48

44

1

47

WARNING

Do not alter or modify any part of

this equipment.

Check equipment for proper operation

before each use.

Do not operate equipment without

safety devices installed.

Failure to comply may result in

equipment malfunction and/or damage

and result in serious personal injury.

Before connecting air

motor to air line

Lincoln series III air motors are fully

pneumatic and require a minimum specified

size of air supply hose for proper operation.

Check specification for minimum ID of air

supply hose and select corresponding sizes

of air controls and accessories for non-

restrictive air flow. Lincoln filter and

regulator with gauge are available as

combination units.

It is recommended to use micron

minimum pneumatic filter along with

pressure regulator with system. Special

lubricant is used in assembly of air motors.

It is not recommended to lubricate system

after it has been installed as new lubricant

will wash away factory lubricant, and could

result in air motor failing. Added lubrication

could also result in critical small pneumatic

paths being blocked resulting in malfunction.

• For 3/8in air line

–Model -

• For 1/2in air line

–Model -

• For 3/4in air line

–Model -

If quick disconnect coupling should be used,

install supplied coupler to ensure proper air

motor operation.

Operating

precautions

Use Lincoln replacement parts to assure

compatible pressure rating. Comply with

all warnings.

Do not operate air motor in excess of

recommended pressure range.

Disconnect air line and relieve (vent)

pressure when air motor sits idle for long

periods of time and before servicing.

Attach air motor to

pump tube

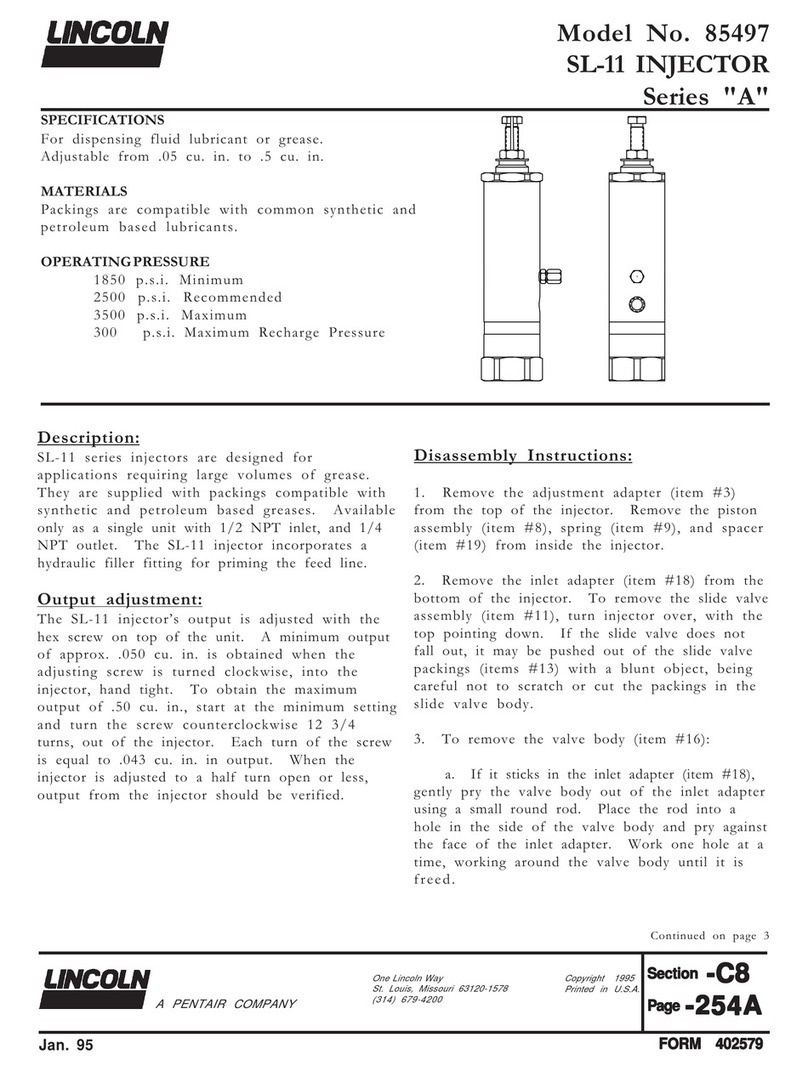

1 Tightly attach connecting rods (48) to air

motor lower casting (44). Use short

threaded end of connecting rods

(†Fig. 8).

2 Mount air motor on top of pump tube

outlet and tightly connect pump

tube coupling nut to air motor

piston rod (1).

3 Attach connecting rods (48) to pump tube

with four nuts (47) supplied with air

motor. Leave nuts loose.

4 Connect air supply and slowly cycle pump

several times using only enough air

pressure to operate pump without stalling.

5 Stop pump on up stroke and tighten four

nuts to securely fasten air motor to

pump tube.

WARNING

Do not pump flammable material

or operate this equipment with

combustible gas.

Failure to comply may result in death

or serious injury.

WARNING

Do not exceed maximum air or fluid

working pressure of lowest rated

system component.

Failure to comply may result in death

or serious injury.

Fig. 8

NOTE*

Do not operate with air contaminated

with materials not compatible with

nitrile seals.

Use only with in (152 mm) stroke

pump tubes.

WARNING

Do not operate pump without

recommended protective equipment.

Failure to comply may result in death

or serious injury.

*Indicates change.