1

Johnson Controls Metasys N2 Communications Interface

JOHNSON CONTROLS N2 TECHNOLOGY OPTION

A System Overview

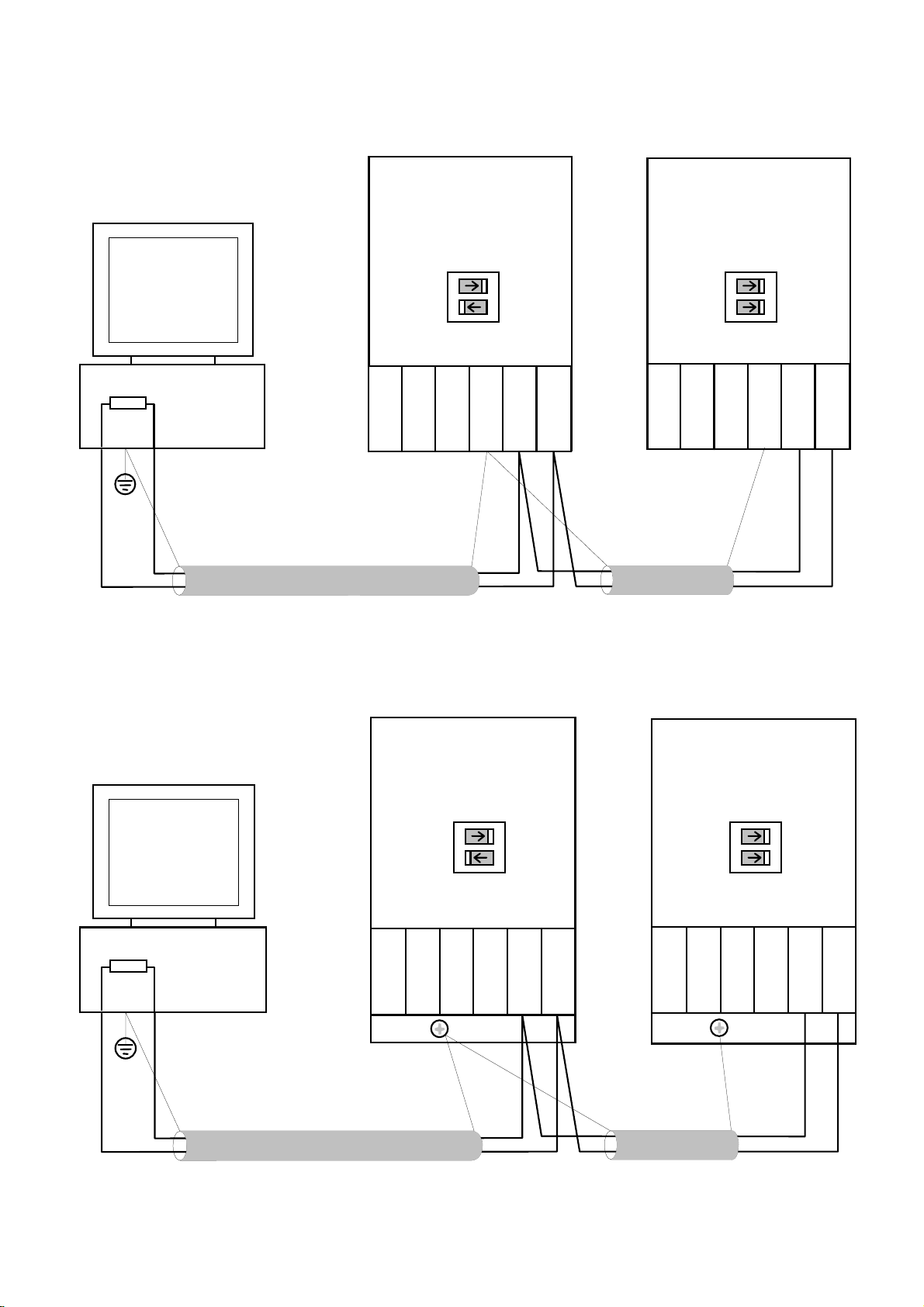

The Johnson Controls N2 Technology Option provides a serial data port, allowing VSDs

(variable speed drives) to be linked to form a network. Using a Network Control Module, this

network can be continuously controlled to provide supervision and monitoring for each VSD in

the system.

With each unit under local

control, the central

supervisor performs only

periodic setpoint updating,

control sequencing and data

collection.

In the system, the Network

Control Module acts as the

Master, and the VSD as the

Slave.

The network of VSDs can

be set-up using each unit’s

MMI/Operator Station.

Protocol

This card communicates using the Johnson Controls N2 protocol. Any connections made to it

most comply with this protocol. All effort has been made to maintain compatibility with devices

using this protocol.

Product Features

•Suitable for use with:

HVAC10 Drive Products software version 4.6 onwards

•Connection using 2-wire shielded twisted pair (RS485)

•Protocol tag access for defined N2 parameters

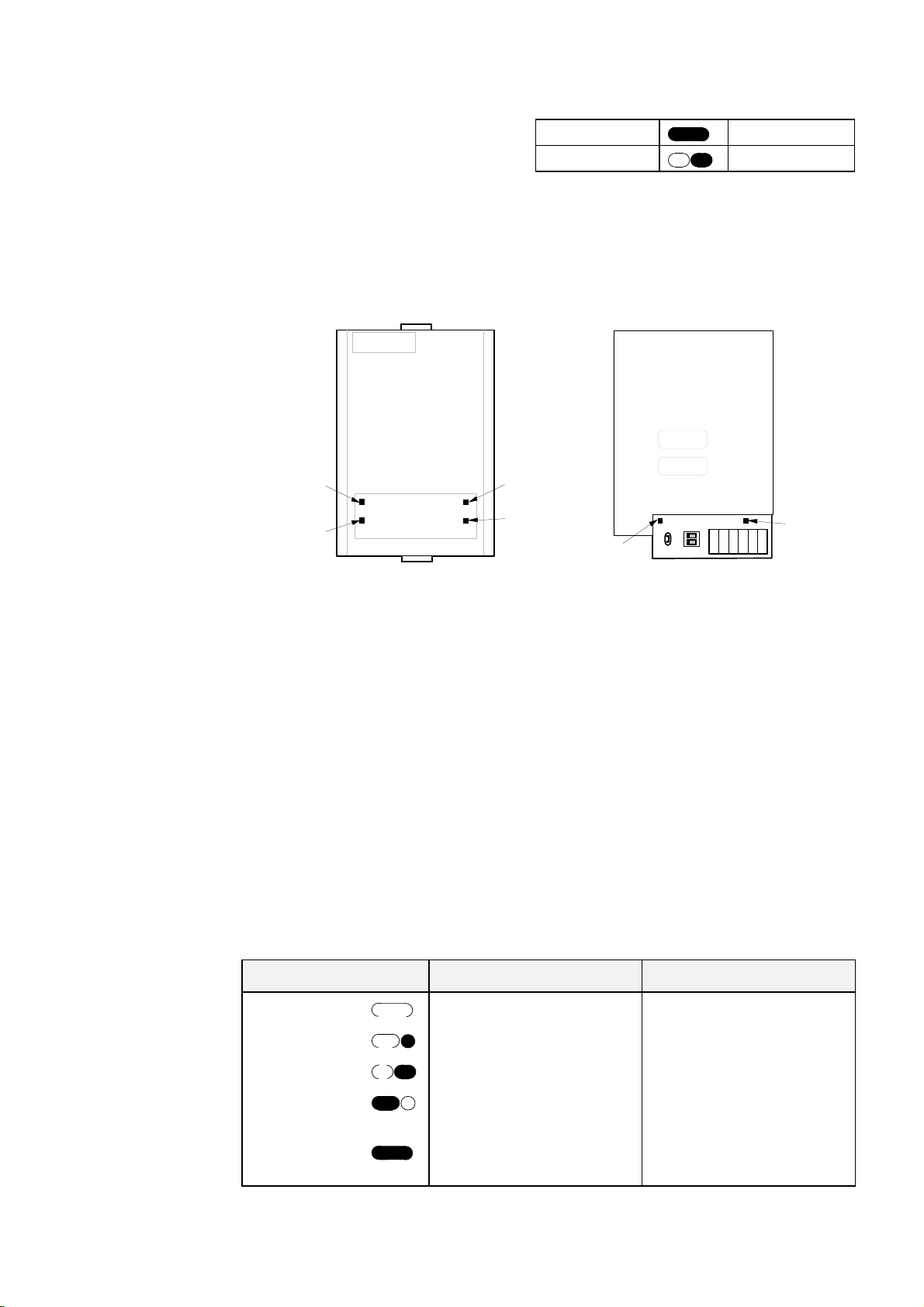

Size Notation – Part Numbers

Size 1 HVAC10 drives use the 6053-JMET Metasys N2 Technology Box.

All Size 2 and 3 HVAC10 drives use the 6055-JMET Metasys N2 Technology Box.

Advantages with this type of control system

1. Multi-wire analog transmission from a central programmable

controller is replaced by a bussed digital system using serial

data transmission over differential twisted-pair wires.

2. Digital transmission is fundamentally less noise-prone than

analog methods, and the accuracy of the transmitted data is

unaffected by the transmission medium. The use of intelligent

devices at either end of the data link allows error checking to

be used. This virtually eliminates the effects of electrical noise

on data integrity. It is therefore possible to issue setpoints to

drives with much higher accuracy using this method.

3. The communication standard used allows up to 32 drives to be

connected to a single link which can be driven from a

computer serial port.

4. The chosen standard and protocol are compatible with other

Eurotherm Group products. Temperature controls, process

controls, data loggers and drives can communicate easily with

a common supervisory system.

This manual was downloaded on www.sdsdrives.com