Euroterm ESK 2.5 SB User manual

The highest

eciency

The eciency of the

selective collectors is the

highest, commercially

accessible for residential

types of applications.

More power

Release up to 50% more

power by square meter

than conventional solar

collector.

Attractive design

Unique product, with

optimize and attractive

design.

Reliable and

tested materials

Tempered glass,

selective foil, embossed

back side metal sheet

and strong aluminum

prole, enabling reliable

functioning.

SOLAR

COLLECTORS

Excellent eciency,

the best characteristics, high quality

Installation manual

CONTENTS

Remarks ............................................................................................................................................. 5

Technical specications ........................................................................................................... 6-9

Safety instructions ...................................................................................................................... 10

Installation instructions ...................................................................................................... 11-12

Filling and testing ..................................................................................................................... 13

Fixing and mounting .......................................................................................................... 14-15

Connections ............................................................................................................................ 16-19

Collector array layout .............................................................................................................. 20

Pipe connections ........................................................................................................................ 21

Installation schemes .................................................................................................................. 22

REMARKS

A solar collector generates heat

from sunlight and all other types

of light. This leads to collector con-

nectors getting very hot, even when

they are not lled. This creates a

risk of burning. Cover the collec-

tors with opaque material until the

installation has been completed. It

is recommended you leave the col-

lector inside its packaging until it is

installed.

Never install any shut-o valves in

the line between the collectors and

the safety valve. The safety valve re-

sponds at 87 PSI pressure.

Never set the Solar loop presure

greater then potable pressure.

Neither drop the collector nor any-

thing onto the collector.

Never step onto or stand on the col-

lector.

Never leave the collector unsup-

ported or unsecured. The glass

could break if the collector falls over.

All sensor wiring needs to be rated

for expected temperatures. All sen-

sor wiring needs to be protected

from degradation and false signals.

!

!

!

!

!

!

!

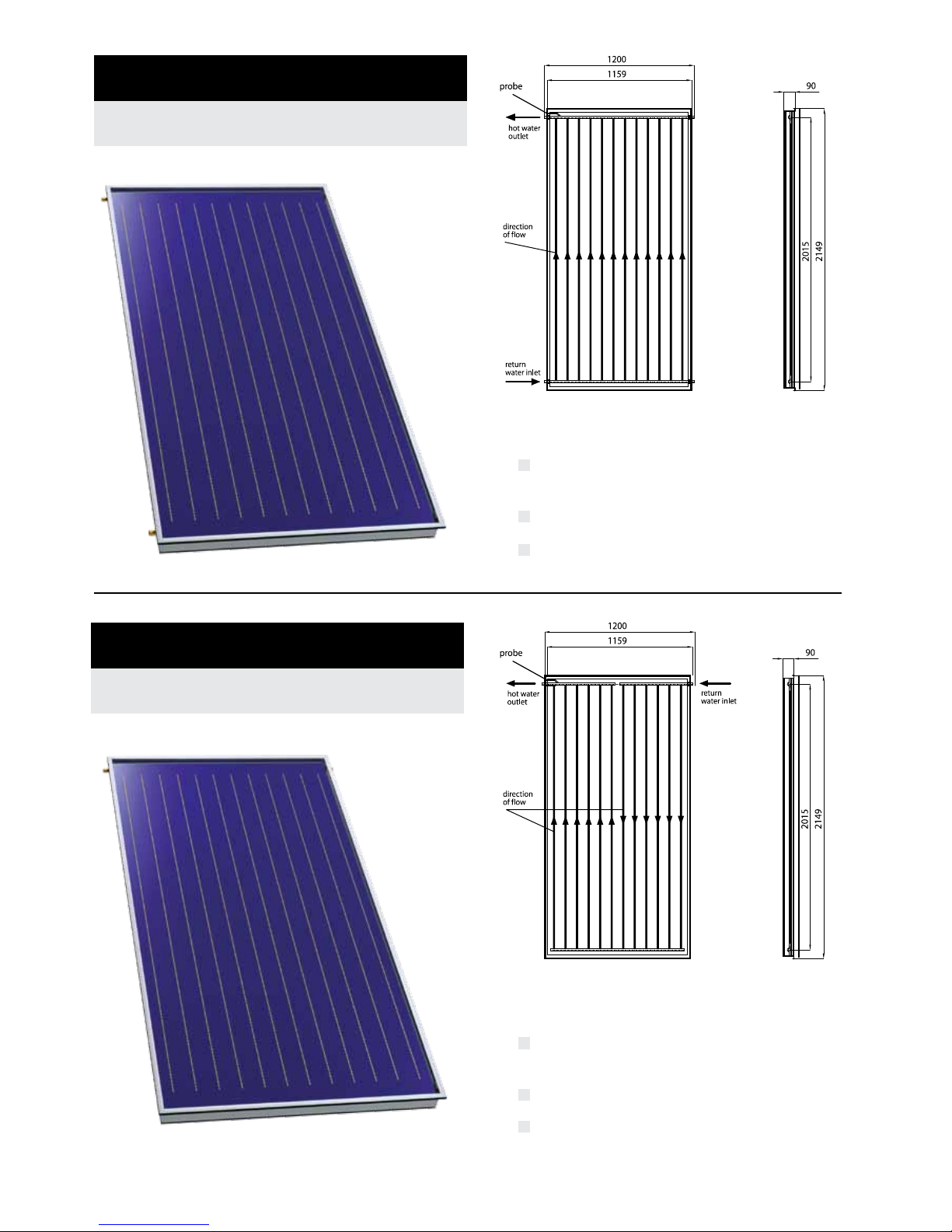

copper absorber with Eta plus selective foil

0.2 mm, corrugated

low iron tempered glass, 4 mm thick

dimensions 2149 x 1159 x 90 mm

Technical characteristics:

SELECTIVE SOLAR COLLECTOR

TYPE ESK 2.5 - SB

copper absorber with Eta plus selective foil

0.2 mm, corrugated

low iron tempered glass, 4 mm thick

dimensions 2149 x 1159 x 90 mm

Technical characteristics:

SELECTIVE SOLAR COLLECTOR

TYPE ESK 2.5 - SB U

ESK 2.5 SB - U

ESK 2.5 SB

Tip

Gross area

Light entering area

Absorber surface (corrugate)

Absorber material

Absorption coefficient (Eta plus)

Emission coefficient (Eta plus)

Cu Pipe register frame

Collective Cu pipe frame

Absorber volume

Transparent front cover

Solar light transmission through glass

Solar energy transmission through glass

Number of connections

Connection diameter

Max. working / test pressure

Stagnation temperature

Insulation - back side

Insulation - on the sides

Back area

Collector construction

Welding method

Height

Width

Depth

Weight

(m

2

)

(m

2

)

(m

2

)

(%)

(%)

(mm)

(mm)

(l)

(%)

(%)

(R)

(bar)

(

o

C)

(mm)

(mm)

(mm)

(kg)

copper sheet with "Eta plus" selectiv surface coating

4mm tempered solar glass - AGC

10 / 14

199

40 mm glass wool (50kg/m

3

)

-

0.5 mm embossed aluminium sheet

aluminium profil AlMgSi 0,5 F22

ultrasonic

2,49

2,35

2,32

95 ± 2

5 ± 2

Ф 8 x 0,5

Ф 22 x 0,8

1,7

92 ± 2

91 ± 2

4

Ф 22

2149

1159

90

44

2,49

2,35

2,32

95 ± 2

5 ± 2

Ф 8 x 0,5

Ф 22 x 0,8

1,7

92 ± 2

91 ± 2

2

Ф 22

2149

1159

90

44

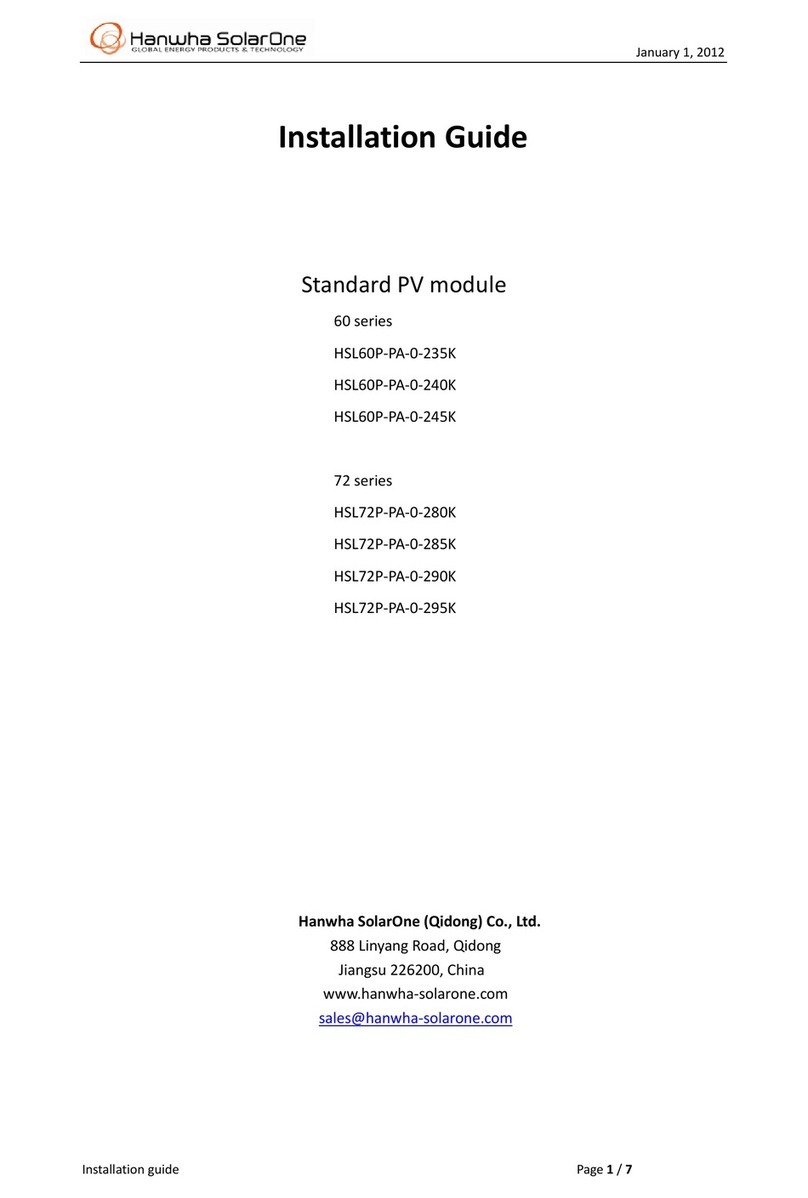

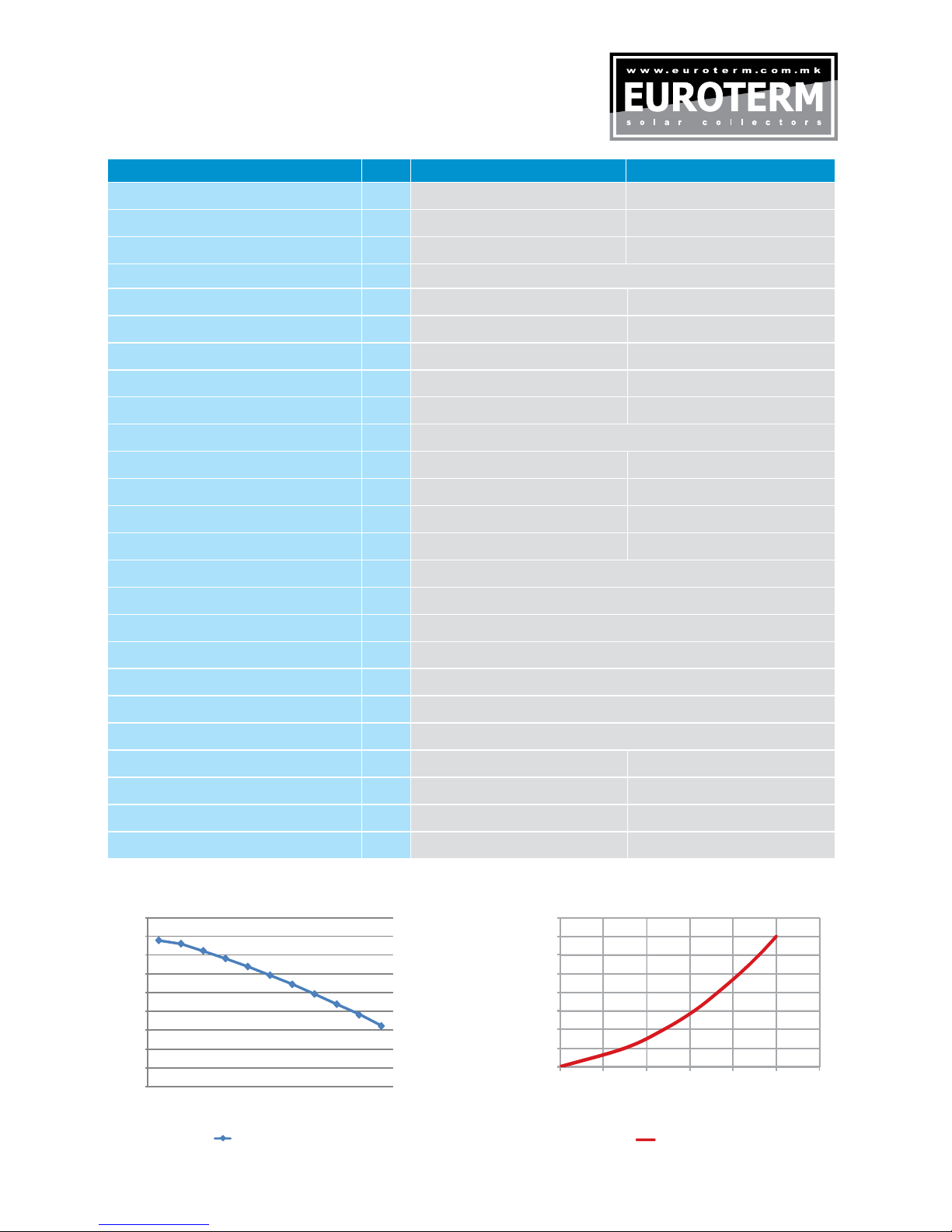

Collector eciency Pressure drop

Collector efficiency for G = 800 W/m2

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

0.00 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10

Tm* [Km2/W]

Absorber

Aperture

Gross

Reference area Absorber area Aperture area Gross area

η0(-) 807.0457.0667.0

a181.454.425.4)K²m/W(

a2(W/m²K²) 0.0042 0.0041 0.0039

Pressure drop in Pa

0

200

400

600

800

1000

1200

1400

0 50 100 150 200 250 300 350 400

Flowrate [l/h]

20° C

Flow rate [l/h] 0 80 160240320400

Pressure drop [Pa] 0 1553525938771203

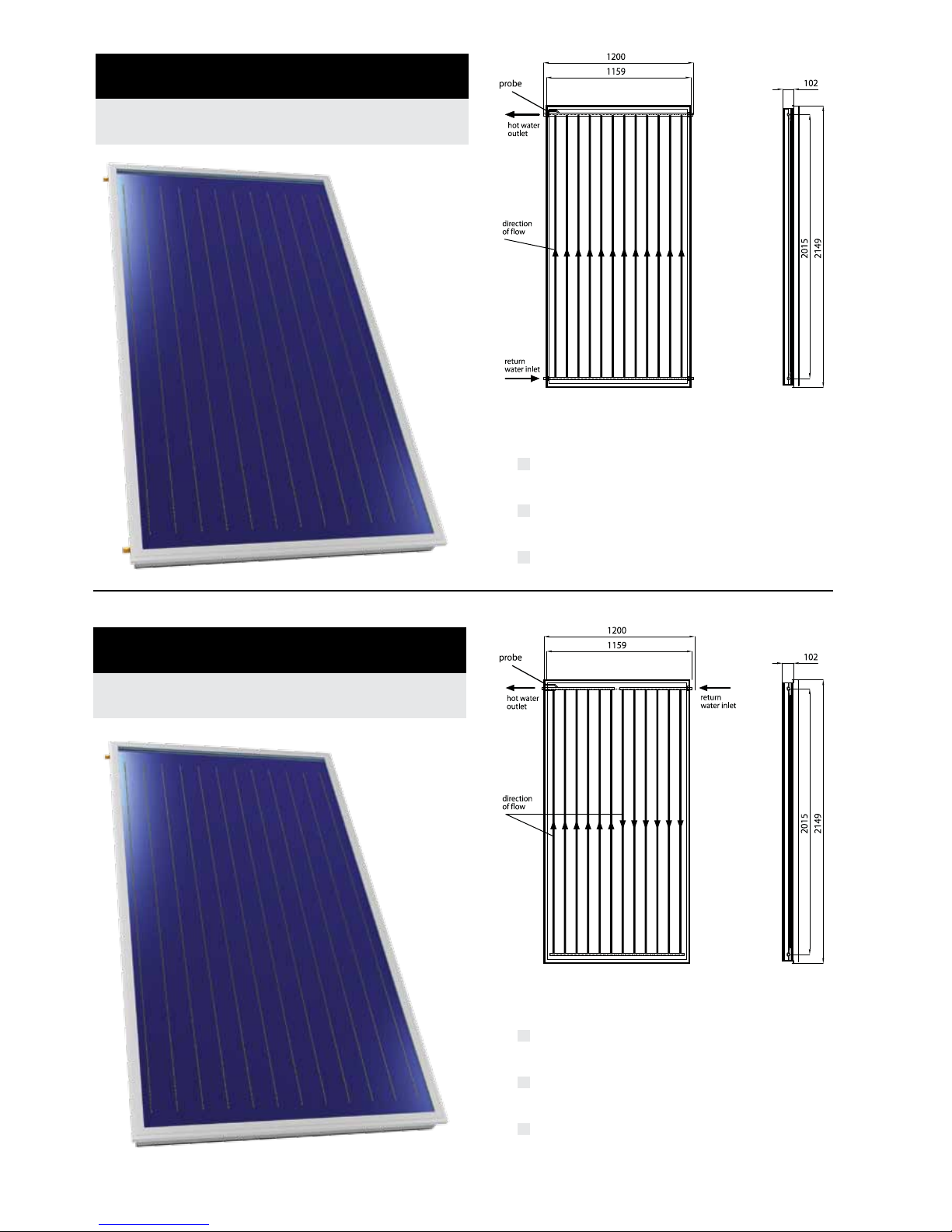

copper absorber with Eta plus selective foil

0.2 mm, corrugated

low iron tempered glass, 9mm lled with ar-

gon, 2 x 4 mm thick

dimensions 2149 x 1159 x 102 mm

Technical characteristics:

Technical characteristics:

copper absorber with Eta plus selective foil

0.2 mm, corrugated

low iron tempered glass, 9mm lled with ar-

gon, 2 x 4 mm thick

dimensions 2149 x 1159 x 102 mm

SELECTIVE SOLAR COLLECTOR

TYPE ESK 2.5 - SB T

SELECTIVE SOLAR COLLECTOR

TYPE ESK 2.5 - SB TU

Tip

Gross area

Light entering area

Absorber surface (corrugate)

Absorber material

Absorption coefficient (Eta plus)

Emission coefficient (Eta plus)

Cu Pipe register frame

Collective Cu pipe frame

Absorber volume

Transparent front cover

Solar light transmission through glass

Solar energy transmission through glass

Number of connections

Connection diameter

Max. working / test pressure

Stagnation temperature

Insulation - back side

Insulation - on the sides

Back area

Collector construction

Welding method

Height

Width

Depth

Weight

(m

2

)

(m

2

)

(m

2

)

(%)

(%)

(mm)

(mm)

(l)

(%)

(%)

(R)

(bar)

(

o

C)

(mm)

(mm)

(mm)

(kg)

copper sheet with "Eta plus" selectiv surface coating

2 x 4mm tempered solar glass with 9 mm space gap, filled up with argon

10 / 14

236

12 mm elastomeric rubber foam / 40 mm glass wool (50kg/m

3

)

12 mm elastomeric rubber foam / 10 mm glass wool (50kg/m

3

)

0.5 mm embossed aluminium sheet

aluminium profil AlMgSi 0,5 F22

ultrasonic

ESK 2.5 SB T

2,49

2,22

2,20

95 ± 2

5 ± 2

Ф 8 x 0,5

Ф 22 x 0,8

1,7

96 ± 2

95 ± 2

4

Ф 22

2149

1159

102

70

2,49

2,22

2,20

95 ± 2

5 ± 2

Ф 8 x 0,5

Ф 22 x 0,8

1,7

96 ± 2

95 ± 2

2

Ф 22

2149

1159

102

70

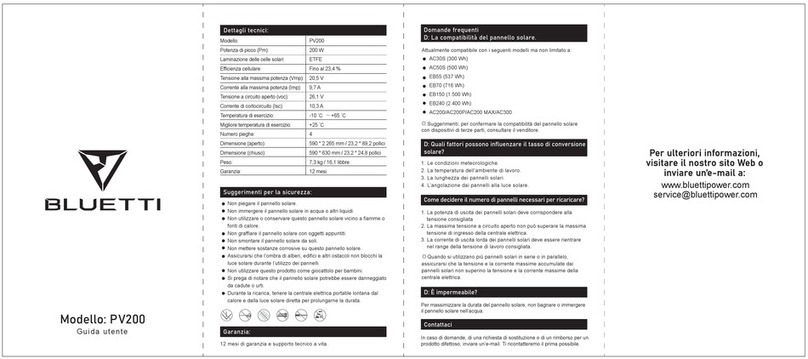

ESK 2.5 SB - TU

0

10

20

30

40

50

60

70

80

90

5 10 20 30 40 50 60 70 80 90 100

Efficiency ( %)

Ta-Tm

Collector efficiency

Collector efficiency

0

0,05

0,1

0,15

0,2

0,25

0,3

0,35

0,4

0 0,02 0,04 0,06 0,08 0,1 0,12

Δp (kPa)

Flow (kg/s)

Pressure drop

η0 = 0,8

a1 = 3,175 W/(m²K)

a2 = 0,01 W/(m²K²)

Collector eciency Pressure drop

SAFETY INSTRUCTIONS

Installation & Transportation

Solar Collectors must be secured during transportation. You must secure the collectors from falling out of

the packaging, and from scratching each other.

• Use of a carrying strap is recommended

• Do not lift the collector by the connection ports or header tube

• Avoid impacts & vibration on the collectors as much as possible

• Please lift collector by lifting lugs (if included)

On Roof Operation

Please follow the following safety & operational guidelines when installing Solar Collectors

• Included Mounting Hardware(2 x antislip protection and 4 x side bracket) is intended for

On Roof Installations Only

• Additional Mounting Hardware is needed for Pitched Roof & Tilt Mount Installations

• You will be intervening in existing roof and roof coverings during installation

• Please ensure that proper measures are taken for protection of all installation crew

• Familiarize yourself with local laws & regulations, and follow them carefully

Important Note - Solar Collectors should not be lled when the sun is out because scalding can occur

due to steam being released from the system. If you must ll the Solar Collectors during sunny periods,

please cover the collectors.

Lightning Protection

Solar Collectors should be electrically connected to each other, and to the building’s Earth ground via the

shortest possible route. An authorized lightning protection specialist should be consulted to examine the

installation and installation site.

INSTALLATION INSTRUCTIONS

Collector Layout, Orientation, and Siting

Place the collector where it will receive the maximum amount of sunlight available in your location. Eu-

roterm ESK 2.5 SB collectors may be installed on a roof, against a south facing wall, or on the ground.

Orientation

Orientation and tilt are critical to performance. The Euroterm ESK 2.5 SB collectors should be ori-

ented (faced) as close to true south as practical, although they may be faced as much as 20° east or

west of true south with less than 5% loss in capacity.

Shading

Trees, chimneys, dormers, other buildings, new construction, and even fences may shade the collec-

tor array, especially in the winter when sun angles are low and shadows are long. Be sure the collec-

tors are placed where they will be not shaded by these obstructions. As a rule, no more than 5% of the

collector area should be shaded between the hours of 9:00 a.m. and 3:00 p.m.

To avoid shading by collectors on each other, the front to front dimension must be 2.5 times the high-

est point of the front collector.

Angle of Inclination or Tilt Angle

For domestic water, use an optimum tilt of the site’s latitude plus 5°, although the slope may be 10°

greater or less with a capacity loss of under 5% for the system. For a solar space heating system, a

steeper tilt angle is important for optimal winter performance. The steeper tilt will favor winter system

operations when the sun is low in the sky. Therefore, for space heating systems chose a tilt of latitude

plus 15°. The variation of 10° either way will not seriously affect the total annual performance of the

system, all other things being equal.

Shedding Snow

A tilt angle of 50° or more is necessary in regions of heavy snowfall and accumulation. Tilt angles of

50° and above will shed snow from OVSOL evacuated tube collectors even after severe storms. It is

critical in heavy snow areas that the collectors be sloped to at least a 50° tilt angle. If collectors are

installed on a at roof in an area which receives heavy snowfalls, the lower end of the units should

be at least 40 cm above the roof level to minimize chances of snow build-up on the bottom end of the

collectors.

Wind & Snow Load

The wind and snow loads for your location should be taken into account when installing a Euroterm

ESK 2.5 SB Flat Plate Solar Collector and calculating the overall weight-carrying capacity of the roof.

Euroterm ESK 2.5 SB Flat Plate Solar Collector Mounting Hardware is designed for:

• 1.2 kN/m2 (snow load)

• 1.1 kN/m2 (wind load)

Operation, Checks and Maintenance

The solar system offers unmanned and almost maintenance-free operation. Despite that, it is important

to check the right functioning of the system within the rst days of operation. First of all the temperature,

system pressure and pump operation shall be checked. Once a year, preferably during a sunny day,

it is necessary to check the working order and tight xing of the collectors, verify the system tightness

and pressure (incl. pressure in the expansion vessel) and the pump operation. At least once in every

2 years the heat carrying uid shall be checked for its antifrost properties. The system shall be always

replenished with the same uid as the original lling was.

INSTALLATION INSTRUCTIONS

FILLING

PREPARATION OF MIXTURE OF WATER + glycol

Glycol is supplied separately in the standard package and mixed with water in the tank before lling the

installations (for example. 40% glycol and 60% water-resistant to frost temperatures from -21 ° C).

Fill the solar system exclusively with polypropylene glycol which is intended specically for use in solar

devices. Polypropylene glycol retains its properties in the area of 32 ÷ 180 ° C.

Polypropylene glycol is biologically compatible and not toxic.

Do not ll pure glycol rst and then add water.

If the water contains a high level of chlorine is it necessary to use a distilled water .

Antifreeze temperature Density

50% -32 ° C 1.045 kg/dm3

40% -21 ° C 1037 kg/dm3

30% -13 ° C 1.029 kg/dm2

FILLING

1 - Open the valve (A)

2 - The manual venting valve at the highest point (see

drawing ) shall be open during charging

3 - Open the venting valve (7)

4 - Allow the liquid driven by external pump circulates until all air

bladders are removed. Close the manual venting valve.

5 - Raise the pressure in the installation at 4 bar.

6 - Leave the installation to work about 20 minutes

7 - Repeat the procedure from point 2, while

the air is completely dropped

8 - Adjust the pressure in the installation of 3 bar.

- Close the valve (A) and venting valves, to prevent possible

evaporation of heat transfer uid.

Do not ll the installation during full insolation and while collectors are hot.

The system must not be replenished with water.

7

A

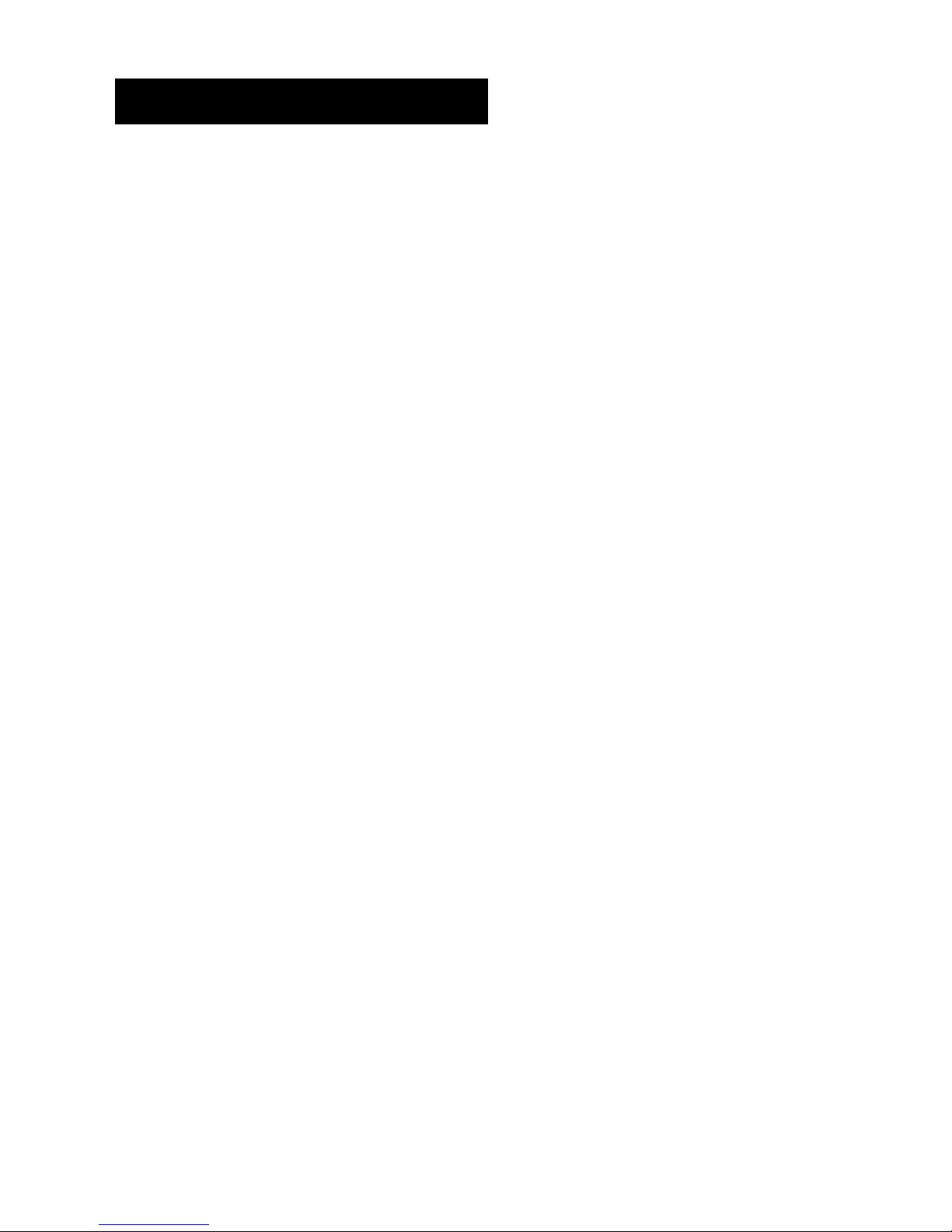

The base plate - Tray 1 (art. 50 206), is mounted on

the roof beam using the M8 x 80 screws (art. 50 210).

Base plate (Art. 50 206), is prepared so that it is al-

ways possible to use at least three screws.

Carrier Prole - Tray 2 (art. 50 207), is placed on the

basic plate - Tray 1 (art. 50 206). Grooved carrier pro-

le and the base plate, allows removal of steps, such

as height adjustment of the screw, and thus shortens

the time of installation, as well as number of hours of

the installer on the roof.

Using self-locking screw M10 x 20 (art. 50 .210) angu-

lar prole is associated with the carrier prole - Tray 2

(art.50 207). Angular prole (art. 50 203), is an impor-

tant element in universal mounting system. It is used in

cross-mounting and it is connecting element between

the universal prole (art. 50 100) and roof hooks - Tray

2 (art. 50 207).

Universal prole (art. 50 100), is set to the angle pro-

les (art. 50 203). Fixing is done with self - locking

screw M10 x 20 (art. 50 210) and screw channels.

Screw channels are designed so that the screw can be

tightened with torque of 17 Nm.

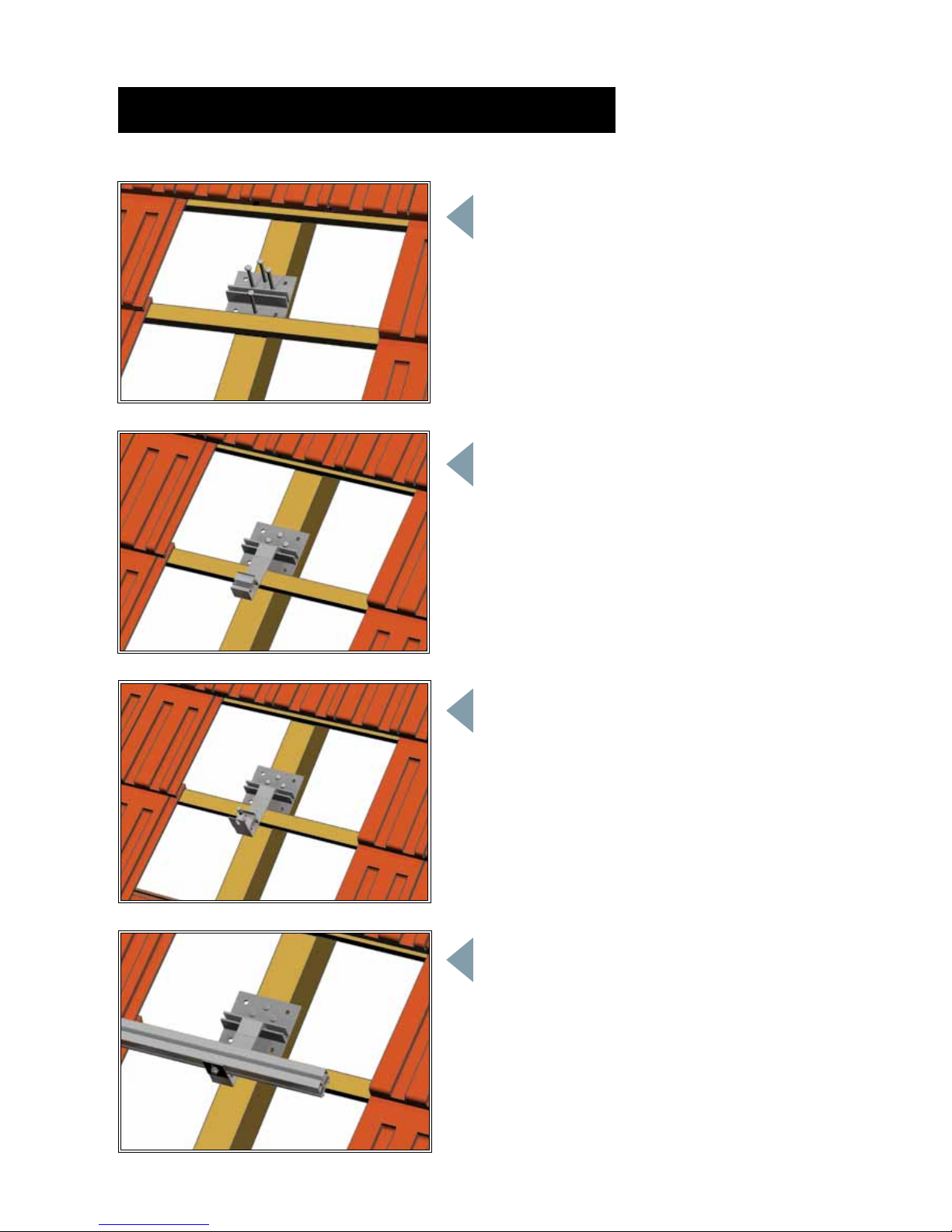

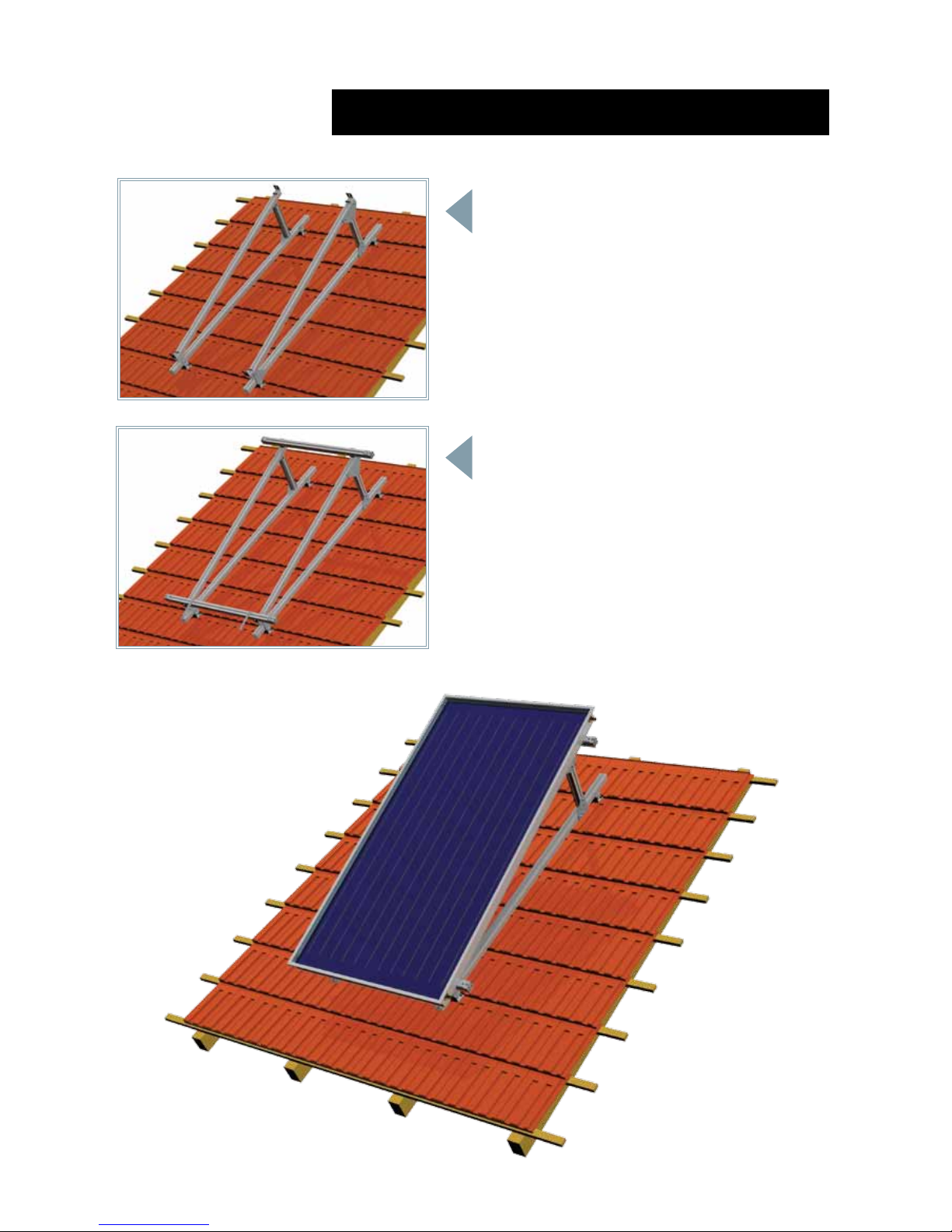

PARALLEL MOUNTING WITH THE ROOF LINE

Anti slip protection - stainless steel shafts (art. 50 215),

is placed on the lower prole for prevent sliding of the

collectors during installation.

Attaching the solar collector on a universal platform is performed using side brackets (art. 50 211).

PARALLEL MOUNTING WITH THE ROOF LINE

PARALLEL MOUNTING WITH THE ROOF LINE

On the already mounted base plate - Tray 1 (art. 50

206) and carrier prole - Tray 2 (art. 50 207), we placed

the angle prole (art. 50 203) rotated for 90 degrees,

using self - locking screw M10 x 20 (art. 50 210).

Universal proles (art. 50 100), using self-locking

screw M10 x 20 (art. 50 210) and screw channels are

placed on angular prole (art. 50 203), parallel to the

roof beams.

With angular panels - 90o (art. 50 205), universal

mounting platform is adapted for mounting under a

certain angle.

Achieving the desired angle is allowed by using varia-

ble angular plates (art. 50 204). Universal proles with

self-locking screw M10 x 20 (art. 50 210) and screw

channels are placed on the corner plates (art. 50 205)

and (art. 50 204).

PARALLEL MOUNTING WITH THE ROOF LINE

The angular proles (art. 50 203) are placed on the

universal proles (art. 50 100), using self - locking

screw M10 x 20 (art. 50 210) and screw channels.

On the angular prole (art. 50 203), which is rotated

for 90 degrees, universal proles (art. 50 100) are set

normal to the roof beams. On the lower prole of an

already mounted, universal platform, is placed antislip

protection - stainless steel shafts (art. 50 215), for pre-

vent sliding of the collectors during installation.

Attaching the solar collector on a

universal platform is performed as

well as in the parallel mounting with

the roof line.

FACADE MOUNTING

rain protection

prole

use four antislip

protection bracket

Hold rmly with the size 24 spanner and tighten the

union nut onto the cutting connection with the size 27

spanner.

Avoid applying extra torsion on the Header as you

install the connectors. Always use a spanner to x the

header and then install the connectors.

EUROTERM solar thermal collectors are interconnected throught 22 mm common joints.

Straight and corrugated stainless steel joints are recommended.

CONNECTING COLLECTORS

-

-

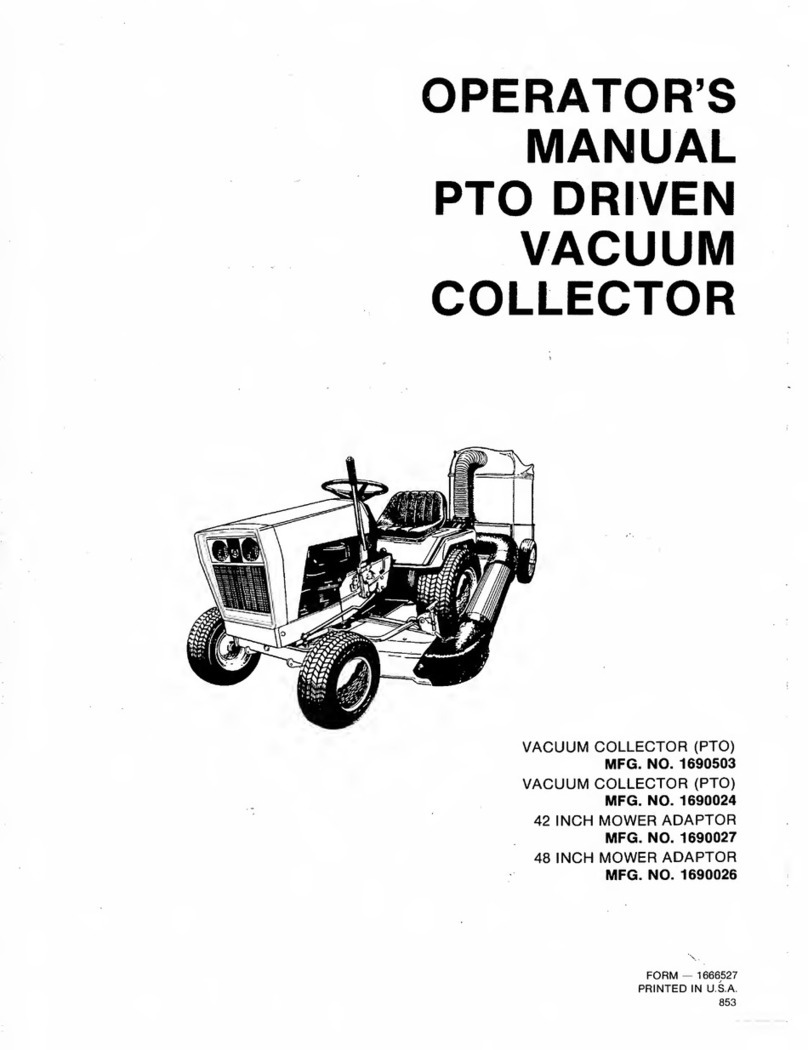

COLLECTOR ARRAY LAYOUT

1200

150

900 900 302

2404

max 1700

max 1700

900 900 900 454

3608

max 1700

900 900 900 900 900

156

4812

900

900 900 900 900 900 900 308

6016

max 1700max 1700

900 900 900 900 900 900 900 460

7220

max 1700

Collector eld measurement (after distance 900 mm)

Collector dimensions: 2149x1159x90 (all specied dimensions in mm)

Weight: 45 kg

Roof rafter

The base plate and carrier

prole (Tray 1 and 2)

Universal prole

This manual suits for next models

2

Table of contents

Popular Solar Panel manuals by other brands

Viessmann

Viessmann VITOSOL-F Service instructions

Viessmann

Viessmann Vitosol 300-TM Installation information

Donaldson Torit

Donaldson Torit E-100 Installation and operation manual

Panasonic

Panasonic EVERVOLT EVPV Series General installation manual

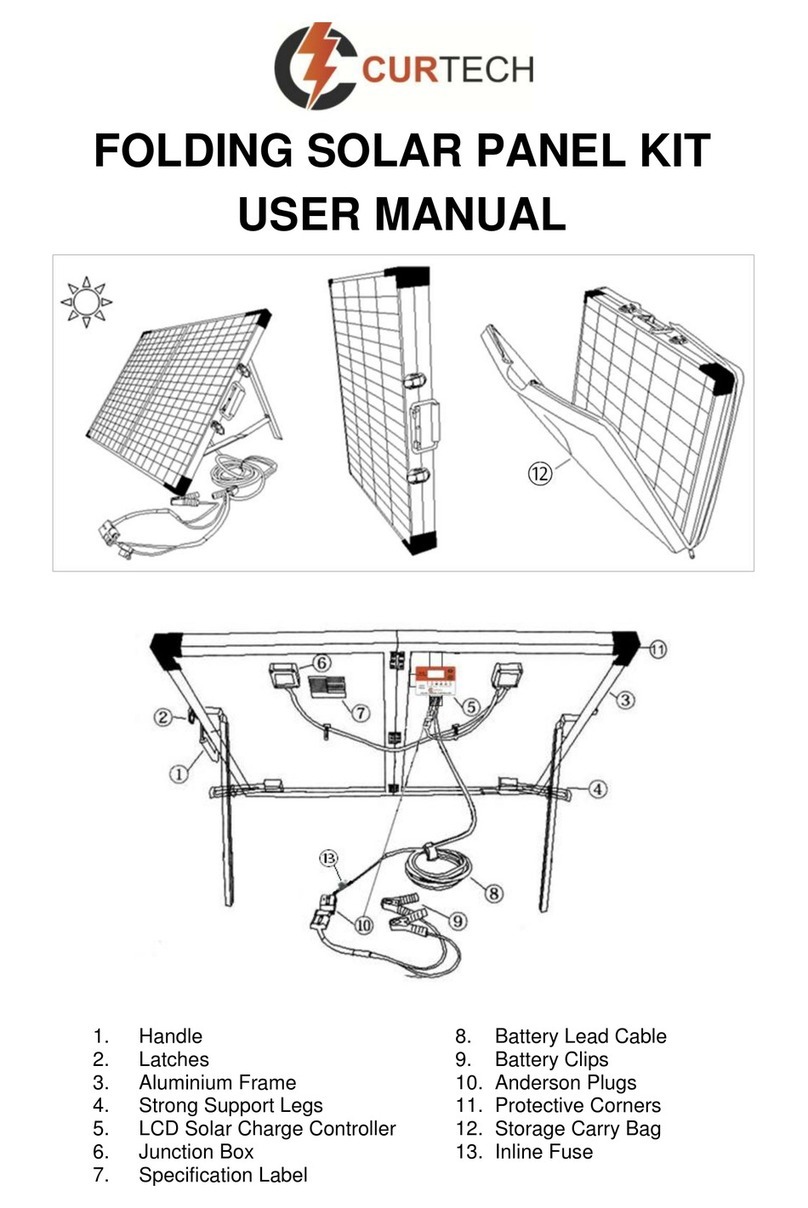

Curtech

Curtech CT-K80 user manual

oventrop

oventrop ovsol installation guide