TRIAC TMC-4 User manual

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

1

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

Installation and Operation Manual

TMC4 Modbus Module

Single and Dual Channel Modbus RTU, Single Port ModbusTCP

1. Overview

The Triac Modbus modules are a plug-in option module for use with the

TMC4 controller providing communication with the TMC4 control card

through Modbus RTU or ModbusTCP protocol. The TCP module, item

TMC-4C006-002, is available with a single port connection. The RTU

module is available in both a single isolated channel, item TMC-4C005-

001, and dual isolated channel, item TMC-4C005-003. The dual channel

module supports communication via two independent ports under one ID.

This dual channel configuration is useful for operating physically redundant

networks. Wiring, communication parameters, and best practices are all

common between the single and dual channel module operation.

Features

RTU Modules

•Addresses from 1 to 246

•None, Odd or Even parity

•9600, 19.2k, 57.6k, 115.2k baud rates

TCP Module

•IP parameters configurable via TMC4 menus or by terminal

program with on-board USB connection

•Supports up to 8 concurrent connections.

Installation

The TMC4 Modbus module is installed in the TMC4 control board option

module slot using (2) 4-40 x 1/4" screws. Insert card edge in the mini PCI

express connector and rotate module flat to secure with the screws.

Single Channel

TMC-4C005-001

Dual Channel

TMC-4C005-003

ModbusTCP

TMC-4C006-002

Insert option module into

connector and rotate flat. Tighten

with #4-40 x 1/4” fasteners.

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

2

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

Wiring

The wiring pinout for the RTU single channel and RTU dual channel module is shown below. The TCP module only

requires RJ45 connection.

RTU Single Channel

TMC-4C005-001

ModbusTCP

TMC-4C006-002

RTU Dual Channel

TMC-4C005-003

COM1 A

COM1 B

COM

RJ45

JACK

COM1 A

COM1 B

SHIELD

COM2 A

COM2 B

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

3

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

2. Network

Modbus RTU modules communicate over RS-485 network. For best results using either of the RTU modules, a RS-485

cable with recommended 120Ω characteristic impedance should be used for network wiring. For the dual channel RTU

module, separate RS-485 communication cables must be used for both Network 1 and Network 2 as shown. For single

channel RTU module, only Network 1 cabling is required.

A 120Ω termination resistance at master and last slave node on the network is required for best performance. Maximum

number of nodes per multi-drop network should be limited to 32 nodes. If greater than 32 nodes are required on a

network, repeaters should be utilized.

Polling nodes simultaneously on both ports for a dual channel network should be avoided. A minimum 500ms polling rate

and delay of 20ms between polls of the same device on both channels is recommended.

ModbusTCP module implements the Modbus protocol onto a TCP/IP based communication. TCP module should be wired

using standard Ethernet network components (switch etc.) and IT practices.

RTU Cable Length

The theoretical maximum cable length for RS-485 network is 1.2 km (3900 feet). This also includes the length of any

network stubs used. Maximum cable length decreases as the data rate increases as shown below. Other considerations

may decrease actual maximum cable length, such as characteristic impedance mismatch of cable to master.

120Ω

Termination

120Ω

Termination

Maximum 32 nodes per multi-drop network

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

4

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

Network Topology

The Modbus RTU module should be wired in either a daisy chain topology, or a bus/backbone with stubs for best results.

If backbone with stubs topology is used, the length of stubs should be kept as short as possible. Star, ring, or

combinations thereof, should be avoided. ModbusTCP module can be connected using any topology compatible with

Ethernet networks such as star, ring, or combination thereof.

Network Type

RTU Module

TCP Module

Daisy Chain

Yes

No

Bus or Backbone with Stubs

Yes

No

Star

No

Yes

Ring

No

Yes

Backbone with Stars

No

Yes

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

5

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

3. Setup

To operate with Modbus commands, the TMC4 controller must first be configured for Modbus RTU or ModbusTCP

communication. Refer to TMC4 IOM for details.

•Set Command Type in the COMMAND CONFIG submenu to Comms.

•Set Position Type in the POSITION CONFIG submenu to either Limit Switch or Potentiometer depending on if

on/off actuation or proportional/modulating actuation.

oIf operating as Potentiometer positioning, program the 0% and 100% positions in the Calibrate Close and

Calibrate Open setting.

•Set Communication Type in the COMMS CONFIG submenu to Modbus RTU or ModbusTCP.

Set communication settings such as unit address, baud rate and parity for RTU modules, and IP address, subnet

mask and gateway for TCP modules in the COMMS CONFIG submenu.

NOTE: Cycle power to the TMC4 after communication settings are changed to ensure connection.

4. Operation

Limit Switch Positioning Operation

When operating with limit switches for on/off or two position control, the TMC4 Position Type setting in the POSITION

CONFIG submenu should be set to Limit Switch. When operating in this mode, Bit 1 and Bit 2 in Register 40009 control the

actuator direction and movement. The actuator can also be controlled by writing specific values to Register 40010.

Bits 1 –4 in Register 40001, provide the feedback information about the travel direction and end of travel position of the

actuator. Operating details are provided below.

OPERATION

Register 40009, Action Bits/Flags 2

Bit 2

Bit 1

Description

0

x

De-energize motor outputs

and stop actuator.

1

0

Energize motor outputs and

drive actuator CW.

1

1

Energize motor outputs and

drive actuator CCW.

FEEDBACK

Register 40001, Status Flags 1

Position

Movement

Description

Bit 4

Bit 3

Bit 2

Bit 1

Position

Movement

0

0

0

0

Between limits

Stopped

0

0

0

1

Between limits

CCW

0

0

1

0

Between limits

CW

0

0

1

1

?

?

0

1

0

0

CCW limit

Stopped

0

1

0

1

?

?

0

1

1

0

CCW limit

CW

(1)

0

1

1

1

?

?

1

0

0

0

CW limit

Stopped

1

0

0

1

CW limit

CCW

(1)

(1) This state will be present immediately when reversing direction until the position

cam disengages the position limit switch. If this state persists, it may indicate jam or

obstruction condition.

OPERATION

Register 40010, Command Position

Value

Description

0

Energize motor outputs and

drive actuator CW.

500

De-energize motor outputs

and stop actuator.

1000

Energize motor outputs and

drive actuator CCW.

Note that even though the motor stops when the destination travel limit switch is closed, the motor outputs of the control

board remain energized until a stop command is written to Register 40009 or 40010.

In Register 40009, Bit 1 establishes the direction of actuator travel and Bit 2 energizes or de-energizes the motor output

corresponding to the direction determined by Bit 1.

If Bit 1 = 0, the actuator is set to move in the CW direction. If Bit 1 = 1, the actuator is set to move in the CCW direction.

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

6

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

If Bit 2 = 0, the motor output is not energized. If Bit 2 = 1, the CW motor output is energized when Bit 1 = 0 and the CCW

motor output is energized when Bit 1 = 1. Unless Bit 2 is cleared, the actuator will continue to move in the specified direction

until the corresponding end of travel limit switch closes.

It is acceptable to change direction with Bit 1 while maintaining Bit 2 = 1. If the direction is changed while the actuator is

moving, a short delay occurs before the actuator begins moving in the opposite direction.

Writing values into Register 40010 will automatically set Bit 1 and Bit 2 in Register 40009 according to the action specified.

CAUTION! When writing to Bit 1 and Bit 2 of Register 40009, be careful not to change the other register bits.

In Register 40001, Bit 1 and Bit 2 indicate the direction of travel. Bit 3 and Bit 4 indicate if the actuator is at the full CCW or

full CW limit respectively.

While the actuator is moving in the CW direction, Bit 2 = 1. When the actuator reaches the CW end of travel limit switch, Bit

2 = 0 and Bit 4 = 1. The CW motor output is de-energized.

While the actuator is moving in the CCW direction, Bit 1 = 1. When the actuator reaches the CCW end of travel limit

switch, Bit 1 = 0 and Bit 3 = 1. The CCW motor output is de-energized.

Potentiometer Positioning Operation

When operating with feedback potentiometer for proportional or modulating control, the TMC4 Position Type setting in the

POSITION CONFIG submenu should be set to Potentiometer. In this mode, the actuator is controlled using the Command

Position Register 40010, and the Sensitivity/Deadband Register 40013. Note, the deadband can also set by the on-board

menus. The actual location of the actuator is indicated by the Current Position Register 40008.

When a new command position value is written to Register 40010, the new value is compared to the current position value

in Register 40008. If the difference between the twovalues is greater than the sensitivity/deadband value in Register 40010,

the actuator begins moving towards the new command position. When the current position value is within the limits of the

command position and sensitivity/deadband value in Register 40010, the actuator is stopped.

Bit 1 and Bit2 in Register 40001 are also usedto indicate the direction of travel. If the actuator ismoving in the CW direction,

Bit 2 = 1. If the actuator is moving in the CCW direction, Bit 1 = 1. When the actuator reaches the command position value

and is stopped, Bit 1 and Bit 2 will equal 0.

Obstruction or Jam Detection

When a move command is given by either setting Bit 1 and Bit 2 in Register 40009, or by writing valid value to Register

40010, a timer is immediately started. The timer continues to increment once every second. After each increment, the timer

value is compared to the value set in Register 40011 for the Travel Timeout.

If the destination travel limit switch closes, or the position setpoint is reached before the timer value is greaterthan the value

in Register 40011, the actuator is operating normally.

If the destination travel limit switch IS NOT closed, or the position setpoint is not reached before the timer value is greater

than the value in Register 40011, a jam or obstruction has prevented the valve from operating properly. The active motor

output is de-energized, and Bit 5 in Register 40001 is set.

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

7

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

5. Modbus

Function Codes

The TMC4 Modbus RTU and TCP modules are a Modbus slave that supports the following Modbus functions.

Code

Code

(hex)

Code Definition

03

0x03

Read Holding Registers

16

0x10

Write Multiple Registers

Function 03 reads the contents of a contiguous block of holding registers. All registers, 40001-40017 are readable with this

function.

Function 16 writes values into a sequence of adjacent holding registers. Only registers, 40009-40017 can be written to with

this function.

Registers

All registers are 16 bits in length. When the register is addressed in the data communications, the register is assigned a

hexadecimal value starting with 0x00. Therefore, registers numbered 40001-40017 are addressed as 0-16 in decimal, or

0x00 to 0x10 in hexadecimal resulting in the register always addressed one value below the specified decimal register

number.

Register

No.

Register

Address

Address Name

16 bit / Digital Name

Unit

Scale

Range

Default

Read / Write

40001

0x00

STATUS FLAGS 1

INT

bit 1

CCW Movement

Bit

N/A

True/False

N/A

Read

bit 2

CW Movement

Bit

N/A

True/False

N/A

Read

bit 3

CCW Travel Limit

Bit

N/A

True/False

N/A

Read

bit 4

CW Travel Limit

Bit

N/A

True/False

N/A

Read

bit 5

Actuator Obstructed

Bit

N/A

True/False

N/A

Read

bit 6

-

-

-

-

-

-

bit 7

Control Mode

Bit

N/A

True/False

N/A

Read

bit 8

Operating Mode

Bit

N/A

True/False

N/A

Read

bit 9-16

-

-

-

-

-

-

40002

0x01

TOTAL POWER

ON TIME HI /

FIRMWARE

VERSION

INT

bit 1-8

Total Power On Time

(Upper Byte)

Hour

1

65,536 –16,711,680

(0 –16,777,215 when used with

Register 40003)

0

Read

bit 9-16

Firmware Version

Int.

1

0-255

N/A

Read

40003

0x02

TOTAL POWER

ON TIME LO

INT

Hour

1

0 –65,535

(0 –16,777,215 when used with

Register 40002 bits 1-8)

0

Read

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

8

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

40004

0x03

TOTAL MOTOR

RUN TIME HI

INT

bit 1-8

Total Motor Run Time

(Upper Byte)

Count

1

65,536 –16,711,680

(0 –16,777,215 when used with

Register 40005)

0

Read

bit 9-16

-

-

-

-

-

-

40005

0x04

TOTAL MOTOR

RUN TIME LO

INT

Count

1

0 –65,535

(0 –16,777,215 when used with

Register 40004 bits 1-8)

0

Read

40006

0x05

TOTAL MOTOR

STARTS HI

INT

bit 1-8

Total Motor Starts

(Upper Byte)

Count

1

65,536 –16,711,680

(0 –16,777,215 when used

with Register 40007)

0

Read

bit 9-16

-

-

-

-

-

-

40007

0x06

TOTAL MOTOR

STARTS LO

INT

Count

1

0 –65,535

(0 –16,777,215 when used

with Register 40006 bits 1-8)

0

Read

40008

0x07

CURRENT

POSITION

INT

%

0.1

0-1000

N/A

Read

40009

0x08

ACTION BITS /

STATUS FLAGS 2

INT

bit 1

Direction

Bit

N/A

True/False

N/A

Read / Write

bit 2

Motor Output

Bit

N/A

True/False

N/A

Read / Write

bit 3

Reset Actuator

Bit

N/A

True/False

N/A

Read / Write

bit 4

-

-

-

-

-

-

bit 5

-

-

-

-

-

-

bit 6

-

-

-

-

-

-

bit 7

Fault Action

Bit

N/A

0,0 –In Place

0,1 –CCW

1,0 –CS

1,1 –To Position (40017)

0,0

Read / Write

bit 8

bit 9

Power Interrupt Flag

Bit

N/A

True/False

N/A

Read / Write

bit 10

Reset Flag

Bit

N/A

True/False

N/A

Read / Write

bit 11

-

-

-

-

-

-

bit 12

Save To EEPROM

Bit

N/A

True/False

N/A

Read / Write

bit 13

Fault Flag

Bit

N/A

True/False

N/A

Read / Write

bit 14

-

-

-

-

-

-

bit 15

-

-

-

-

-

-

bit 16

-

-

-

-

-

-

40010

0x09

COMMAND

POSITION

INT

%

0.1

0 –1000 (Modulating)

0, 500, 1000 (Limit Switch)

N/A

Read / Write

40011

0x0A

TRAVEL TIMEOUT

INT

sec

1

5 - 255

60

Read / Write

40012

0x0B

RESERVE

-

-

-

-

-

-

40013

0x0C

SENSITIVITY

INT

%

0.1

1 - 25

5

Read / Write

40014

0x0D

COMMUNICATION

TIMEOUT

INT

sec

0.01

100 - 10,000

1000

Read / Write

40015

0x0E

RESERVE

-

-

-

-

-

-

40016

0x0F

RESERVE

-

-

-

-

-

-

40017

0x10

FAULT POSITION

INT

%

0.1

0 - 1000

N/A

Read / Write

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

9

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

Status Flags 1 Register

Register Number

40001

Unit

Scale

Range

Default

Register Address

0x00

n/a

n/a

n/a

n/a

Read/Write

R

40001

Byte 2 (MSB)

Byte 1 (LSB)

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

The Status Flags 1 register provides flags to indicate various status and operating conditions. The register bits are assigned

the functionality provided below.

Bit

Description

Bit 1

CCW Movement bit indicates if the CCW motor output terminal is energized and is used to indicate CCW movement.

Bit 2

CW Movement bit indicates if the CW motor output terminal is energized and is used to indicate CW movement.

Bit 3

CCW Travel Limit bit indicates if the open travel limit switch is closed.

Bit 4

CW Travel Limit bit indicates if the close travel limit switch is closed.

Bit 5

Actuator Obstruction bit indicates if the time set in the Travel Timeout register 40011 has been exceeded before the

actuator reaches its appropriate end of travel position.

Bit 6

Not used

Bit 7

Positioning Mode bit indicates if the Position Type in the menus is set to Limit Switch or Potentiometer. Limit Switch is

for two position control using limit switches for position feedback. Potentiometer is used for proportional or modulating

control using a potentiometer for position feedback.

Bit 8

OperatingMode bit indicates if the controller is in Run mode or Configuration mode. The controller is considered to be in

configuration mode when entering into any of the configuration submenus.

Bit 9-16

Not used

Byte 1 (LSB)

Bit 8

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Operating

Mode

Positioning

Mode

-

Obstruction

CW

Limit

CCW

Limit

CW

Move

CCW

Move

0: Motor CCW output not on

1: Motor CCW output on

0: Motor CW output not on

1: Motor CW output on

0: CCW limit switch not closed

1: CCW limit switch closed

0: CW limit switch not closed

1: CW limit switch closed

0: No obstruction detected

1: Obstruction detected

0: n/a

1: n/a

0: Position Type = Limit Switch

1: Position Type = Potentiometer

0: Run mode

1: Configuration mode

Byte 2 (MSB)

Bit 16

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

-

-

-

-

-

-

-

-

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

10

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

Total Power On Time / Firmware

Register Number

40002 / 40003

Unit

Scale

Range

Default

Register Address

0x01 / 0x02

Hour

1

0 –16,777,216

0x00000000 –0x00FFFFFF

n/a

Read/Write

R

Version

1

0 –255

0x00 –0xFF

n/a

40002

40003

Byte 2 (MSB)

Byte 1 (LSB)

Byte 2 (MSB)

Byte 1 (LSB)

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

Firmware Version

Total Powered On Time

0 –255

0 –16,777,216 (hours)

The Total Power on Time/Firmware registers store the total time (in hours) the board has been powered on as well as the

current version of the firmware. The firmware version is stored in the upper 8 bits of Register 40002. The lower 8 bits of

Register 40002 and all 16 bits of Register 40003 contain the 24-bit value representing the time the board has been powered

on, providing for between 0 and 16,777,216 hours. This value resets when board power is removed.

When reading the registers, the 8 bits in Register 40002 represent the most significant bits of the time, while all 16 bits in

Register 40003 represent the least significant bits of the time. It is recommended to read both registers with the same

command. In order to extract the length of time the board has been powered on, the upper 8 bits of Register 40002 must

be masked off. In order to extract the firmware version, the lower 8 bits of Register 40002 must be masked off.

Total Motor Run Time

Register Number

40004 / 40005

Unit

Scale

Range

Default

Register Address

0x03 / 0x04

Hour

1

0 –16,777,216

0x00000000 –0x00FFFFFF

n/a

Read/Write

R

40004

40005

Byte 2 (MSB)

Byte 1 (LSB)

Byte 2 (MSB)

Byte 1 (LSB)

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

-

0 –16,777,216 (hours)

The Total Motor Run Time registers store the total combined time (in hours) the CW and CCW motor outputs of the board

have been energized. The lower 8 bits of Register40004 and all 16 bits of Register 40005 contain the 24-bit value, providing

for between 0 and 16,777,216 hours. This value resets when board power is removed.

When reading the registers, the 8 bits in Register 40004 represent the most significant bits of the time, while all 16 bits in

Register 40005 represent the least significant bits of the time. It is recommended to read both registers with the same

command.

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

11

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

Total Motor Starts

Register Number

40006 / 40007

Unit

Scale

Range

Default

Register Address

0x05 / 0x06

Count

1

0 –16,777,216

0x00000000 –0x00FFFFFF

n/a

Read/Write

R

40004

40005

Byte 2 (MSB)

Byte 1 (LSB)

Byte 2 (MSB)

Byte 1 (LSB)

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

-

0 –16,777,216 (count)

The Total Motor Starts registers store the total count fornumber of times the CW and CCW motor outputs of the board have

been energized. The lower 8 bits of Register 40006 and all 16 bits of Register 40007 contain the 24-bit value, providing for

between 0 and 16,777,216 total number of starts. This value resets when board power is removed.

When reading the registers, the 8 bits in Register 40006 represent the most significant bits of the count, while all 16 bits in

Register 40007 represent the least significant bits of the count. It is recommended to read both registers with the same

command.

Current Position

Register Number

40008

Unit

Scale

Range

Default

Register Address

0x07

%

0.1

0 –1000

0x0000 –0x03E8

n/a

Read/Write

R

40008

Byte 2 (MSB)

Byte 1 (LSB)

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

0 –1000

0.0% to 100.0%

The Current Position register is used to track the current actuator position in potentiometer positioning using a feedback

potentiometer. The range is automatically scaled based on the calibrated 0% and 100% positions.

The values inthe register span from0 to 1000, which corresponds to 0.0% and100.0% respectively. With0.0% representing

a fully closed actuator, and 100.0% representing a fully open actuator, a value of 674 represents the actuators is 67.4%

open.

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

12

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

Action Bits/Flags 2 Register

Register Number

40009

Unit

Scale

Range

Default

Register Address

0x08

n/a

n/a

n/a

n/a

Read/Write

R / W

40009

Byte 2 (MSB)

Byte 1 (LSB)

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

The Action Bits/Flags 2 register provides individual bits for multiple operation settings as well as resettable flags used to

indicate various status changes.

Bit

Description

Bit 1

Direction bit sets the direction to move the actuator when using limit switch positioning. Use this bit with Bit 2 to move

the actuator in on/off applications. The status of this bit determines which motor output is energized when Bit 2 is set.

Bit 2

Output Status bit energizes the motor output determined by Bit 1. Set the desired travel direction with Bit 1 and either

turn on or off the motor output with this bit.

Bit 3

Reset bit resets registers 40001 (bits 1-6), 40009 (bits 1-4), 40010.

Bit 4-6

Not used

Bit 7 & 8

Fault Action bits determine the movement when the time between communication exceeds the Communication Timeout

value in Register 40014. This can also be configured in the on-board menus.

Bit 9-16

Not used

Byte 1 (LSB)

Bit 8

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Fault Action

-

-

-

Reset

Motor Out

Status

Direction

0: Move CW

1: Move CCW

0: Motor output not energized

1: Motor output energized

0: No effect

1: Register reset sent

0: n/a

1: n/a

0: n/a

1: n/a

0: n/a

1: n/a

(0,0): Fail in place (default)

(0,1): Fail full CCW

(1,0): Fail full CW

(1,1): Fail to position (potentiometer positioning)

Byte 2 (MSB)

Bit 16

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

-

-

-

-

-

-

-

-

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

13

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

Command Position

Register Number

40010

Unit

Scale

Range

Default

Register Address

0x09

%

0.1

0 –1000

0x0000 –0x03E8

(32,768 –33,768)

(0x8000 –0x83E8)

n/a

Read/Write

R / W

40010

Byte 2 (MSB)

Byte 1 (LSB)

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

0 –1000

0.0% to 100.0%

If a value outside of the acceptable range of 0 to 1000 is written, the actuator will not move. When control board has power

applied, or is reset using Bit 3 in Register 40009, Bit 16 is set to 1 resulting in a value of 32,768 added to the value currently

in the register. Setting Bit 16 forces the Command Position register value outside of the acceptable 0 to 1000 range and

therefore prevents the actuator from moving. The actuator can be controlled again by writing another value between 0 and

1000.

The Command Position register is used to initiate an actuator move. When the board is configured for potentiometer

positioning, the values span from 0 to 1000, corresponding to 0.0% and 100.0% respectively. Therefore, with 0.0%

representing a fully closed actuator, and 100.0% representing a fully open actuator, a written value of 674 indicates a

command to move the actuator to 67.4% open.

When the board is set to limit switch positioning, a 0 will move the actuator CW, a 500 will stop the actuator, and 1000 will

move the actuator CCW.

Value

Description

Register 40009 bit equivalent

0

Energize motor outputs and drive actuator CW.

Bit 1 = 0, Bit 2 = 1

500

De-energize motor outputs and stop actuator.

Bit 1 = x, Bit 2 = 0

1000

Energize motor outputs and drive actuator CCW.

Bit 1 = 1, Bit 2 = 1

Travel Timeout

Register Number

40011

Unit

Scale

Range

Default

Register Address

0x0A

Second

1

5 –255

0x0005 –0x00FF

60

Read/Write

R / W

40011

Byte 2 (MSB)

Byte 1 (LSB)

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

5 –255

5 Seconds to 255 Seconds

The Travel Timeout register is to determine a stall or obstruction condition identified by Bit 5 in Register 40001. The value

stored in this register represents the maximum time allowed between energizing a motor output and reaching the command

position or limit before identifying an obstruction. This value should typically be set greater than the normal travel time of

the actuator from full open to full close.

Values in this register can be between 5 and 255 with each integer representing 1 second. The default value is set to 60

representing a time of 60 seconds.

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

14

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

Reserved

Register Number

40012

Unit

Scale

Range

Default

Register Address

0x0B

n/a

n/a

n/a

n/a

Read/Write

R / W

This register is currently not used.

Sensitivity/Deadband

Register Number

40013

Unit

Scale

Range

Default

Register Address

0x0C

%

0.1

1 –25

0x0001 –0x0019

5

Read/Write

R / W

40013

Byte 2 (MSB)

Byte 1 (LSB)

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

1 –25

1.0% to 2.5%

The Sensitivity/Deadband register storesthe necessarychange between the value written toRegister 40010 and the current

value in Register 40008 before an actuator movement is initiated. It also represents the range outside of the setpoint the

actuator will stop.

Values in this register can be between 1 and 25 with each integer representing 0.1%. The default value is set to 5

representing 0.5%. Using the default value of 0.5%, if the actuator position is at 50.0%, indicated by a value of 500 in

Register 40008, the value written to Register 40010 must be greater than 505 or less than 495.

Communication Timeout

Register Number

40014

Unit

Scale

Range

Default

Register Address

0x0D

Second

0.01

100 –10,000

0x0064 –0x2710

1000

Read/Write

R / W

40014

Byte 2 (MSB)

Byte 1 (LSB)

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

100 –10,000

0.1 Seconds to 100 Seconds

The Communication Timeout register stores the maximum time allowed with no communication received from the master

device before entering a fault condition. When this time is exceeded, the actuator will move to the position set by Bit 7 and

Bit 8 in Register 40009.The master should communicate with each actuator on the bus within the time set in this register.

Doing so will ensure the actuator moves to the fault position determined by Bit 7 and Bit 8 in Register 40009 only when an

unintended lapse in communication is encountered.

Values in this register can be between 100 and 10,000 with each integer representing 0.01 seconds. The default value is

set to 1000 representing 10 seconds.

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

15

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

Reserved

Register Number

40015

Unit

Scale

Range

Default

Register Address

0x0E

n/a

n/a

n/a

n/a

Read/Write

R / W

This register is currently not used.

Reserved

Register Number

40016

Unit

Scale

Range

Default

Register Address

0x0F

n/a

n/a

n/a

n/a

Read/Write

R / W

This register is currently not used.

Fault Position

Register Number

40017

Unit

Scale

Range

Default

Register Address

0x10

%

0.01

0 –1000

0x0000 –0x03E8

n/a

Read/Write

R / W

40017

Byte 2 (MSB)

Byte 1 (LSB)

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

0 –1000

0.0% to 100.0%

The Fault Position register is used in potentiometer positioning to set a position to move the actuator for a fault condition.

The values inthe register span from0 to 1000, which corresponds to 0.0% and100.0% respectively. With0.0% representing

a fully closed actuator, and 100.0% representing a fully open actuator, a value of 674 represents the actuator will fail to the

67.4% open position either from fault condition.

Failing to the position specified in this register when a fault condition occurs is achieved by setting both Bit 7 and Bit 8 in

Register 40009 high.

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

16

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

Appendix A

Number System Conversion

DEC

OCT

HEX

BIN

DEC

OCT

HEX

BIN

DEC

OCT

HEX

BIN

DEC

OCT

HEX

BIN

0

000

00

0000 0000

16

020

10

0001 0000

32

040

20

0010 0000

48

060

30

0011 0000

1

001

01

0000 0001

17

021

11

0001 0001

33

041

21

0010 0001

49

061

31

0011 0001

2

002

02

0000 0010

18

022

12

0001 0010

34

042

22

0010 0010

50

062

32

0011 0010

3

003

03

0000 0011

19

023

13

0001 0011

35

043

23

0010 0011

51

063

33

0011 0011

4

004

04

0000 0100

20

024

14

0001 0100

36

044

24

0010 0100

52

064

34

0011 0100

5

005

05

0000 0101

21

025

15

0001 0101

37

045

25

0010 0101

53

065

35

0011 0101

6

006

06

0000 0110

22

026

16

0001 0110

38

046

26

0010 0110

54

066

36

0011 0110

7

007

07

0000 0111

23

027

17

0001 0111

39

047

27

0010 0111

55

067

37

0011 0111

8

010

08

0000 1000

24

030

18

0001 1000

40

050

28

0010 1000

56

070

38

0011 1000

9

011

09

0000 1001

25

031

19

0001 1001

41

051

29

0010 1001

57

071

39

0011 1001

10

012

0A

0000 1010

26

032

1A

0001 1010

42

052

2A

0010 1010

58

072

3A

0011 1010

11

013

0B

0000 1011

27

033

1B

0001 1011

43

053

2B

0010 1011

59

073

3B

0011 1011

12

014

0C

0000 1100

28

034

1C

0001 1100

44

054

2C

0010 1100

60

074

3C

0011 1100

13

015

0D

0000 1101

29

035

1D

0001 1101

45

055

2D

0010 1101

61

075

3D

0011 1101

14

016

0E

0000 1110

30

036

1E

0001 1110

46

056

2E

0010 1110

62

076

3E

0011 1110

15

017

0F

0000 1111

31

037

1F

0001 1111

47

057

2F

0010 1111

63

077

3F

0011 1111

64

100

40

0100 0000

80

120

50

0101 0000

96

140

60

0110 0000

112

160

70

0111 0000

65

101

41

0100 0001

81

121

51

0101 0001

97

141

61

0110 0001

113

161

71

0111 0001

66

102

42

0100 0010

82

122

52

0101 0010

98

142

62

0110 0010

114

162

72

0111 0010

67

103

43

0100 0011

83

123

53

0101 0011

99

143

63

0110 0011

115

163

73

0111 0011

68

104

44

0100 0100

84

124

54

0101 0100

100

144

64

0110 0100

116

164

74

0111 0100

69

105

45

0100 0101

85

125

55

0101 0101

101

145

65

0110 0101

117

165

75

0111 0101

70

106

46

0100 0110

86

126

56

0101 0110

102

146

66

0110 0110

118

166

76

0111 0110

71

107

47

0100 0111

87

127

57

0101 0111

103

147

67

0110 0111

119

167

77

0111 0111

72

110

48

0100 1000

88

130

58

0101 1000

104

150

68

0110 1000

120

170

78

0111 1000

73

111

49

0100 1001

89

131

59

0101 1001

105

151

69

0110 1001

121

171

79

0111 1001

74

112

4A

0100 1010

90

132

5A

0101 1010

106

152

6A

0110 1010

122

172

7A

0111 1010

75

113

4B

0100 1011

91

133

5B

0101 1011

107

153

6B

0110 1011

123

173

7B

0111 1011

76

114

4C

0100 1100

92

134

5C

0101 1100

108

154

6C

0110 1100

124

174

7C

0111 1100

77

115

4D

0100 1101

93

135

5D

0101 1101

109

155

6D

0110 1101

125

175

7D

0111 1101

78

116

4E

0100 1110

94

136

5E

0101 1110

110

156

6E

0110 1110

126

176

7E

0111 1110

79

117

4F

0100 1111

95

137

5F

0101 1111

111

157

6F

0110 1111

127

177

7F

0111 1111

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

17

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

DEC

OCT

HEX

BIN

DEC

OCT

HEX

BIN

DEC

OCT

HEX

BIN

DEC

OCT

HEX

BIN

128

200

80

1000 0000

144

220

90

1001 0000

160

240

A0

1010 0000

176

260

B0

1011 0000

129

201

81

1000 0001

145

221

91

1001 0001

161

241

A1

1010 0001

177

261

B1

1011 0001

130

202

82

1000 0010

146

222

92

1001 0010

162

242

A2

1010 0010

178

262

B2

1011 0010

131

203

83

1000 0011

147

223

93

1001 0011

163

243

A3

1010 0011

179

263

B3

1011 0011

132

204

84

1000 0100

148

224

94

1001 0100

164

244

A4

1010 0100

180

264

B4

1011 0100

133

205

85

1000 0101

149

225

95

1001 0101

165

245

A5

1010 0101

181

265

B5

1011 0101

134

206

86

1000 0110

150

226

96

1001 0110

166

246

A6

1010 0110

182

266

B6

1011 0110

135

207

87

1000 0111

151

227

97

1001 0111

167

247

A7

1010 0111

183

267

B7

1011 0111

136

210

88

1000 1000

152

230

98

1001 1000

168

250

A8

1010 1000

184

270

B8

1011 1000

137

211

89

1000 1001

153

231

99

1001 1001

169

251

A9

1010 1001

185

271

B9

1011 1001

138

212

8A

1000 1010

154

232

9A

1001 1010

170

252

AA

1010 1010

186

272

BA

1011 1010

139

213

8B

1000 1011

155

233

9B

1001 1011

171

253

AB

1010 1011

187

273

BB

1011 1011

140

214

8C

1000 1100

156

234

9C

1001 1100

172

254

AC

1010 1100

188

274

BC

1011 1100

141

215

8D

1000 1101

157

235

9D

1001 1101

173

255

AD

1010 1101

189

275

BD

1011 1101

142

216

8E

1000 1110

158

236

9E

1001 1110

174

256

AE

1010 1110

190

276

BE

1011 1110

143

217

8F

1000 1111

159

237

9F

1001 1111

175

257

AF

1010 1111

191

277

BF

1011 1111

192

300

C0

1100 0000

208

320

D0

1101 0000

224

340

E0

1110 0000

240

360

F0

1111 0000

193

301

C1

1100 0001

209

321

D1

1101 0001

225

341

E1

1110 0001

241

361

F1

1111 0001

194

302

C2

1100 0010

210

322

D2

1101 0010

226

342

E2

1110 0010

242

362

F2

1111 0010

195

303

C3

1100 0011

211

323

D3

1101 0011

227

343

E3

1110 0011

243

363

F3

1111 0011

196

304

C4

1100 0100

212

324

D4

1101 0100

228

344

E4

1110 0100

244

364

F4

1111 0100

197

305

C5

1100 0101

213

325

D5

1101 0101

229

345

E5

1110 0101

245

365

F5

1111 0101

198

306

C6

1100 0110

214

326

D6

1101 0110

230

346

E6

1110 0110

246

366

F6

1111 0110

199

307

C7

1100 0111

215

327

D7

1101 0111

231

347

E7

1110 0111

247

367

F7

1111 0111

200

310

C8

1100 1000

216

330

D8

1101 1000

232

350

E8

1110 1000

248

370

F8

1111 1000

201

311

C9

1100 1001

217

331

D9

1101 1001

233

351

E9

1110 1001

249

371

F9

1111 1001

202

312

CA

1100 1010

218

332

DA

1101 1010

234

352

EA

1110 1010

250

372

FA

1111 1010

203

313

CB

1100 1011

219

333

DB

1101 1011

235

353

EB

1110 1011

251

373

FB

1111 1011

204

314

CC

1100 1100

220

334

DC

1101 1100

236

354

EC

1110 1100

252

374

FC

1111 1100

205

315

CD

1100 1101

221

335

DD

1101 1101

237

355

ED

1110 1101

253

375

FD

1111 1101

206

316

CE

1100 1110

222

336

DE

1101 1110

238

356

EE

1110 1110

254

376

FE

1111 1110

207

317

CF

1100 1111

223

337

DF

1101 1111

239

357

EF

1110 1111

255

377

FF

1111 1111

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

18

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

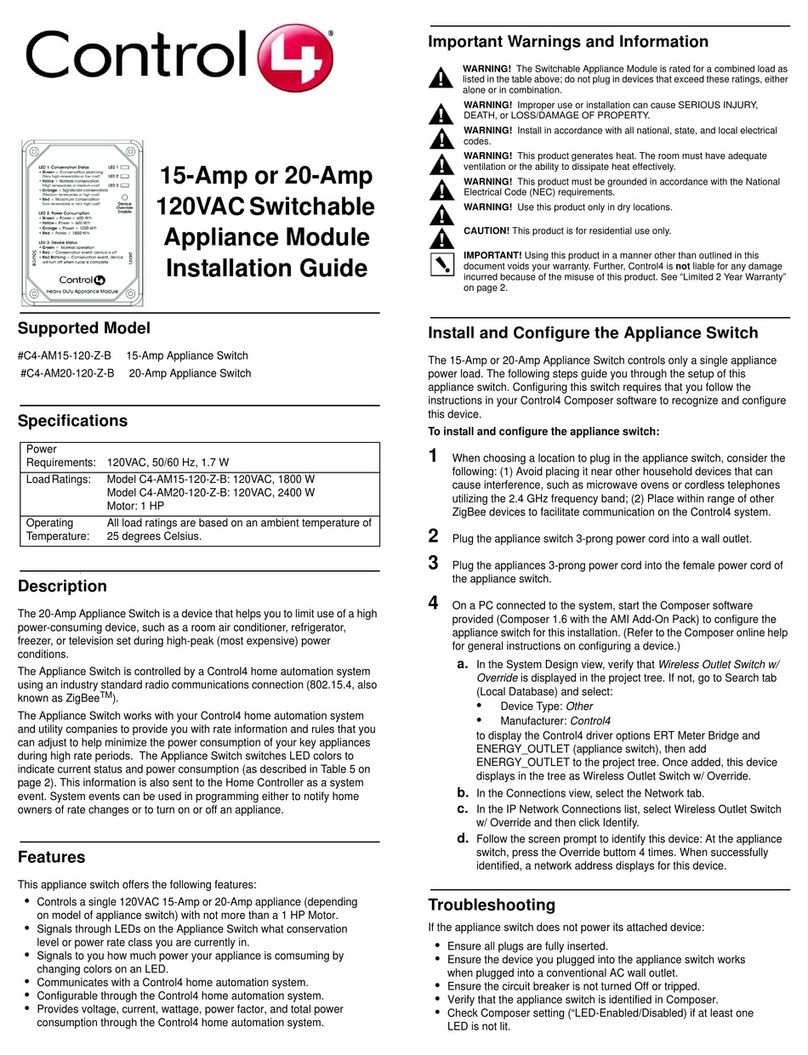

Appendix B

ModbusTCP Configuration via Terminal Program

The IP settings for the TMC4 with ModbusTCP module can be configured using the standard on-board menus. However,

the TMC4 can also be configured using a computer terminal interface program through the USB connection. Note the

ModbusTCP is only compatible with firmware versions 2.03 and later.

1. Install ModbusTCP module in the TMC4 module slot.

2. Power on the TMC4.

3. Set the command type to “Comms” and ensure the communication type is set for ModbusTCP.

4. Configure the IP settings to match the user network via USB to the TMC4 micro USB connection.

a. Connect USB to micro USB cable between TMC4 and PC.

b. Once new serial port is assigned to the TMC4, open a terminal program (TeraTerm, Putty, etc.) under

the newly assigned comm port with parameters: 115200-8-N-1

c. In the terminal, type “help” to see the available commands

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

19

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

5. To read the current IP settings, type “ipget”

6. To set IP address, type “ipset 192 168 0 101” to set IP address to 192.168.0.101

7. To set subnet mask, type “subset 255 255 255 0” to set mask to 255.255.255.0

8. To set gateway IP, type “gwset 192 168 0 1” to set gateway to 192.168.0.1

9. The TMC4 confirms the change is successful after each command.

10. Cycle power to the TMC4 to complete configuration of the new network settings.

11. TMC4 is now ready for ModbusTCP communications. Use a ModbusTCP master with the IP set as per above and

use TCP port 502.

TMC4

Modbus RTU and TCP Modules

Installation & Operation Manual

20

11/10/22

www.atcontrols.com

IOM08147 REVISION 03

A-T Controls product, when properly selected, is designed to perform its intended function safely during its useful life. However, the purchaser or user of

A-T Controls products should be aware that A-T Controls products might be used in numerous applications under a wide variety of industrial service

conditions. Although A-T Controls can provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser

/ user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of A-T Controls

products. The user should read and understand the installation operation maintenance (IOM) instructions included with the product and train its employees

and contractors in the safe use of A-T Controls products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only. Because

A-T Controls is continually improving and upgrading its product design, the specifications, dimensions and information contained in this literature are

subject to change without notice. Should any question arise concerning these specifications, the purchaser/user should contact A-T Controls.

For product specifications go to http://download.a-tcontrols.com/

A-T Controls, Inc. • 9955 International Boulevard, Cincinnati, OH 45246 • Phone: (513) 530-5175 • Fax: (513) 247-5462 • www.atcontrols.com

Other manuals for TMC-4

1

Table of contents

Popular Control Unit manuals by other brands

protech

protech 62-102635-81 instructions

R+M Suttner

R+M Suttner ST-162 user manual

Contro l4

Contro l4 C4-AM15-120-Z-B installation guide

Life Smart

Life Smart Nature Mini user guide

System air

System air BOR-S Series Installation, maintenance and operation instructions

Qcells

Qcells Q.PEAK DUO BLK ML-G10/t Series Installation and operation manual

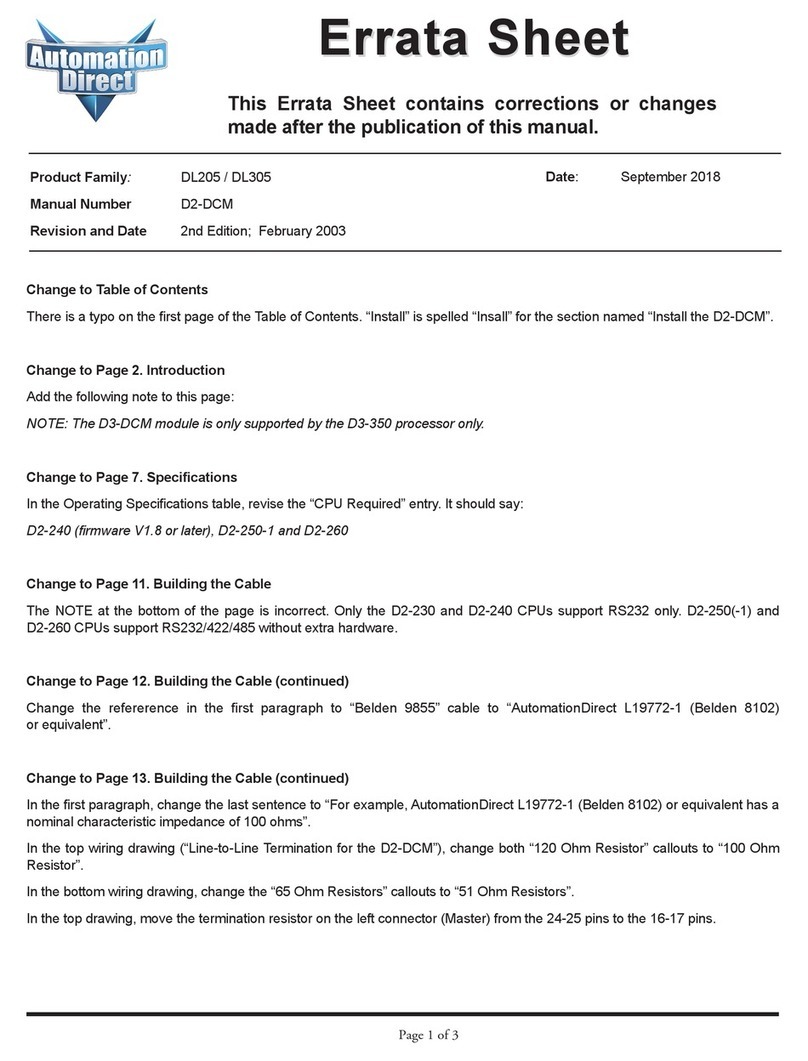

AutomationDirect

AutomationDirect D2-DCM user manual

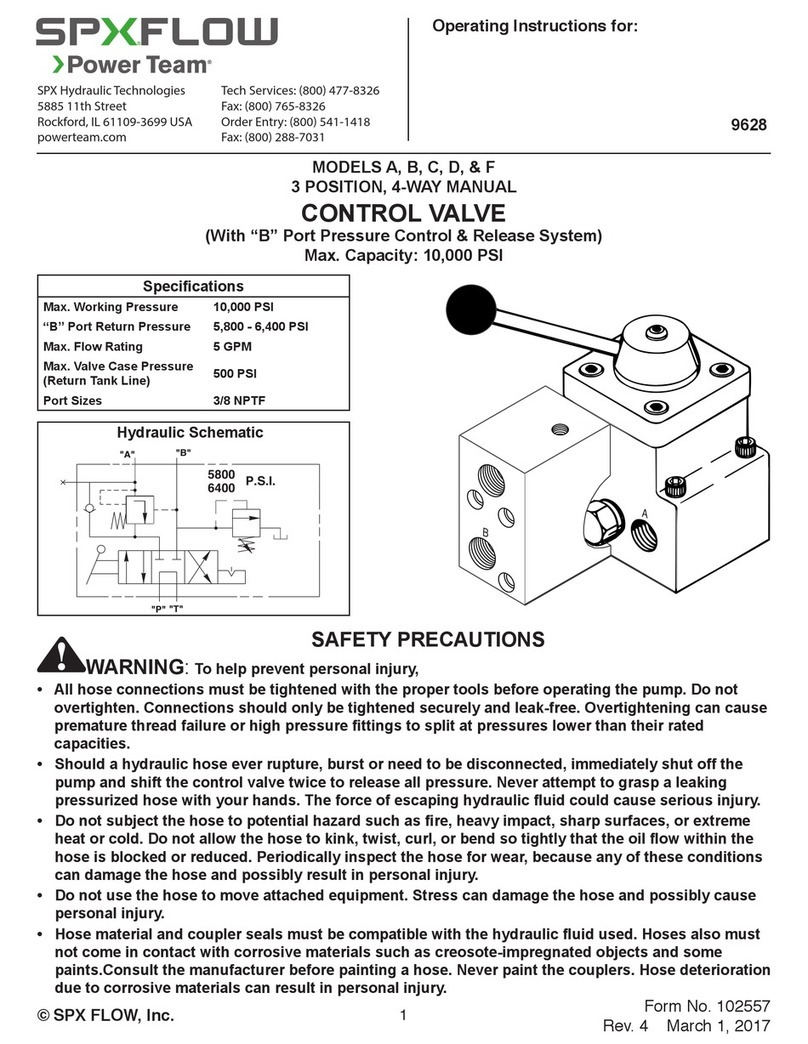

SPX FLOW

SPX FLOW Power Team A operating instructions

CIAT

CIAT CS1B installation manual

MOIXA

MOIXA Smart Battery user manual

Emerson

Emerson Fisher GX instruction manual

Navim Group Company

Navim Group Company EsiWelma Sensigas UCE1 installation instructions