eSeek M500 Driver's License Scanner Maintenance

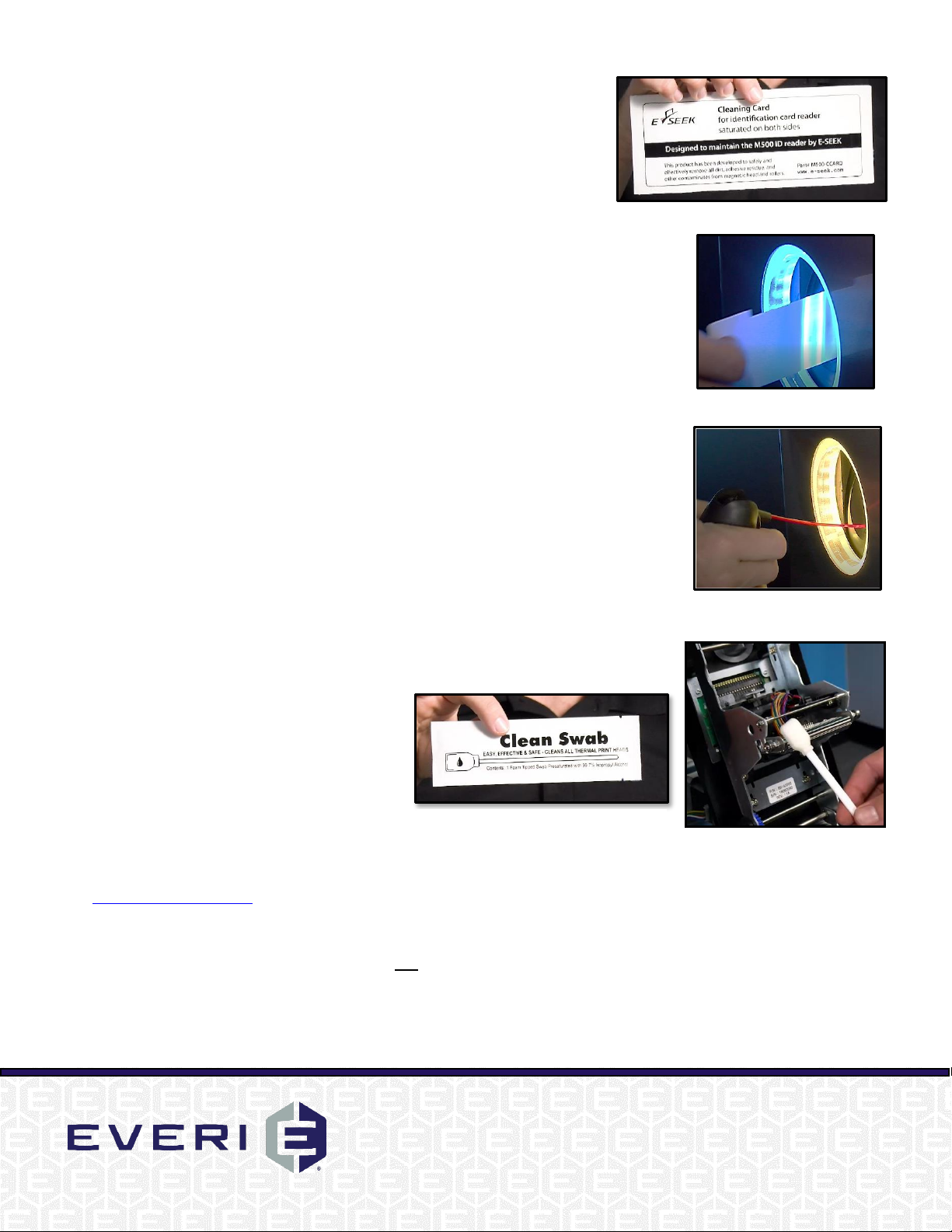

1. Cleaning

a. Open the eSeek M500 Cleaning Card and insert into the scanner with

the tab up. The scanner will run through a cleaning cycle.

b. It is recommended to repeat this process twice, once on each side of

the eSeek M500 Cleaning Card.

c. Once completed, discard the eSeek M500 Cleaning Card.

2. Calibration

a. Insert the Calibration Card into the scanner with the arrow facing outward.

The card will automatically feed in and out of the scanner.

b. Once completed, check the scanned images of the card to ensure they are

streak free and clear. If the card scan images appear dirty, proceed to the

internal mirror cleaning.

3. Cleaning Internal Mirrors

a. Open the M500 side door.

b. Insert the Air Divider into the M500 by positioning it under the top grey

spring-loaded line.

c. Align the Air Divider with the scanner’s side wall and push the Air Divider in

until it snaps into place.

d. Use a Can of Air with a nozzle to blow a few short bursts of compressed air into

the M500 scanner opening.

e. Remove Air Divider and close the M500 side door.

Print Head and Sensor Cleaning

1. Open the Alcohol Swab package and gently press the tip of the alcohol swab

against the thermal print head and 3 path sensors.

2. Only clean the portion located below the two marked lines.

NOTE: Do not touch thermal print heads with your hands.

3. Allow the alcohol to fully evaporate before

continuing printer use.

Out of Cleaning Supplies?

Kiosk cleaning supplies can be ordered directly through Everi’s Parts Department by

emailing PartsOrder@everi.com

Best Practices

It is recommended to run the card printer through a full cleaning cycle with each ribbon change (after 1,000 prints).

Additionally, preventative maintenance should be conducted on all the above kiosk components at least once a month, and as

needed based on kiosk use.