Ever Sharp Technology ES2070 User manual

永匯豐科技有限公司

Ever Sharp Technology, Inc

INNOVATION TECHNOLOGY ADVANCES WORKFLOW

http://www.eversharp.com.tw

ES2070 Digital Quantification Dispenser Manual

1. Package contains the following items:

zES2070 Digital Quantification Dispenser

zPower Cord

zAir Pressure Connector

zBarrel Adapter Set

zStartup Kit

zFoot Pedal or Finger Switch

2. Hardware Setup:

a. Please connect theAir Pressure Connector on the back of the system to the nearby air compressor line.

b. Connect the Foot Pedal on the back of the system or Finger Switch on the front of the system.

c. Fill the dispensing barrel with adhesive up to 2/3 full and adapt with barrel adapter. Connect the adapter to the

front of the system.

d. If you are using Finger Switch, please stick the switch on the dispensing barrel.

e. Connect the Power Cord on the back of the system and switch the power on. Please make sure all the display

and light indicator are working properly. (110V-240V full voltage)

f. Install the dispensing barrel with appropriate needle and adjust with appropriate air pressure and vacuum.

(Please refer to Table 1)

永匯豐科技有限公司

Ever Sharp Technology, Inc

INNOVATION TECHNOLOGY ADVANCES WORKFLOW

http://www.eversharp.com.tw

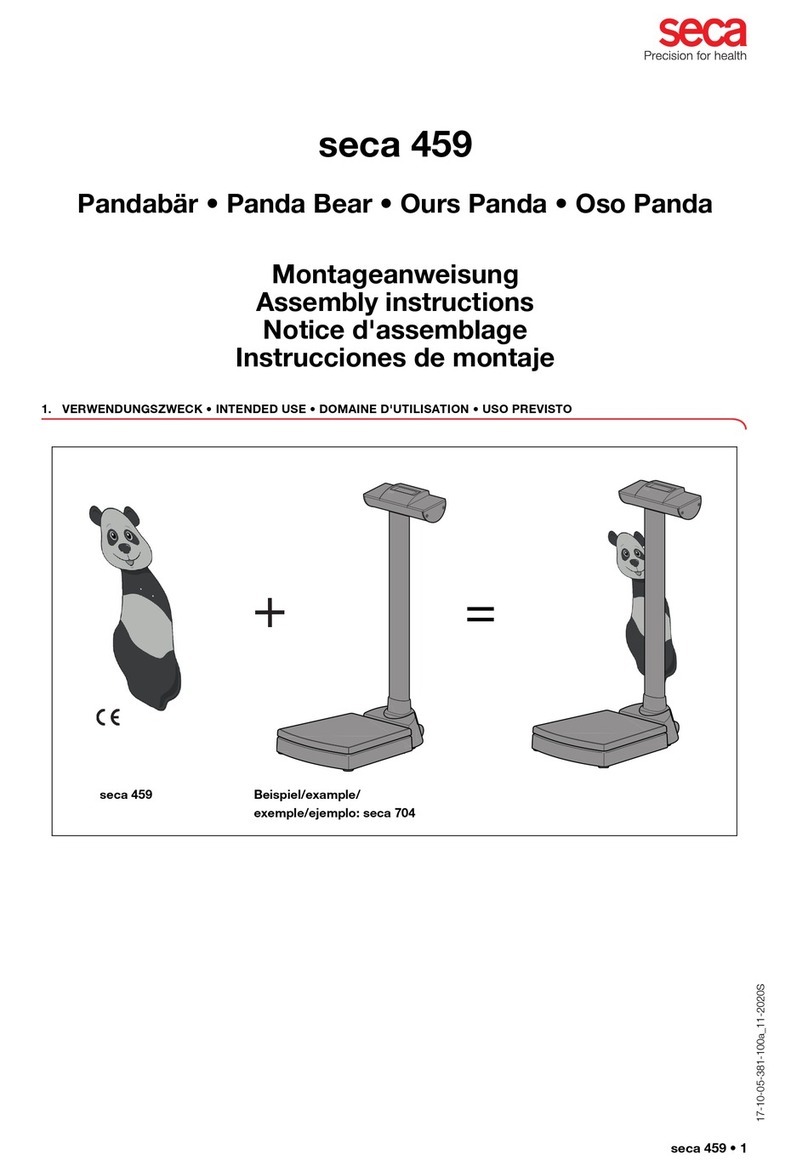

Watery Low viscosity Middle to High viscosity Barrel adapter assembly

Table 1:Air pressure setting with appropriate needle

Adhesive Air Pressure Setting Appropriate Needle

Watery 0.1-1.0 kg/cm2 (7-15 psi) TD / TS / SS series metal needle

Low viscosity 1.5-2.0 kg/cm2 (22-30 psi) TD / TS / SS series metal needle

Middle viscosity 2.0-3.0 kg/cm2 (30-45 psi) All series needle

High viscosity 3.0-5.0 kg/cm2 (45-75 psi) TT / TL series plastic needle

* If you normally work with low viscosity adhesive with high precise dispensing, you will need to use low pressure dispenser (0-30 psi)

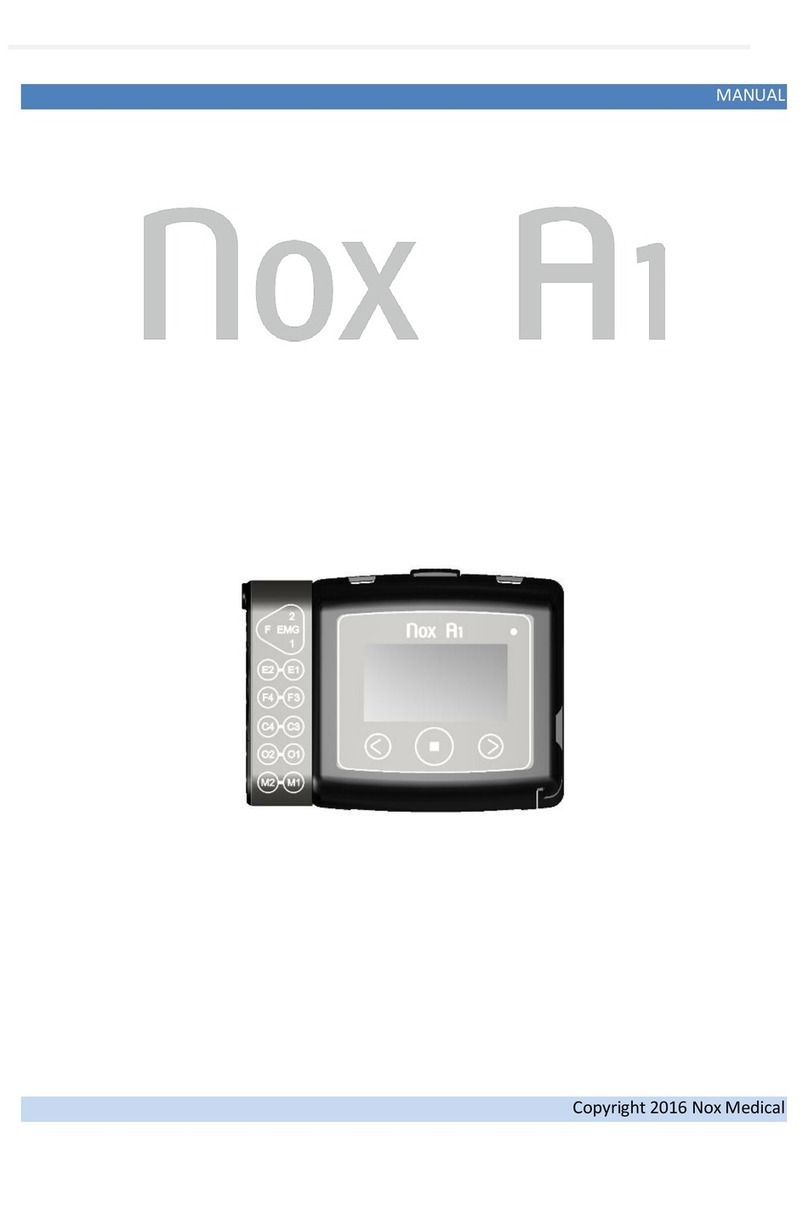

3. Control Setting:

1….. Pressure Indicator Display the currently air pressure in the system

2….. Pressure Regulator Adjust the air pressure in the system, increase with clockwise and

decrease with counter clockwise.

3….. Barrel Adapter Port Connect with barrel adapter, press down and rotate to adapt.

4….. Vacuum Knob Adjust the suck-back pressure in the barrel to prevent adhesive dripping,

decrease with clockwise and increase with counter clockwise.

5….. Timer Setting (Up) Increase the dispensing time setting when using timer

6….. Timer Display Display the timer or dispensing time (0.01sec – 99.99sec)

7….. Timer Setting (Down) Decrease the dispensing time setting when using timer

8….. Dispensing Indicator The indicator will light up during dispensing.

9….. Finger Switch Port Connect with finger switch, insert to adapt.

永匯豐科技有限公司

Ever Sharp Technology, Inc

INNOVATION TECHNOLOGY ADVANCES WORKFLOW

http://www.eversharp.com.tw

10….Power Switch System main power, switch on and the power light will light up.

11….Timer Switch Timer controller, switch on and the power light will light up.

4. Operation:

a. Please refer to table 1 for appropriate needle and pressure setting.

b. If the adhesive is dripping from barrel, turn up the vacuum until it is not dripping.

c. Turn off the timer switch; use the foot pedal to activate the dispensing until the adhesive fill up the needle and

flow out the barrel smoothly. If the adhesive cannot flow out the barrel please adjust the pressure or replace the

needle and repeat step a again.

d. Place the barrel 45 degree to the process object and fit the needle on top of the dispensing point.

e. – Manual dispensing:turn off the timer switch and step on the foot pedal to activate the dispensing, remove to

stop the dispensing. Timer display will display the current dispensing time for your reference. It is suitable for long

straight line and irregular dispensing route.

– Timer dispensing:turn on the timer switch and set the timer; step on the foot pedal once to activate one single

timed dispensing, repeat the process by stepping the pedal again. It is suitable for repeat and uniform dispensing

route.

5. Three main reasons that control the dispensing volume:

Needle type and size Air pressure volume Dispensing time

6. Maintenance and Precaution:

The dispenser is designed and built to be relatively maintenance free. To assure trouble free operation, the following

recommendations should be followed:

a. Make certain air supply is clean and dry.

b. Avoid turning barrels upside down or laying barrel so that material may run through air line to internal

components.

c. Avoid turning the vacuum to large and cause the generation of bubbles in the material or the material to run back

into the system.

d. If the piston inside the barrel is running up and down during the dispensing, it is mean the material has really high

viscosity and you will need to replace the piston with red or rigid piston.

永匯豐科技有限公司

Ever Sharp Technology, Inc

INNOVATION TECHNOLOGY ADVANCES WORKFLOW

http://www.eversharp.com.tw

e. Avoid connecting the unit to excessive moisture or solvent saturation.

f. Avoid connecting air supply exceeding 7 kg/cm2 (100 psi) and 2 kg/cm2 (30 psi) for low pressure dispenser.

g. Use only Amyl Alcohol to clean outside surface of the main housing.

h. Please take off the barrel with needle after use and rinse through solvent. If you want to save the barrel for further

use, please take off the needle and replace with safety tip (optional) or place the barrel on the barrel stand to

prevent solidification.

7. Troubleshooting:

Problem Possible Cause Correction

Indicator or

display does not

light

• no power input

• PCB main board damage

• check power cord connection

• turn on power

• replace new PCB main board

Cannot dispense • foot pedal not plugged in properly

• defective foot pedal

• foot pedal port broken or loosen

• defective Solenoid Valve

• check connection

• foot pedal needs to be repaired or replaced

• remove the cover and check for broken or

loosen

• replace the valve and make sure you use

the appropriate piston and do not turn the

vacuum too large

System will not

pressurize

• Insufficient air pressure

• air pressure connector not plugged in

• regulator defective

• increase air supply pressure

• check connection

• replace pressure regulator

System will not

pull vacuum

• vacuum setting is too low

• barrel piston not appropriate

• adhesive too watery or full

• increase vacuum volume

• replace with appropriate piston

• replace with different adhesive and fill only

3/4 full in the barrel

Inconsistent

dispensing

• air bubbles in adhesive

• dispensing needle not appropriate

• dispensing needle clogged

• decrease vacuum setting and de-bubble

the adhesive before filling

• replace with different type of needle

• replace needle

8. Limited warranty:

Ever Sharp warrants this product to the original purchaser for a period of one year from date of purchase to be free from

material and workmanship defects but not normal wear-and-tear, abuse and faulty installation. Defective product or

subassembly and components under warranty will be repaired or replaced (at Ever Sharp option) free of charge. Customer

with defective product under warranty must contact the nearest Ever Sharp office or distributor to secure a return

authorization prior to shipping the product to the assigned Ever Sharp authorized service center. For nearest Ever Sharp

office or distributor contact information, please visit www.eversharp.com.tw or contact our stuff. Ever Sharp reserves the

right to make engineering product changes without notice.