Eurotrac W10 User manual

Page 1/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

W10 Mini Loader

operation manual

Page 2/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

Foreword

W10 Mini loader is one of self-developed multi-function mini loaders, this loader

is a ideal product for material loading and unloading, short-distance transport,

can be matched with many tools, can be realized more kinds of uses, such as

lifting, pulling, clamp hold, digging drill, ground, weeding, feeding fodder, etc. It

can widely used in farm, ranch, infrastructure, road construction, stations,

boatyard and other work places, this machine has the characteristics of the best

economy, safety, and driving comfort. And these good characteristics depend on

you, loaders and other operators to maintain, fully play during operating.

This manual covers all important knowledge of the starting use of the new loader,

driving and operation, care and maintenance for W10 mini loaders. Please follow

the instructions of the loaders, regular inspect and maintenance the working

content specified on the table, and use the provisions of the working media.

This manual can be used for W10 and the improvement model..

For some special technical skills and knowledge about maintenance and repair,

because of needing to use special tools, be not mentioned in this statement,

please contact the dealer.

Loader maintenance and repair work is only allowed to be done by qualified

professionals who are authorized by manufacturer

In order to make your loader to obtain a valid warranty services, the maintenance

must be must be done on time by qualified professionals who is authorized by

manufacturer.

This loader already passed the CE certification of European Certification

Organization and got certificate of conformity.

This manual follows the CE directive relative safety requirements of.arrangement

of information corresponds to this accepted format. Page numbers run

consecutively within each chapter. Pages are identified in the lower corner of

each page with chapter number, section number, page number within that

section, and the date of publication or revision.

Page 3/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

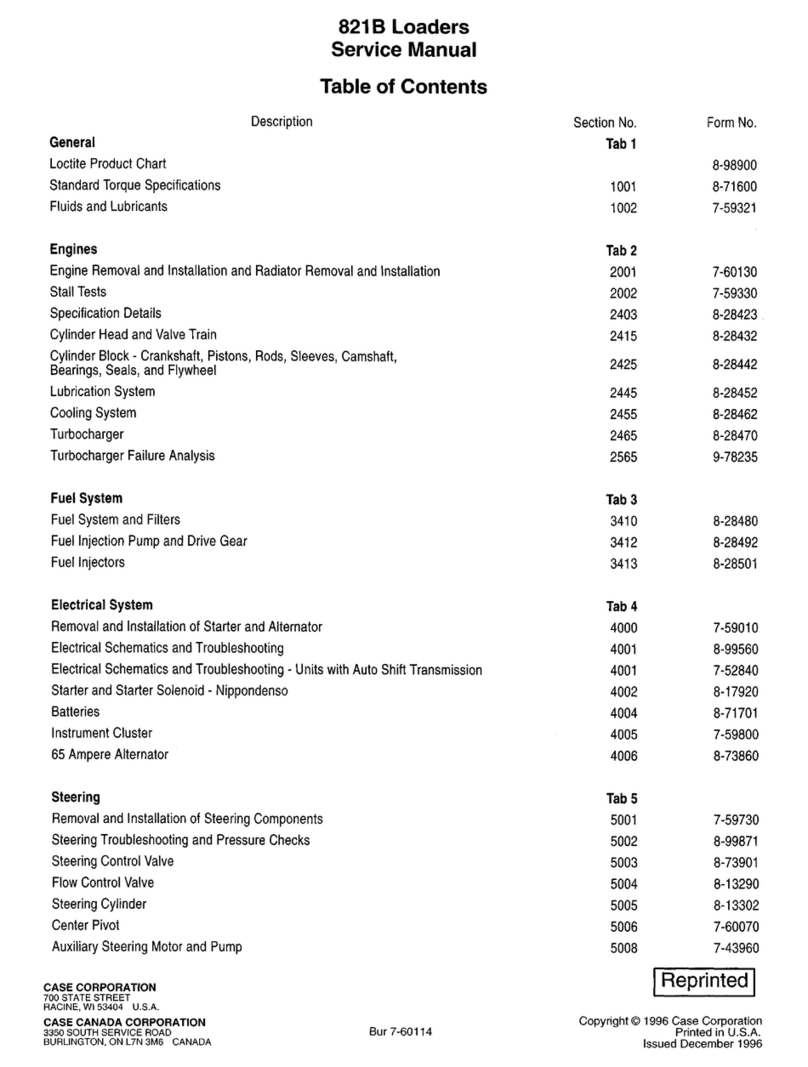

Catalogue

Foreword.......................................................................................................

2

Catalogue..................................................................................................................

3

Section 1:Revision record....................................:.................................

5

S e c t i o n 2 G e n e r a l g u a r a n t e e … … … … … … … … … … … … … … … … … … … … … … …

7

Section 3 General warning…………………………………………………………………

8

S e c t i o n 4 I n f o r m a t i o n a n d o p e r a t i o n … … … … … … … … … … … … … … … … … … … … …

10

A. Main configuration…………………………………………………………………………

10

B. Ope rato r’s responsibili ty……………… ……………………………………………………

10

C. M A C H I N E R Y R E S P O N S I B I L I T Y ……………………………………………………

12

C H A P T E R 1 G E N E R A L I N F O R M A T I O N & O P E R A T I N G I N S T R U C T I O N s … … … …

15

S E C T I O N 1 M A I N C O M P O N E N T S …………………………………………………………

16

A. E N G I N E A N D P U M P ………………………………………………………………

16

B. CYCLOID MOTOR AND DRIVE AXLE…………………………………………………

16

C. B R A K E S Y S T E M ………………………………………………………………………

16

D. W H E E L A N D T Y R E ……………………………………………………………………

16

E. O I L T A N K ……………………………………………………………………………

16

F. ELECTRIC SYSTEM ………………………………………………………………………

17

G. Q U I C K R E M O V A L D E V I C E ………………………………………………………

17

H. S E A T ……………………………………………………………………………………

17

I. A T T A C H M E N T ……………………………………………………………………

17

J. M U L T I - F U C T I O N C O N T R O L H A N D L E …………………………………………

17

K. MULTI-FUCTION CONTROL HANDLE…………………………………………………………

17

L.P E D A L …………………………………………………………………………………

17

M. Steering wheel…………………………………………………………………………………

18

N. DISPLAY PANE L …………………………………………………………………………

18

S E CT IO N 2 O PE RA T IN G P R OC ED U RE … … … … … … … … … … … … … … … … … … … … … …

20

SECTION 3 SPE CIF I C ATI O N S A N D PE R FORM A NCES ………………………………………

29

S E C T I O N 4 T R A N S P O R T P R O C E D U R E …………………………………………

32

S E C T I O N 5 T R A I L E R P R O C E D U R E …………………………………………………

33

SECTION6 STORAGE PROCEDURE…………………………………………………

34

CHAPTER 2 MAINTENANCE PARTS……………………………………

35

SECTION 1 SERVICE………………………………………………………………

38

A.USING PREPARATION…………………………………………………………………

38

B.REGULAR MAINTENANCE TABLE………………………………………………………

39

C.OIL&LUBRICATING OIL……………………………………………………

43

SECTION2: CORRECTIVE MAINTENANCE………………………………………………………

44

A.ENEGY OF MOTION REDUCTION…………………………………………………………

44

B.BRAKE SYSTEM……………………………………………………………………

45

C.GENERATOR……………………………………………………………………………

46

D.BATTERY………………………………………………………………………………

47

CHART 1:HYDRAULIC DIAGRAM………………………………………………

48

CHART 2:ELECTRIC DIAGRAM…………………………………

49

CHART 3:FRAME LABLE DIAGRAM……………………………………

50

ANNEX 1:DAILY EQUIPMENT INSPECTION………………………………………

51

Page 4/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

SECTION1:RECORD OF REVISIONS

Continuing improvement and advancement of product design may cause changes to the

model group which may not be included in this publication.

Each publication is reviewed and revised, as required, to update and include the changes in

late additions.

We reserves the right to modify or make changes within a specific model group without

notice and without incurring any liability to retrofit tractors previously shipped from the factory.

Contact your dealer for maintenance that is not covered in this publication.

Issue Date

Update Number

Disassembly

Inserted

Description of change

Page 5/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

SECTION2:GENERAL WARRANTY CONDITIONS

This document presents the warranty conditions offered to any customer for all the

pieces of equipments manufactured in the manufacturer facilities and sold to him through the

authorized Sales and Service network.

The general warranty conditions hereunder described do govern the relationship

between final customers of a manufacturer product, hereunder called “the buyer” and

manufacturer factory, called “the manufacturer“.

The fact that the buyer places an order of a product means that he has read the present

policy and does accept its provision. Any other general or particular provision, that differs

from or contradicts one of the general or particular conditions described hereafter which may

appear in any document from the buyer and especially in its general purchasing conditions,

cannot be used against the manufacturer unless accepted by manufacturer in a written

agreement.

ARTICLE 1:

Manufacturer warrants that each new item of equipment is of good workmanship and is free

from mechanical defects provided that:

1) The product is installed and operated in accordance with printed manufacturer

Equipment’s Instructions.

2) The product is used under normal operating conditions, for which it is designed,

3) The product is not subject to misuse, negligence or accident,

4) The product receives proper care, lubrication, protection and maintenance under the

supervision of trained personnel,

5) The product is normally protected from exterior aggressions whatever their origin.

ARTICLE 2:

This warranty expires, unless otherwise agreed by manufacturer in a special provision, 15

months after shipment by the manufacturer, or 12 months after being placed in service, or

after 1000 operating hours.

ARTICLE 3:

The manufacturer Warranty is strictly limited to the replacement of defective parts and if the

repair does justify it, to the assistance of a technician. Parts shipping expenses, traveling and

housing expenses of personnel are to be paid by customer.

ARTICLE 4:

The manufacturer Warranty does not apply to fluids, oils, fuses, bulbs, accumulators, paint,

seals, tires, bumpers, pads and other consumables or normally wearing type items unless

found to be defective prior to use.

ARTICLE 5:

All warranty claims from the Buyer must be sent by written to Seller who will be in charge of

dealing with the Manufacturer to address the problem in a timely manner.

ARTICLE 6:

All the expenses related to a warranty claim will be invoiced to the buyer until manufacturer

employees have evaluated the claim. Whatever the circumstances, the buyer should not

refuse or delay the payment. If the evaluation concludes to manufacturer’ s full responsibility,

a credit memo will be issued in favor of the buyer.

Under no circumstance other than those accepted by manufacturer, the buyer of the

defective parts at the manufacturer address can accept without a formal letter from the buyer

and without the effective return no warranty claim.

ARTICLE 7:

This warranty is extended by manufacturer only to the buyer of new products from

manufacturer or of its authorized distributors. The products purchased under this warranty

are intended for use exclusively by the buyer and his employees and by no other person.

Therefore, there shall be no third party beneficiary of this warranty.

Page 6/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

ARTICLE 8:

This warranty does only apply to the primeval reason. In other words, the consequences on

the product linked to its use after first problem are not covered by this warranty.

ARTICLE 9:

Under no circumstances whatever shall manufacturer and the seller be liable for any special

or consequential damages, whether based on lost goodwill, lost resale profits, work stoppage,

impairment of other goods or otherwise, and whether arising out of breach of any express or

implied warranty, breach of contract, negligence or otherwise, except only in the case of

personal injury as may be required by applicable law

ARTICLE 10:

The warranty is automatically void in the following cases:

1) The product has received some modification, not advised by Manufacturer or not done

following Manufacturer requirements

2) Some original parts have been replaced by parts not provided by Manufacturer.

ARTICLE 11:

This warranty and all undertaking of Manufacturer shall be governed by the laws of

manufacturer’s country and discussed in front of nearest court from the manufacturer’s facility

even in case of multiple of defenders.

Page 7/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

Section 3 GENERAL WARNING

FOREWORD

This instruction manual is intended for all users of the machine: the company

manager, the Department Head, the driver, as well as the whole personnel who

works with or near to the equipment

GENERAL WARNING:

1. Before using the machine, go through this manual and comply with all its instructions

2. Also carefully read the instructions that appear on the plates fixed onto the machine and keep

them readable

3. Keep this instruction manual at the disposal of all operators

4. Make sure that any person to whom you entrust the machine is qualified to fulfill the safety

requirements linked to its use

5. Avoid unsupervised interventions on your equipment when not being used

6. Never use a machine which does not looks to be in good condition

7. Never apply a load or a stress exceeding the maximum operating load of the machine

8. Never use the machine for an operation it is not designed to perform

9. Become thoroughly familiar with the safety regulations applicable to the machine and enforce

them scrupulously

10.The manufacturer declines his responsibility for the consequences of a disassembly of the

machine or any modification made without his supervision

OBLIGATION TO GO THROUGH THE USER’S MANUAL

The company manager is compelled to make the operators fully acquainted with the

regulations of the instruction manual.

Read this entire chapter BEFORE attempting to operate this loader

The company manager is responsible for the enforcement of the applicable “user’s

regulation”

The user must imperatively read and assimilate this instruction manual in order to be able

to comply with it during start- up and use

The instruction manual must be kept during the life- span the machine, including in the

event of a resale, of a change of user or manager

The instruction manual is not a training manual but it specifies, when required, if training

is necessary.

GENERAL INSTRUCTION

The company manager must make sure that the machine is delivered with the

instruction manual and the certificate of conformity for the member states of the European

Community

* The location of the instruction manual is specified on the dispatch note when leaving

the factory

The certificate of conformity is placed with the dispatch note

Only trained and qualified operators with appropriate driving license and accredited by

the company manager may operate the vehicle within the scope of the use for which it

has been designed

The loader may only be used in accordance with the conditions established by the

manufacturer in this instruction manual and declines the manufacturer his responsibly.

Any use that does not comply with the regulations of this instruction manual might cause

risks of injury to people, property and the environment

The manufacturer’s responsibility is limited to the assembly configuration of the

equipment as described in the certificate of conformity. Before each use, the driver should

Page 8/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

check that the machine is in good condition

The certificate of conformity is placed with the dispatch note

MACHINE NORMAL USING DOMAIN

W10 Wheel loader –THE ALLOWED MAXIMAL LOAD AND THE

GENERAL USING CONDITIONS ARE INCLUED IN THIS DOCUMENTATION

PROHIBIT THE USE OF LOADERS TO LOAD ANYTHING OTHER THAN THE SCOPE

THE ADAPT TEMPERATURE RANGE OF THIS LOADER IS - 30℃-50℃

MAKE IN THESE CIRCONSTANCES CAN’T BE HELD TO RESPONSIBLILITY OF MANUFACTURER

NOTE

Safety is more than quality design and construction. It also requires proper operation and

maintenance practices.

Every component is specifically designed and carefully built by Manufacturer to produce the safest

equipment available

Your responsibility is operating safely.

Good understanding of the instructions mentioned below will enable operators to use the loader in

safe

SAFETY INFORMATION

This manual provides important information to familiarize you with safe operating and maintenance

procedures for Manufacturer loader.

Even though you may be familiar with similar equipment, you must read and understand this manual

before operating this loader.

Safety is everyone's business and must be one of your primary concerns.

Knowing the guidelines covered in this manual will help provide for your safety, for the safety of those

around you, and for the machine's proper operation

MODIFICATION OF THE LOADER

The manufacturer is not responsible in case of any modification, addition or combination with

equipment from another origin.

The manufacturer declines any responsibility for consequences resulting from changes in the

characteristics or modifications made without his written consent, and concerning either the mechanical,

electrical, hydraulic part or the mechanically welded structure.

If the client wants a modification to be made, he must imperatively consult the manufacturer.

For your safety and in order to benefit from the total guarantee of the manufacturer, you must only

use guaranteed genuine spare parts.

Page 9/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

SECTION 4: INFORMATION AND OPERATION

The following features are standard equipment on the Loader series::

1. Diesel engine

2. Hydrostatic traveling drive system

3. Power steering

4. Recessed multi-function rear lights

5. Mechanically operated parking brake

6. Multi-function hydraulic control joystick

7. Fast change and lock attachment system

8. Adjustable absorbing seat with belt

9. Six linkage lifting system

10. Anti-skid floor

11. Roll cage with shade cover

12. Working lights

13. Combination meter

14. Adjustable steering wheel

15. Front steering light

B.OPERATOR RESPONSIBILITIES

This chapter must be read and thoroughly understood prior to operating or performing any

maintenance on this equipment.

WARNING: FAILURE TO COMPLY WITH THE FOLLOWING SAFETY

PRECAUTIONS CAN RESULT IN SERIOUS INJURY OR DEATH AS WELL AS

EQUIPMENT DAMAGE.

1. Always follow the global safety rules applicable in your field.

2. Before using this loader, always check for proper operation and condition of the lights,

brakes, steering, transmission shifter, park brake and tires.

3. Do not operate a loader with defective features; refer to the maintenance section of the

Operation and Service Manual.

4. Always wear suitable footwear when operating this equipment and avoid loose fitting

clothing that might get caught in moving parts.

Before starting this loader, should wear seat belts, and confirm the lock had been fastened.

5. Always bring the unit to a complete stop, place the transmission in neutral, and set the

park brake before quit the unit.

6. Always bring the unit to a complete stop before shifting from forward to reverse or from

reverse to forward.

7. Always check the path clear prior to backing.

8. When loading the speed should be reduced to 5KM / H

9. Lift the bucket up to the transport position (about 20cm from the ground)

10. In crowded areas and when close to the Blind corners and a row of car, be more careful.

Be vigilant to other equipment and personnel.

11. Do not operate when the speed does not meet the operational conditions. Always limit a

good speed in order to ensure sufficient time for emergency braking.

12. Do not allow to use loaders to transport hazardous materials.

13. Do not allow to carry person by this loader.

14. The loader does not allow to drive on the soft road if do not know very clearly about the

road condition.

Page 10/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

15. Before operating this loader, the roll cage must be raised, and make sure the pin in the

locking position.

16. In addition to the dragging outside hook, any form of traction is not allowed in loaders.

17. Do not remove the radiator cap when the engine is hot, otherwise, can cause severe

burns. Allow to remove the radiator cap after cooling.

18. Do not try to touch the just being run or down engine exhaust pipe and muffler, otherwise

it will cause serious burns.

19. After open the engine back cover, do not try to start the engine, if must start, take care

the hurt from the fan to hand.

20. Never refuel the unit while the engine is running.

21. When injecting the fuel, it can stop when the refueling gun automatic cut off, don’t inject

too much. When refueling, no smoking, don’t storage or use the fuel at fire place.

22. Do not fill the fuel cell above the bottom of the filler screen. Do not overfill. Clean off any

spilled oil or fuel. Do not smoke while refueling. Do not store, spill or use fuel near an open

flame.

23. Do not check the engine oil while the engine is running.

24. Do not use the battery in this unit to start other vehicles.

Before starting this loader, should wear seat belts, and confirm the lock had

been fastened.

The maximum ear noise measured value of this loader is 88dB, for your

good health, please wear personal protective equipment (such like the

earplug isolated the noise) when controlling the machine, to reduce the hurt

of the machine noise to your body.

Always exercise good common sense, stay alert and be aware of what is

happening around the loader all times.

When a vehicle roll or roll-over, the loader roll cage can protect driver’s

safety completely, do not jump. At this point your hands should get hold of

the steering wheel; feet clamp the mounting bracket under the Orientation

column.

The damaged roll cage can’t be reused after repair, unless get the written

authorization or approval from Manufacturer Group.

The rated capacity of this manual mentioned is based on the machine

located in the solid level ground, when operating on non-standard ground

(such as the soft, uneven ground, or on slopes), should consider fully about

those factors impact on the load capacity.

Before open the boonet, please make sure the operating handle was

press down and forward.

C.MECHANICAL RESPONSIBILITIES

This chapter must be read and thoroughly understood prior to performing any maintenance

on this equipment.

WARNING: FAILURE TO COMPLY WITH THE FOLLOWING SAFETY

PRECAUTIONS CAN RESULT IN SERIOUS INJURY OR DEATH AS WELL AS

EQUIPMENT DAMAGE.

Page 11/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

1. Always follow the Station Safety Rules. If a written list of safety rules is not posted at the

station, obtain one prior to operating this loader.

2. Always review the Operator Responsibilities Section prior to operating this equipment.

3. Always keep hands and feet away from rotating parts and tires. Wear secured clothing.

4. Always wear suitable footwear when operating or servicing this equipment. Avoid wearing

loose-fitting clothing that might get caught in moving parts.

5. Always stop the engine when adjusting fan and alternator belts.

6. Always keep hands clear of the cooling fan.

7. Do not remove radiator cap when the engine is hot, as serious burns may result. Allow

the radiator to cool before removing the cap.

8. Do not run the engine long time in the closed room.

9. Do not start the engine in the easy explosion environment.

10. Do not check the engine oil while the engine is running.

11. Always disconnect the battery positive cable when working on the engine or under the

hood.

12. if electrolyte is spilled, always wash hands or clothing immediately.

13. Do not touch the engine, exhaust or hydraulic components when they are hot as serious

burns may result.

14. Do not smoke near the battery. Fumes from charging electrolyte are explosive. Always

keep the battery away from sparks, flame and smoking materials.

15. Always remove metal bracelets, watch bands, etc. prior to installing, removing or

servicing the battery.

16. Do not short circuit the battery terminals.

17. When connecting the battery, the positive terminal must always be connected first

prevent sparks from accidental grounding.

18. Do not substitute the throttle return springs with lighter or other springs.

19. Check all lights.

20. Check the horn operation.

21. Check the neutral start only switch for proper adjustment and operation.

22. Check tire and wheel condition along with proper inflation pressures. Unless beads are

seated when mounting tires, over-inflation can result in explosion.

23. Torque all lug nuts to 100 ft-lbs. Check again the torque after 5 hours of operation.

24. Always use proper lifting equipment safely when removing or replacing heavy

components.

25. When working underneath the loader, be sure it is supported properly on secure jack

stands. Do not rely on hydraulic jacks to support the loader.

26. If the loader is on a hydraulic or air operated lift, always be sure the safety support or

lock

is in position prior to working under the loader.

27. Always use a proper transmission jack, and secure the transmission when removing or

replacing it.

28. Always jack the drive wheels off the floor when troubleshooting the drive system.

29. Never refuel the unit when the engine is running.

30. Do not smoke while refueling.

31. Do not store, spill or use fuel near an open flame.

32. Do not use the battery in this unit to start other vehicles.

33. Do not attempt to install or adjust control cables with the engine running.

34. Always replace a control cable which exhibits any gradual or sudden increase in no-load

friction or resistance or decrease in usable stroke, or which have moisture inside or have

been frozen.

35. Do not use heat to attempt to dry or thaw a control cable.

36. Do not remove the seals from a control cable or attempt to lubricate it. Any control cable

which exhibits possible lubrication problems should be replaced.

37. Do not attempt to repair or modify a control cable. Any damaged control cable should be

Page 12/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

replaced immediately.

38. Always avoid exposing control cables to fuels, oils, chemicals, paint, water or dirt as

damage may result.

39. Always adjust each control cable so that the utilized stroke of the cable is centered within

the cable’s available stroke.

40. Always deflate a tire and wheel assembly prior to removing it for servicing or dismounting.

41. Do not use wheels or wheel components that are cracked, bent pitted or corroded. Insure

that all wheel components are of the same type and size, and that wheel size and tire size

match. Inspect all components carefully prior to use.

42. Do not attempt to seat a tire by using explosive substance.

43. Do not hammer, pry or weld on or near an inflated or partially inflated wheel and tire

assembly.

44. Do not rework, weld, heat or braze any wheel parts for any reason.

45. Always use a safety cage and a clip-on air chuck with a remote valve and pressure

gauge when inflating a tire. Insure the tire and wheel assembly is properly assembled prior to

inflating it. Visually inspect it for proper seating of beads or sides or lock rings prior to

removing it from the cage.

46. Do not add air to a tire that has been in service with less than 80% pressure without first

fully deflating, removing, disassembling and inspecting the tire assembly for damage.

47.Canopy guard is main part protect operator from injury by falling objects. If any dismantle,

change and install loosen will bring dangerous which may lead big accident

Page 13/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

CHAPTER 1.

GENERAL INFORMATION &

OPERATING INSTRUCTIONS

Page 14/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

SECTION 1: MAIN COMPONENTS

The W10 is a four-wheel drive mini-loader. It contains:

o 3-cylinder diesel engine,

o Hydrostatic travel drive system,

o Multi-function operating handle,

o 12 Volt electrical system.

A. ENGINE AND PUMP

The loader is powered with industrial engines, with four stroke cycle and direct

injection. The engines are certified by the manufacturer to meet the more

advanced emissions standards.

W10 series loader has an automatically variable piston pump.

B.MOTOR

There is no drive axle in W10, the four wheel of front and rear axle are hydraulic gerotor

motors.

C.BRAKING SYSTEM

Hydrostatic drive can serve as a driving brake, and be installed on the drum brake of the two

rear wheel as a parking brake.

D.WHEELS AND TIRES

Four bolts are used to fix the tires on the drive wheel. The LOADER tires are pneumatic type

which gives a smooth ride combined with maximum drawbar pull. Remember to check the

pressure of your pneumatic tires regularly. Uneven tire pressure will not only increase tire

wear, but will also decrease tractive performance.

W10 Tire model:23 x8.5-12NHS Tire pressure:4.5 bar

E.FUEL CELL

The fuel cell is integrated in the front frame, and it is equipped with a filler cap and a fuel

gauge.

F.ELECTRICAL SYSTEM

The W10 uses a 12 Volt, automotive type, negative ground, electrical system. The system includes a

45 A.h battery, one combination instrument, three working lights, two turn lights, two

taillights, horn, various sensors and other circuits.

G. QUICK REMOVAL DEVICE

The demolition equipment of the tool is controlled by a Joint Multi-way valve, which can

realize a quick assembly and disassembly.

H.SEAT

Seats of the loader with seat belts can be adjusted forward and backward. The class of

seat is EM8.As an option the loader can be fitted with a comfortable suspended seat.

Page 15/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

I.ATTACHMENT

Loader is equipped with a standard six-bar working device which can maintain the

balance of the bucket while in the rising process.

J.MULTI-FUNCTIONAL CONTROL HANDLE

The control handle is on the right of the driver's position.W10 adopt simple handle without

shift control(Shift control was achieve by foot brake), handle can only control multi-channel

valve, to make raise and tilt movements can be separated or join together. Before open the

boonet, please make sure the operating handle was press down and forward.

K.PARKING BRAKE LEVER

The accelerator pedal which on the operator right is connected with engine by cable,

it can control drive speed by controlling engine speed. The parking brake lever is

connected by a rod to the park brake drum mounted on the drive axle. The park brake is

used for parking or holding the loader on grades and should always be set for parking and

released before driving. The brakes are engaged as the lever is pulled toward the operator.

Push the lever away from the operator (down) to release the brake.

L.PEDALS

The foot brake pedal on the left of the driver is connected to the Pump, which can

control the oil supply, so as to control the speed of the loader, forward and reverse.

M. STEERING WHEEL

Steering wheel is just like normal that is when steering wheel rotate right, the loader will

turn right, when steering wheel rotate left, the loader will turn left.

N.INSTRUMENT PANEL

Monitoring the status of machine, feedback the operation information to operator in time..

IT IS ESSENTIAL THAT THE OPERATOR BECOMES ACCUSTOMED TO

BOTH THE LOCATION AND OPERATION OF THE CONTROLS, BEFORE

ATTEMPTING TO DRIVE THE LOADER FOR SAFE OPERATION.

The root are value of machine vibration acceleration to the arm is lower than

2.5m/s2

The root are value of machine vibration acceleration to the body is lower

than 0.5m/s2

Switches

Ignition Switch

●

Waterproof loader ignition switch, including the anti-

re-start function.

Horn control switch

●

Installed in the steering gear box

Headlamp Switch

●

Installed in the steering gear box

Direction-indicator switch

●

Installed in the steering gear box

Page 16/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

Light

Preheat indicator light

●

Instructs when the engine is warm

Parking brake lamp

●

Show if the parking brake brings

Low battery capacity light

●

Show when the battery level is low

Turn signal / warning lights

●

Show when the turn signal / warning lights are

light

Low oil pressure light

●

Show when the engine pressure is low

High-temperature light

●

Show when the coolant temperature is above

115 ℃

Indicator

Fuel Level Indicator

●

Read the status of the remaining fuel

Engine timer

●

Read the cumulative time when the vehicle is

running

The engine coolant temperature indicator

●

Measure the temperature of the engine cooling

system

1.Hourmeter

7—High-temp. water alert

light

2—Backward indication light

8—Battery charging,

Page 17/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

voltmeter

3—Fuel meter

9—Oil pressure alert light

4—Turn right alert indicator

10-Turn left alert indicator

5—Parking brake lamp

11—Water temp meter

6—Preheat indicator light

12—Forward indication

light

Page 18/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

SECTION 2: OPERATING PROCEDURE

Read this entire chapter BEFORE attempting to operate this loader

-No unauthorized person may drive this loader

-Be familiar with the controls and their functions before you start the loader

-Inspect your machine by doing a pre-operational inspection

-Observe the limits on weight of the loads to be towed and unloaded weight of the loader

-Maintain the loader in accordance with the instructions of the manufacturer

-Have any broken or missing parts, correct or replace before use

-Verify that all maintenance has been performed

-Verify that all the instruction and safety labels are in a place and readable

These are as important as any other equipment on the loader

Before putting the loader into service, the following items must be checked and executed

BEFORE DRIVING

●

At each team work beginning, check condition of the battery, pneumatic and bandages of trails

and be sure that tire pressures are correct .Be sure that all driving parts are in good working

condition and fill all the fluid levels if necessary .Advise immediately all defects and use a

defective trail before it is not repaired Verify the brakes of trails

●

Set parking brake

●

Walk around and inspect the loader for damage or missing equipment

Check for :

- Pressure and the good state of the pneumatic tires

- Look for cuts, cracks in side walls, foreign objects in treads

- Look for loose wheel nuts

- Damage to lights

- Fire extinguishers fully loaded and in place (if have)

●

Look underneath loader for leaks of coolant, hydraulic fluid, transmission fluid, or lubricating

oil. If leaks are detected, repair as soon as possible

●

Check engine oil level

●

Check engine coolant level. Add coolant as necessary, but do not overfill. Make a visual check

for leaks

●

Check hydraulic system reservoir by removing filler cap to ensure there is enough fluid for

operation

A very low fluid level indicates a serious leak in the system. Repair as soon as possible

●

Inspect engine compartment for loose hardware, loose wires, and leaking lines or fittings

●

When all mechanical checks are completed, check the operation of the stop and tail lights,

head

lights, and dash panel lights

●

Check fuel level gauge to make sure tank is full

●

Make sure the roll cage arise and fasten.

●

Check that the driving seat whether damaged (change the seat if damaged), adjusted to your

requirements

●

Check that all controls are in working order

WARNING: DO NOT LOOSEN OR REMOVE RADIATOR CAP WHILE COOLANT IS HOT,

HOT COOLANT UNDER PRESSURE CAN CAUSE SEVERE BURNS

Page 19/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

Fuel contamination due to moisture condensing on the inner surfaces of fuel tank can

be minimized or eliminated by keeping the fuel tank as full as possible. The fuel tank

should always be filled up at the end of the day's operation (as part of the post-

operation maintenance routine)

DRIVING INSTRUCTION

●

Place shift lever in park.

●

Adjust the driver seat and steering wheel to the comfortable location, fasten the seat belt.

●

Make sure parking brake is set.

●

Verify that nobody and nothing is ahead of you BEFORE starting any motion of the wheel

loader.

●

Turn ignition switch and engage starter.

●

Press the micro-pedal (left pedal).

●

Press the parking brake, forward or backward, release and the pedal will return to parking

position.

●

Proposal on the drivers' own facility with the empty wheel loader.

●

Press foot valve pedal and gently press the accelerator pedal, further press the accelerator

until the required speed is obtained. Foot valve can change drive speed and direction by

control pump displacement. Accelerate pedal change drive speed by control engine speed.

●

To slow the wheel loader, slowly release the accelerator pedal and the foot valve pedal. For

stop, release the accelerator pedal and then release foot valve pedal. Release the foot valve

pedal slowly or quickly, wheel loader can be controlled flat or sharp braking. For emergency

stop, release the foot valve pedal or press slowly the foot valve pedal on reverse direction.

●

Each time you park, apply the hand brake, turn the starter switch to the OFFposition and

return the transmission shift lever to park.

Release the foot valve pedal or press slowly the foot valve pedal(left side) on reverse

direction. when emergency brakes .

Warning: one operator can drive less than 6 hours one day.

Warning: The driving speed depend on the loader load and weather conditions.

Especially on the full load or the damp and the frozen surface road should be slow

down the speed.

Warning: When load the goods, the speed need to reduce to 5km/h and keep the bucket

to the transport position(20cm above the ground).

Warning: When the loader is moving (uphill),if parking immediately, the driver can not

leave the driving seat, can not change the switch gear, need to press the accelerator

pedal by you right foot in order to eliminate the slippage phenomenon due to technical

reasons, then pull the brake. When the loader is moving downhill, if parking

immediately, the driver can not leave the driving seat, keep the switch on the reverse

gear, press the accelerator pedal on you right foot, parking the loader slowly, then pull

the hand brake.

Warning: It is forbidden to parking on the ramp, if it’s necessary to parking on

the ramp, pull the hand brake and use the wedge cushion under the wheel loader.

警告: 不允许在坡道上停车,如果有必要将车停在斜坡上(由于故障等引起),必须,同时拉起手制

动器,同时用楔形物垫在装载机车轮下。

Page 20/47

W10 series loader operation manual

Updated 10/6/2016

JST

Series

Warning: Before moving, confirm the roll is installed firmly, to fixed the unreliable roll

stand, it can not protect the driver.

Loading instruction

●

Lifting device and attachment(the standard bucket)can only be used for the earmarking.

●

Ensure the loads of the loader is safe and the loads is within the scope of rated load.(See the

technical parameters on page 26)

●

Before loading, make sure the quick switch device is in the locked position.

●

On load moving, the speed should be down to 5km/h.

●

On load moving, confirm the bucket is on the transport location(20cm above ground)

●

On the ramp, the goods must be in uphill direction. It is forbidden to horizontal drive or turn

around on the ramp.

●

When the line of sight is blocked, should be worked with the wizard.

●

When unload, lifting the bucker to the suitable height, as careful as you can, accurate

approach to loader truck or goods pile up; careful manipulation the multi-way valve lever,

unloading and reset; confirm the bucket and the loader(shelves) are completely separated, the

loader slowly driving back from shelves, then falling down the shelves.

●

Ensure that the loader width to load is narrow than the traffic road.

●

Arrived the parking position, after the machine stopped completely, pull the parking brake, and

close the ignition switch.

Safe and efficient loading, depends entirely on the operator. If you are an experienced

driver, the following rules will refresh your memory. If you are a student, they will help

you become a professional pilot.

Warning: Only qualified and authorized driver allowed driving.

Warning: Before loading, please confirm the quick switch device of cylinder is in the

locked position, locked the attachment, cut-off the two three-way ball valve.

Warning: When it’s moving on the ramp (forward or backward), the goods must be on

the uphill direction; it’s forbidden to transverse moving or turn around.

Warning: When the goods is on the raising status, stay in the loaders.

Warning: When the goods is on the lifting status, forbidden the loader swerve; keep not

in the high speed condition.

Multi-way valve focus controlling lifting devices and tools :

Locking tools - push the back of a small handle to the right.

Table of contents

Other Eurotrac Compact Loader manuals