Ethicon Gynecare ThermaChoice II User manual

ThermaChoice UBT System Service Manual

P/N 01035 Rev. C

THERMACHOICE

™

II UBT System

Service Manual

ThermaChoice UBT System Service Manual

P/N 01035 Rev. C

About This Document

Overview

The THERMACHOICE™II UBT System is a software-controlled device

designed to ablate uterine tissue by thermal energy. The system is comprised of a

single-use balloon catheter, a reusable controller, umbilical cable, and power cord.

The THERMACHOICE™II UBT catheter is designed for use only with the

THERMACHOICE™II UBT controller.

Purpose

The THERMACHOICE™II UBT System Service Manual is to be used as a guide

to maintaining and servicing the THERMACHOICE™II UBT System.

Scope

This manual is to be used by all personnel responsible for maintaining and

servicing the THERMACHOICE™II UBT System. It provides procedure level

detail on maintenance and service. Troubleshooting and repair is to be performed

on the system down to the level of field replaceable units (FRU) rather than to the

component level.

Audience Description

The primary audience for the manual is trained GyneCare repair personnel,

Colorado MEDtech manufacturing personnel, hospital maintenance personnel and

biomedical technicians responsible for performing specific maintenance and

service operations on-site.

ThermaChoice UBT System Service Manual

P/N 01035 Rev. C

How to Use This Guide

The GyneCare THERMACHOICE™II UBT Service Manual is an important

resource when performing maintenance and service. Read the entire document to

become familiar with its content and structure. Use Section One to get an overall

understanding of the THERMACHOICE™II UBT System. Later sections will

provide details for troubleshooting the individual FRUs, removal and replacement

of failed FRUs, and additional reference information.

Organization

Section One contains an overview of the system. It includes descriptions of the

mechanical and electronic sub-systems.

Section Two covers diagnostics and troubleshooting to help locate the causes of

typical system failures, including a table of diagnostic error codes and their

meaning and a troubleshooting guide.

Section Three details the field replaceable units including photographs and part

numbers.

Section Four covers remediation, including removal and replacement procedures

for field replaceable electrical and mechanical assemblies and a procedure for

returning the instrument for repair.

Section Five details the maintenance of the system including pressure and

temperature calibration, fuse and power cord replacement, cleaning, and

disinfection.

Appendix A contains detailed schematics including the functional block diagram,

wiring diagram, and discrete components diagram.

Appendix B contains electrical/electronic parts lists and component values.

Appendix C contains a copy of the Operating Manual.

ThermaChoice UBT System Service Manual

P/N 01035 Rev. C

Contents Section-Page

System Overview 1-1

Device Description

Indications

Precautions

Functional Description of Circuits

Diagnostics and Troubleshooting 2-1

Diagnostic Error Codes 2-1

Troubleshooting Decision Trees

Field Replaceable Unit Listing 3-1

Table of Field Replaceable Units 3-1

Catalog of Field Replaceable Units 3-2

Repair Procedures 4-1

Assembly, AUX Board 01204 4-1

Assembly, ISO Board 00983 4-2

Power Supply 00808 4-4

Power Entry Module (PEM) 01353 4-7

Assembly, Motor Drive Unit (MDU) 01014 4-8

Heater Fuse 01620 4-10

Power Entry Module Fuse 00861 4-11

Assembly, Micro (Micro) 01200 4-11

LCD Display 00877 4-13

Switch, Power, Mains 01033 4-14

Power Entry Cable 00868 4-16

Power Supply Cable 00855 4-17

ISO Micro Cable 01504 4-18

CCS Switch Cable 01293 4-19

Ribbon Cable, 40 Cond. 00874 4-20

Assy, Cable, Surge Arrestor 01347 4-21

Maintenance 5-1

Calibration 5-1

Pressure Calibration 5-1

ThermaChoice UBT System Service Manual

P/N 01035 Rev. C

Schematics A-1

Functional Block Diagram

Wiring Diagram

Detailed Schematics

Electrical/Electronic Parts List B-1

THERMACHOICE™II UBT System Operating Manual C-1

ThermaChoice UBT System Service Manual 1 - 1

P/N 01035 Rev. C

Section One

System Overview

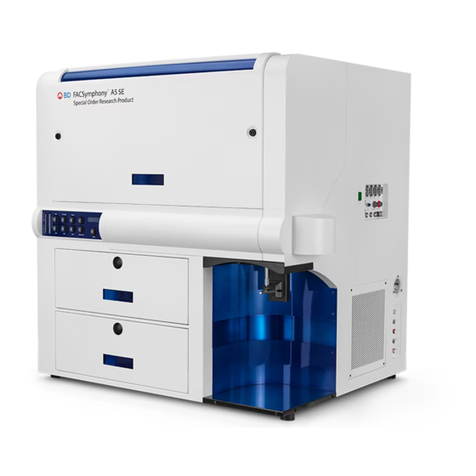

Figure 1-1

Device Description

The THERMACHOICE™II UBT System is a software-controlled device

designed to ablate uterine tissue by thermal energy. The system is comprised of a

single-use balloon catheter, a reusable controller, umbilical cable, and power cord.

The THERMACHOICE™II UBT catheter is designed for use only with the

THERMACHOICE™II UBT controller.

The balloon catheter is 1) connected to the controller, 2) inserted through the

cervix into the uterus, 3) filled with sterile, injectable fluid (plain 5% dextrose in

water – D

5

W) carefully stabilizing the pressure to 160-180 mmHg pressure, and

4) activated to thermally ablate endometrial tissue by maintaining a temperature

of approximately 87°C (188°F) for 8 minutes.

The THERMACHOICE™II UBT controller is designed to work with 3 different

versions of the balloon catheter. They are:

a) Balloon catheter version 2.0: This balloon catheter has a fluid circulation

mechanism inside the balloon.

b) Balloon catheter version 1.4: This version does not have a fluid circulation

mechanism inside the balloon.

ThermaChoice UBT System Service Manual 1 - 2

P/N 01035 Rev. C

c) Balloon catheter version 1.2: This version does not have a fluid circulation

mechanism inside the balloon.

Indications

The THERMACHOICE™II UBT System is a thermal ablation device intended to

ablate the endometrial lining of the uterus in pre-menopausal women with

menorrhagia (excessive uterine bleeding) due to benign causes for whom

childbearing is complete.

Functional Description of Circuits

Purpose

The purpose is to describe the THERMACHOICE™II Uterine Balloon Therapy

(UBT) system and to give an overview of the functional components that make up

the electronic unit, referred to as the controller. The document as written should

aid the technician in troubleshooting the product for service and manufacturing

assembly.

Scope

This document is limited to the controller.

ThermaChoice UBT System Service Manual 1 - 3

P/N 01035 Rev. C

Product Overview

The THERMACHOICE™II Uterine Balloon Therapy (UBT) system is an

instrument designed to ablate endometrial tissue in the uterus, where excessive

uterine bleeding is diagnosed. A balloon on a semi-rigid plastic catheter

containing a resistive heating element is inserted into the uterus and manually

filled with sterile D5W to a pre-specified pressure range. The fluid is then heated

to 87°C and maintained at that temperature for the duration of the 8-minute

therapy cycle.

The UBT system normalizes or alleviates the excessive uterine bleeding by

ablating the endometrial lining within the uterus utilizing a thermal ablation

technique. The thermal ablation process uses heated fluid to cause endometrial

tissue necrosis during the treatment cycle. The fluid in the balloon is maintained

under pressure to increase the balloon surface area contact with the endometrium

and to reduce the blood flow to the endometrium by tissue compression and hence

increase the thermal ablation penetration.

The UBT system consists of a controller, a disposable catheter, an umbilical

cable, and a power cord. The catheter houses the heating element and two

thermocouples in the balloon and a stirring device in newer models. The pressure

transducer is internal to the controller with the pressure port located on the front

panel of the controller. The fluid transport mechanism is manual and external to

the controller. The UBT controller is a microprocessor based system with a LCD

for displaying messages, LED displays for displaying time, temperature, and

pressure, and alarms.

To use the system, the catheter is first connected to the controller via the

umbilical cable pressure line to the pressure port and motor drive unit (MDU)

port, on the front panel of the controller. The power is then turned on. After

purging the balloon and its placement into the uterus, the balloon is filled with

sterile D5W to a pre-specified pressure. Pressing the start button will initiate the

preheat cycle. Once the desired temperature is reached the controller will start the

therapy cycle. Heating is automatically stopped after the therapy cycle is

completed or if a fault is detected. The LCD display along with LED displays and

alarms, inform the user of the status of the procedure and the pertinent

parameters, pressure, temperature, stirring status, and time throughout the

procedure. The background diagnostic routines continuously monitor the

integrity of the controller operations.

Functional Sections

Power Supplies and Isolation

Temperature Measurement

Pressure Measurement

Heater Drive and Protection

ThermaChoice UBT System Service Manual 1 - 4

P/N 01035 Rev. C

Motor Drive Unit (MDU)

Central Processing Unit (CPU)

User Interface, Front Panel Display

For more information regarding the procedure set up, operation of the device,

messages, error conditions, unit calibration, etc. refer to Appendix A of the User

Manual.

Transformer, Power Supplies and Isolation

The system operates on 100 to 240 VAC and 60 Hz power lines. The line

operated power supply is auto input ranging and needs no adjustment. The power

entry module consists of a conducted line noise filter and a sub-module with two

fuses. The two fuses break neutral and line. The front panel power switch breaks

the line and neutral side of the primaries between the rear power module and the

power supply.

The line operated power supply is medical grade. The power supply also provides

4000 Volts of reinforced (Double-Plus) isolation between the primary and at the

secondary side. The power supply outputs +24V, +5V, +12V, -12V. The 24 Volts

is used for the MDU and heater. The 5 Volts is used for logic power. The ±12

Volts are used for analog circuitry. (See Functional Block Diagram in Appendix

A.)

The thermocouple amplifiers and their power up test circuitry are powered by two

isolated +5V to ±12-Volt power supply. The isolation is to allow proper

thermocouple operation in proximity to the heater and not to isolate the patient.

The block diagram in Appendix A illustrates the system power supply

configuration as well as interactions of different subsystems of the unit. As

indicated, the communication between different subsystems is accomplished

serially through the use of analog isolation amplifiers.

The power supply is of a switching type with the ±12 Volts being linearly

regulated.

Temperature Measurement

The temperature measurement inside the catheter balloon is accomplished by

using two "K" type thermocouples. One of the thermocouples, referred to as TC1,

is used as the feedback in controlling the heater. The value of this thermocouple

is displayed by one of the LED displays on the controller front panel. The second

thermocouple reading is used only as a check against TC1 reading. This value is

not displayed.

The low level thermocouple signals are transmitted to the controller via the

umbilical cable. The raw signals are amplified by use of thermocouple amplifiers.

ThermaChoice UBT System Service Manual 1 - 5

P/N 01035 Rev. C

These are two of the nine inputs to the multiplexing analog-digital converter

(ADC). The ADC is a high precision serial ADC that operates from an

independent voltage source and a 5.000 VDC precision voltage reference.

The positive and negative terminals of each of the two thermocouples are

connected to the inputs of the amplifiers through two single pole double throw

relays. These relays are used at power up to switch the inputs of the amplifiers to

a 3.25 mV reference to check for any accuracy in the measurement channels.

The cold junction compensation is done by the thermocouple ICs (AD595

thermocouple amps). These ICs are thermally bonded to the cold junctions. Each

IC measures the offset caused by the cold junctions and adds it to the output

voltage of the thermocouples, which produces the corrected measured

temperature.

Pressure Measurement

The balloon pressure measurement is accomplished by the use of two pressure

transducers inside of the controller. The catheter balloon is connected to the

pressure port located on the front panel of the controller via a pressure tube. The

port is in turn connected to the transducers inside the controller unit. To stop the

fluid from flowing back inside the controller when the catheter is pressurized, the

catheter pressure line is equipped with a filter that is permeable to air only.

The transducer is of a differential type, which measures the balloon pressure

relative to the atmospheric pressure. The pressure measurement is similar to that

of the temperature measurement. The raw transducer signals are amplified and fed

to the multiplexing ADC.

These transducers need to be biased approximately halfway in their output range

so they can output negative pressures. There is no adjustment for this zero point

so each new unit must be calibrated by entering calibration mode. The zero point

of each transducer is measured (with no pressure port attachment) and written into

the nonvolatile memory of the 68 HCII microprocessor.

Heater Drive and Protection Circuitry

The software that controls the heater uses a proportional – integral algorithm that

varies the power from 0 to 60 watts to heat and maintain the temperature of the

fluid. During heat up, the power is limited if the temperature ramps faster than 2

degrees per second leading to a minimum heat up time of about 30 seconds. The

software heater control algorithm regulates to a constant set point of 87°C after

the initial heat up.

ThermaChoice UBT System Service Manual 1 - 6

P/N 01035 Rev. C

The current in the heater is constantly monitored while the heater voltage is

greater than 2.8 volts. If the current is less than 0.14 amps or greater than 2.5

amps, the controller will shut down with and generate an Error 65. If the heater

voltage varies more than +/- 10% from the desired control voltage, the same error

is generated.

The heater is powered from a 28 VDC SEPIC (Single Ended Primary Inductance

Converter) topology regulator. The heater load is nominally at 13.2 ohms.

Therefore, the nominal current of the heater is about two amps. The SEPIC

regulator has three control inputs. 1) 0 - 5 volts in to control; 0 - 28 volts out. 2)

HEATER_1_ON* and HEATER_2_ON*. HEATER_1_ON* enables the

switching IC in the power supply. HEATER_2_ON* enables a series pass

transistor to the heater and simultaneously disables a short circuit short transistor.

These transistors cannot both be on at the same time. If this were to happen, the

shunt transistor would draw all of the SEPIC output through a 4 amp fuse,

blowing it. This is to cover the short circuit failure of the series pass transistor.

During preheat, the temperature is checked to make sure it is rising at least 2

degrees every 10 seconds. This test is intended to catch the unlikely dual fault

condition of two shorted thermocouples. If the measured temperature persistently

fails to meet the criteria for 30 seconds, an error is declared.

The temperature must also reach the 87 °target within four minutes to prevent a

hazard from shutting the system down.

Microprocessor Circuitry

The microprocessor used in the system is a Motorola 68HC11. The processor runs

at 8 MHz. The processor controls the digital displays, LCD, Alarm LED, Beeper,

Start LED, therapy sequence of events, timing, heater on/off control, and RS-232

port.

Support components are the 2KB Static Memory (RAM), 56KB Electronically

Programmable Read Only Memory (EPROM), and address decoding. These

devices are all contained in U15 on the microboard. This one-time programmable

part is a WSI PSD312-P. A special test mode or calibration mode places the unit

in constant therapy cycle. The constant therapy cycle is used for burn-in testing.

The Static RAM stores intermediate values being temporarily stored by the

microprocessor. This information is lost if power is turned off.

The EPROM stores the operational software for the processor.

The RS232 serial port is used only in manufacturing and for investigational

purposes. It is not intended to be used by the end user. It can be used to display

both thermocouples and both pressure transducer readings.

ThermaChoice UBT System Service Manual 1 - 7

P/N 01035 Rev. C

Front Panel Display, User Interface

The power switch is located on the front panel. It is an illuminated switch that

breaks both line and neutral of the AC line on the primary side of the transformer.

The thermocouple temperature of the catheter, the pressure of the balloon, and the

time of the procedure are displayed by three LED seven segment type displays. A

sixteen by two character backlit LCD on the front panel is used as a message

center, informing the user of the status of the unit and the procedure. The front

panel also includes two membrane type switches. The START and the STOP

switch. The START switch is used to start the PREHEAT cycle of the procedure.

This switch is enabled once the balloon pressure titration has been completed. The

activation of the STOP switch turns the heater off and terminates the procedure. A

green start light indicator on the front panel further informs the user that the

procedure can start. This light blinks when the START button is enabled. There is

also a yellow hazard indicator on the front panel. This indicator lights up when a

hazard condition is encountered and the system is stopped.

Two audio generators simultaneously sound all alarms. The frequency

components of the Alerts and Alarms are EN475 compliant. Upon powering on

the unit, the audio generators make a distinctive ding dong sound. If either the

"ding" or "dong" does not sound, one of the audio generators on the AUX board is

defective.

ThermaChoice UBT System Service Manual 1 - 8

P/N 01035 Rev. C

Specifications

POWER SOURCE (Controller)

Power Requirements 100 to 240VAC; 50/60 Hz; 110 watts; 3-wire grounded system

Regulation Voltage 90 to 264VAC, 47-63 Hz, single phase

Mains Fuses 250VAC, 5x20 mm 1.6A standard

Heater Fuse 250VAC, 4.0A slo-blo

MECHANICAL CHARACTERISTICS

Dimensions Height 10.2 cm (4 in.), width 41.2 cm (16.25 in.), depth 37.0

cm (14.56 in.)

Weight 6.9 kg (15.3 lbs.) (controller only)

Case Aluminum and impact-resistant plastic

Umbilical Cable Length 152 cm (60 in.)

ENVIRONMENTAL CONDITIONS

Transport and Storage

Ambient temperature -20 to +50

o

C

Relative humidity 20% to 85% non-condensing

Operation

Ambient temperature 10 to 40

o

C

Relative humidity 20% to 85% non-condensing

Electromagnetic Compatibility

ESD Direct & Indirect: Conforms to IEC 601-1-2

EMI Conforms to IEC 601-1-2

Leakage Currents

Patient Leakage Current Conforms to IEC 601-1

Earth Leakage Current Conforms to IEC 601-1

Electromagnetic Interference

In general, sensitive electronic equipment should always be positioned as far

away as possible from sources of high frequency voltages and currents, such as

electrosurgical generators. Moreover, cables connected to high frequency sources

should be kept as short as possible and must never be routed near or parallel to

cables of sensitive equipment.

ThermaChoice UBT System Service Manual 2- 1

P/N 01035 Rev. C

Section Two

Diagnostic and Troubleshooting Guide

Error Codes

The instrument will perform a power-up self test every time the unit is started. If an

error is detected, it will appear on the display if possible.

Note:

The Error Code Format is: xxyy, where xx=error code and yy=system state. Reference

the first two numbers on the display for use with the table below.

Problem or Error No. Probable Source of Problem Notes

Blank Display no Audio Power Supply, Micro Board,

Display, ISO Board, or AUX

Board

Blank Display w/ Audio Micro or Display

00, 01, 02, 03, 12 Micro If unit consistently

displays these unused

error codes

MDU Warning MDU

17 PS or Micro

26, 29, 30 AUX or Micro

28, 31, 33, 35 ISO or Micro

50,.58, 68 Disposable or Umb or ISO or

Placement

59, 60, 61, 64 66 AUX or PS Test Procedure Update

Required, Check output

of TP19, and TP31

62, 63 Micro or Pressure F

ittings & Lines

65 AUX or ISO or Micro

Diagnostic and Troubleshooting Decision Trees

The following pages contain diagnostic and troubleshooting flowcharts.

Warning:

The following diagnostic and troubleshooting flowcharts, the repair procedures in

Section Four, and the controllers’s start-up diagnostic test will not detect faults in the

heater circuit or the motor drive unit. If you suspect a problem with either of these field

replaceable units, send the device to the authorized Gynecare service center.

Notes:

1. Decision trees cover single faults.

ThermaChoice UBT System Service Manual 2- 2

P/N 01035 Rev. C

2. First troubleshooting step should be to perform a visual inspection of the connectors

making sure they are seated properly.

3. Check FRUs by swapping out the suspect FRU with a known good FRU.

4. Replace the Micro Assembly to correct problems with the Pressure display,

Temperature display, Time display, Start Button Light, or the Hazard Light.

5. Replace the Front Panel Assembly to fix problems with the Start and Stop buttons.

6. Replacement of the Motor Drive Unit (MDU) may be required if the instrument

consistently displays the MOTOR FAULT WARNING using known good catheters.

ThermaChoice UBT System Service Manual 3 - 1

P/N 01035 Rev. C

Section Three

Field Replaceable Units

Assy,

Motor

Drive Unit

PN 01014

Switch,

Power,

Mains

PN 01033

(on front

bezel)

Assy, AUX

PN 01204

Power Entry

Module

PN 01353

Power

Supply

PN 00808

Assy, ISO,

PN 00983

Assy, Micro

PN 01200

(behind front

bezel)

Display, LCD

PN 00877

(on Micro

Assy, w/ Flex

cable

attached)

ThermaChoice UBT System Service Manual 3 - 2

P/N 01035 Rev. C

Assy, Cable,

GND,

EQPOST-

CHASSIS

PN 00866

Assy, Cable,

ISO-Micro

PN 01504

Assy, Cable,

Surge

Arrestor

PN 01347

Assy, Cable,

Ribbon, 40

Cond, 3.5”

PN 00874

Assy, Cable,

CCS_SWITCH

PN 01293

(shown as dotted

line for location)

Assy, Cable,

PWR,ENTRY

PN 00868

Assy, Cable,

GND-PS-

CHASSIS

PN00864

Assy, Cable,

DC 150W

PN 00855

ThermaChoice UBT System Service Manual 3 - 3

P/N 01035 Rev. C

Table of Field Replaceable Units

Common Name Bill of Materials Designation Assy No.

AUX Board ASSY,PCBA,AUXILLARY 01204

ISO Board ASSY,PCB,ISO 00983

Micro Board ASSY,PCBA,MICROPROCESSOR 01200

Motor Drive Unit (MDU) ASSY,MOTOR DRIVE UNIT 01014

Power Supply PSUPPLY,UNIV INPUT,+5V,-24V-/-12V 00808

Power Entry Module (PEM) PEM,FILTER,W/FUSEHOLDER 01353

Power Switch, Mains SWITCH,SPDT,AMP,.187”TERM,MDU 01033

LCD Display DISPLAY, LCD,16X2,BACKLIT 00877

Heater Fuse Fuse, 5X20MM, SLOWBLOW, 4.0A,250 01620

Power Entry Module Fuse Fuse, 5X20MM, FASTBLOW, 1.6A,250 00861

Eqpost Ground Cable Assy, Cable, GND, EQPOST-CHASSIS 00866

Power Entry Cable Assy, Cable, PWR, ENTRY 00868

Ribbon Cable Assy, Cable, RIBBON, 40 COND, 3.5" 00874

CCS Switch Cable Assy, Cable, CCS_SWITCH 01293

ISO-Micro Cable Assy, Cable, ISO-MICRO 01504

Power Supply Cable Assy, Cable, DC, 150W 00855

Power Supply Ground Cable Assy, Cable, GND-PS-CHASSIS 00864

Surge Arrestor Cable Surge Arrestor Cable 01347

ThermaChoice UBT System Service Manual 3 - 4

P/N 01035 Rev. C

AUX Board

ASSY,PCBA,AUXILLARY

PN 01204

ISO Board

ASSY,PCBA,ISO

PN 00983

Micro Board

ASSY,PCBA,

MICROPROCESSOR

PN 01200

ThermaChoice UBT System Service Manual 3 - 5

P/N 01035 Rev. C

Motor Drive Unit

ASSY,MOTOR DRIVE UNIT

PN 01014

Power Supply

PSUPPLY,UNIV INPUT,+5V,-24,V-

/-12V

PN 00808

(ground cable not included)

Power Entry Module

PEM,FILTER,

W/FUSEHOLDER,

3A,.250"TERM

PN 01353

Table of contents

Other Ethicon Medical Equipment manuals

Ethicon

Ethicon MEGADYNE User manual

Ethicon

Ethicon ENSEAL G2 Super Jaw User manual

Ethicon

Ethicon DERMABOND PRINEO User guide

Ethicon

Ethicon Gynecare Morcellex User manual

Ethicon

Ethicon NTLC55 User manual

Ethicon

Ethicon ECHELON FLEX User manual

Ethicon

Ethicon DERMABOND PRINEO User manual

Ethicon

Ethicon CONTOUR CS40B Application guide

Ethicon

Ethicon ECHELON FLEX Powered Plus User manual

Popular Medical Equipment manuals by other brands

TRI-TECH MEDICAL

TRI-TECH MEDICAL MCP100A Installation & operating instructions

Zepter

Zepter Vital System PBG-866 instruction manual

Anthro

Anthro Zido ZGCSSB Assembly instructions

GE

GE Vivid P3 Service manual

Stanley

Stanley Bed-Check Vr Quick programming guide

VitalSignum

VitalSignum Beat2Phone instruction manual