Last Revised 06/21/2018 Copyright © Missouri Wind and Solar, LLC 2017 pg. 8

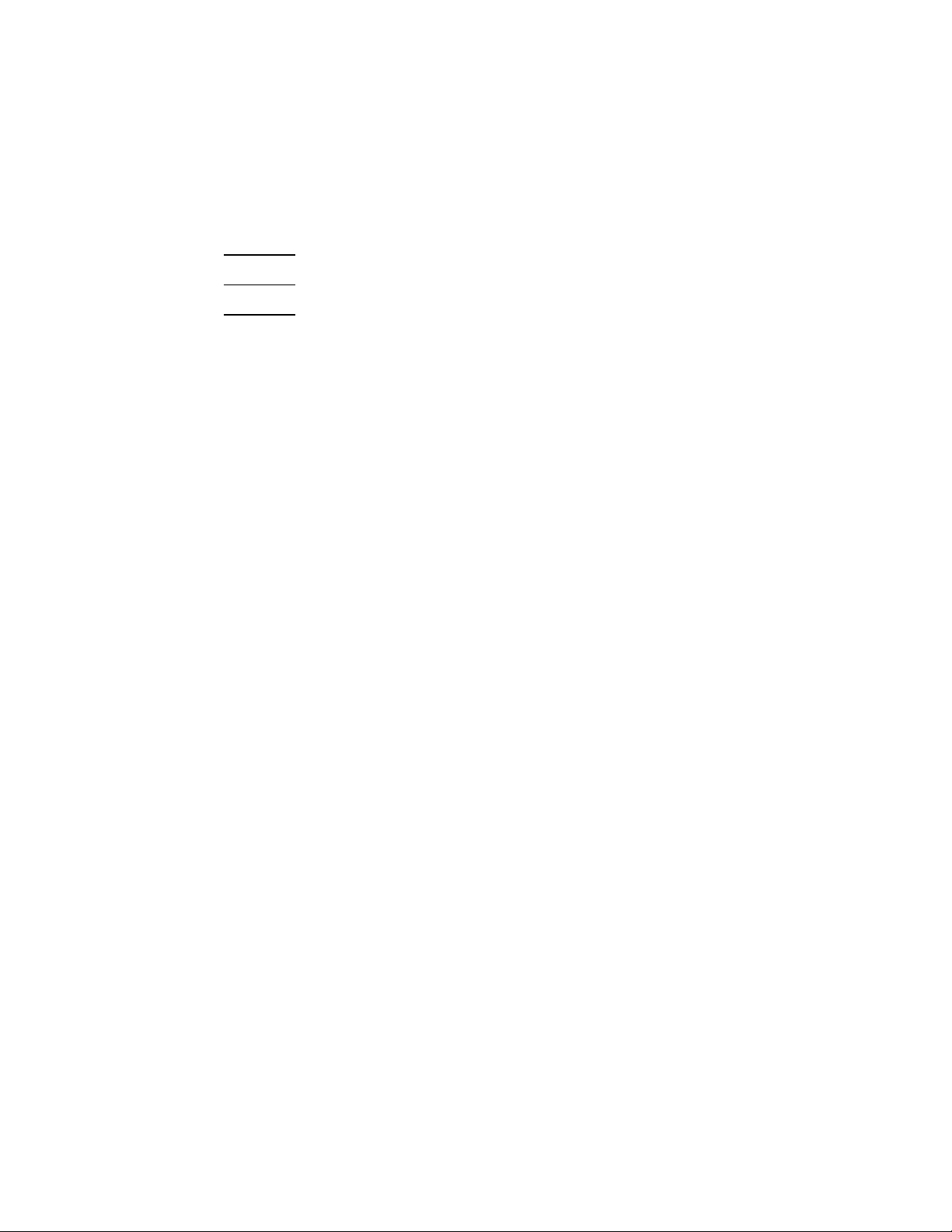

NOTE: Set brake switch set to “Brake” or leave turbine/tower on the ground before installing

hub/blade assembly. DO NOT install the turbine onto the tower during windy conditions. Ensure the

blades are stationary (not rotating) before connecting the battery bank to the divert controller. This

can be accomplished by either using the brake switch or installing the hub and blade assembly AFTER

making the electrical connections.

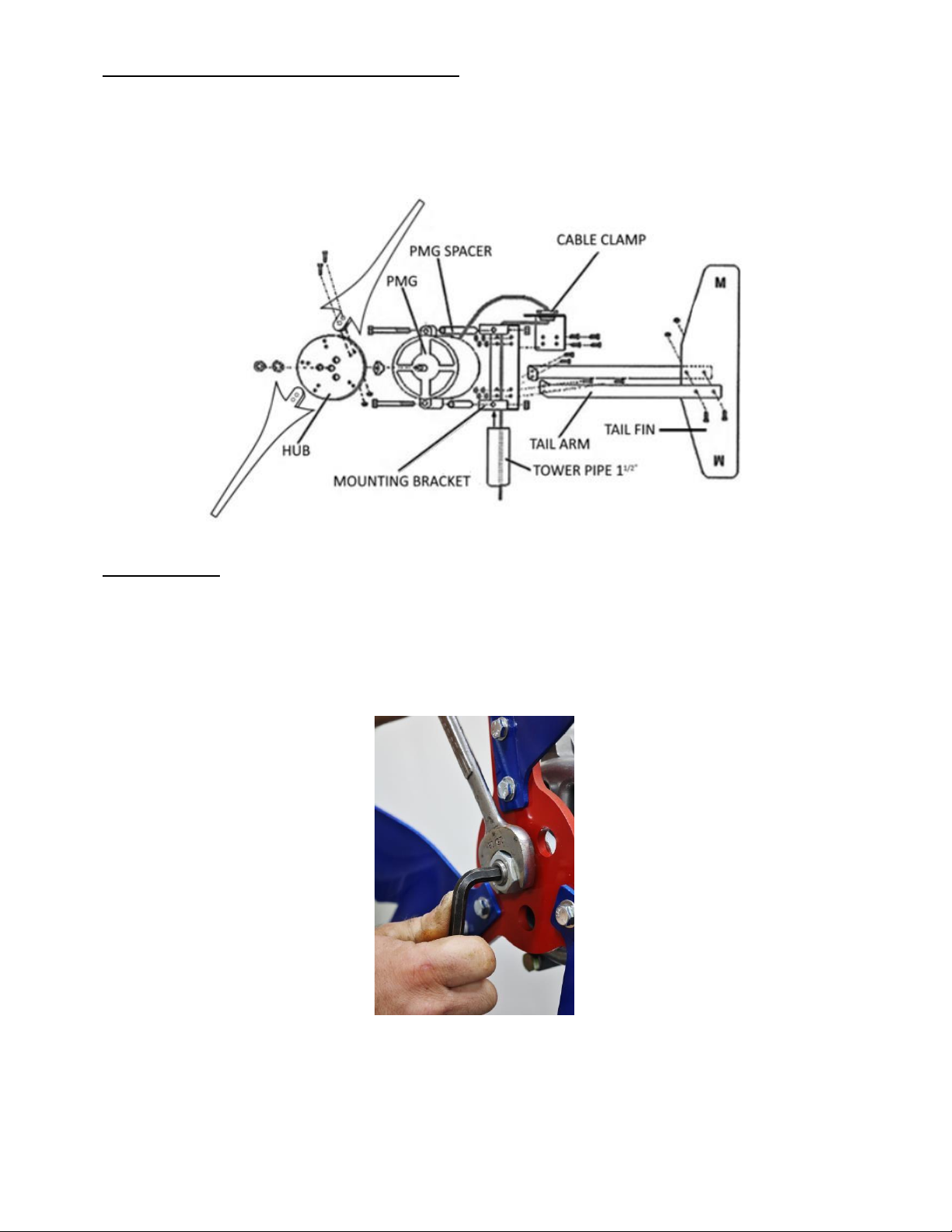

Operation

1. Assuming the tower is erected and level, the turbine is installed, and all electrical connections are

made, toggle the brake switch to the “On” position. Make sure to always connect charge controllers to

your batteries before connecting the wind turbine.

2. Monitor battery bank voltage as displayed on the divert controller. Ensure it reads close to the bank

voltage. For example, if you planned to have a 24V bank and the divert controller reads 11.7V, then

something is wrong.

3. If you have an ammeter, watch for current flow when the turbine blades spin.

4. It is a good idea to watch/listen (solenoid clicks audibly) to the divert controller during high winds or

when the battery bank is nearly full to ensure the divert controller “dumps” at the preset voltage level.

For a 12V bank, dump occurs at 14.4V-13.6V.

Troubleshooting Guide

NOTE: Before you call or e-mail, PLEASE read and understand all the PMG and associated components’

instructions. PLEASE read the entire troubleshooting section. PLEASE have a list with all the products’

model numbers (i.e., purchase invoice) when you call for help. It is easier and quicker for us to

troubleshoot your issues if you e-mail us pictures of your entire system, from the PMG to the inverter, and

everything in between.

1. Wind turbine output voltage varies based on wind speed, battery bank voltage, and blade count

(torque). We advise measuring volts and current on the DC side of the bridge rectifier using DC meters,

versus measuring on the AC side. Only check the DC output at the rectifier when the turbine is

disconnected from the charge controller and during no high-wind conditions.

NOTE: Disconnecting turbine from battery bank during high winds may allow turbine to free-spin

wildly, which can damage the turbine and/or blades.

2. The turbine will only charge a battery when the turbine output exceeds the battery bank voltage. It is

possible to see your battery voltage rise quickly with a strong wind gust, then fall back to the original

voltage level, or slightly above that level.

3. Mismatched batteries: Using old batteries with new, large batteries with small, or a mismatched

battery bank of any kind is not optimal and will result in an undercharged battery bank. In this case,

lack of charging is not a fault of the wind turbine. Additionally, the batteries will not last very long in

most cases.

4. To determine the amount of power being produced by your turbine at any one moment, multiply the

battery bank voltage by the turbine's current output to determine watts produced. Some divert

controllers have a built-in ammeter; otherwise, use a shunt with ammeter inline on the DC positive

wire between the rectifier and the divert controller.

5. A slight hum from the turbine is normal.

6. If the turbine severely shakes or vibrates, this is usually caused by one or more unbalanced blades or a

blade(s) installed backwards. If you have a bent blade that will not straighten itself over time, heat the