designed for portable, nonxed installation. Blowers have no mounting

features to support rigid duct or x installations.

• Perform careful inspection of each blower system to ensure ducting is securely

attached to blower. All components of the blower system are made of electrically

conductive material. It is very important to properly and securely attach each

component to maintain a ground path.

• Inspect fan power cable and plug for damage or wear that could render the cable

unsafe for hazardous locations.

• Ensure set-up, installation, operation and maintenance are performed only by properly

trained personnel.

• Operation after a faulty installation or maintenance shall be considered as

Before STARTING the FIRST time

DO NOT start operation if there are any signs of shipping damage to the blade, guards or

housing. STOP, call your dealer. USE Ex-Rated receptacles for this equipment. IT IS NOT

recommended to use extension cords for high amperage load. (See power rating label on

limit)

INSTRUCTIONS AND CARE

SM-EFATEX Rev F2 - Page 6 of 16SM-EFATEX Rev F2 - Page 5 of 16

OPERATION

Always ensure the switch is in the “Down/OFF” position prior to connecting the ventilator to

a power source.

Completely uncoil fan power cable to the AC power source.

Route fan power cable to avoid contact with heavy machinery that could possible damage

cable or possible be a trip hazard for workers.

Connect plug end of the fan power cable to the AC power source. Verify AC power source is

providing an electrical ground connection.

NOTE: For ATX connectors lift dust covers and insert plug into coupler until coupler dust cap

latches snaps into position on plug. To break connection between coupler and plug lift dust

cap to pull connectors apart.

NOTE: For CEAG connectors lift dust cover, insert plug into coupler, and rotate clockwise,

to lock plug into coupler and to close power switch within the coupler. To break connection

between coupler and plug lift dust cap and rotate plug counter-clockwise to pull connectors

apart.

Note: For R.STAHL connectors insert plug into coupler and rotate outer ring clockwise to

secure plug to coupler.

See Illustrations (Pg.6)

Stop the blower if mechanical noise, vibration or other abnormal conditions occur. Any

noise other than turbine-type pitch is not normal.

This unit is equipped with thermal overload protection with automatic reset. Motor will

restart without warning after protector trips. To protect the user, disconnect unit and

determine cause of protector trip.

Conductive RAMFAN Portable Ventilators are made with statically conductive materials.

When ducting is required to remote the ventilator from the point of application in a

potentially explosive environment, the ducting must be:

1. Statically Conductive, Surface resistance ≤106 ohms.

2. Flexible.

MAINTENANCE

• Disconnect power before inspection, disassembly or cleaning.

• Never immerse or directly spray motor with liquids.

• Clean ventilator with commercially available biodegradable cleaning solutions. Do not

use solvents containing hydrocarbons (i.e. MEK, Acetone).

• Inspect clearance between impeller tips and fan casing for minimum acceptable

clearance with pin gauges as shown in picture below. Minimum acceptable impeller tip

clearance is 0.079” / 2mm.

• Clean fan, impeller, & motor to remove accumulated dust or debris. Clean the impeller

and motor with a damp cloth only, to avoid any possibility of a disruptive breakdown

due to electrostatic charging.

• Inspect impeller & nger guards annually for damage. Replace as necessary.

• Inspect fan power cable and plug for damage or wear that could render the cable

unsafe for hazardous locations.

• Disconnect fan power cable plug from the power source before cleaning. Never

immerse or directly spray cable and plugs with uids. Clean cables with commercially

available biodegradable cleaning solutions. Do not use solvents containing

hydrocarbons (i.e. MEK, Acetone).

• At a minimum, check power cables during maintenance work on the fans for:

• Firm t of the conductors.

• Damage on the enclosure; seals or surface.

• Dirt on the sleeves.

• To avoid electrostatic charging, the devices located in potentially explosive areas may

only be cleaned using a damp cloth.

• When cleaning with a damp cloth, use water or mild, non-abrasive, non-scratching

cleaning agents.

• Do not aggressive detergents or solvents.

• Prevent water and cleaning agents from penetrating the socket contacts.

• There are no user serviceable parts. Contact factory for replacement part applicability.

• Do not change make or model number of motors for any reason!

SM-EFATEX Rev F2 - Page 8 of 16SM-EFATEX Rev F2 - Page 7 of 16

CAUTIONS

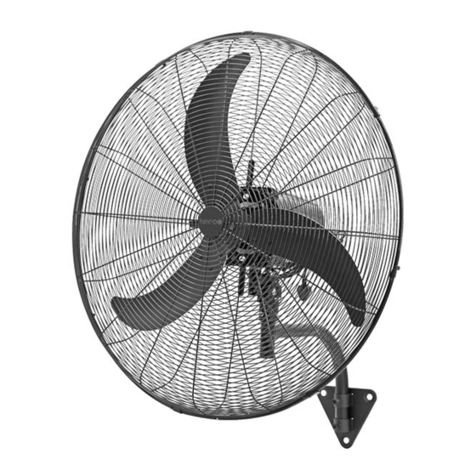

Do not move ventilator while fan is in operation. Use good lifting practices when moving

ventilator to prevent bodily injury.

Blower should be operated and repaired by trained personnel only.

Do not operate if there is any physical damage to cord, plug or receptacle.

Keep ngers and hands clear of fan blade. Keep fan guard securely in place. Do not operate

with damaged or missing fan guards.

Use properly grounded power receptacle in potentially explosive atmospheres, and for

operation safety. Ensure continuity to the earth.

Fatal electrical shock may result if motor frame and adjacent metal are not grounded in

compliance with electrical code.

Keep area clear of rock and debris.

Keep away from children.

WARRANTY

Positive Pressure Ventilators Turbo Ventilators and portable blowers, excluding motor

and wear items, are warranted for one year from date of original purchase, to be free of

defects in material and workmanship. Electric motors are warranted by their respective

manufacturers. Wear items include feet, fasteners, handles, wheels, and paint are not

covered under the warranty. Fan impellers and shrouds are warranted to be free of defects

in material and workmanship for ve years. Components exposed to salt water service are

warranted for a period of one year from date of original purchase. Duct is not warranted

due to its intended use.

Authorization for warranty repairs must be obtained from the factory. There are no

other warranties expressed or implied.

Fan Performance Characteristics

Fan performance is characterized as airow as a function of backpressure. Backpressure is

typically a function of the length of exible duct attached to the fan.

Maximum airow also referred to as free air occurs at 0 mm/ 0” w.g.

The rst chart shows 4 performance curves for all four ATEX fans running on 50Hz AC

power. The second chart show 3 performance curves for three of the ATEX fans, running on

60Hz. Please note that the EFi120xx is not designed to run eciently on 60Hz AC power and

does not appear on the 60Hz chart for this reason.

SM-EFATEX Rev F2 - Page 10 of 16SM-EFATEX Rev F2 - Page 9 of 16

Fan Performance Characteristic for Fans Running on 60Hz AC power

Fan Performance Characteristic for Fans Running on 50Hz AC power TYPICAL VENTILATOR EXPLODED VIEW ACCESSORIES

FOR ATEX, IECEx AND INMETRO HAZARDOUS LOCATION FANS

Euramco Group has several optional antistatic / conductive airow duct accessories

designed explicitly for use with our Hazardous Location Fans to support various end user

applications as identied in the list below.

ACCESSORIES LIST

Fan Model Accessory P/N Description

UB20xx EF7004CS Quick-Couple Canister with 8” x 15’ Duct, Antistatic

EF7004CL/DS Quick-Couple Canister with 8” x 5’ & 8” x 15’ Duct,

Antistatic

EF7004CL/DL Quick-Couple Canister with 8” x 5’ & 8” x 25’ Duct,

Antistatic

EF7004CL Quick-Couple Canister with 8” x 25’ Duct, Antistatic

FDT-0815CBB Duct, 8” x 15’, Antistatic with Belt and Belt

FDT-0825CBB Duct, 8” x 25’, Antistatic with Belt and Belt

EF0304X Duct Adapter, 8” / 20cm

DC8 Duct Coupler, 8”, Stainless Steel

MED189XX Manhole Entry Device, Conductive

MED90XX MED 90oElbow, Conductive

MED5100XX Manhole Entry Device (MED), Conductive, Assembly

MEDIUM MED Universal Mount

EFi75xx FDT-1215CBB Duct, 12” x 15’, Antistatic with Belt and Belt

FDT-1225CBB Duct, 12” x 25’, Antistatic with Belt and Belt

EC0301 Duct Adapter, 12”/30cm to 8”/20cm

DC12 Duct Coupler, Stainless Steel

EB 5006 Duct Adapter, 12” to 10” Reducer

EFi120xx & EFi150xx FDT-1615CBR Duct, 16” x 15’, Antistatic with Belt and Ring

FDT-1625CBR Duct, 16” x 25’, Antistatic with Belt and Ring

FDT-1625CBB Duct, 16” x 25’, Antistatic with Belt and Belt

EA7106 Duct Adapter, 16” / 40cm

DC16 Duct Coupler, Stainless Steel

SM-EFATEX Rev F2 - Page 12 of 16SM-EFATEX Rev F2 - Page 11 of 16

UB20XX EF7002 / EF8002

10

1

2

3

4

5

6

9

11 12

1

7

8

TYPICAL VENTILATOR EXPLODED VIEW

1. E7205K – DUCT ADAPTER KIT 7. EZ-080305003CE – JUNCTION BOX

2. EF7019 – PULL ROD 8. EZ-16/3-E POWER CABLE

3. EM-F.33-60XPEX – EF7002 ATEX MOTOR 9. EF7105AC – HOUSING, CONDUCTIVE

4. EM-F.33-230VXP – EF8002 ATEX MOTOR 10. ST010 - STATOR

5. ED0170 – MOTOR MOUNTING RING 11. ED0170 – MOTOR MOUNTING RING

6. EX-312-RWB – CORD STRAP 12. BL011 - IMPELLER

EFi75XX EB7201XX / EB7201XX-230

TYPICAL VENTILATOR EXPLODED VIEW

1

2

34

56

10

911 1

7

8

1. E7205K – DUCT ADAPTER KIT

• EB5006 - Alternative Duct Adapter, 12”

to 10” Reducer

7. EZ-14/3E – POWER CABLE

2. EB7018 - EFi75xx SWITCH ROD 8. EA7007 - ADAPTER CASTING, C-FACE

3. EZ-CAP-A027 – PUSH CAP 9. EB7201XXHA - 12” BLOWER HOUSING ASSY

4. EM-F.75-60XPEX – MOTOR 10. EZ-312-RWB CORD STRAP

5. EA7004 – FLANGE 11. BL008 – IMPELLER

6. EZ-080305002CE – JUNCTION BOX

SM-EFATEX Rev F2 - Page 14 of 16SM-EFATEX Rev F2 - Page 13 of 16

TYPICAL VENTILATOR EXPLODED VIEW

EFi120XX EA8120XX / EA8120XX-110

TYPICAL VENTILATOR EXPLODED VIEW

EFi150XX EG8200XX/ EG8200XX-230

12

3

457

8

10 11

9

6

1

2

34

57

8

6 9

10

11

1. EA7116 - 16”/40 cm DUCT ASSY (INLET) 7. EZ-312-RWB - CORD STRAP

2. EC7018 - SWITCH ROD 8. EG8200XXHA - HOUSING ASSY

3. EM-F1.5-60/50XPEX - MOTOR 9. EA7007 - ADAPTER CASTING, C-FACE

4. EA7004 - FLANGE 10. BL914 - IMPELLER

5. EZ-080305002CE - JUNCTION BOX 11. EA7117- 16”/40 cm DUCT ASSY (EXHAUST)

6. EZ-14/3 AWG - POWER CABLE

1. EA7116 - 16”/40 cm DUCT ASSY (INLET) 7. EZ-312-RWB - CORD STRAP

2. EC7018 - SWITCH ROD 8. EG8200XXHA - HOUSING ASSY

3. EM-F1.5-60/50XPEX - MOTOR 9. EA7007 - ADAPTER CASTING, C-FACE

4. EA7004 - FLANGE 10. BL914 - IMPELLER

5. EZ-080305002CE - JUNCTION BOX 11. EA7117- 16”/40 cm DUCT ASSY (EXHAUST)

6. EZ-14/3 AWG - POWER CABLE

SM-EFATEX Rev F2 - Page 16 of 16SM-EFATEX Rev F2 - Page 15 of 16

WIRING DIAGRAM

MOTOR LEADS LINE CORD

Ground Screw

Yellow/Green wire from Motor Cord

Black Wire #1

from Motor Cord

Black wire #2 from

Motor Cord

Ground Screw

Yellow/Green wire from Power Cord

Brown Wire from Power

Cord

Blue Wire from Power Cord

DECLARATION OF CONFORMITY

Euramco Group | 2746 Via Orange Way, Spring Valley CA 91978 USA | Ph: +1-619-670-9590 | www.Euramco.com

Page 1 of 1

DECLARATION OF CONFORMITY

ATEX Certified Portable Fans

This Declaration of Conformity is issued for ATEX certified, flame proof, increased safety, portable fans,

intended for use in potentially explosive atmospheres, manufactured by Euramco Safety, Inc. as referenced

herein.

Issue Date: June 24, 2021

Manufacturer: Euramco Safety, Inc.

2746 Via Orange Way

Spring Valley, CA 91978 USA

Equipment Descriptions: UB20xx 8" / 20 cm ATEX Blower Exhauster

EFi75xx 12" / 30 cm ATEX Blower Exhauster

EFi120xx16" / 40 cm ATEX Blower Exhauster

EFi150xx16" / 40 cm ATEX Blower Exhauster

Hazardous Location Rating:II 2 G Ex db eb IIB T6 Gb

II 2 G Ex h IIB T6 Gb

Zone 1, 2

T6, non-mining gases up to 85˚C

Certification Number: 0539 DEMKO 09 ATEX 0926969X

IECEx Certification Number: IECEx UL 13.0062X

Notification Number: 10 ATEX Q137286

Notified Body: UL International DEMKO A/S, Notified Body Number 0539

Borupvang 5A

2750 Ballerup, Denmark

Standards to which

Certificate Applies:

EN 60079-0:2018

EN 60079-1:2014

EN 60079-7:2015+A1:2018

EN 14986:2017

Self-Declared Compliance

Directives:

2006/42/EC – Machinery Directive

2014/30/EU – EMC Directive

2011/65/EU – RoHS – Reduction of Hazardous Substances Directive

Euramco Safety, Inc. hereby declares that equipment described above conforms with the protection

requirements of ATEX Council Directive 2014/34/EU on the approximation of the laws of the Member States

Concerning Equipment and Protection Systems Intended for use in Potentially Explosive Atmospheres.

06/24/2021

DOC-ATEX

SM-EFATEX Rev F1 - Page 1 of 16

USA Headquarters

2746 Via Orange way

Spring Valley, CA

91978 USA

Toll Free: (800) 472-

6326

Phone: +1 (619)

670-9590

Fax: +1 (619) 670-7345

Europe

68 Avenue De La

Liberte

L-1930 Luxembourg,

Luxembourg

VAT Nr LU

18816418

MIDDLE EAST

Dubai Logistic City

Dubai,

United Arab Emirates

CHINA

No. 128, Hezhou Road

Ningbo, Zhejiang,

China

SINGAPORE

1 Fullerton Road

#02-01 One Fullerton

Singapore 049213

Tel : +65-9773 33 35

SM-EFATEX REV F2

This manual suits for next models

3

Table of contents

Other Euramco Fan manuals

Popular Fan manuals by other brands

Lasko

Lasko S18965 operating manual

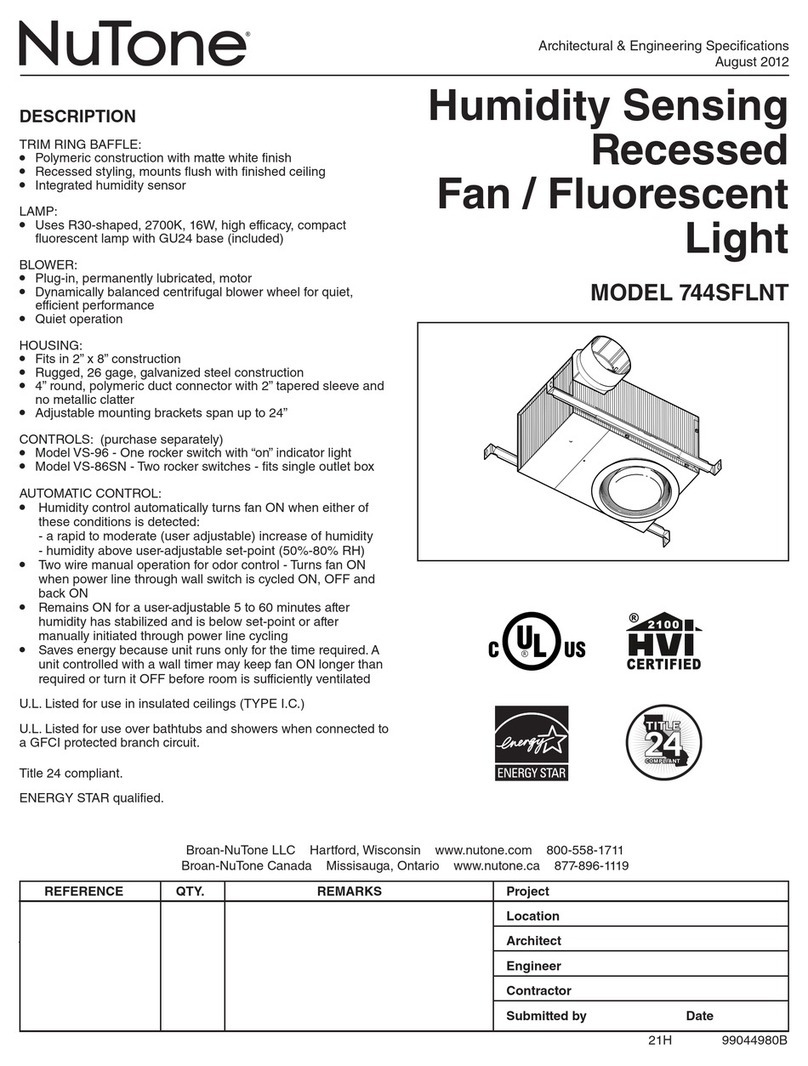

NuTone

NuTone 744SFLNT Architectural & engineering specifications

Multifan

Multifan V-FloFan installation instructions

Helios

Helios VDD T120 Series Installation and operating instructions

Sencor

Sencor SFN 4031BK manual

ZIEHL-ABEGG

ZIEHL-ABEGG FB Series Translation of the original operating instructions