8

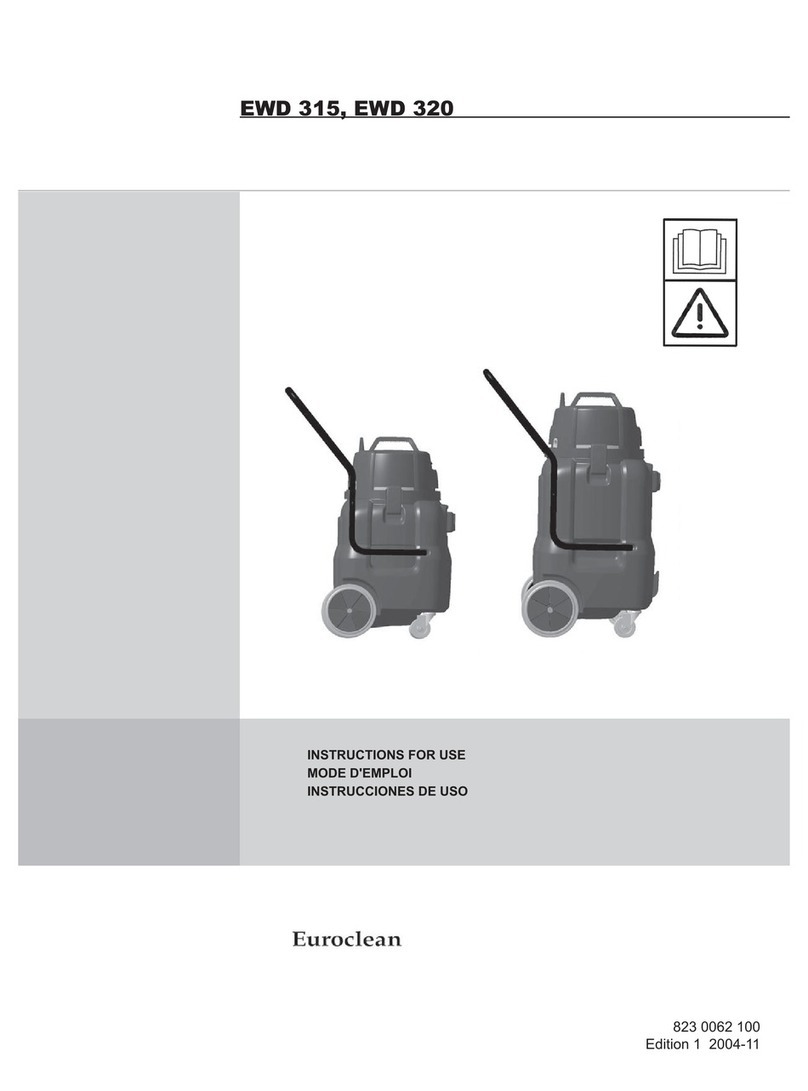

INSTRUCTION FOR USE

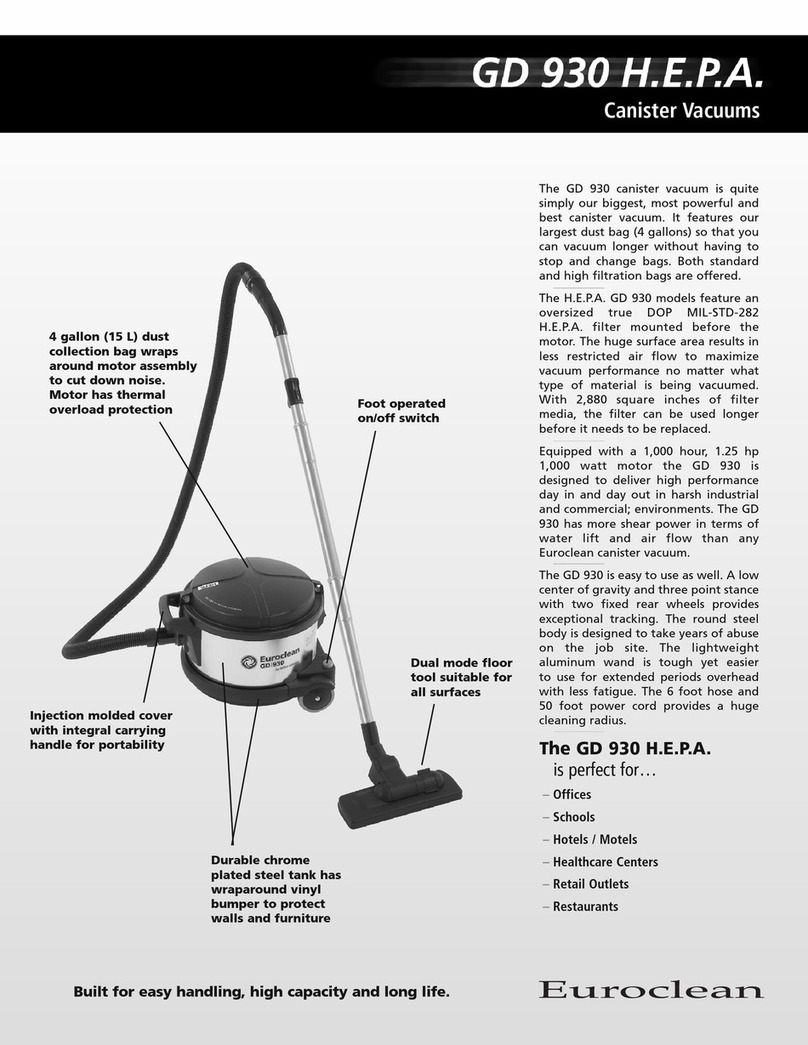

Wet and dry cleaning

Donot use the machinewithoutthe main filterinstalled.

Use dustbag when picking up dry material. Remove the

dust bag before picking up liquids.

1 Start/Stop

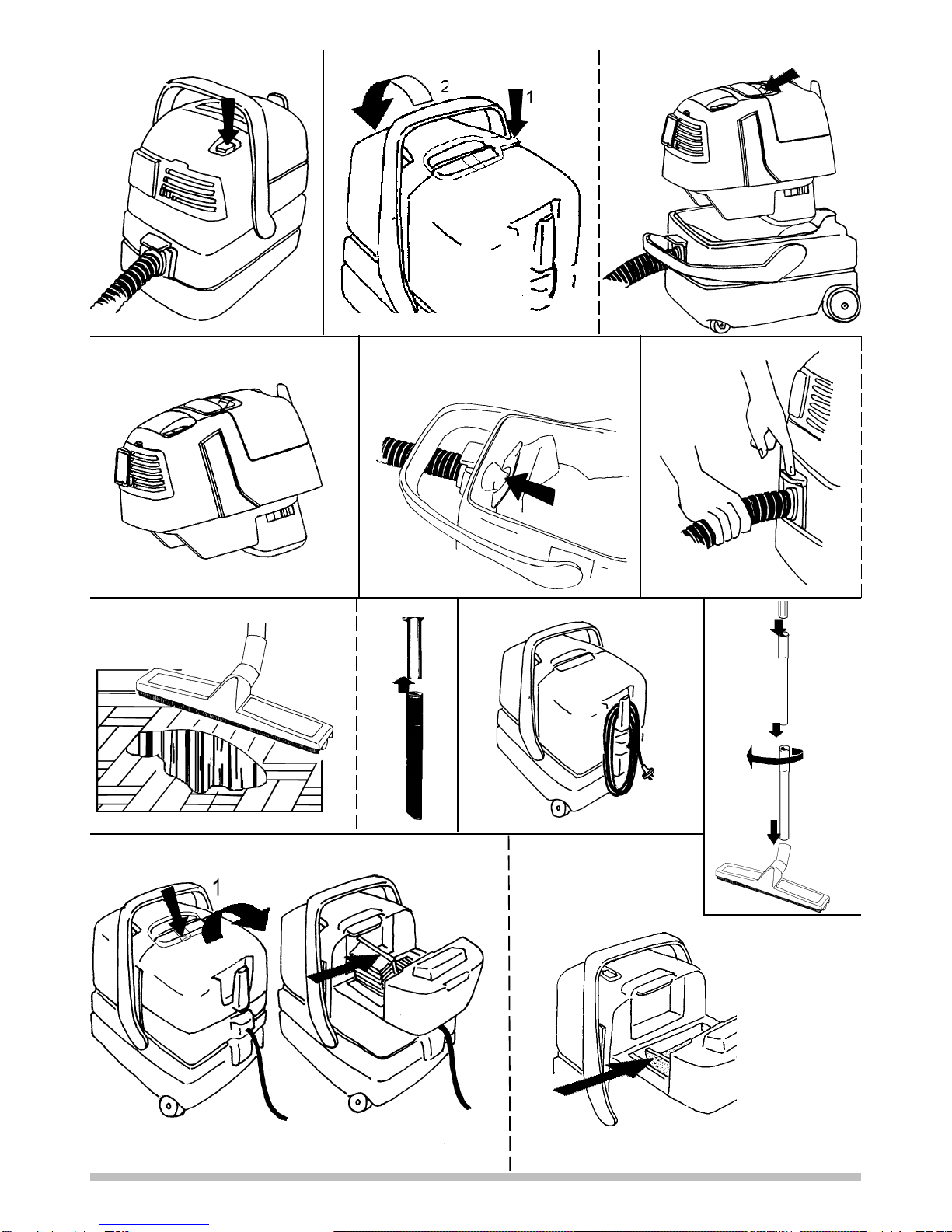

2 How to remove the motor top

Turn off the machine and pull the plug out of the electrical outlet.

a) Press the button next to the handle, and push the handle

forward.

b) Lift the motor top by using the grip on top of the motor top.

c) Rest the motor top on a flat surface as illustrated.

3 Installing the dustbag

Use only approved original Nilfisk-Advance dust bags. When the

bagis2/3fullitshouldbereplaced.Excessiveoverfillingofthisbag

makes it difficult to remove from the vacuum tank and can result in

breakageandspills.Fitthe openingofthedustbagovertheairinlet.

Make sure the cardboard piece has been pressed all the way past

the raised bumps on the air inlet. The flap on the cardboard piece

isusedtoclosethedustbagwhenitisremoved.Placethemotortop

on the tank. Grab the handle and rotate it back to its upright

position, where it locks in place.

4 Hose connection

Push the hose coupling in to the hose connection until it locks.

Press the button on the hose connection down to remove the hose.

5 Tools

The accessories shown in the pictures may vary on different

models.

a) Universal nozzle

Can be used on all types of flooring and for both wet and dry

pickup.

b) Crevice nozzle:

Use to clean furniture, radiators and other hard to reach places.

6 Power cord storage

Windupthecordstartingatthemachine.Storeitonthehook onthe

rear of the machine.

7 Wand assembly

Fit the sections together and twist to lock in place. Clean the nylon

insertswhen needed. Separatethesections bypullingandtwisting

at the same time.

8 Filter replacement

Use only approved Nilfisk-Advance vacuum filters. Turn off and

unplug the machine before exchanging filters. The following is a

recommendedreplacementintervalforallofthefilters.Theseitems

should be replaced more often if you experience a loss of perfor-

mance.

Pre-filter – This filter should be replaced or vacuumed thoroughly

using a HEPA vacuum with every fifth change of paper bag or

whenever there is a visible collection of debris on the filter.

Main filter – This filter should be replaced with every fifth change

of the pre-filter or whenever there is a visible collection of debris

on the filter.

HEPA filter – Replace this filter at least every six months or more

often if a loss of vacuum continues after you have replaced all

other filters and the paper bag.

Motor Cooling Air Exhaust Filter - This filter should be replaced

with every fifth change of paper bag or whenever there is a visible

collection of debris on the filter.

Procedures for exchanging filters

Main filter- Open the filter cover by pressing the release button

and rotate the filter cover open. Remove the filter by pulling one

end of it out of the housing. Clean the sealing surfaces before

reinstallingthemainfilter.Installthefilterwiththe sealthatsurrounds

the filter edge facing upwards. Close the filter lid and press firmly

to lock the lid in place.

Pre-filter- Remove the main filter, as the pre-filter is located

beneath it. Make certain that the colored side of the filter is

positioned downward when installed.

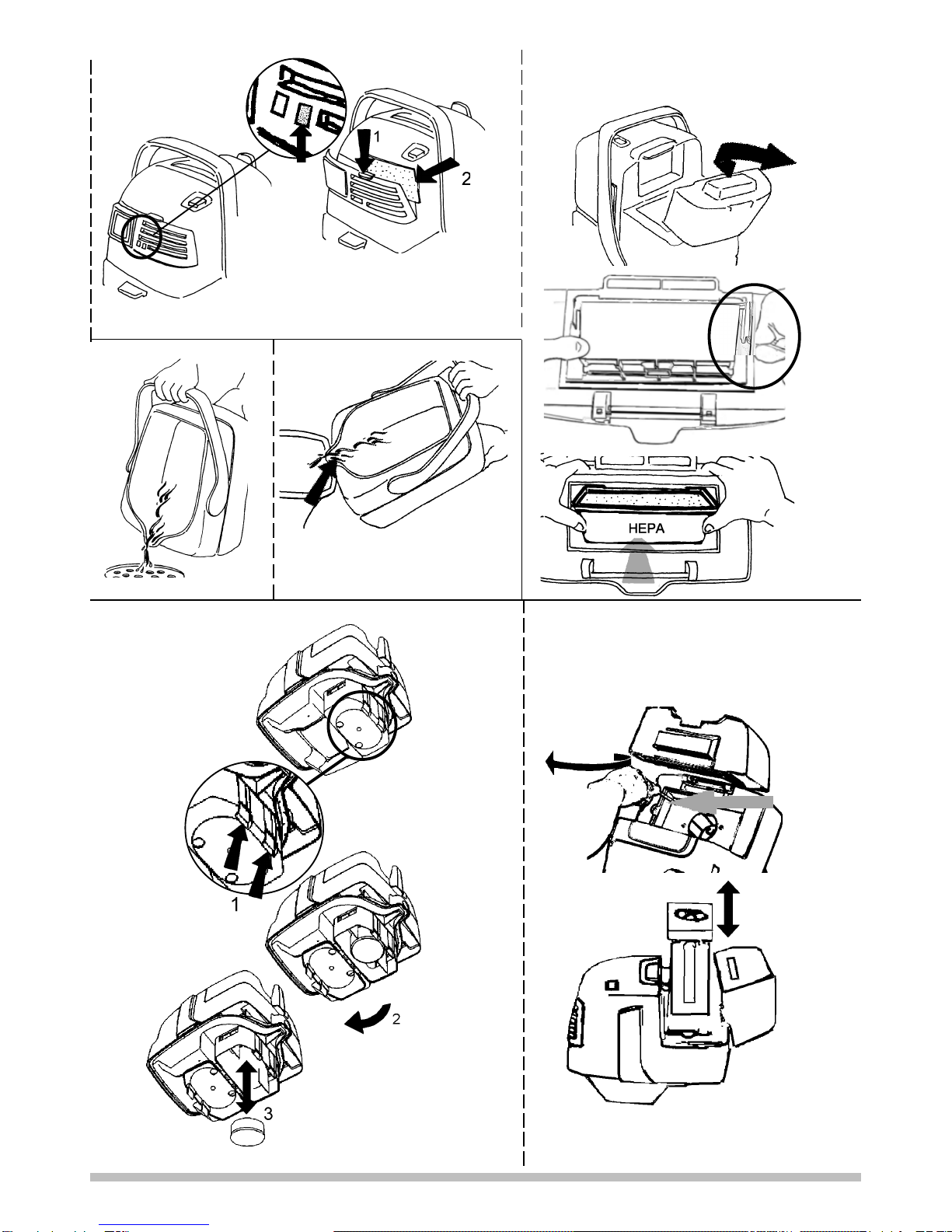

HEPA filter- Open the filter cover by pressing the release button

and rotate the filter cover open. Remove the filter cover by pulling

one side of the filter cover upward/forward until it separates from

the motor housing. The HEPAfilter is attached to the filter cover by

two hooks, one at each side the plastic filter housing. Use a flat

screwdriver or similar tool, and push the outer section of the hooks

inward toward the filter until the hooks loosen from the filter cover.

Remove the filter from the cover. Clean the sealing surfaces before

reinstalling the HEPA filter. When installing the HEPA filter, always

push on the plastic housing of the filter, NEVER on the pleated

filter media. Damage will result to the filter and it will be ineffective

in filtering out substances. Position the filter into the filter cover

with the “HEPA” label facing outward. Making certain that the

bottom of the filter is correctly secured under the mounting lip at

the bottom of the filter lid, press the filter forward into the filter

cover until the hooks on each side of the filter housing snap in

place with the edges of the filter cover. If the filter is correctly

mounted, you will hear a noticeable “clicking” sound. Confirm that

the filter is secured under the mounting lip at the bottom of the

filter lid and that the filter is properly seated at the sealing surface.

Snap the filter cover back onto the hinge on the motor housing.

Close the filter lid and press firmly to lock the lid in place.

Motor Cooling Air Exhaust Filter- Remove the filter holder by

pressing the button on top of the holder. Grasp of the filter flap and

remove the filter from the filter holder. Insert the new filter, making

certain that the longest side of the filter is down and the flap is

facing toward the outside of the cleaner. Reinsert the filter holder

and snap it in place.

9 Draining the tank

When the water level in the tank reaches maximum the float valve

will shut off the air flow through the machine. You will then hear a

noticable change of the sound from the motor and notice that the

suction power decreases. When this occurs, switch the machine

off. Disconnect the machine from the power supply. Remove the

motor top according to earlier instruction (2). Always empty and

clean the tank after picking-up liquids. Allow all parts to dry

thoroughly before the motor top is reassembled.

a) Emptying in a draining gutter: Hold the tank by the carrying

handleandgrabtheemptyinggrip locatedonthebottomsideofthe

tank. Use the emptying grip to tilt the tank and empty it through the

spout.

b) Emptying in a toilet or wash-basiner etc: Lift the tank by the

handle. Let the bottom side of the spout rest on the edge. Use the

emptying grip to tilt the tank and empty it through the spout.

10 Float valve

The machine is equipped with a float valve that shuts of the air

flowthroughthemachinewhenthemaximumfluidlevelis reached.

The float system is placed at the lower edge of the motor top.

Clean the float valve when needed.

Cleaning of the smaller float system: Remove the motor top.

Open the lid on the float valve and remove the float body. Wipe

both the float valve and body with a damp cloth.

Reinstall the float body and close the lid.

Cleaning of the larger float system: Open the filter lid. Remove

the main filter and the pre-filter. Remove the rubber cover for the

screws. Use a TORX T 20 screwdriver and loosen the 4 screws

that ´s fastening the float basket to the motor top. Lift up the float

basket. Wipe both the float valve and body with a damp cloth.

Reinstall the float body and put back the pre filter and the main

filter. Close the lid.

Note! Never pick-up liquid without the float body in place in

the float. Always use a chemical defoamer when picking-up

water containing foaming detergents. Use a defoamer

recommended by the detergents manufacturer. To achieve

the best results with chemical defoamer, add the defomer

through the hose.

Inspect the filter cover sealing ring (part number 140 7249 000)

anytime the filter lid is opened to assure it is not damaged or

missing.