Evenlite ELCD User manual

Emergency Lighng Control Device

Installaon / Operaon Manual

IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety precauons should always

following:

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

This product can be used with LED Drivers, Fluorescent Ballasts, Incandescent,

/Quartz

and general use loads

Servicing shall be performed by qualified service personnel

Ensure all wiring complies with applicable standards such as NFPA, NEC, and

This product is not intended for use in wet locaons –

seal appropriately

when

Do not mount near gas or electric heaters

Do not use this equipment for other than intended use

cause an unsafe condion

WARNING

ONLY QUALIFIED

SAVE THESE INSTRUCTIONS

UL-924 Listed for Emergency Lighng

Factory Calibrated Zero-Cross switching

compared to convenonal relays

Industries lowest standby power consumpon

120 - 277 VAC Universal Input

NEMA 410 Tested

IEC 61000-4-5 Surge Tested

Aracve standard faceplate - single or

Breakaway tabs for mulple mounng

reduces relay arcing and inrush current up to 5X

is less than 0.25W @120V

mul-gang box

configuraons

be followed including the

Tungsten

local codes

using outdoors

The use of accessory equipment not recommended by the manufacturer may

TURN POWER OFF BEFORE INSTALLATION,

ELECTRICIANS SHOULD INSTALL

ELCD / ELCD-D / ELCD-F / ELCD-FD

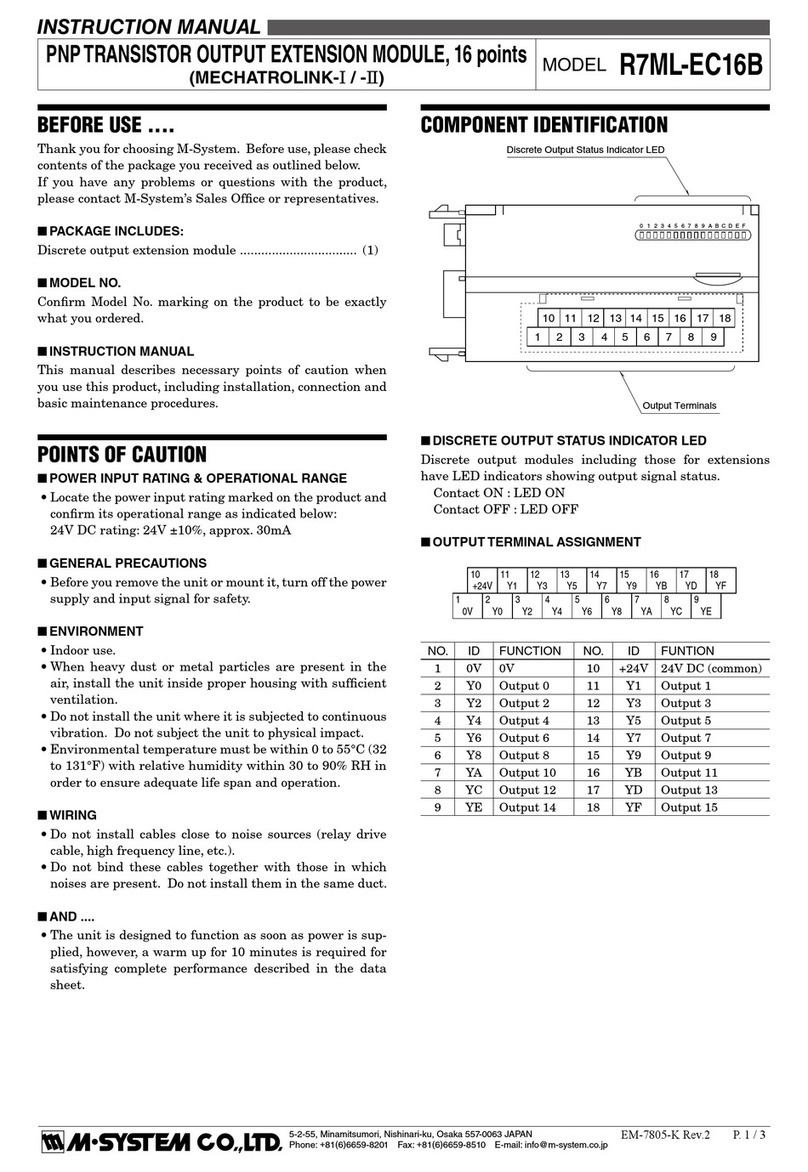

Electrical Specications:

Inputs:

EMERGENCY, UTILITY and SWITCHED 120-277VAC, 47-63 Hz

0-10V controls (ELCD-D/FD model) 0-10V DC, 200mA maximum

Fire Alarm 12-24V AC/DC

Max Load Requirements:

LED, Ballast, Tungsten, Incandescent: 20A @ 120/277V

Standby Power Consumption: 0.25W@120V, 0.60W@277V

Dielectric Strength: 1550 VAC between ALL Inputs

Mechanical Specications:

Size: 1.73"W x 1.28"D x 2.72"H Warranty:

Weight: 4.5 oz. 5 Year full replacement

Color: RAL9003 White

Indicators: LED's - EMERGENCY (Green), UTILITY (Green), ALARM (Red) Conformance:

User Controls: Test Button UL-924, NEMA 410, IEC 6100-4-5,

Mounting: Standard electrical box or xture mount NEC, OSHA, NFPA

Breakaway tabs for mounting congurations

Environment: 0-50 deg. C

Connections: Flying Leads – Pre-Tinned

12AWG for EMERGENCY INPUT (Blue) and LOAD (Yellow)

18AWG for UTILITY (Black), SWITCHED (Red),

UTILITY NEUTRAL (White), EMERGENCY NEUTRAL (Gray)

20AWG Teon for Fire Alarm (Red), 0-10V Dimming (Violet)

Programming Mode – Changing the Time Delay function

The ELCD has 5 pre-programmed time intervals which allows the user to extend the relay’s “on time” when returning from an Emergency condition.

The factory default time interval is set to 2 seconds and can be eld modied to either No Delay, 1, 5, or 15 Minutes.

To change the time interval, press and hold the TEST button for at least 15 seconds to enter the programming mode. Once the programming mode is

entered, the ALARM LED will illuminate solid red until the TEST button is released. Once the TEST button is released, a blinking pattern between the

EMERGENCY LED and the ALARM LED will start. Blinking will alternate between the ALARM and EMERGENCY LED’s followed by a pause and then

repeated continuously. The quantity of blinks on the green EMERGENCY LED indicates which time interval is currently selected. To advance the time

interval to a different pre-programmed setting, simply press the TEST button again. The Programming mode is a continuous loop so that if the button

is pressed too many times, it will go back to the starting location. Once the desired time interval has been selected, press and hold the TEST button

for at least 5 seconds until the ALARM LED is OFF to exit the programming mode.

Programming Mode Sequence 1) One Blink = No Delay

Programming Mode Sequence 2) Two Blinks = 2 Second Time Interval (Default)

Programming Mode Sequence 3) Three Blinks = 1 Minute Time Interval

Programming Mode Sequence 4) Four Blinks = 5 Minute Time Interval

Programming Mode Sequence 5) Five Blinks = 15 Minute Time Interval

Press TEST Button

momentarily to advance

to new sequence

QUICK GUIDE - PROGRAMMING PROCEDURE (for details – see PROGRAMMING MODE description)

Step 1 – Enter the Programming mode

Step 2 – Momentarily press the TEST button to advance to the desired Time Interval

Step 3 – Exit the Programming mode

Press and Hold

(15+ Seconds) TEST

ALARM

LED ReleaseTEST Button

After ALARM LED is ON

***NOTE***

Count the blinks on the Green

EMERGENCY LED

after the Red Alarm

EMERGENCY

LED

3 Blinks = 1 Min.

2 Blink = 2 Sec.

4 Blinks = 5 Min.

5 Blink = 15 Min.

Press and Hold

TEST

TEST Release TEST Button

After ALARM LED is OFF

User Programmable Time Delay up to 15 min.

1 Blink = No Delay.

120 - 277V 20A 47-63hz

SPEC GRADE FOLLOW INSTRUCTIONS

TEST

EMERGENCY

LIGHTING CIRCUITS

ALARM

EMERGENCY

UTILITY

ELCD

EMERGENCY LIGHTING

CONTRO L DEVICE

US

Z410153 Rev A

General Description:

The ELCD Product is listed to the emergency lighting standard UL-924 and is intended to operate so that normal lighting xtures can also serve as

emergency lighting xtures. Use of the ELCD allows full control of any light xture(s) during normal operating mode and during the EMERGENCY mode, it

will automatically connect the attached light xtures to the EMERGENCY power source. This device is particularly suited for use with an Emergency

Lighting Central Inverter which can supply a continuous source of power to the connected light xtures during a power outage.

This device DOES NOT transfer power between two different power sources. The internal power relay opens or

closes between the EMERGENCY input to the EMERGENCY output. UTILITY power is a sense line (NOT CURRENT

CARRYING) and is used to control the state of the internal power relay. Load current therefore is always derived from

the EMERGENCY power.

Use in conjunction with lighting control systems such as photo-cells, time clocks, occupancy sensors, etc. the ELCD will signicantly reduce power

consumption to meet energy savings initiatives such as California's CEC Title 24.

Installation:

All models should be installed in accordance with state, local and national electrical codes and requirements.

Intended for xture mount or installation in standard junction boxes covered with faceplate.

This unit has more than one power supply connection point. To reduce the risk of electrical shock disconnect both the branch

circuit breakers or fuses and emergency power supplies before servicing.

Figure 1 – Basic ELCD Model Illustrates how to connect the Emergency Power Input, Emergency Power Output, Utility Power and Switched Power. This

conguration allows normal xtures and emergency xtures to use the same switched source so that they form a lighting zone.

Figure 2 – ELCD-FD Model Illustrates how to connect a 0-10V dimming circuit with similar controls as Figure 1.

The 0-10V (Violet and Gray) signal is connected to the dimmer during normal operation and during emergency mode, the 0-10V signal (Violet) is opened

so that the xtures go to full brightness.

Fire Alarm - Red wires (not shown) accept 12-24 VAC/VDC.

Upon receiving a voltage from the re alarm system, the ELCD-F and ELCD-FD models will force an emergency condition and turn on the Emergency Light

xtures and bring them to full brightness.

Testing/Troubleshooting:

Use the LED indicators on the front face to ensure proper connectivity. EMERGENCY LED only illuminates when EMERGENCY Input Power (Blue and Gray)

are connected. UTILITY LED only illuminates when UTILITY power is present (Black and White). Both power sources must be present for proper operation.

If either LED is not illuminated, please check for proper connections.

With both EMERGENCY and UTILITY power connected and both LED’s illuminated, press the TEST button on the front face or energize the Switched Input

to energize the emergency loads.

When using the ELCD-D or ELCD-FD models, ensure that the emergency xtures go to full brightness when the TEST button is pressed and also ensure the

dimmer has full control of normal and emergency xtures during normal mode.

The ALARM LED should NEVER be illuminated during normal operation.

In the event the ALARM LED is illuminated, the ELCD should be replaced immediately.

WIRE LEGEND

FIGURE 1

GENERAL WIRING DIAGRAM

ELCD MODEL

CIRCUIT SHOWS NORMAL AND EMERGENCY OPERATING FROM SAME WALL SWITCH

WALL SWITCH CAN BE REPLACED WITH CONTACTOR, OCCUPANCY SENSOR, TIME CLOCK, ETC.

EMERGENCY POWER INPUT (HOT) = BLUE

EMERGENCY POWER (NEUTRAL) = GRAY

LIGHTING LOAD (HOT) = YELLOW

UTILITY POWER (HOT) = BLACK

Power Relay

Control

Circuit

BLACK

RED

BLUE YELLOW

Wall Switch

EMERGENCY FIXTURES

(Use Emergency Neutral )

NORMAL FIXTURES

(Use Ulity Neutral)

SWITCHED POWER (HOT) = RED

UTILITY/SWITCHED (NEUTRAL) = WHITE

DIMMING = VIOLET

(ELCD-D/FD MODEL)

FIRE ALARM = RED (ELCD-F/FD MODEL)

FIGURE 2

DIMMING (0-10V) WIRING DIAGRAM

ELCD-D/FD Models

CIRCUIT SHOWS NORMAL AND EMERGENCY FIXTURES OPERATING FROM SAME WALL SWITCH

WALL SWITCH CAN BE REPLACED WITH CONTACTOR, OCCUPANCY SENSOR, TIME CLOCK, ETC.

VIOLET SIGNAL PATH IS OPEN DURING EMERGENCY MODE FOR FULL BRIGHTNESS

Power Relay

Control

Circuit

BLACK

RED

BLUE

YELLOW

Wall Switch

W/Dimmer

VIOLET

VIOLET

Signal Relay

VIOLET

EMERGENCY FIXTURES

(Use Emergency Neutral)

NORMAL FIXTURES

(Use Ulity Neutral)

ON EMERGENCY FIXTURE

Ulity

Power

Source

Emergency

Power

Source

UL 1008

Transfer

Switch

Emergency

Power

Panel

Ulity

Power

Panel

UTILITY

Power

Source

Emergency

Power

Source

UL 1008

Transfer

Switch

Ulity

Power

Panel

Emergency

Power

Panel

Figure 1 and Figure 2 illustrate typical wiring for Non-Dimmed and Dimmed Loads

For Additional wiring instructions, please consult factory

ELCD-D and ELCD-FD are for 0-10V dimming and are NOT compatible with 2-Wire dimming

GRAY

GRAY

VIOLET

GRAY

HOT

HOT

ELCD Model

No Dimming

No Fire Alarm

ELCD-F Model

Includes Fire Alarm

ELCD-D Model

Includes Dimming

ELCD-FD Model

Includes Fire Alarm

and Dimming

This manual suits for next models

4

Popular Control Unit manuals by other brands

American Standard

American Standard R127 installation instructions

schmersal

schmersal CSS 34 operating instructions

Link

Link 1500 Series installation instructions

ADLINK Technology

ADLINK Technology USB-1210 user manual

Gaspardo

Gaspardo PRECIMAT USE AND ASSEMBLY INSTRUCTIONS / SPARE PARTS

DuraComm

DuraComm DC-RMCU1 owner's guide

Raspberry Pi

Raspberry Pi Compute quick start guide

Vaillant

Vaillant VR 15 installation instructions

National Instruments

National Instruments NI 9375 Getting started guide

Miele

Miele SE 247 operating instructions

National Instruments

National Instruments NI 9351 Getting started guide

NKK SWITCHES

NKK SWITCHES CL01 user manual