Everhard Industries NUGLEAM 35L Installation guide

INSTALLING YOUR LAUNDRY UNIT

1. Carefully lift product out of the carton.

2. The laundry unit must be installed at the location of the drain (refer to Connecting the Laundry Sink to the Drain

section). Check the dimensions of the area where the laundry unit will be installed to ensure it will fit within the

allocated space.

3. Ensure the back wall of the area where the laundry unit will be installed is straight and level.

4. Carefully remove the laundry sink from the unit using protective gloves and set aside.

5. Install the basket waste onto the sink. The basket waste is a two part waste, therefore the screw within the middle of

the waste needs to be removed before installing the waste onto the sink. Insert the top part of the waste including

the thin black rubber seal into the waste hole of the sink. From underneath install the bottom part of the basket

waste including the thick black rubber onto the waste hole. Screw the stainless steel threaded screw through the

top part of the basket waste into the bottom part of the basket waste and tighten using a screwdriver.

6. Ensure the laundry unit is installed level by using a spirit level across the top of the unit. If the floor is not level we

recommend using the optional adjustable feet which can be purchased separately.

NUGLEAM 35L & 45L SOFT CLOSE LAUNDRY UNIT

INSTALLATION & CARE INSTRUCTIONS

1

Drainage

Solutions

Interior

Products

everhard.com.au | 131 926

Environmental Civil &

Commercial

35L | EI code: 71S02

45L | EI code: 71S01

510

555

871

560

513

886

90

886

180

567

568

390

871

395

570

886

90

886

180

567

7. Using two screws or wall anchors, fasten the laundry unit to the wall by drilling two holes into the top bracket

approx 300mm centres and insert fastening screws (M6) or wall anchors to secure the unit to the finished wall.

WASHING MACHINE DRAINAGE HOSE CONNECTION

CONCEALED CONNECTION

1. Remove the waste junction from the packaging and drill the inside component from the 25mm side connection

on the junction using a 15mm drill bit.

2. Install the waste junction onto the bottom of the basket waste and tighten by hand.

3. Feed the washing machine hose through the top hole located on the side of the unit adjacent to the washing

machine and connect to the 25mm drilled out connection on the waste junction. Using a stainless steel clamp,

tighten the clamp onto the washing machine drainage hose connection on the waste junction using a screwdriver.

CONNECTING THE LAUNDRY SINK TO THE DRAIN

1. Locate the current waste installed in your home, this could be coming through the floor or through the wall.

2. If through the floor, measure the distance from the back and from the side of the unit to the centre of the drainage

pipe located on the floor. Mark the centre location of the drainage pipe on the floor panel. Using a 60mm hole saw,

drill a hole through the floor panel to fit the drainage pipe.

3. Using 50mm DWV pipe, connect the existing drainage pipe using approved plumbing fittings to an approved

50mm PVC Trap. The 50mm PVC Trap (not included) is installed onto the bottom of the waste junction. Tighten

by hand.

4. To cover the hole through the floor panel, a 50mm floor flange can be used and slide over the top of the 50mm

DWV pipe.

5. Test and ensure there are no leaks. Pop the rivet floor panel at the back of the unit.

INSTALLING THE TAPWARE

1. Carefully remove the laundry sink from the laundry unit using protective gloves.

2. Install your chosen tapware onto the sink using the supplied tap bracket and seals. Follow the manufacturer’s

instructions on how to install the tapware.

3. Once the tapware is installed, place the laundry sink onto the laundry unit. Seal the top edge of the unit using a

suitable sealant prior to placing the laundry sink onto the unit.

EVERHARD INDUSTRIES

ABN: 41 009 690 859

everhard.com.au | 131 926

Head Oce: 454 Newman Rd, Geebung, QLD, 4034

2

version: 001

Drainage

Solutions

Interior

Products

everhard.com.au | 131 926

Environmental Civil &

Commercial

35L

EI code: 71S02 Washing machine

drainage hose hole

Holes for concealing

washing machine taps

45L

EI code: 71S01

886

375

452

792

EVERHARD INDUSTRIES

ABN: 41 009 690 859

everhard.com.au | 131 926

Head Oce: 454 Newman Rd, Geebung, QLD, 4034

3

version: 001

Drainage

Solutions

Interior

Products

everhard.com.au | 131 926

Environmental Civil &

Commercial

REVERSING THE LAUNDRY UNIT DOOR

The Nugleam Soft Close Door can be reversed from right to left hinged if required.

1. To reverse the door, remove the two white hinge caps located on the door by using a screwdriver.

2. Remove the screws located on the door hinge attached to the door.

3. Reattach the door hinge to the holes located on the opposite side of the door. Re install door hinge screws and

tighten.

4. Place the two white hinge caps onto the original door hinge locating holes and insert screws and tighten.

ADJUSTING THE SOFT CLOSE HINGE

During transportation, your Nugleam Soft Close Door Laundry Unit may have slightly moved. To adjust the door, follow

the instructions on how to adjust the soft close hinges.

Adjustable Feet Installation (Optional)

Adjustable Feet can be installed onto the Nugleam Soft Close Door Laundry Unit by using the Everhard Adjustable

Feet (97943). Remove the nut and washer from the thread of the adjustable feet and insert the threaded component

through the four holes located on the base of the laundry unit.

Place the washer and nut onto the threaded rod of the adjustable feet on the inside of the base of the unit and tighten.

Adjust the feet to the desired height of the installation.

White Hinge Cap

SIDE ADJUSTMENT

Loosen or tighten adjusting screw (A) until the door

is balanced

DEPTH ADJUSTMENT

Loosen or tighten hinge arm fastening screw (B),

regulate distance between door and side wall

HEIGHT ADJUSTMENT

With the height adjustment mounting plates (C),

doors can accurately be adjusted in height

B A

C

EVERHARD INDUSTRIES

ABN: 41 009 690 859

everhard.com.au | 131 926

Head Oce: 454 Newman Rd, Geebung, QLD, 4034

4

version: 001

Drainage

Solutions

Interior

Products

everhard.com.au | 131 926

Environmental Civil &

Commercial

POSITIONING OF HOT AND COLD WATER PLUMBING CONNECTIONS

CARING FOR YOUR LAUNDRY UNIT AND LAUNDRY SINK (STAINLESS STEEL)

ROUTINE

Clean your laundry sink on a regular basis using bicarb soda or stainless steel cleaner. This will improve the look of your

laundry sink.

ACIDS + CLEANERS

Cleaning chemicals used around the home can contain chloride which can cause surface rust on the laundry sink.

Remove all chemicals left on the surface with clean water and dry the surface with a soft cloth.

RINSE

After use, rinse your laundry sink thoroughly with clean water to remove any chemicals, iron deposits or acids on

the surface.

FUMES

Storing chemicals such as chlorine, bleach or acid based products underneath your laundry sink will cause the surface

to rust rapidly due to the fumes attacking the surface. Always use air tight and sealed containers.

DRY

Wipe your laundry sink dry using a dry cloth after every use to keep the stainless steel fresh and spot free.

SOAKING

Avoid leaving damp sponges or cloths inside the laundry sink or around the edge of your sink when not in use. Over

time this can cause the surface to become pitted if not cleaned properly.

For further assistance, please visit us at https://www.everhard.com.au/contact-us/ or call us at 131 926.

605,9

354

695,6

530,9

605,9

519

695,6

530,9

Ideal location

for hot and

cold plumbing

connections

35L LAUNDRY UNIT 45L LAUNDRY UNIT

Ideal location

for hot and

cold plumbing

connections

This manual suits for next models

3

Table of contents

Other Everhard Industries Laundry Accessories manuals

Popular Laundry Accessories manuals by other brands

American Dryer Corp.

American Dryer Corp. ML-758 parts manual

CASA SI

CASA SI 295780 manual

Electrolux Professional

Electrolux Professional Jetsave installation manual

Proton

Proton InteliSENS PD30 instruction manual

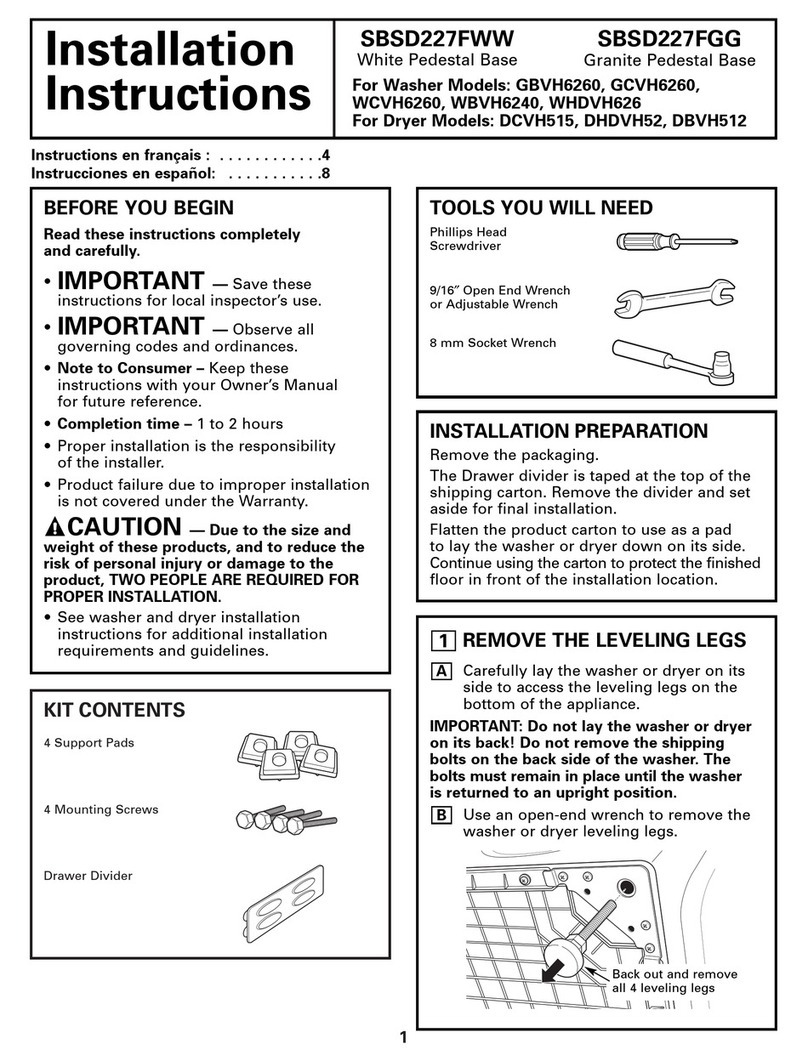

GE

GE SBSD227FWW installation instructions

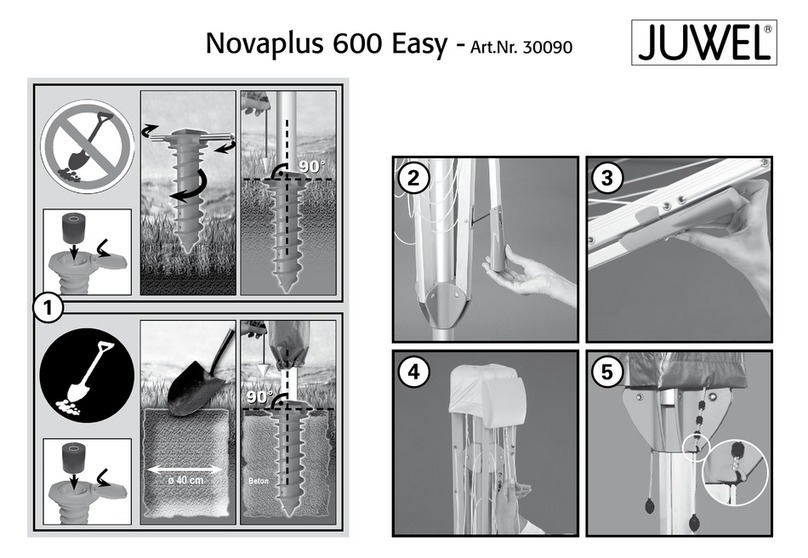

juwel

juwel Novaplus 600 Easy operating instructions