5

by a factor of eight (23= 2 x 2 x 2 = 8). One result

of this relationship is that there is very little energy

available in light winds. For the average site,

winds in the range of 5.5 – 9 m/s (12 – 20 mph)

will provide most of the system’s annual energy

production.

B. High Winds - AutoFurl

During periods of high wind speeds the AutoFurl

system will automatically protect the wind turbine.

When furled, the power output of the turbine will

be significantly reduced. In winds between 13 m/s

(29 mph) and 18 m/s (40 mph) it is normal for the

turbine to repeatedly furl, unfurl and then furl

again. In winds above 18 m/s (40 mph) the tur-

bine should remain continuously furled.

AutoFurl is a simple and elegant method of pro-

viding high wind speed protection. The AutoFurl

system is based on aerodynamic forces on the

rotor, gravity, and the carefully engineered ge-

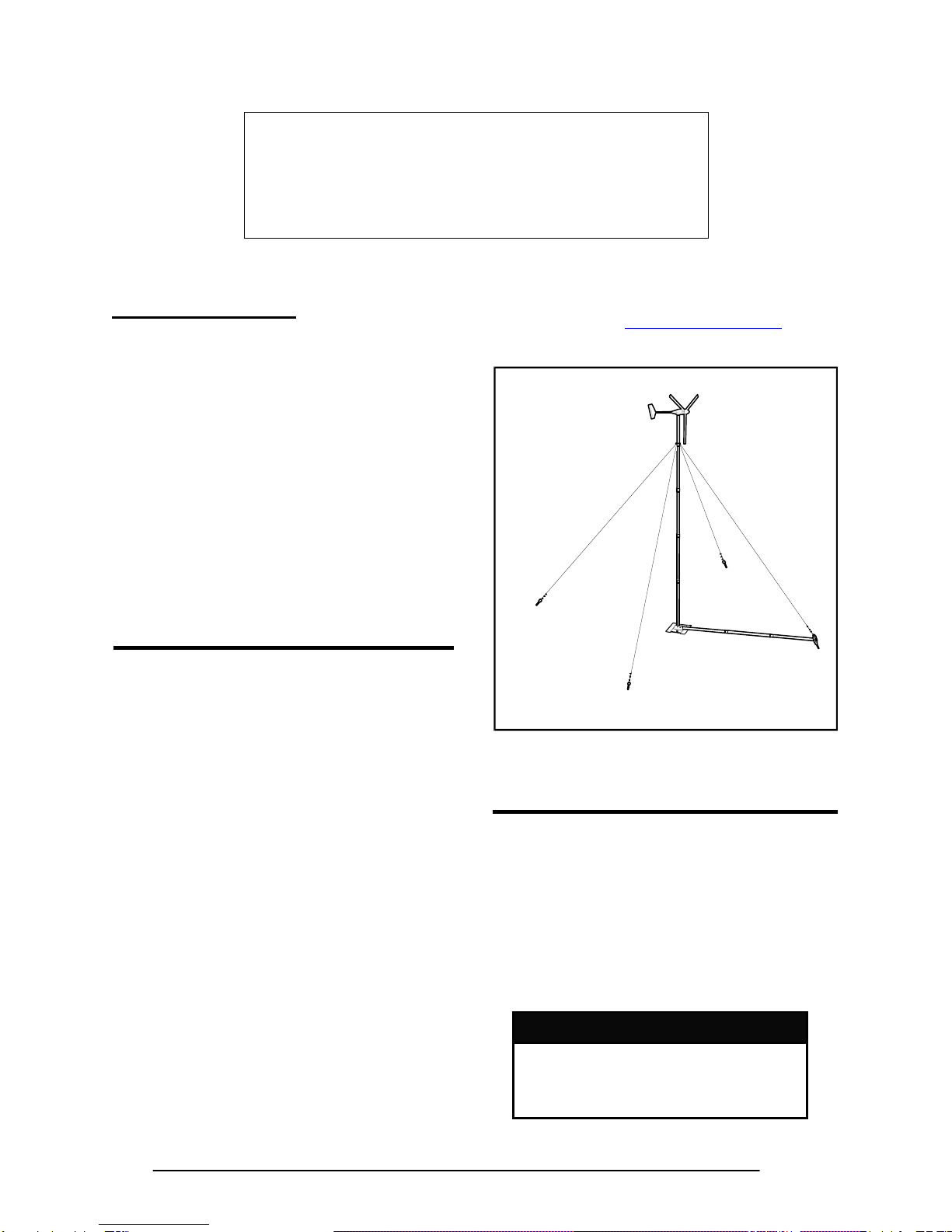

ometry of the wind turbine. As shown in Figure 4,

the aerodynamic forces acting on the blades

cause a thrust force pushing back on the rotor.

This force increases with increasing wind speeds.

Figure 4, AutoFurl

The thrust force acts through the centerline of the

rotor, which is offset from the centerline of the

tower pivot axis (yaw axis). Therefore, the thrust

force on the rotor is always trying to push the rotor

over to the side, away from the wind.

But the rotor is kept facing into the wind at speeds

up to ~ 12.5 m/s (28 mph) by the wind turbine’s

tail assembly. The tail, in turn, is kept straight by

its own weight because its pivot at the back of the

nacelle is inclined. So the weight of the tail holds

it against a rubber bumper and the tail holds the

rotor into the wind.

The geometries in the systems are carefully bal-

anced so that at ~ 12.5 m/s (28 mph) the rotor

force acting on the yaw-offset is large enough to

overcome the preset force holding the tail straight.

At this point the rotor will start turning away from

the wind or furling. The tail stays aligned with the

wind direction. The speed of furling depends on

the severity of the wind gusts and whether the

wind turbine stays furled depends on the wind

speed.

As the wind turbine furls the geometry of the tail

pivot causes the tail to lift slightly. When the high

winds subside the weight of the tail assembly re-

turns the whole turbine to the straight position.

The AutoFurl system is completely passive so it is

very reliable and since there are no wear points,

like in a mechanical brake system, it is very ro-

bust. AutoFurl was used in the very first wind sys-

tem produced by Bergey Windpower in 1980 and

in every unit produced since. AutoFurl is an im-

portant element of our success.

There is one situation in the field, however, that

we have found can disrupt the operation of Auto-

Furl. If the wind turbine is installed on a sharp hill

or next to a cliff so that the wind can come up

through the rotor on an incline (e.g., from below;

as opposed to horizontally) we know that this will

affect furling and can produce higher peak out-

puts. We strongly recommend avoiding this situa-

tion.

Caution

Do not install the XL.1 wind turbine near

cliffs or precipices or on sharp hills such

that the wind does not travel horizon-

tally through the rotor.

C. Unloaded Operation

As the battery bank voltage rises the PowerCenter

controller will try to regulate this voltage by switch-

ing off the solar charging and applying the op-

tional Extra Load (or “dump load”). If these

measures are not adequate then the PowerCenter

will momentarily disconnect the XL.1 wind turbine,