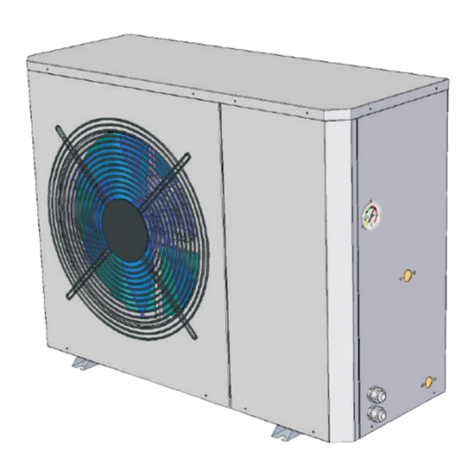

Evi GT-SKR015KBDC-M10 User manual

EVI DC Inverter Air Source Heat Pump

Instruction Manual

Model number: GT-SKR015KBDC-M10

GT-SKR020KBDC-M10

GT-SKR030KBDC-M10

GT-SKR040KBDC-M10

GT-SKR050KBDC-M10

◆Please read the manual carefully before installation and maintenance.

◆Please keep this manual well for future reference.

CONTENTS

Part I: General Information......................................................................................................................... 1

1.1 Caution........................................................................................................................................... 1

Part II Installation ....................................................................................................................................... 2

2.1 Transportation................................................................................................................................ 2

2.2 Installation site requirement........................................................................................................... 2

2.3 Minimum distance to wall ............................................................................................................. 3

2.4 Clearance between outdoor module and ground............................................................................ 4

2.5 Installation guide............................................................................................................................ 4

2.6 Recommended hydraulic connection............................................................................................. 5

2.7 Electrical Connection..................................................................................................................... 6

2.8 Trial Operation............................................................................................................................... 7

Part III Control System............................................................................................................................... 8

3.1 Controller position......................................................................................................................... 8

3.2 Controller introduction................................................................................................................... 9

3.3 Operation introduction................................................................................................................... 9

Part IV Maintenance ................................................................................................................................. 28

Part V Trouble Shooting ........................................................................................................................... 29

Part VI Wiring Diagram............................................................................................................................ 35

Disposal.............................................................................................................................................. 38

- 1 -

Part I: General Information

1.1 Caution

1. Ensure proper operation on the unit,

2. The unit must be installed and repaired by qualified technician.

3. A leakage protection switch must be installed near the unit.

4. Do not use any damaged cables and switches to avoid any leakage.

5. Do not open the electrical box of the unit without shutting off power supply.

6. Along transportation, don’t incline the unit more than 45°in any direction.

7. Before maintenance, please shut off the power to the unit first.

8. The unit is designed for outdoor installation, do not install it in a close space without

good ventilation.

9. Do not install the unit near inflammable or explosive goods.

10. Do not block the air intake or outlet of the unit.

11. When the unit is in off status for more than 5 hours with the ambient temperature lower

than 2℃, please drain the unit to prevent the formulation of ice in it.

12. This unit is not intended for operation by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience or knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety.

13. Keep safety distance between the unit and other equipment or structures according

local norm, and ensure that adequate space for maintenance or service operations.

14. Power supply: the diameter of electrical cables must be suitable for the unit and the

power supply voltage must correspond with the value indicated on the units. All units

must be earthed in conformity with legislation in force in the country concerned.

15. Please attention that hot water produced by the unit is not to be used for drink.

- 2 -

Part II Installation

2.1 Transportation

Along transportation, don’t incline the unit more than 45°in any direction

The unit in its packaging can be transported with a lift truck or hand truck.

2.2 Installation site requirement

This unit is designed for outdoor installation, do not install it in an close space.

Please consider the condition as following factors when selecting installation site.

●The installation site should be large enough and well ventilation.

●The installation site should be convenient for water drainage.

●Select a smooth, horizontal site where it can support the weight of the unit.

●Do not install the unit where there is pollution, accumulation, fallen leaves or bad ventilation.

●Don’t install the unit near inflammable or explosive goods.

- 3 -

2.3 Minimum distance to wall

Air discharge

Minimum 1000mm to obstacles obstructing the air discharge.

Minimum 3000mm to footpaths and patios due to the formation of ice, even when outside

temperatures are above 0 °C

- 4 -

2.4 Clearance between outdoor module and ground

The minimum installation height must be 300mm.

A canopy must be constructed over the outdoor module in areas with heavy snowfall.

2.5 Installation guide

2.5.1 Installation

a. Install 4 pieces shockproof rubber pad under the feet of the unit.

b. If the unit work with a water tank, the vertical distance between the unit and the water

tank should be less than 6m, and the horizontal distance should be less than 20m.

c. Connect the condensate drainage connector to the hole at the bottom sheet.

2.5.2 Accessories

Accessories inside the package as below table

No

Item

Quantity

1

Instruction Manual

1

2

Condensate drainage connector

2

3

shockproof rubber pads

4

- 5 -

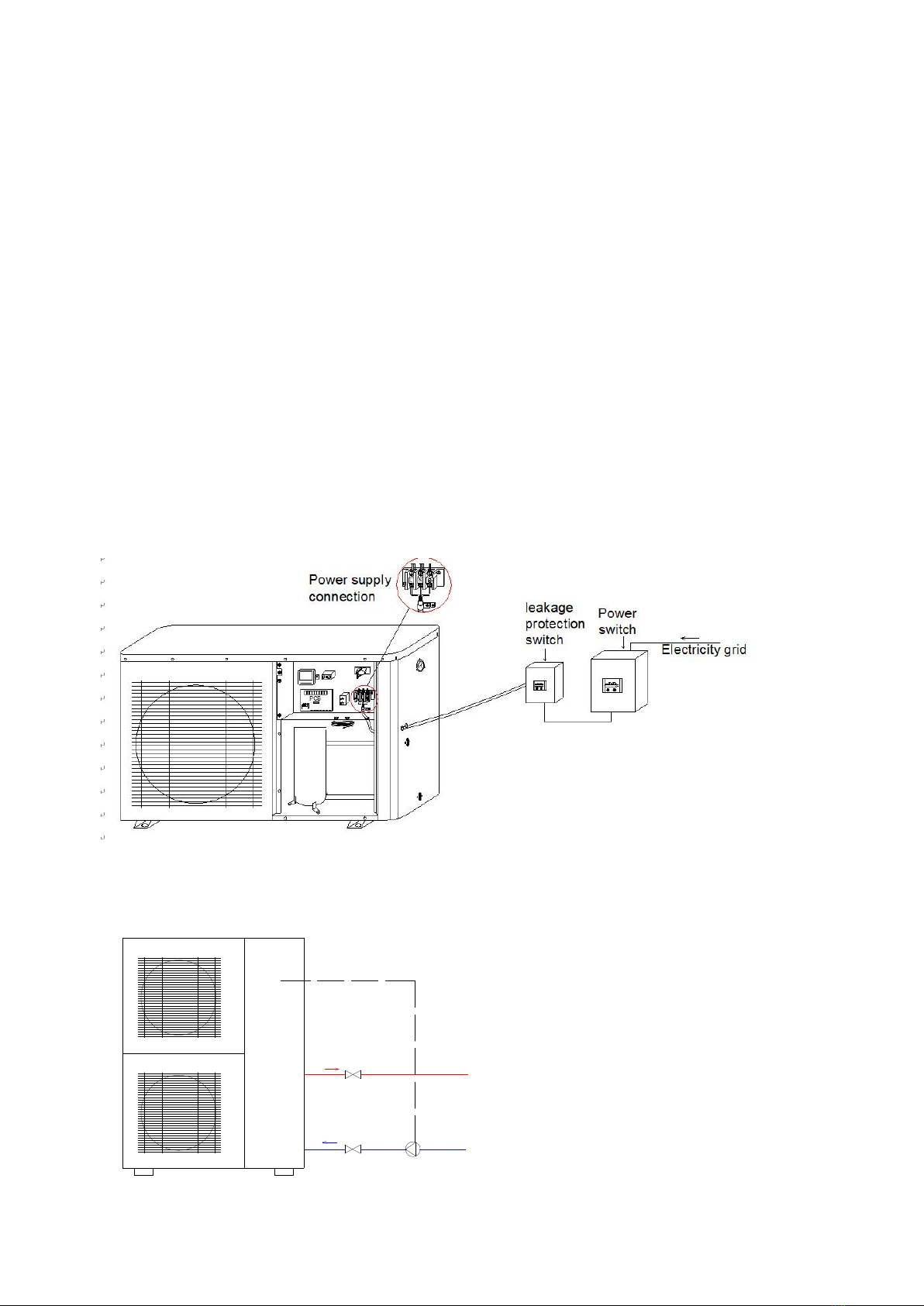

2.6 Recommended hydraulic connection

- 6 -

2.7 Electrical Connection

1. Ensure proper operation of the unit, the unit must be installed and repaired by qualified

technician.

2. A leakage protection switch must be installed near the unit.

3. Do not use any damaged cable and switch.

4. Do not open the electrical box without shutting off all power to the unit.

All the wiring must meet the local electrical safety norm and performed by qualified

electricians.

Ensure that the heat pump water heater is well connected to the earth, do not disconnect

the earth connection of the power in any condition.

Provide a separate power supply which meets rated requirements for the unit.

When the unit connects to the electricity network, there must be a short-circuit protection.

Choose the suitable cable when use the power outdoor.

Do not control the unit on or off by the main power switch.

After finish installation, check before connect the unit to the power.

Connect the signal (power) from PCB to water circulation pump

Heat pump Water circulation pump

Water circulation pump

signal (power)

- 7 -

The Specification of Power

Following information is for reference, please subject to the local safety norm.

Type

GT-SKR015KB

DC-M10

GT-SKR020KB

DC-M10

GT-SKR030KB

DC-M10

GT-SKR040KB

DC-M10

GT-SKR050KB

DC-M10

Power supply

220-240V/1Ph/

50Hz

220-240V/1Ph/

50Hz

220-240V/1Ph/

50Hz

220-240V/1Ph/

50Hz

380-415V/3Ph/

50Hz

Circuit

Breaker/Fuse(A)

20

25

32

32

32

Min. power

wiring (mm2)

1.5

2.5

4.0

4.0

2.5

Ground wiring

(mm2)

1.5

2.5

2.5

2.5

2.5

2.8 Trial Operation

The unit should only be operated by qualified technician.

Please drain air inside hydraulic system before operation.

The unit is designed according to the conditions as follows: the range of ambient

temperature is -25℃~43℃and the range of water pressure is 0.15~0.8Mpa.

2.8.1 Preparation

The following items should be checked before startup:

a. The heat pump should be connected completely.

b. All valves that could impair the proper flow of the heating water in the heating circuit must be

open.

c. The air intake and air outlet paths must be cleared.

d. The ventilator must turn in the direction indicated by the arrow.

e. The settings of the heat pump controller must be adapted to the heating system in

accordance with the controller’s operating instructions.

f. Ensure the condensate outflow functions.

g. Drain the air inside hydraulic system.

2.8.2 Trial run

●Turn on the power, start up the unit by the controller, after 30 seconds, the unit (compressor)

start to work, then observe whether the unit works normally.

●When you restart the unit, the compressor will start up after three minutes to protect the

compressor.

- 8 -

2.8.3 Caution

When following happen during trial operation, please stop the unit immediately and cut off the

power and contact with our authorized agent or maintenance technician.

Fuse blown or protection activated frequently.

●The wire and switches are heated abnormally

●Abnormal sounds coming from the unit

●Abnormal smell comes out of the unit.

●Electricity leakage.

Part III Control System

3.1 Controller position

The controller is installed inside the unit before factory, open the front panel as following picture,

you will find the controller.

There is 8 meters cable for the controller, it is allowable to move the controller to outside the unit,

but avoid a place with sunshine and rain.

- 9 -

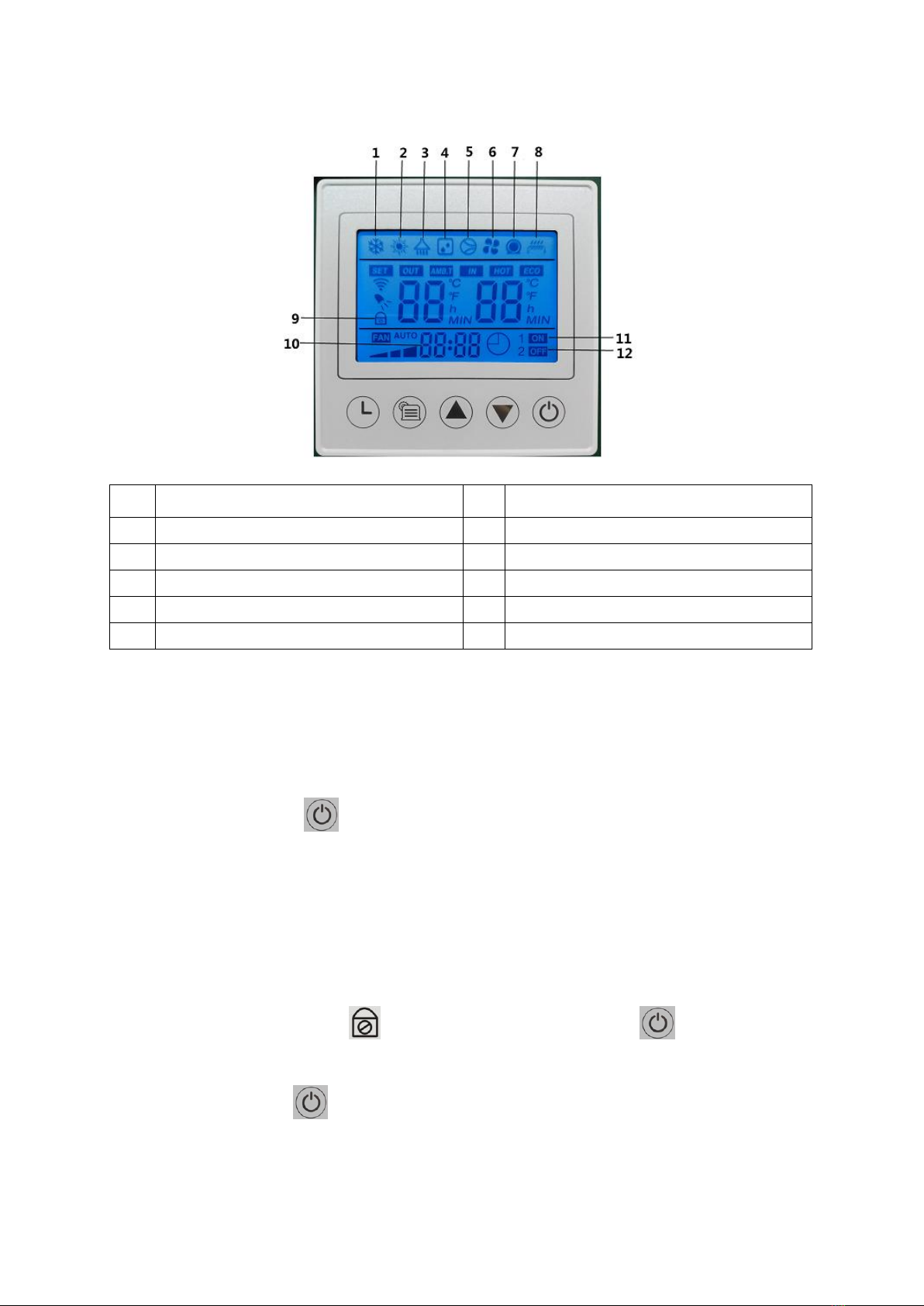

3.2 Controller introduction

1

Cooling

7

Water pump

2

Heating

8

E-heater

3

DHW

9

Lock the keys

4

Defrosting

10

Clock

5

Compressor

11

Timer on

6

Fan

12

Timer off

3.3 Operation introduction

Lock and unlock buttons

1. In locked status, press button for 5 seconds, the buzzer will sound and unlock the

buttons.

2. If there is no operation for 60 seconds, buttons will be locked automatically, and the

backlight will be off.

Turn on/Off the unit

1. When the buttons are locked, displace on the screen, press button for 5 seconds

to unlock the screen;

2. In unlock status, press button for 1 second to switch on/off;

3. In unlock status, if there is no operation on the controller for 60 seconds, the buttons will be

locked automatically.

- 10 -

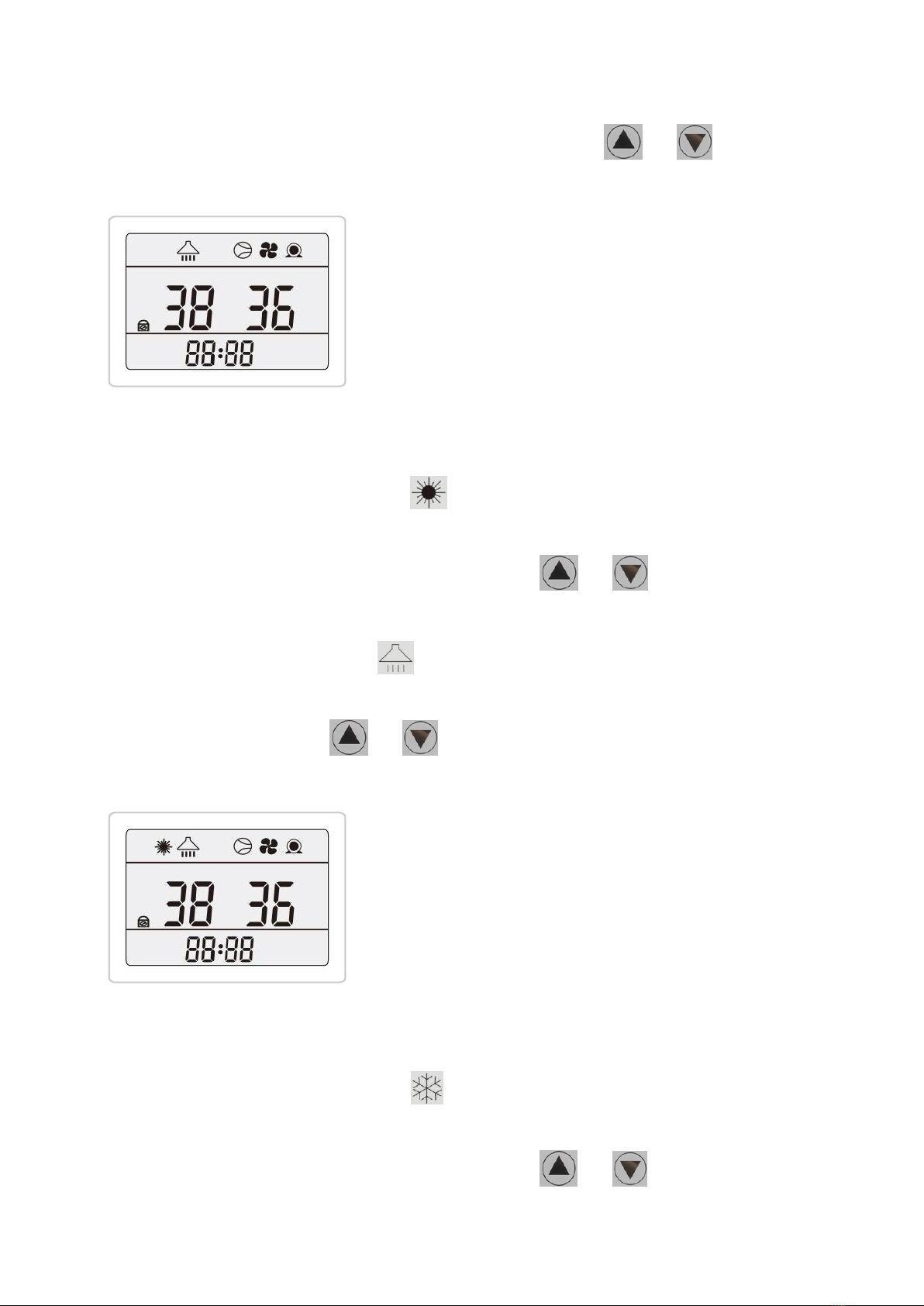

Standby status

Function button

1. In main menu, press button to switch working mode.

The units have 5 working modes as below:

(1): Heating mode

The left side of the screen shows the set water temperature of buffer tank; The right side of

the screen shows the measured water temperature of buffer tank. Press or to

adjust the set water temperature of buffer tank, the maximum water temperature can be

set is 60℃.

Heating status

(2): cooling mode

The left side of the screen shows the set water temperature of buffer tank; The right side of

the screen shows the measured water temperature of buffer tank. Press or to

adjust the set water temperature of buffer tank, the minimum water temperature can be set

is 8℃.

Cooling status

- 11 -

(3): DHW mode

The left side of the screen shows the set DHW water temperature; The right side of the

screen shows the measured DHW water temperature. Press or to adjust the set

DHW water temperature, the maximum DHW water temperature can be set is 55℃.

DHW status

(4): heating + DHW mode (DHW priority)

-When the unit is in heating status, flash on the screen, the left side of the screen

shows the set water temperature of buffer tank; The right side of the screen shows the

measured water temperature of buffer tank. Press or to adjust the set water

temperature of buffer tank, the maximum water temperature can be set is 60℃.

-When the unit is in DHW status, flash on the screen, the left side of the screen shows

the set DHW water temperature; The right side of the screen shows the measured DHW

water temperature. Press or to adjust the set DHW water temperature, the

maximum DHW water temperature can be set is 55℃.

Heating+ DHW status

(5): cooling + DHW (DHW priority)

-When the unit is in cooling status, flash on the screen, the left side of the screen

shows the set water temperature of buffer tank; The right side of the screen shows the

measured water temperature of buffer tank. Press or to adjust the set water

- 12 -

temperature of buffer tank, the minimum water temperature can be set is 8℃.

-When the unit is in DHW status, flash on the screen, the left side of the screen shows

the set DHW water temperature; The right side of the screen shows the measured DHW

water temperature. Press or to adjust the set DHW water temperature, the

maximum DHW water temperature can be set is 55℃.

Cooling+ DHW status

Parameter inquiry

1. In main menu, press button for 3 seconds to enter user parameter inquiry menu,

press or button to inquire parameters.

2. In user parameter inquiry menu, if there is no operation for 30 seconds, will automatically

exit user parameter inquiry and back to main menu. Or press button to back to main

menu.

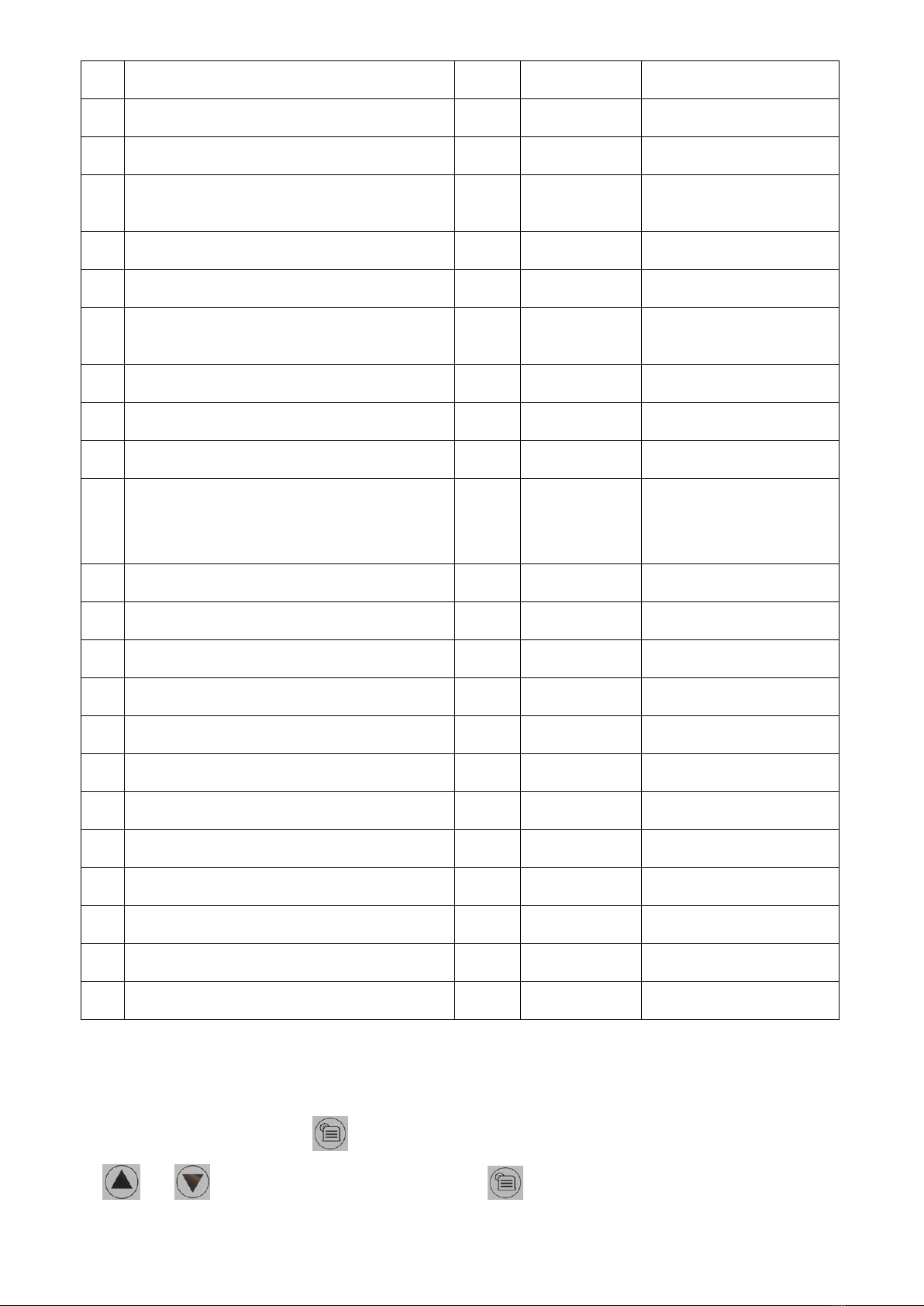

Item

Description

Unit

Range

Remark

00

DHW tank temperature

℃

-30~105

01

Frequency of compressor

Hz

0~99

02

Current of compressor

A

-30~105

03

DC bus voltage

V

-30~105

*10

04

Temperature of IPM module

℃

-30~105

05

AC voltage

V

-30~105

*10

06

AC current

A

-30~105

07

Current operating power of compressor

W

-30~105

*100

08

Fan speed

RPM

-30~105

*10

09

Target overheating of suction in main circuit

℃

-30~105

/10

10

Actual overheating of suction in main circuit

℃

-30~105

- 13 -

11

EEV opening in main circuit

P

-30~105

*10

12

EEV opening in injection circuit

P

*10

13

High pressure

Kpa

-30~105

*100

14

High pressure saturated evaporation

temperature

℃

-30~105

15

Current exhaust superheat

℃

-30~105

16

Low pressure in main circuit

Kpa

-30~105

*100

17

Low pressure saturated evaporation

temperature

℃

-30~105

18

Target overheating in auxiliary circuit

℃

-30~105

19

Actual overheating in auxiliary circuit

℃

-30~105

20

Low pressure in auxiliary circuit

KPa

-30~105

*100

21

Inlet temp of auxiliary circuit

℃

-30~105

Low pressure saturated

evaporation temperature in

auxiliary circuit

22

Outlet temp of auxiliary circuit

℃

-30~105

EVI suction temperature

23

Exhaust temp

℃

-30~140

24

Outdoor coil temperature

℃

-30~105

25

Outdoor environment temperature

℃

-30~105

26

Buffer tank temperature

℃

-30~105

27

Temperature of after throttling

℃

-30~105

28

Inlet water temperature

℃

-30~105

29

Outlet water temperature

℃

-30~105

30

Suction temperature

℃

-30~105

31

Casecade switch selection

0: OFF; 1: ON

32

Casecade switch status

0: OFF; 1: ON

33

Status of water pump

0:OFF; 1: ON

Factory parameters setting ( only for technician operate)

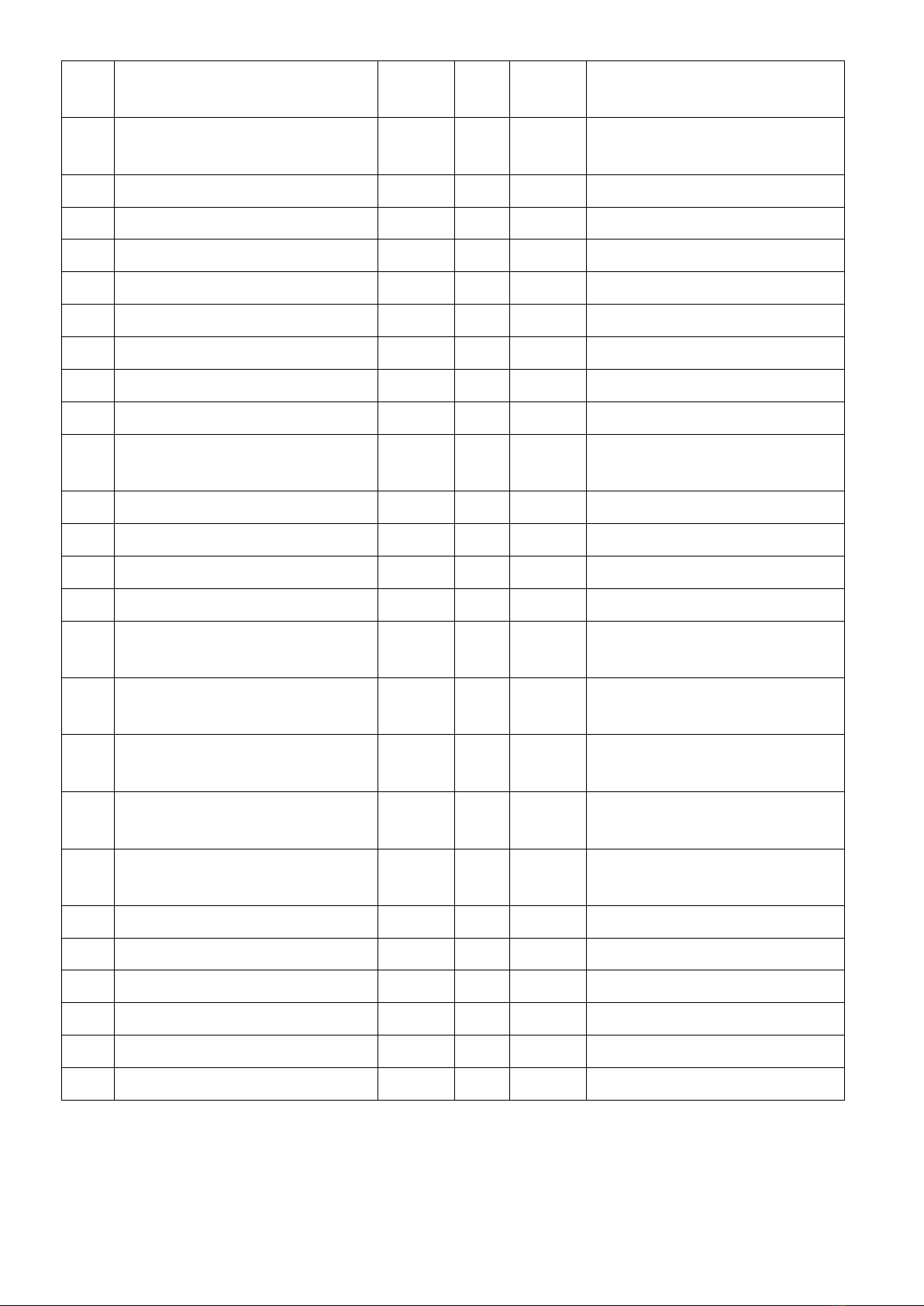

1. In main menu, press button for 3 seconds to enter parameter setting menu, press

or button to set parameters. Press button to save setting.

- 14 -

2. In parameter setting menu, if there is no operation for 30 seconds, will automatically exit

parameter setting and back to main menu. Or press button to back to main menu.

Item

Description

Default

value

Unit

Range

Remark

b01

Water difference to start

compressor in heating mode

3

℃

0~15

b02

Water difference to start

compressor in cooling mode

3

℃

0~15

b03

Max. set temperature in heating

mode

60

℃

20~60

b04

Min. set temperature in heating

mode

15

℃

10~20

b05

Max. set temperature in cooling

mode

32

℃

20~60

b06

Min. set temperature in cooling

mode

8

℃

7~20

b07

Water temperature compensation

0

℃

-9~9

b08

Circulation running mode

2

0~2

0: run 2 mins every b09 mins

1: run as compressor run

2: always run

b09

Circulation pump interval time

5

min

0~99

b10

Inlet and outlet water temperature

difference protection value

40

℃

5~40

b11

Working mode

3

0~1

0: heating

1:heating+DHW

2: heating+cooling

3: heating+cooling+DHW

After setting, it needs to be

powered off to take effect.

b12

Power lost memory function

1

0~1

0: off

1: on

b13

Air temperature to start E-heater

-15

-30~20

b14

Air temperature to enter EVI

8

0~10

b15

Type of fan

0

0~3

0: DC

1: single speed

2: double speed

3: three speed

After setting, it needs to be

powered off to take effect.

- 15 -

b16

Water temperature compensation

function

1

0~1

0: no

1: yes

b17

Set room temperature

25

℃

15~25

b18

Initial BTW temperature

20

℃

15~25

b19

Max. BTW temperature

43

℃

24~50

b20

Extend defrosting interval 1

0

min

-30~50

b21

Extend defrosting interval 2

0

min

-30~50

b22

Defrosting enter temp 1

0

℃

-30~30

b23

Defrosting enter temp 2

0

℃

-30~30

b24

Defrosting running time

12

min

6~16

b25

Defrosting exit temperature 1

EE

℃

12~25

b26

Defrosting exit temperature 2

5

℃

4~11

b27

Reserved

0

b28

Reserved

0

b29

Reserved

0

b30

Main valve target exhaust

superheat in heating

EE

℃

0~10

b31

Main valve target exhaust

superheat in cooling

EE

℃

0~10

b32

Main valve regulating interval time

EE

s

30~90

b33

Min. opening of main valve in

cooling

EE

P

50~480

b34

Min. opening of main valve in

heating

EE

P

50~480

b35

Main valve target return superheat

max. value in heating

EE

℃

0~10

b36

Main valve target return superheat

max. value in cooling

EE

℃

0~10

b37

Reserved

0

b38

Auxiliary valve target superheat

EE

℃

0~15

b39

Auxiliary valve regulating interval

time

EE

s

30~90

b40

Reserved

b41

Reserved

b42

Reserved

b43

Reserved

b44

Reserved

- 16 -

b45

Max. operating temperature in

heating

55

℃

10~60

b46

Min. operating temperature in

heating

-25

℃

-35~10

b47

Reserved

0

b48

Reserved

0

1~13

b49

Reserved

0

1~13

b50

Reserved

0

1~10

b51

Reserved

0

1~10

b52

Reserved

0

0~1

b53

Reserved

0

℃

0~5

b54

Reserved

0

b55

Quantity of machines work in

series

1

1~8

b56

Display machine work in series

1

1~8

b57

Reserved

0

b58

Reserved

0

b59

Reserved

0

cure

b60

Manual debugging mode

0

0~1

0: off

1: on

b61

Manual compressor running

frequency

60

HZ

0~95

Default value is current running

frequency

b62

Manual main valve opening

300

HZ

0~480

Default value is current running

frequency

b63

Manual auxiliary valve opening

100

P

0~480

Default value is current running

frequency

b64

DC fan speed

850

P

400~10

00

Default value is current running

frequency

b65

Reserved

b66

Reserved

b67

Reserved

b68

Reserved

b69

Reserved

b70

Reserved

- 17 -

Defrosting parameters setting (only for technician operating)

1. In main menu, press button for 3 seconds to enter parameter setting menu, press

or button to set parameters. Press button to save setting.

2. In parameter setting menu, if there is no operation for 30 seconds, will automatically exit

parameter setting and back to main menu. Or press button to back to main menu.

Item

Description

Default

value

Unit

Range

Remark

b20

Extend defrosting interval 1

0

min

-30~50

value=x, interval time of

defrosting=(60+x) mins.

b21

Extend defrosting interval 2

0

min

-30~50

value=x, interval time of

defrosting=(60+x) mins.

b22

Defrosting enter temp 1

0

℃

-30~30

this value is temp difference

(environment temp-coil temp)

b23

Defrosting enter temp 2

0

℃

-30~30

this value is temp difference

(environment temp-coil temp)

b24

Defrosting running time

12

min

6~16

b25

Defrosting exit temp 1

15

℃

12~25

b26

Defrosting exit temp 2

5

℃

4~11

ECO mode

In ECO mode, the unit runs according to heating curve.

The heating curve is the relationship between the heating system supply temperature and the

outside air temperature. In the case of a heating curve, it is done automatically thanks to the

weather-based control, which adjusts the supply temperature based on the outside

temperature.

- 18 -

1. Press , and buttons simultaneously to enter / exit ECO mode,

display on the screen.

The heating curve parameters setting (only for technician operation)

a. In main menu, press button for 3 seconds to enter parameter setting menu, press

or button to set parameters. Press button to save setting.

b. In parameter setting menu, if there is no operation for 30 seconds, will automatically exit

parameter setting and back to main menu. Or press button to back to main menu.

Item

Description

Default value

Unit

Range

b17

Set room temp

25

℃

15~25℃

b18

Initial BTW temp

20

℃

15~25℃

b19

Max. BTW temp

43

℃

24~50℃

Target buffer tank temp = Initial BTW temp + (Max BTM temp - Initial BTW temp) / 35 x (Set

room temp - Outside temp)

For example, Set room temp = 25°C, Max BTW temp = 43°C, Initial BTW temp = 20°C

a. When outside temp=20°C, Target buffer tank temp = 20+(43-20)/35x(25-20)=23°C

This manual suits for next models

4

Table of contents

Other Evi Heat Pump manuals

Popular Heat Pump manuals by other brands

Hitachi

Hitachi YUTAKI S Series Installation and operation manual

Bosch

Bosch Compress 7000 AWM/AWMS 5-17 user guide

Boge

Boge BEKOMAT 32 Instructions for operation

Apricus

Apricus APHP-R290-260 installation manual

Carrier

Carrier Aquasnap plus 30AW Installation, operation and maintenance instructions

Haier

Haier MRVII-S AU482FIERA Installation & maintenance instructions