1.0 INTRODUCTION

The purpose of this guide is to provide general information regarding the proper installation and handling of SunEdison

photovoltaic modules that serve residential, commercial, and industrial segments. System design, construction, and

commissioning should be performed by qualified personnel only.

To ensure system integrity, designers, installers and operators must meet all mechanical and electrical requirements for

the system and its components. It is the responsibility of the system designer and installer to ensure that all codes and

requirements are followed as well.

Please review all the sections that pertain to proper installation of modules listed in this guide. The instructions detailed in this

guide must be followed throughout the module’s lifetime deployment. If you need additional information about the safe, proper

use and handling of SunEdison photovoltaic module products, please contact SunEdison.

2.0 PHOTOVOLTAIC MODULES PRODUCT CODE

This guide is to be used for SunEdison Silvantis 60 cell photovoltaic (PV) module installation. Please refer to the following

module numbers before using the guide:

Original Version: M245CyC, M250CyC, M255CyC, M260CyC, M265CyC, M270CyC, M245KyC, M250KyC,

M255KyC, M260KyC, M265KyC, M270KyC, F245CyC, F250CyC, F255CyC, F260CyC, F265CyC, F270CyC,

F245KyC, F250KyC, F255KyC, F260KyC, F265KyC, F270KyC

3.0 MODULE OVERVIEW

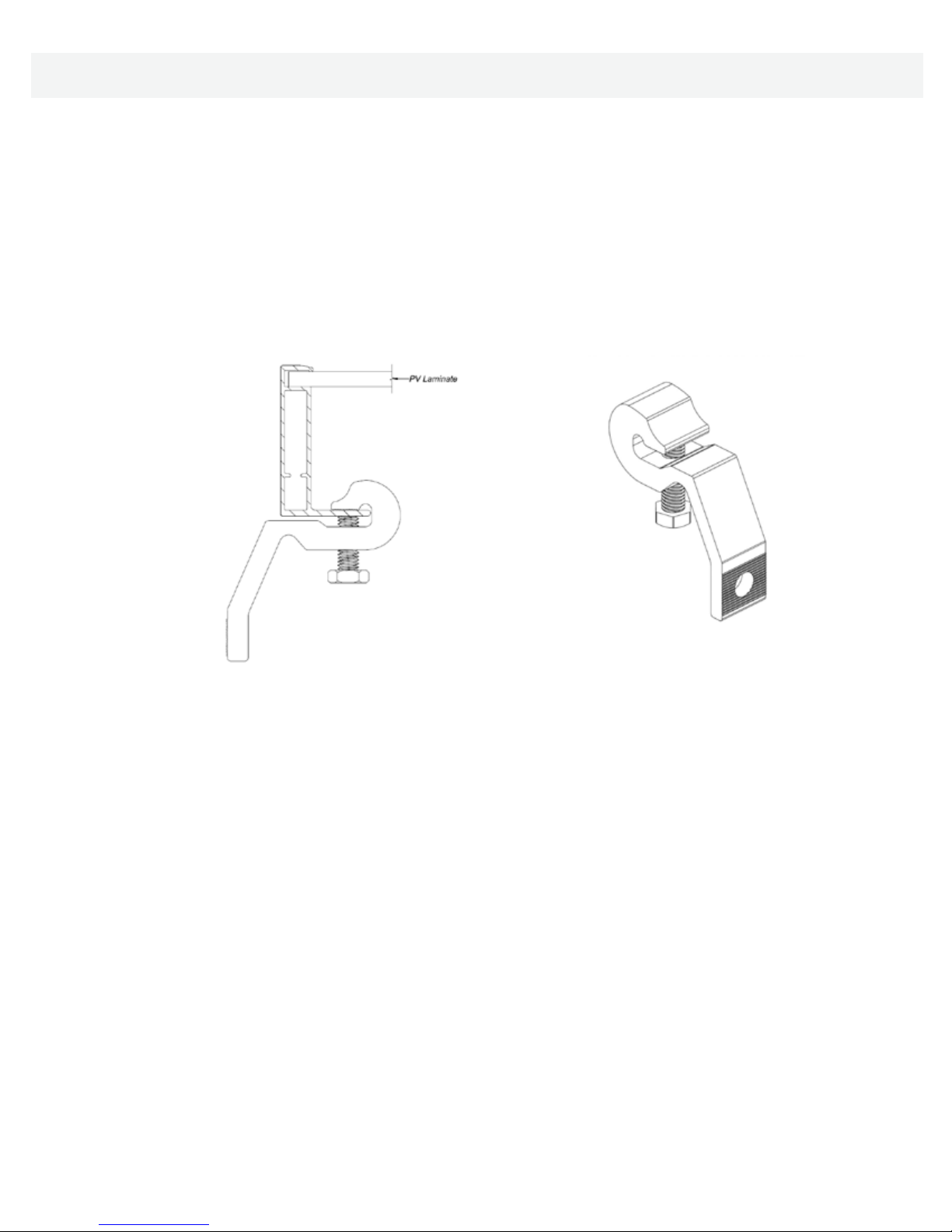

SunEdison Silvantis Photovoltaic modules consist of a series of electrically interconnected crystalline silicon solar cells that are

sealed within a laminated sheet of tempered glass superstrate* and EVA/back-sheet substrate. These laminates are secured

inside an aluminum frame to provide rigidity and a means for attachment to mounting sub-structures. The frames should not be

modified or removed. * Tempered glass may have anti-reflective coating.

• Photovoltaic modules are designed and constructed for outdoor use. Do not submerge modules in water at any time.

• The front and back of each module is labeled with a product bar code. Do not cover, remove or deface these labels. This

may be required for product identification.

• Damage to the glass surface or the anti-reflective coating can impact the power output and overall efficiency of the

system. Scratches, handling marks, or any damage to the glass surface must be avoided.

• For best performance and to avoid potential issues, keep the front side of the module clean and free of obstructions

including covers, tape, adhesives, paint and debris.

3.1 STORAGE, UNPACKING, AND HANDLING

• Packaged modules must be stored in a dry and ventilated area.

• Packaged modules must not be exposed to rain, snow, hail or other environmental conditions that may compromise the

packaging material and the modules.

• Packaged modules must be on appropriate provided pallets and must not be stacked more than two pallets high for

storage.

• Once the modules are opened, store modules in a dry and ventilated room.

• Modules should never be stored in a wet environment.

• Upon unpacking, do not carry a module by its wires or junction box. Only carry a module by its frame with two or more

people.

• Precaution should be taken to avoid damage to the glass surface with or without anti-reflective coating due to improper

handling during storage or unpacking. Do not place or store modules with the glass facing down.

• Keep all electrical contacts clean and dry.

• All modules are manufactured with a sealed junction box and pre-attached cables and locking connectors. These

components should not be modified or tampered with in any way.

2 of 12

Installation Manual: SunEdison Silvantis 60 Cell PV Modules

© Copyright 2013 SunEdison, Inc.