Eurolube 16721 User manual

www.eurolube.com 205203 EUROLUBE EQUIPMENT AB

PART NO 16721, 16724, 16813, 16868 / ART.NR. 16721, 16724, 16813, 16868

HIGH VOLUME OIL CONTROL GUN

SERVICE GUIDE

2020-02 ORIGINAL MANUAL

1

General

High volume hose end control gun with ergonomic and

progressive grip for better control of dispensing and

In-line meter both with digital volume meter for oil and

glycol (certain models). Maximum working pressure 100

bar. Please refer to the sales Catalogue for details on

accessories. Or visit our website: www.eurolube.com

WARNING! Do NOT use solvents or other explosive

fluids. Never point a control valve at any portion of

your body or another person. Accidential discharge

of pressure and/or material can result in injury. Read

these instruction carefully before installation, operation

or service.

DO NOT EXCEED MAXIUMUM PRES-

SURE

Allmänt

Handmätare för höga öden med ergonomiskt handtag

och progressiv ventil för optimal ödeskontroll. Digital

volymmätare för olja och glykol (vissa modeller). Maxi-

malt arbetstryck 100 bar. För detaljerad information,

hänvisar vi till vår kompletta produktkatalog, eller vår

hemsida: www. eurolube.com

VARNING! Ventilerna får EJ användas för tappning av

bensin eller andra (explosiva) kemikalier. Rikta aldrig

utloppsmunstycke mot någon kroppsdel eller någon

annan person. Vätska kan lätt tränga in igenom hud och

förorsaka skador. Läs dessa intruktioner innan installa-

tion, användning eller vid service.

ÖVERSKRID EJ MAX ARBETSTRYCK

PART NO / ART.NR 16721, 16724, 16813, 16868

Maximum ow (with extension) / max öde (inkl. utloppsrör) 80 l/min

Pressure drop at max ow / tryckfall vid max öde 3 bar (44 psi)

Max working pressure / max arbetstryck 100 bar (1450 psi)

Temperature operating range / temperaturarbetsområde -10°C – +70°C

Burst pressure / sprängtryck 400 bar (5800 psi) minimum

Fluid inlet / anslutning 3/4” BSP (F/Inv.)

Fluid compatibility / vätskekompabilitet Engine oil, hydraulic oil, antifreeze uid /

motorolja, hydraulolja, glykol

Vikt / weight 2,05 kg (4,52 lbs)

TECHNICAL DATA / TEKNISKA DATA

MEASUREMENTS / MÅTT

130 mm

580 mm

130 mm

506 mm

30°

16721

16724

www.eurolube.com

EUROLUBE EQUIPMENT 205203

PART NO 16721, 16724, 16813, 16868 / ART.NR. 16721, 16724, 16813, 16868

HIGH VOLUME OIL CONTROL GUN

2

General

The control valve has been designed to dispense a variety of uids. These include

engine oils, hydraulic oils and antifreeze uid.

The balanced control valve allows a progressive opening for better control of uid

delivery. The valve can be locked in open position by means of the trigger button.

The control valve includes a trigger guard to prevent accidental opening.

Safety precautions

1. Only use the unit for the purposes for which is intended.

2. Do not alter or modify the unit.

3. Do not exceed the maximum working pressure or temperature. See page of

technical specications.

4. Do not point dispense valve at anyone or at any part of the body. Use the

equipment with uids which are compatible with the moist parts of the equipment.

See the relevant section of technical specications.

5. Observe the manufacturer´s safety warnings for the uids used.

Dispensing

To dispense uid, proceed as follows:

1. Pull the trigger to begin dispensing.

2. Release the trigger to stop dispensing.

3. After use, the nozzle should be closed to prevent leakage onto oors etc.

Locking the trigger

To lock the trigger in dispensing position, proceed as follows:

1. Pull the trigger to its maximum opening (g. 1).

2. Push the lock button (g. 2).

3. Release the trigger holding the button down until it locks (g. 3).

4. Once the desired quantity is dispensed, pull the trigger to its maximum position to

release the lock.

Allmänt

Oljeventilen har utformats för att tappa en mängd olika vätskor. Dessa inkluderar

motoroljor, hydrauloljor och glykol.

Den balanserade ventilen tillåter en progressiv öppning för bättre kontroll av

vätskeleveransen. Ventilen kan låsas i öppet läge med hjälp av en spärr.

Ventilen är utrustad med ett skydd för avtryckaren för att förhindra oavsiktlig öppning.

Säkerhetsanvisningar

1. Använd bara enheten för de ändamål för vilka den är avsedd.

2. Ändra inte eller bygg ej om enheten.

3. Överskrid inte maximalt arbetstryck eller temperatur. Se tekniska specikationer.

4. Rikta inte ventilen mot någon eller mot någon del av kroppen. Använd utrustningen

med vätskor som är kompatibla med våtdelarna i utrustningen. Se relevanta avsnitt

av tekniska specikationer.

5. Beakta vätskeleverantörens säkerhetsvarningar för de vätskor som hanteras.

Tappning av vätska

Gör så här för att tappa vätska:

1. Tryck in avtryckaren för att börja tappningen.

2. Släpp avtryckaren för att stoppa tappningen.

3. Efter användning bör non-drip munstycket stängas för att undvika läckage på golv

och dylikt.

Låsning av avtryckaren

För att låsa avtryckaren:

1. Håll in avtryckaren så mycket det går (g 1).

2. Tryck in låsknappen (g 2).

3. Släpp avtryckaren tills spärren går i (g 3).

4. När önskad volym uppnås, håll in avtryckaren helt för att lossa på spärren.

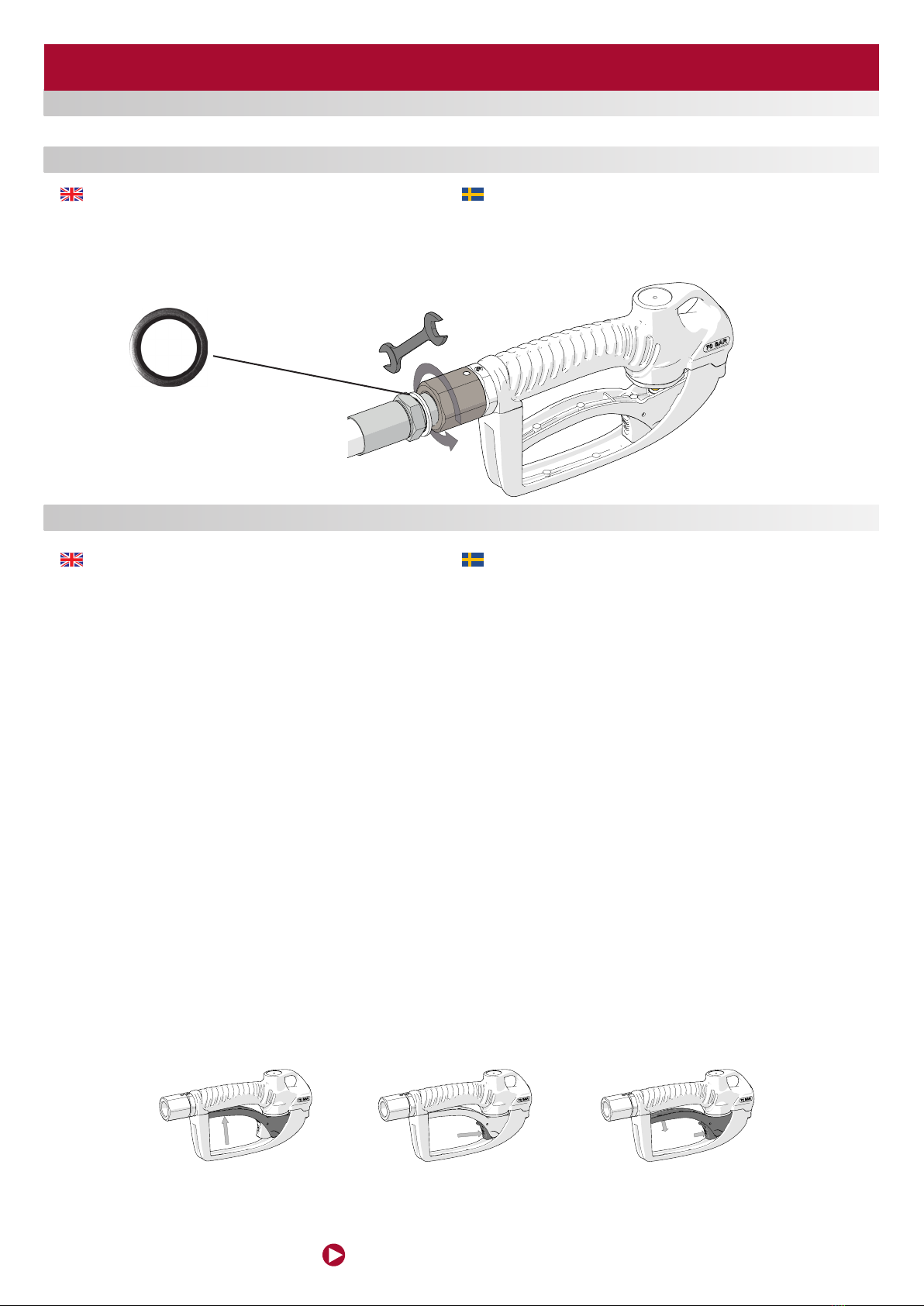

General

The connection of the extension to the control valve outlet is performed by a 3/4”

bonded seal. Check the tightness to prevent leakage.

To connect the control valve to the uid line, keep xed the control valve body and the

end of the hose while rotate the free end of the swivel until achieves the desired torque.

Sealing should be achieved by means of 3/4” bonded seal (part no 1367422)

Allmänt

Anslutning av utloppsröret sker med hjälp av en 3/4” gummistålbricka. Kontrollera dess

täthet för att undvika läckage.

För att enklast ansluta oljeventilen till vätskeledningen, xera oljeventilens hus och

slangen, och gänga på sviveln på slangen och dra åt tills det blir tätt.

Anslutningen bör tätas med en 3/4” gummistålbricka (art nr 1367422)

INSTALLATION / INSTALLATION

OPERATION / ANVÄNDNING

1367422

FIG 1 FIG 2 FIG 3

www.eurolube.com 205203 EUROLUBE EQUIPMENT

PART NO 16721, 16724, 16813, 16868 / ART.NR. 16721, 16724, 16813, 16868

HIGH VOLUME OIL CONTROL GUN

3

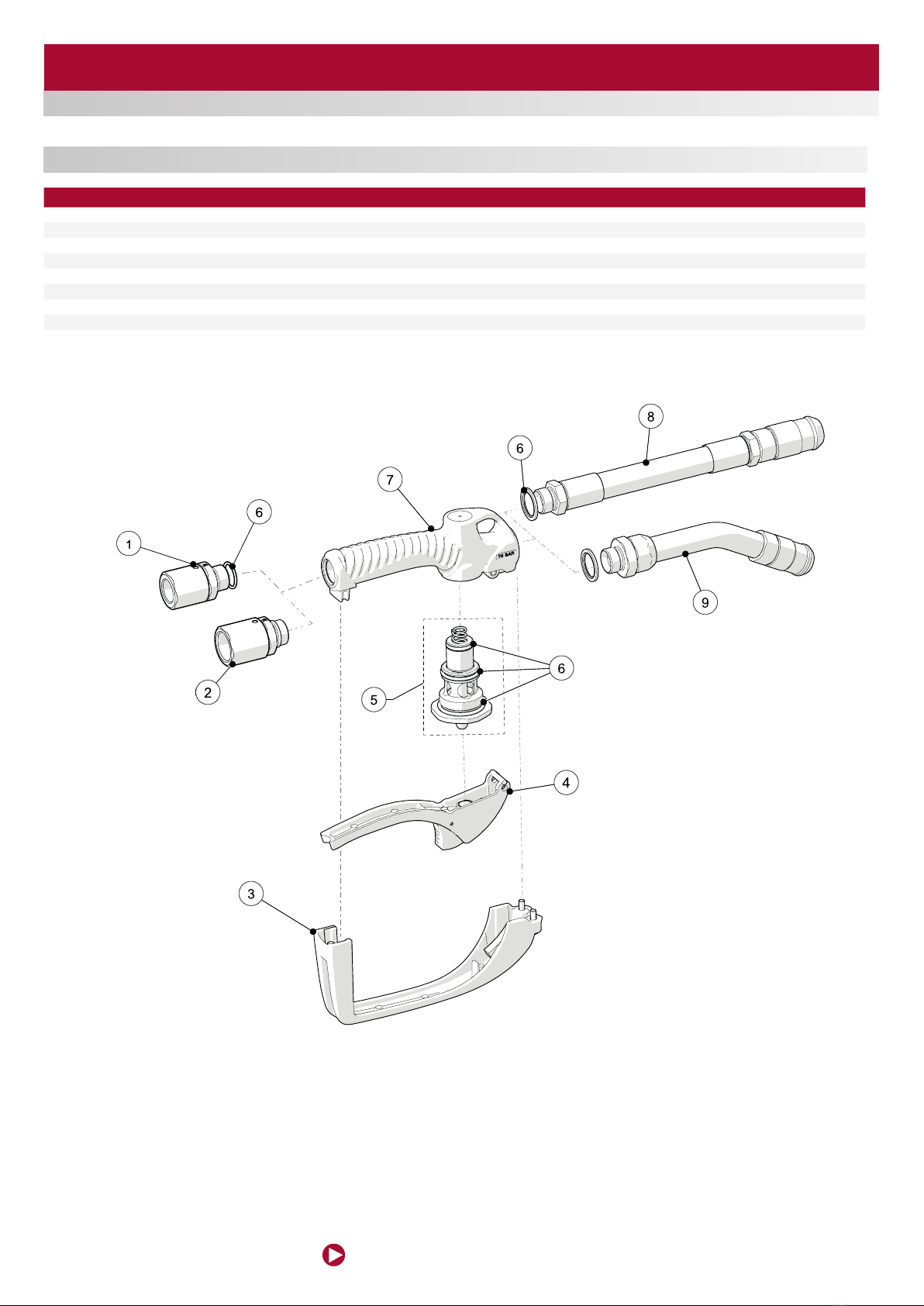

ITEM / POS NAME / BENÄMNING PART NO / ART.NR.

1 Swivel 3/4” / svivel 3/4” 1060101

2 Swivel 1” / svivel 1” 16711

3 Trigger guard / avtryckarskydd 1060102

4 Trigger / avtryckare 1060103

5 Valve / ventil 1060104

6Seal kit / tätningssats 1060105

7Valve body / ventilhus 1060106

8Outlet hose / utloppsslang 1060107

9Outlet tube / utloppsrör 1168690

EXPLODED VIEW / SPRÄNGSKISS

www.eurolube.com

EUROLUBE EQUIPMENT 205203

PART NO 16721, 16724, 16813, 16868 / ART.NR. 16721, 16724, 16813, 16868

HIGH VOLUME OIL CONTROL GUN

4

DEUTSCH

ESPAÑOL ENGLISHSVENSKAFRANÇAIS

Pos. Réf Désignation Qte.

1Vis de carter 8

Couvercle de chambre de mesure 1

2

Joint torique 1

Engrenages ovales 2

Aimant 2

3 2040700

Carte électronique 1

Carter 1

Vis avec pas en plastique PCB 4

Vis de carter en plastique 4

4Carter 1

Vis autotaraudeuse 4

105088

Alentec & Orion AB Grustagsvägen 4, SE-13840, Älta, SWEDEN · info@alentec.se · www.alentec.com

3

PIÈCES DE RECHANGE POUR 25050, 25055, 25052, 25051

8836 889 R. 12/18

GARTEC SRL · Castronno (VA) · Via Olona 4/A · Phone: +39 0332 895026 · Fax: +39 0332 895061 · Email: [email protected]

EN

2018_12_14-12:00

Pos. Part No. Description Qty.

1 369636 Countersunk screw 8

Measuring chamber lid 1

2 369633

O-ring 1

Oval gear 2

Magnet 2

3 369635.700

Electronic card 1

Casing 1

Screw with plastic thread PCB 4

Screw with plastic thread casing 4

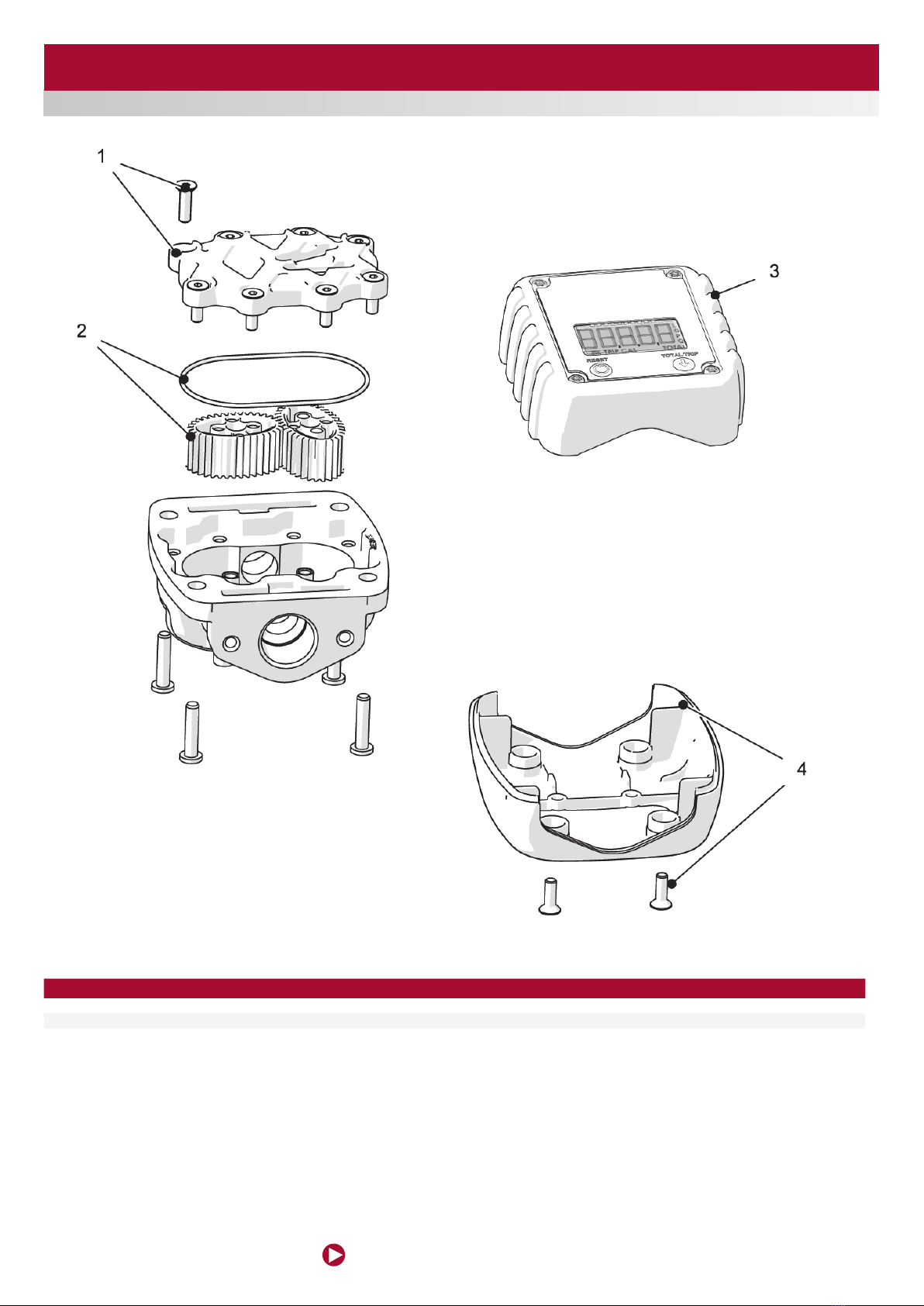

SPARE PARTS

ITEM / POS NAME / BENÄMNING PART NO / ART.NR.

1 Meter chamber cover including 8 screws / täcklock inkl skruvar 8st 1064001

2 Oval gears and O-rings / ovala kugghjul inkl o-ring 1064002

3Cover and circuit board / kåpa med kretskort 1060070

www.eurolube.com 205203 EUROLUBE EQUIPMENT

PART NO 16721, 16724, 16813, 16868 / ART.NR. 16721, 16724, 16813, 16868

HIGH VOLUME OIL CONTROL GUN

5

The calibration process is semi-automatic. To start the process, the meter must be in

partial meter mode (g. 14) and is accessed by simultaneously pressing the buttons

RESET and TOTAL/TRIP for 3 seconds (g. 15). After releasing the buttons the current

calibration factor is shown on the meter (g. 16).

If the screen does not show the correct measuring unit (g. 16) press the TOTAL/TRIP

button (g. 17) successively until displaying the required unit (g. 18). Press RESET (g.

19) to start the calibration process (g. 20).

It now starts to release the desired volume into the container. Remember that you

must release at least 2 litres to perform a good calibration. In the example shown in

the gures it is assumed that 2 litres are released according to the reading on the

calibrated container and that the meter records 2.1 litres (g. 21).

To administer the real quantity released (which is that measured in the calibrated

container or scales), press the RESET button for 1 second (g. 22). The digits start to

ash (g. 23) indicating that the value shown can be modied. Each press of the RESET

button increases the value by 0.1 litres and each press of the TOTAL/ TRIP button (g.

24) reduces this value by 0.1 litres (g. 25).

Once the real value released is set (g. 25) press the RESET button for 1 second (g.

26). The meter shows the new stored calibration factor (g. 27) and then exits the

calibration process. The screen shows the partial meter with the units set during the

calibration process (g. 28). If, during any phase of the calibration process, you wish

to exit without saving the changes made you must press the TOTAL/TRIP button for

1 second. Likewise, if 30 seconds of inactivity elapse during the process, the meter

switches off automatically and exits the calibration process without storing the data.

Kalibreringsproceduren är halvautomatisk. För att starta kalibreringen måste mätaren

stå i normal läge (g. 14). Tryck och håll in TOTAL/TRIP samt RESET knappen i tre

sekunder. När knapparna släpps kommer kalibreringsfaktorn visas i fönstret (g. 16).

Om fel enhet visas i fönstret (g. 16) tryck på TOTAL/TRIP tills önskad enhet visas. Tryck

på RESET (g. 19) för att starta kalibreringsprocessen (g 20).

Fortsätt genom att tappa upp minst två liter i mätcylindern. I följande exempel antas att 2

liter är tappat enligt mätcylindern och att mätaren har registrerat 2,1 liter (g. 21).

För att mata in det faktiska värde som är uppmätt i mätcylindern (eller våg)Tryck och

håll in RESET i en sekund. Siffrorna i displayen kommer att börja blinka för att visa att

de går att ändra. Varje intryckning av RESET kommer att öka värdet med 0,1 liter, varje

tryck på TOTAL/TRIP kommer minska värdet med 0,1 liter.

När det önskade värdet visas i fönstret (i detta fall 2,00), tryck och håll in RESET i en

sekund (g 26). Mätaren kommer nu att visa den nya kalibreringsfaktorn, och sedan

återgå till normalläge. Vill man i något steg avbryta kalibreringsproceduren utan att

spara några ändringar, görs detta genom att hålla in TOTAL/TRIP knappen i en sekund.

Om trettio sekunders inaktivitet inträffar kommer mätaren stängas av och återgå till

normalläge utan att spara ändringar.

CALIBRATION / KALIBRERING

105088

Alentec & Orion AB Grustagsvägen 4, SE-13840, Älta, SWEDEN · info@alentec.se · www.alentec.com

5

ENGLISHSVENSKAFRANÇAISDEUTSCH

ESPAÑOL

To administer the real quantity released (which is that measured in

the calibrated container or scales), press the RESET button for 1

second (fig. 22). The digits start to flash (fig. 23) indicating that the

value shown can be modified. Each press of the RESET button

increases the value by 0.1 litres and each press of the TOTAL/

TRIP button (fig. 24) reduces this value by 0.1 litres (fig. 25).

After the calibration process you will obtain precision within the

range of ±0.5% with the meter. If the meter exceeds this range it

could be due to the following:

• Unsuitable container used for the calibration.

The calibration process is semi-automatic. To start the process, the

meter must be in partial meter mode (fig. 14) and is accessed by

simultaneously pressing the buttons RESET and TOTAL/TRIP for

3 seconds (fig. 15). After releasing the buttons the current

calibration factor is shown on the meter (fig. 16).

If the screen does not show the correct measuring unit (fig. 16)

press the TOTAL/TRIP button (fig. 17) successively until displaying

the required unit (fig. 18).

Press RESET (fig. 19) to start the calibration process (fig. 20).

It now starts to release the desired volume into the container.

Remember that you must release at least 1 litre to perform a good

calibration. In the example shown in the figures it is assumed that

2 litres are released according to the reading on the calibrated

container and that the meter records 2.1 litres (fig. 21).

• The container is not empty before the calibration.

• Air in the fluid which has not been completely removed.

• The values are not properly introduced into the calibration

process.

Once the real value released is set (fig. 25) press the RESET

button for 1 second (fig. 26). The meter shows the new stored

calibration factor (fig. 27) and then exits the calibration process.

The screen shows the partial meter with the units set during the

calibration process (fig. 28).

If, during any phase of the calibration process, you wish to exit

without saving the changes made you must press the TOTAL/TRIP

button for 1 second. Likewise, if 30 seconds of inactivity elapse

during the process, the meter switches off automatically and exits

the calibration process without storing the data.

CALIBRATION

CALIBRATION CAPACITY

CALIBRATION PROCEDURES

Fig. 14 Fig. 15 Fig. 16

Fig. 21

Fig. 17 Fig. 19Fig. 18 Fig. 20

Fig. 22 Fig. 23 Fig. 24 Fig. 25

3"

1"

1"

Fig. 26 Fig. 27 Fig. 28

TOTAL / TRIP

TOTAL / TRIP

TOTAL / TRIP

105088

Alentec & Orion AB Grustagsvägen 4, SE-13840, Älta, SWEDEN · info@alentec.se · www.alentec.com

5

ENGLISHSVENSKAFRANÇAISDEUTSCH

ESPAÑOL

To administer the real quantity released (which is that measured in

the calibrated container or scales), press the RESET button for 1

second (fig. 22). The digits start to flash (fig. 23) indicating that the

value shown can be modified. Each press of the RESET button

increases the value by 0.1 litres and each press of the TOTAL/

TRIP button (fig. 24) reduces this value by 0.1 litres (fig. 25).

After the calibration process you will obtain precision within the

range of ±0.5% with the meter. If the meter exceeds this range it

could be due to the following:

• Unsuitable container used for the calibration.

The calibration process is semi-automatic. To start the process, the

meter must be in partial meter mode (fig. 14) and is accessed by

simultaneously pressing the buttons RESET and TOTAL/TRIP for

3 seconds (fig. 15). After releasing the buttons the current

calibration factor is shown on the meter (fig. 16).

If the screen does not show the correct measuring unit (fig. 16)

press the TOTAL/TRIP button (fig. 17) successively until displaying

the required unit (fig. 18).

Press RESET (fig. 19) to start the calibration process (fig. 20).

It now starts to release the desired volume into the container.

Remember that you must release at least 1 litre to perform a good

calibration. In the example shown in the figures it is assumed that

2 litres are released according to the reading on the calibrated

container and that the meter records 2.1 litres (fig. 21).

• The container is not empty before the calibration.

• Air in the fluid which has not been completely removed.

• The values are not properly introduced into the calibration

process.

Once the real value released is set (fig. 25) press the RESET

button for 1 second (fig. 26). The meter shows the new stored

calibration factor (fig. 27) and then exits the calibration process.

The screen shows the partial meter with the units set during the

calibration process (fig. 28).

If, during any phase of the calibration process, you wish to exit

without saving the changes made you must press the TOTAL/TRIP

button for 1 second. Likewise, if 30 seconds of inactivity elapse

during the process, the meter switches off automatically and exits

the calibration process without storing the data.

CALIBRATION

CALIBRATION CAPACITY

CALIBRATION PROCEDURES

Fig. 14 Fig. 15 Fig. 16

Fig. 21

Fig. 17 Fig. 19Fig. 18 Fig. 20

Fig. 22 Fig. 23 Fig. 24 Fig. 25

3"

1"

1"

Fig. 26 Fig. 27 Fig. 28

TOTAL / TRIP

TOTAL / TRIP

TOTAL / TRIP

105088

Alentec & Orion AB Grustagsvägen 4, SE-13840, Älta, SWEDEN · info@alentec.se · www.alentec.com

5

ENGLISHSVENSKAFRANÇAISDEUTSCH

ESPAÑOL

To administer the real quantity released (which is that measured in

the calibrated container or scales), press the RESET button for 1

second (fig. 22). The digits start to flash (fig. 23) indicating that the

value shown can be modified. Each press of the RESET button

increases the value by 0.1 litres and each press of the TOTAL/

TRIP button (fig. 24) reduces this value by 0.1 litres (fig. 25).

After the calibration process you will obtain precision within the

range of ±0.5% with the meter. If the meter exceeds this range it

could be due to the following:

• Unsuitable container used for the calibration.

The calibration process is semi-automatic. To start the process, the

meter must be in partial meter mode (fig. 14) and is accessed by

simultaneously pressing the buttons RESET and TOTAL/TRIP for

3 seconds (fig. 15). After releasing the buttons the current

calibration factor is shown on the meter (fig. 16).

If the screen does not show the correct measuring unit (fig. 16)

press the TOTAL/TRIP button (fig. 17) successively until displaying

the required unit (fig. 18).

Press RESET (fig. 19) to start the calibration process (fig. 20).

It now starts to release the desired volume into the container.

Remember that you must release at least 1 litre to perform a good

calibration. In the example shown in the figures it is assumed that

2 litres are released according to the reading on the calibrated

container and that the meter records 2.1 litres (fig. 21).

• The container is not empty before the calibration.

• Air in the fluid which has not been completely removed.

• The values are not properly introduced into the calibration

process.

Once the real value released is set (fig. 25) press the RESET

button for 1 second (fig. 26). The meter shows the new stored

calibration factor (fig. 27) and then exits the calibration process.

The screen shows the partial meter with the units set during the

calibration process (fig. 28).

If, during any phase of the calibration process, you wish to exit

without saving the changes made you must press the TOTAL/TRIP

button for 1 second. Likewise, if 30 seconds of inactivity elapse

during the process, the meter switches off automatically and exits

the calibration process without storing the data.

CALIBRATION

CALIBRATION CAPACITY

CALIBRATION PROCEDURES

Fig. 14 Fig. 15 Fig. 16

Fig. 21

Fig. 17 Fig. 19Fig. 18 Fig. 20

Fig. 22 Fig. 23 Fig. 24 Fig. 25

3"

1"

1"

Fig. 26 Fig. 27 Fig. 28

TOTAL / TRIP

TOTAL / TRIP

TOTAL / TRIP

105088

Alentec & Orion AB Grustagsvägen 4, SE-13840, Älta, SWEDEN · info@alentec.se · www.alentec.com

5

ENGLISHSVENSKAFRANÇAISDEUTSCH

ESPAÑOL

To administer the real quantity released (which is that measured in

the calibrated container or scales), press the RESET button for 1

second (fig. 22). The digits start to flash (fig. 23) indicating that the

value shown can be modified. Each press of the RESET button

increases the value by 0.1 litres and each press of the TOTAL/

TRIP button (fig. 24) reduces this value by 0.1 litres (fig. 25).

After the calibration process you will obtain precision within the

range of ±0.5% with the meter. If the meter exceeds this range it

could be due to the following:

• Unsuitable container used for the calibration.

The calibration process is semi-automatic. To start the process, the

meter must be in partial meter mode (fig. 14) and is accessed by

simultaneously pressing the buttons RESET and TOTAL/TRIP for

3 seconds (fig. 15). After releasing the buttons the current

calibration factor is shown on the meter (fig. 16).

If the screen does not show the correct measuring unit (fig. 16)

press the TOTAL/TRIP button (fig. 17) successively until displaying

the required unit (fig. 18).

Press RESET (fig. 19) to start the calibration process (fig. 20).

It now starts to release the desired volume into the container.

Remember that you must release at least 1 litre to perform a good

calibration. In the example shown in the figures it is assumed that

2 litres are released according to the reading on the calibrated

container and that the meter records 2.1 litres (fig. 21).

• The container is not empty before the calibration.

• Air in the fluid which has not been completely removed.

• The values are not properly introduced into the calibration

process.

Once the real value released is set (fig. 25) press the RESET

button for 1 second (fig. 26). The meter shows the new stored

calibration factor (fig. 27) and then exits the calibration process.

The screen shows the partial meter with the units set during the

calibration process (fig. 28).

If, during any phase of the calibration process, you wish to exit

without saving the changes made you must press the TOTAL/TRIP

button for 1 second. Likewise, if 30 seconds of inactivity elapse

during the process, the meter switches off automatically and exits

the calibration process without storing the data.

CALIBRATION

CALIBRATION CAPACITY

CALIBRATION PROCEDURES

Fig. 14 Fig. 15 Fig. 16

Fig. 21

Fig. 17 Fig. 19Fig. 18 Fig. 20

Fig. 22 Fig. 23 Fig. 24 Fig. 25

3"

1"

1"

Fig. 26 Fig. 27 Fig. 28

TOTAL / TRIP

TOTAL / TRIP

TOTAL / TRIP

105088

Alentec & Orion AB Grustagsvägen 4, SE-13840, Älta, SWEDEN · info@alentec.se · www.alentec.com

5

ENGLISHSVENSKAFRANÇAISDEUTSCH

ESPAÑOL

To administer the real quantity released (which is that measured in

the calibrated container or scales), press the RESET button for 1

second (fig. 22). The digits start to flash (fig. 23) indicating that the

value shown can be modified. Each press of the RESET button

increases the value by 0.1 litres and each press of the TOTAL/

TRIP button (fig. 24) reduces this value by 0.1 litres (fig. 25).

After the calibration process you will obtain precision within the

range of ±0.5% with the meter. If the meter exceeds this range it

could be due to the following:

• Unsuitable container used for the calibration.

The calibration process is semi-automatic. To start the process, the

meter must be in partial meter mode (fig. 14) and is accessed by

simultaneously pressing the buttons RESET and TOTAL/TRIP for

3 seconds (fig. 15). After releasing the buttons the current

calibration factor is shown on the meter (fig. 16).

If the screen does not show the correct measuring unit (fig. 16)

press the TOTAL/TRIP button (fig. 17) successively until displaying

the required unit (fig. 18).

Press RESET (fig. 19) to start the calibration process (fig. 20).

It now starts to release the desired volume into the container.

Remember that you must release at least 1 litre to perform a good

calibration. In the example shown in the figures it is assumed that

2 litres are released according to the reading on the calibrated

container and that the meter records 2.1 litres (fig. 21).

• The container is not empty before the calibration.

• Air in the fluid which has not been completely removed.

• The values are not properly introduced into the calibration

process.

Once the real value released is set (fig. 25) press the RESET

button for 1 second (fig. 26). The meter shows the new stored

calibration factor (fig. 27) and then exits the calibration process.

The screen shows the partial meter with the units set during the

calibration process (fig. 28).

If, during any phase of the calibration process, you wish to exit

without saving the changes made you must press the TOTAL/TRIP

button for 1 second. Likewise, if 30 seconds of inactivity elapse

during the process, the meter switches off automatically and exits

the calibration process without storing the data.

CALIBRATION

CALIBRATION CAPACITY

CALIBRATION PROCEDURES

Fig. 14 Fig. 15 Fig. 16

Fig. 21

Fig. 17 Fig. 19Fig. 18 Fig. 20

Fig. 22 Fig. 23 Fig. 24 Fig. 25

3"

1"

1"

Fig. 26 Fig. 27 Fig. 28

TOTAL / TRIP

TOTAL / TRIP

TOTAL / TRIP

105088

Alentec & Orion AB Grustagsvägen 4, SE-13840, Älta, SWEDEN · info@alentec.se · www.alentec.com

5

ENGLISHSVENSKAFRANÇAISDEUTSCH

ESPAÑOL

To administer the real quantity released (which is that measured in

the calibrated container or scales), press the RESET button for 1

second (fig. 22). The digits start to flash (fig. 23) indicating that the

value shown can be modified. Each press of the RESET button

increases the value by 0.1 litres and each press of the TOTAL/

TRIP button (fig. 24) reduces this value by 0.1 litres (fig. 25).

After the calibration process you will obtain precision within the

range of ±0.5% with the meter. If the meter exceeds this range it

could be due to the following:

• Unsuitable container used for the calibration.

The calibration process is semi-automatic. To start the process, the

meter must be in partial meter mode (fig. 14) and is accessed by

simultaneously pressing the buttons RESET and TOTAL/TRIP for

3 seconds (fig. 15). After releasing the buttons the current

calibration factor is shown on the meter (fig. 16).

If the screen does not show the correct measuring unit (fig. 16)

press the TOTAL/TRIP button (fig. 17) successively until displaying

the required unit (fig. 18).

Press RESET (fig. 19) to start the calibration process (fig. 20).

It now starts to release the desired volume into the container.

Remember that you must release at least 1 litre to perform a good

calibration. In the example shown in the figures it is assumed that

2 litres are released according to the reading on the calibrated

container and that the meter records 2.1 litres (fig. 21).

• The container is not empty before the calibration.

• Air in the fluid which has not been completely removed.

• The values are not properly introduced into the calibration

process.

Once the real value released is set (fig. 25) press the RESET

button for 1 second (fig. 26). The meter shows the new stored

calibration factor (fig. 27) and then exits the calibration process.

The screen shows the partial meter with the units set during the

calibration process (fig. 28).

If, during any phase of the calibration process, you wish to exit

without saving the changes made you must press the TOTAL/TRIP

button for 1 second. Likewise, if 30 seconds of inactivity elapse

during the process, the meter switches off automatically and exits

the calibration process without storing the data.

CALIBRATION

CALIBRATION CAPACITY

CALIBRATION PROCEDURES

Fig. 14 Fig. 15 Fig. 16

Fig. 21

Fig. 17 Fig. 19Fig. 18 Fig. 20

Fig. 22 Fig. 23 Fig. 24 Fig. 25

3"

1"

1"

Fig. 26 Fig. 27 Fig. 28

TOTAL / TRIP

TOTAL / TRIP

TOTAL / TRIP

105088

Alentec & Orion AB Grustagsvägen 4, SE-13840, Älta, SWEDEN · info@alentec.se · www.alentec.com

5

ENGLISHSVENSKAFRANÇAISDEUTSCH

ESPAÑOL

To administer the real quantity released (which is that measured in

the calibrated container or scales), press the RESET button for 1

second (fig. 22). The digits start to flash (fig. 23) indicating that the

value shown can be modified. Each press of the RESET button

increases the value by 0.1 litres and each press of the TOTAL/

TRIP button (fig. 24) reduces this value by 0.1 litres (fig. 25).

After the calibration process you will obtain precision within the

range of ±0.5% with the meter. If the meter exceeds this range it

could be due to the following:

• Unsuitable container used for the calibration.

The calibration process is semi-automatic. To start the process, the

meter must be in partial meter mode (fig. 14) and is accessed by

simultaneously pressing the buttons RESET and TOTAL/TRIP for

3 seconds (fig. 15). After releasing the buttons the current

calibration factor is shown on the meter (fig. 16).

If the screen does not show the correct measuring unit (fig. 16)

press the TOTAL/TRIP button (fig. 17) successively until displaying

the required unit (fig. 18).

Press RESET (fig. 19) to start the calibration process (fig. 20).

It now starts to release the desired volume into the container.

Remember that you must release at least 1 litre to perform a good

calibration. In the example shown in the figures it is assumed that

2 litres are released according to the reading on the calibrated

container and that the meter records 2.1 litres (fig. 21).

• The container is not empty before the calibration.

• Air in the fluid which has not been completely removed.

• The values are not properly introduced into the calibration

process.

Once the real value released is set (fig. 25) press the RESET

button for 1 second (fig. 26). The meter shows the new stored

calibration factor (fig. 27) and then exits the calibration process.

The screen shows the partial meter with the units set during the

calibration process (fig. 28).

If, during any phase of the calibration process, you wish to exit

without saving the changes made you must press the TOTAL/TRIP

button for 1 second. Likewise, if 30 seconds of inactivity elapse

during the process, the meter switches off automatically and exits

the calibration process without storing the data.

CALIBRATION

CALIBRATION CAPACITY

CALIBRATION PROCEDURES

Fig. 14 Fig. 15 Fig. 16

Fig. 21

Fig. 17 Fig. 19Fig. 18 Fig. 20

Fig. 22 Fig. 23 Fig. 24 Fig. 25

3"

1"

1"

Fig. 26 Fig. 27 Fig. 28

TOTAL / TRIP

TOTAL / TRIP

TOTAL / TRIP

105088

Alentec & Orion AB Grustagsvägen 4, SE-13840, Älta, SWEDEN · info@alentec.se · www.alentec.com

5

ENGLISHSVENSKAFRANÇAISDEUTSCH

ESPAÑOL

To administer the real quantity released (which is that measured in

the calibrated container or scales), press the RESET button for 1

second (fig. 22). The digits start to flash (fig. 23) indicating that the

value shown can be modified. Each press of the RESET button

increases the value by 0.1 litres and each press of the TOTAL/

TRIP button (fig. 24) reduces this value by 0.1 litres (fig. 25).

After the calibration process you will obtain precision within the

range of ±0.5% with the meter. If the meter exceeds this range it

could be due to the following:

• Unsuitable container used for the calibration.

The calibration process is semi-automatic. To start the process, the

meter must be in partial meter mode (fig. 14) and is accessed by

simultaneously pressing the buttons RESET and TOTAL/TRIP for

3 seconds (fig. 15). After releasing the buttons the current

calibration factor is shown on the meter (fig. 16).

If the screen does not show the correct measuring unit (fig. 16)

press the TOTAL/TRIP button (fig. 17) successively until displaying

the required unit (fig. 18).

Press RESET (fig. 19) to start the calibration process (fig. 20).

It now starts to release the desired volume into the container.

Remember that you must release at least 1 litre to perform a good

calibration. In the example shown in the figures it is assumed that

2 litres are released according to the reading on the calibrated

container and that the meter records 2.1 litres (fig. 21).

• The container is not empty before the calibration.

• Air in the fluid which has not been completely removed.

• The values are not properly introduced into the calibration

process.

Once the real value released is set (fig. 25) press the RESET

button for 1 second (fig. 26). The meter shows the new stored

calibration factor (fig. 27) and then exits the calibration process.

The screen shows the partial meter with the units set during the

calibration process (fig. 28).

If, during any phase of the calibration process, you wish to exit

without saving the changes made you must press the TOTAL/TRIP

button for 1 second. Likewise, if 30 seconds of inactivity elapse

during the process, the meter switches off automatically and exits

the calibration process without storing the data.

CALIBRATION

CALIBRATION CAPACITY

CALIBRATION PROCEDURES

Fig. 14 Fig. 15 Fig. 16

Fig. 21

Fig. 17 Fig. 19Fig. 18 Fig. 20

Fig. 22 Fig. 23 Fig. 24 Fig. 25

3"

1"

1"

Fig. 26 Fig. 27 Fig. 28

TOTAL / TRIP

TOTAL / TRIP

TOTAL / TRIP

105088

Alentec & Orion AB Grustagsvägen 4, SE-13840, Älta, SWEDEN · info@alentec.se · www.alentec.com

5

ENGLISHSVENSKAFRANÇAISDEUTSCH

ESPAÑOL

To administer the real quantity released (which is that measured in

the calibrated container or scales), press the RESET button for 1

second (fig. 22). The digits start to flash (fig. 23) indicating that the

value shown can be modified. Each press of the RESET button

increases the value by 0.1 litres and each press of the TOTAL/

TRIP button (fig. 24) reduces this value by 0.1 litres (fig. 25).

After the calibration process you will obtain precision within the

range of ±0.5% with the meter. If the meter exceeds this range it

could be due to the following:

• Unsuitable container used for the calibration.

The calibration process is semi-automatic. To start the process, the

meter must be in partial meter mode (fig. 14) and is accessed by

simultaneously pressing the buttons RESET and TOTAL/TRIP for

3 seconds (fig. 15). After releasing the buttons the current

calibration factor is shown on the meter (fig. 16).

If the screen does not show the correct measuring unit (fig. 16)

press the TOTAL/TRIP button (fig. 17) successively until displaying

the required unit (fig. 18).

Press RESET (fig. 19) to start the calibration process (fig. 20).

It now starts to release the desired volume into the container.

Remember that you must release at least 1 litre to perform a good

calibration. In the example shown in the figures it is assumed that

2 litres are released according to the reading on the calibrated

container and that the meter records 2.1 litres (fig. 21).

• The container is not empty before the calibration.

• Air in the fluid which has not been completely removed.

• The values are not properly introduced into the calibration

process.

Once the real value released is set (fig. 25) press the RESET

button for 1 second (fig. 26). The meter shows the new stored

calibration factor (fig. 27) and then exits the calibration process.

The screen shows the partial meter with the units set during the

calibration process (fig. 28).

If, during any phase of the calibration process, you wish to exit

without saving the changes made you must press the TOTAL/TRIP

button for 1 second. Likewise, if 30 seconds of inactivity elapse

during the process, the meter switches off automatically and exits

the calibration process without storing the data.

CALIBRATION

CALIBRATION CAPACITY

CALIBRATION PROCEDURES

Fig. 14 Fig. 15 Fig. 16

Fig. 21

Fig. 17 Fig. 19Fig. 18 Fig. 20

Fig. 22 Fig. 23 Fig. 24 Fig. 25

3"

1"

1"

Fig. 26 Fig. 27 Fig. 28

TOTAL / TRIP

TOTAL / TRIP

TOTAL / TRIP

105088

Alentec & Orion AB Grustagsvägen 4, SE-13840, Älta, SWEDEN · info@alentec.se · www.alentec.com

5

ENGLISHSVENSKAFRANÇAISDEUTSCH

ESPAÑOL

To administer the real quantity released (which is that measured in

the calibrated container or scales), press the RESET button for 1

second (fig. 22). The digits start to flash (fig. 23) indicating that the

value shown can be modified. Each press of the RESET button

increases the value by 0.1 litres and each press of the TOTAL/

TRIP button (fig. 24) reduces this value by 0.1 litres (fig. 25).

After the calibration process you will obtain precision within the

range of ±0.5% with the meter. If the meter exceeds this range it

could be due to the following:

• Unsuitable container used for the calibration.

The calibration process is semi-automatic. To start the process, the

meter must be in partial meter mode (fig. 14) and is accessed by

simultaneously pressing the buttons RESET and TOTAL/TRIP for

3 seconds (fig. 15). After releasing the buttons the current

calibration factor is shown on the meter (fig. 16).

If the screen does not show the correct measuring unit (fig. 16)

press the TOTAL/TRIP button (fig. 17) successively until displaying

the required unit (fig. 18).

Press RESET (fig. 19) to start the calibration process (fig. 20).

It now starts to release the desired volume into the container.

Remember that you must release at least 1 litre to perform a good

calibration. In the example shown in the figures it is assumed that

2 litres are released according to the reading on the calibrated

container and that the meter records 2.1 litres (fig. 21).

• The container is not empty before the calibration.

• Air in the fluid which has not been completely removed.

• The values are not properly introduced into the calibration

process.

Once the real value released is set (fig. 25) press the RESET

button for 1 second (fig. 26). The meter shows the new stored

calibration factor (fig. 27) and then exits the calibration process.

The screen shows the partial meter with the units set during the

calibration process (fig. 28).

If, during any phase of the calibration process, you wish to exit

without saving the changes made you must press the TOTAL/TRIP

button for 1 second. Likewise, if 30 seconds of inactivity elapse

during the process, the meter switches off automatically and exits

the calibration process without storing the data.

CALIBRATION

CALIBRATION CAPACITY

CALIBRATION PROCEDURES

Fig. 14 Fig. 15 Fig. 16

Fig. 21

Fig. 17 Fig. 19Fig. 18 Fig. 20

Fig. 22 Fig. 23 Fig. 24 Fig. 25

3"

1"

1"

Fig. 26 Fig. 27 Fig. 28

TOTAL / TRIP

TOTAL / TRIP

TOTAL / TRIP

EUROLUBE EQUIPMENT

Alentec & Orion AB, Grustagsvägen 4, SE-138 40 Älta, Sweden

www.eurolube.com

PART NO 16721, 16724, 16813, 16868 / ART.NR. 16721, 16724, 16813, 16868

HIGH VOLUME OIL CONTROL GUN

6

DECLARATION OF CONFORMITY / DEKLARATION OM ÖVERENSSTÄMMELSE

Benny Carlsson,

Product director (Authorized representative for

Eurolube Equipment / Alentec & Orion AB and

responsible for technical documentation).

Produktansvarig (Auktoriserad representant för

Eurolube Equipment / Alentec & Orion AB och

ansvarig för teknisk dokumentation).

Alentec & Orion AB, Grustagsvägen 4, 138 40 Älta Sweden, declares hereby that the

products:

HIGH VOLUME OIL CONTROL GUN

PART NO 16721, 16724, 16813, 16868 / ART.NR. 16721, 16724, 16813, 16868 are in confor-

mity with the requirements of the Council´s Machinery Directive 2006/42/EC.

Älta February 26, 2020

Alentec & Orion AB, Grustagsvägen 4, 138 40 Älta, deklarerar härmed att produkterna:

HIGH VOLUME OIL CONTROL GUN

PART NO 16721, 16724, 16813, 16868 / ART.NR. 16721, 16724, 16813, 16868 är tillverkade

i överensstämmelse med bestämmelserna i Maskindirektivet 2006/42/EC.

Älta Februari 26, 2020

This manual suits for next models

3

Table of contents