Evince ELITE EV-ELT-948-1.0 User manual

IAPMO R & T Certified

against CSA B483.1

IAPMO R & T Certified

against NSF/ANSI 44

OWNERS MANUAL

1. Page 18 of this manual contains important maintenance procedures for the continued proper

operation of your unit. These MUST be performed regularly for your warranty to remain valid.

2. Read all instructions carefully before operation.

3. Avoid pinched o-rings during installation by applying NSF certied lubricant to all seals (provided with install kit).

4. This system is not intended for treating water that is microbiologically unsafe or of unknown quality without

adequate disinfection before or after the system.

Evince™ Direct Phone Number: 951.734.7400

108 Business Center Dr

Corona, CA 92880

2

Table of Contents

READ THIS PAGE FIRST

BEFORE STARTING INSTALLATION 3

EFFICIENCY STATEMENT 4

SPECIFICATIONS

SPECIFICATION 5

SYSTEM DIMENSIONS 6

BRINE TANK DIMENSIONS 6

INSTALLATION

UNPACKING / INSPECTION OF TWIN TANK MODEL 7

BRINE TANK ASSEMBLY 9

CHECK VALVE TYPE AND VALVE SERIAL # 10

BEFORE INSTALLATION 11

PREPARATIONS 12

INSTALLATION STEPS 13

WATER CONDITIONER INSTALLATION 14

OPERATION

STARTUP INSTRUCTIONS 15

DURING REGENERATION / PLUMBING SYSTEM CLEAN-UP 17

MAINTENANCE INSTRUCTIONS AND SCHEDULE 18

IMPORTANT WARRANTY AND MAINTENANCE INFORMATION 19

RES-UP® FEEDER INSTALLATION INSTRUCTIONS (OPTIONAL) 20

SERVICING EVINCE ELEVATE VALVE 21

MASTER PROGRAMMING 22

DIAGNOSTIC SCREEN 24

REPLACEMENT

REPLACE PISTON AND/OR BRINE VALVE ASSEMBLY / CLEAN INJECTOR ASSEMBLY 25

REPLACE TIMER / REPLACE MOTOR 26

REPLACING THE BYPASS AND METER CABLE 27

DISPLAY REPLACEMENT / REPLACE MICROSWITCHES 28

REPLACE DRAIN LINE FLOW CONTROL /REPLACE BRINE LINE FLOW CONTROL 29

AFTER SERVICING 29

PARTS BREAKDOWN 30

POWERHEAD 31

VALVE BODY 32

TROUBLE SHOOTING GUIDE 33

MASTER PROGRAMMING GUIDE 34

3

Read this manual thoroughly to become familiar with the

device and its capabilities before installing or operating your

Water Conditioner. Failure to follow instructions in this

manual could result in personal injury or property damage.

This manual will also help you to get the most out of your

conditioner.

This system is intended for use on municipal water only and

its installation must comply with all State, provincial or local

regulations. Check with your local public works department

for plumbing and sanitation codes. In the event the codes

conflict with any content in this manual the local codes

should be followed. Consult your licensed plumber for

installation of this system.

This water conditioner is designed to operate on pressures of

30 psi to 125 psi. If the water pressure is higher than the

maximum use a pressure reducing valve in the water supply

line to the conditioner.

This unit is capable of operating at temperatures between

40°F and 110°F (4°C - 43°C). Do not use this water conditioner

on hot water supplies.

Do not install this unit where it may be exposed to wet

weather, direct sunlight, or temperatures outside of the

range specified above.

Avoid pinched o-rings during installation by applying

(provided with install kit) NSF certified lubricant to all seals.

It is not uncommon for sediment, precipitated iron or

hardness to be present in water supplies. Precipitated

minerals or sediments can cause damage to the seals and

piston. This is considered a harsh environment and the seals

and piston would not be covered by warranty stated or

otherwise.

It is recommended to regularly inspect and service the

control valve on an annual basis. Cleaning and or replacement

of piston, seals, and or spacers may be necessary depending

on how harsh the conditions are. An Annual Maintenance kit

(Part # 60010565) is available for this purpose

Do not use water that is microbiologically unsafe without

adequate disinfection before or after this system.

This publication is based on information available when

approved for printing. Continuing design refinement could

cause changes that may not be included in this publication.

The manufacturer reserves the right to change the

specifications referred to in this literature at any time,

without prior notice.

READ THIS PAGE FIRST

BEFORE STARTING INSTALLATION

INSTALL NOTES &

SAFETY MESSAGES

Watch for the following

messages in this manual:

NOTE

Do not remove or destroy

the serial number. It must be

referenced on request

for warranty repair or

replacement

CAUTION!

Disassembly while

under pressure can

result in flooding.

WARNING!

ELECTRICAL SHOCK

HAZARD! UNPLUG THE UNIT

BEFORE REMOVING THE

COVER OR ACCESSING ANY

INTERNAL CONTROL PARTS

NOTE: used to emphasize

installation, operation or

maintenance information

which is important but does

not present a hazard.

CAUTION: used when

failure to follow directions

could result in damage to

equipment or property.

WARNING: used to

indicate a hazard which

could cause injury or death if

ignored.

4

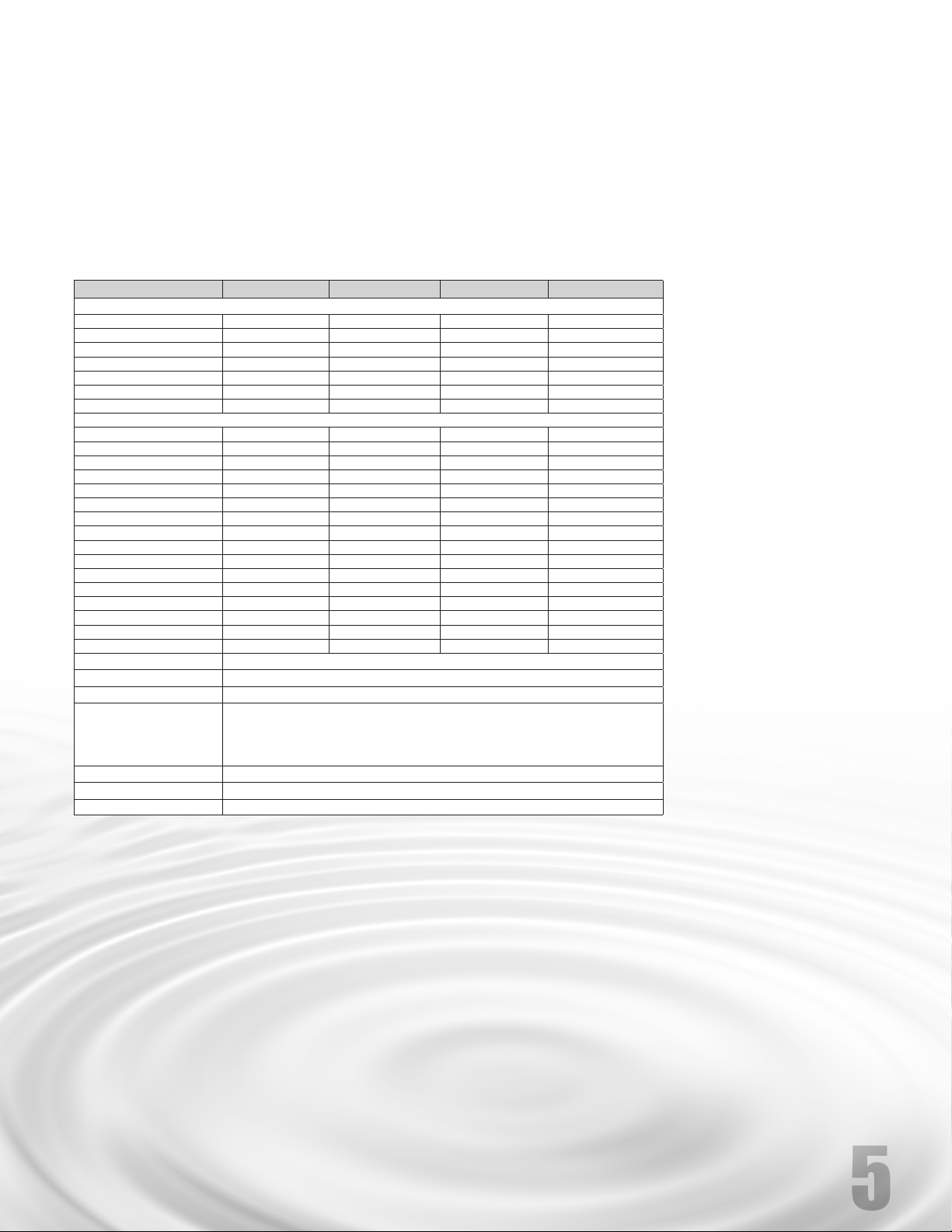

PERFORMANCE DATA SHEET

MODEL NUMBER EVELT9481.0 EVELT10541.0 EVELT12521.0 EVELT13541.25

QTY HIGH CAPACITY RESIN 1.0 FT3 1.5 FT3 2.0 FT3 2.5 FT3

RATED SERVICE FLOW GPM 11.0 11.2 12.4 12.6

PRESSURE DROP AT RATED SERVICE FLOW PSI 15.0 15.0 15.0 15.0

RATED SOFTENING CAPACITY GRAINS 13,629 3LBS 20,443 4.5LBS 27,258 6LBS 34,072 6LBS

EFFICIENCY GRAINS/LB SALT 4,543 4,543 4,543 4,543

MAX. FLOW RATE TO DRAIN GPM 2.0 2.4 3.5 4.0

WORKING PRESSURE MIN. 20 MAX. 125 PSI

OPERATING TEMPERATURE MIN 39 MAX. 100 DEGREES FAHRENHEIT

Certified by IAPMO R&T according to NSF/ANSI 44 for

effective reduction of hardness (calcium and magnesium)

as verified and substantiated by test data.

These refiners conform to NSF/ANSI 44 for the specific performance claims as verified and substantiated by test data.These models are efficiency rated.The efficiency rating

is valid only at the stated salt dose and maximum service flow rate.They have a demand initiated regeneration (D.I.R.) feature that complies with specific performance

specifications intended to minimize the amount of regenerant brine and water used in their operation.These refiners have a rated refiner efficiency of not less than 3350

grains of total hardness exchange per pound of salt (based on sodium chloride) and shall not deliver more salt than their listed ratings.The rated salt efficiency is measured by

laboratory tests described in NSF/ANSI Standard 44.These tests represent the maximum possible efficiency that the systems can achieve. Operational efficiency is the actual

efficiency after the system has been installed. It is typically less than the efficiency due to individual application factors including water hardness, water usage, and other

contaminants that reduce the refiner’s capacity. These systems are not intended for use with water that is microbiologically unsafe or of unknown quality without adequate

disinfection before or after the system. For best results, use plain, white block salt. Refer to Installation/operation manual and warranty for further details on installation, parts

and service, maintenance and further restrictions or limitations to the use of the product.

EFFICIENCY STATEMENT

This product is efficiency rated according to NSF/ANSI 44.The stated efficiencies are valid only at the specified Sodium Chloride dosages and maximum service flow rate.

5

Evince® Elite Automatic Water Refiners: Elite Series 1”

Specications EV-ELT-TT-948-1.0 EV-ELT-TT-1054-1.0 EV-ELT-TT-1252-1.0 EV-ELT-TT-1354-1.0

Optional - High Eciency

Sodium Used - Per Regeneration 3.0 lbs 4.5 lbs 6.0 lbs 7.5 lbs

Water Used - Regeneration 92.2 gal 120.9 gal 164.9 gal 171.3 gal

Hardness Removal - Grains 13,000 19,500 26,000 32,500

Factory Settings - Standard Capacity

Sodium Used - Per Regeneration 6.0 lbs 9.0 lbs 12.0 lbs 15.0 lbs

Water Used - Regeneration 106.5 gal 143.9 gal 190.7 gal 196.7 gal

Hardness Removal - Grains 19,000 28,500 38,000 47,500

Optional - High Capacity

Sodium Used - Per Regeneration 12.0 lbs 18.0 lbs 24.0 lbs 30.0 lbs

Water Used - Regeneration 109.6 gal 147.9 gal 196.8 gal 202.48 gal

Hardness Removal - Grains 27,000 40,500 54,000 67,500

Tank #1 EV-C12 - Cubic Feet 1.0 ft 1.5 ft 2.0 ft 2.5 ft3

Tank #2 EV-UHC100 - Cubic Feet 1.0 ft 1.5 ft 2.0 ft 2.5 ft3

EV-Macro Filtration Included: Yes Yes Yes Yes

EV-Clarication Included: Yes Yes Yes Yes

EV-Gold Filter included: Yes in Tank 2 Yes in Tank 2 Yes in Tank 2 Yes in Tank 2

Tank Size 9x48 10x54 12x52 13x54

Tank Jacket / Media Loaded Yes Yes No No

Brine Tank / Cabinet Size (Inches) 18.7 x 34 18.7 x 34 18.7 x 34 18.7 x 34

Sodium Storage Capacity 240 lbs 240 lbs 240 lbs 240 lbs

Flow Rate @ 15 psi Pressure Drop 11.6 gpm 11.8 gpm 12.8 gpm 13.0 gpm

Flow Rate @ 25 psi Pressure Drop 15.8 gpm 15.9 gpm 17.1 gpm 17.2 gpm

Back Wash Flow Rate 2.0 gpm 2.4 gpm 3.5 gpm 4.0 gpm

Shipping Weight 122 lbs 155 lbs 172 lbs 208 lbs

Regeneration Type Dynamic Regeneration

Maximum Eciency 4,333 grains /lb sodium

Plumbing Connections Includes 1”90°Elbows & 1”Straight NPT

Media Type

EV-Macro Filtration -Tank 1 and 2

EV-C12 Ultra Rener -Tank 1

EV-Clarication -Tank 1 and 2

EV-Gold Filter -Tank 2

EV-UHC100 Hydro Conditioning -Tank 2

Electrical Requirements Input 120V 60 Hz - Output 12V 650mA

Water Temperature Min 39 - Max. 100 degrees Fahrenheit

Water Pressure Min. 20 - Max. 125 psi

All units are factory programmed to the below specifications. Alteration should only be done by a factory trained technician or after consultation with one of our technical

representatives if you have any questions please contact:

Evince® Direct Phone Number: 951.734.7400

Service Related Matters: customerservice@Evincewater.com

General questions: info@Evincewater.com

Working Temperature: This unit must be

operated at temperatures between 40°F and

110°F (4°C - 43°C).

Working Pressure:This water refiner must

be operated on pressures

between 30 psi to 125 psi. If the water

pressure is higher than 125 PSI, use a

pressure reducing valve in the water supply

line to the refiner.

Voltage = 120V / 60 Hz

Pipe Size = 3/4”, 1” and 1.25"

• At the stated service flow rates, the

pressure drop through these devices will

not exceed 15 psig.

• The manufacturer reserves the right

to make product improvements which

may deviate from the specifications

and descriptions stated herein, without

obligation to change previously

manufactured products or to note the

change.

* Do not use water that is microbiologically

unsafe without adequate disinfection

before or after the system.

Peak flow rates intended for intermittent

use only (10 minutes or less) and are for

residential applications only. Do not use

peak flow rate for commercial applications

or for a continuous rate when treated

water supplies are geothermal heat pump,

swimming pool, etc.

For satisfactory operation, the pumping rate

of the well system must equal or exceed

indicated backwash flow rate.

All units come with plastic bypass

Maximum Iron = 1.5 ppm

Maximum Hydrogen Sulde = 0.0 ppm

Maximum Manganese = .75 ppm

pH = 6.5 to 8.5

Note: Evince® Systems can be installed into homes and small commercial applications with up to 1.25" plumbing. Optional 1.25"

connections available upon request.

SPECIFICATION

6

Model Liquid Volume Tank Dimensions

(inches)

5 Pack Carton

Dimensions (inches)

Salt Capacity 5 Pack Carton

Shipping Weight

US Gal Liters L x W x H L x W x H Lbs Kg Lbs Kg

Brine Tanks

BTR-100 29.5 111.5 18.1 x 34.7 18.9 x 18.9 x 65.6 270.0 122.2 52.8 23.9

BTR-145 42.3 159.7 20.3 x 37.4 21.9 x 21.9 x 72.2 385.0 174.2 65.6 29.8

BTR-200 53.0 200.3 23.0 x 40.5 24.6 x 24.6 x 84 700.0 316.7 125.0 56.6

* All brine tanks come with salt grid, safety oat and brine well

175/225/275

salt grid system

918(36.2")

salt tank body

sa

lt

t

an

k

lid

(7.3")

(20.35")

1028

186

(40.5")

517

175/225/275

brine well and brine valve

salt grid system

585(23")

BTR 200l label

BTR100

BRINE TANK DIMENSIONS

SYSTEM DIMENSIONS

Models A (Inches) B (Inches) C (Inches)

EV-ELT-TT-948-1.0 59 3/4” 9" 13”

EV-ELT-TT-1054-1.0 65 3/4” 10" 13”

EV-ELT-TT-1252-1.0 63 3/4” 12" 13”

EV-ELT-TT-1354-1.0 65 3/4” 13" 13”

B

A

C

7

SYSTEM CONTENTS:

MODELS:

EVELT9481.0

EVELT10541.0

EVELT12521.0

EVELT13541.0

YOU WILL EXPECT THE FOLLOWING.

SHIPPING CARTON QUANTITY 1

1. Control Valve*

2. Tank

3. Parts Box

4. Owners Manual

5. Drain Hose & Clamp (Not included in some

brands)

6. Parts Bag

1. Control Valve

Parallel Adapter

7. Tank 1 C/w

Adapter

2. Tank 2

C/w Parallel

Adapter

6. Parts bag 4 x Clips

O-ring X 8

Straight Adapter X 4

Bypass (not

attached)

There are 8 black clips. Please

check to make sure you have

all of them.

UNPACKING / INSPECTION OF TWIN TANK MODEL

Brine Tank

(Round or

Square)

Brine Tank

Tubing

**Brine Well/

Safety Float **FLOAT ASSY

55010023 - BTR100

*GRID

55010013 - For BTR 100

Tube Stiffener Part #

10332

Brine Tank Lid

*Grid (Round or Square)

Grid Legs (3 for

Round and 4 for

Square)

Brine Tank Assembly (Round Brine Tank Shown))

,03257$17

3/($6((1685(7+($77$&+('

78%(67,))(1(5,6,16(57('

,1727+(%5,1(/,1(%()25(

7,*+7(1,1*

7+(187

18280

EW-MACRO

FILTRATION™

3. Parts Box

60090003

2X 1” Straight

Adapter

60010006

Bypass Tool

60010026

O Rings Attached

60090010

2 X 3/4”

Elbow

Adapter)

60010052

Transformer

92360

Grease

Packet

8

Bypass (not

attached)

There are 8 black clips. Please

check to make sure you have

all of them.

4. Control Valve

Tank 1 Tank 2

O-ring Part #

60010077

2. Media Box

For Models EV-ELT-1252-1.0 and EV-ELT-1354-1.0, the media and Control Valve is packaged separately in carton

and bags

WHAT IS INCLUDED WITH EVELT12521.0 AND

EVELT13541.0 MODELS?

YOU WILL EXPECT THE FOLLOWING.

SHIPPING CARTON QUANTITY 1

1. Tank # 2 c/w Adapter

2. Qty 6 of Media Boxes - Number of media boxes dependent

on size of unit purchased. EV-ELT-948-1.0 and

EV-ELT-1054-1.0 come with preloaded tanks

3. Drain Line and Hose Clamp (Not Included with some models)

4. Control Valve with Parts Box

5. Parts Bag

UNPACKING & INSPECTION

5. Parts bag 4 x Clips

O-ring X 8

Straight Adapter X 4

18280

EW-MACRO

FILTRATION™

3. Parts Box

60090003

2X 1” Straight

Adapter

60010006

Bypass Tool

60010026

O Rings Attached

60090010

2 X 3/4”

Elbow

Adapter)

60010052

Transformer

92360

Grease

Packet

9

BRINE TANK ASSEMBLY

6. Install the connectors with

fitting as shown. Also install

the valve on the parallel adapter

Make sure all black clips are

firmly in place before applying

pressure

a) Attach the three brine grid legs to grid plate.The legs

will snap on to the tabs of the salt plate making a

“clicking”sound. Square brine tanks have four legs.

c) Drop the brine grid with brine well inside the

brine tank such that the nut tting faces the

hole on the brine tank. Then press the grid down

evenly inside the brine tank until the brine grid

legs touches the bottom of the brine tank.

b) Insert the brine well assembly inside the grid

plate in the hole provided.

d) Take the brine tube and insert the nut and plastic sleeve as

shown below.

e) Insert the tube in the oat assembly elbow and hand tighten

the nut. In many cases the brine line already comes installed

from the factory. Leave the other end of the brine line tube

inside the brine tank until you are ready to connect to the

control valve on the installation site.

f)Once at the installation site, pull the other end of the brine

tube from the hole on the brine tank.The completed assembly

is shown below.

The hole in

the brine tank

should line up

with the brine

line as shown

IMPORTANT: IT IS IMPORTANT TO ALIGN THE

HANDLE TO THE BRINE WELL AS SHOWN

Insert Sleeve

NOTE

Resin Cleaner

An approved resin cleaner

MUST be used on a regular

basis if your water supply

contains iron.

See Res-Up® Feeder

Installation Instructions

in subsequent pages in

this manual.

Pipe connector - 14”- 18” / 8”- 12”Tanks

10

CHECK VALVE TYPE AND VALVE SERIAL #

Check to make sure Valve Type is Upflow (UF) (left Sticker shown below). The right Sticker shows the serial # of the control valve. The middle sticker is a dataplate which

provides information of Serial # and Date of Manufacture of complete system. Both Serial # labels are important for troubleshooting.

Please record these numbers on the back page of this manual for future reference.

Valve Serial #

%17;;;+(8)$&9

+9%69%+9

:17

7KLV9DOYHLV7HVWHGDQG&HUWLILHGE\16)

LQWHUQDWLRQDODJDLQVW$16,16)6WDQGDUG

IRUPDWHULDOVDQGVWUXFWXUDOLQWHJULW\

UHTXLUHPHQWVRQO\

1

;;;;;;;;

62)7(1(5;;;+(

6HULDO1R

%17;;;+(8)$&9

+9%69%+9

:17

7KLV9DOYHLV7HVWHGDQG&HUWLILHGE\16)

LQWHUQDWLRQDODJDLQVW$16,16)6WDQGDUG

IRUPDWHULDOVDQGVWUXFWXUDOLQWHJULW\

UHTXLUHPHQWVRQO\

1

;;;;;;;;

62)7(1(5;;;+(

6HULDO1R

Complete System Serial #

11

8QILOWHUHG:DWHU%\SDVV

/RRS&XW&DSSHG

*URXQG6WUDS5HTXLUHG%HFDXVH

RI%UHDNLQ&RQWLQXLW\

)LOWHUHG:DWHU/LQHLQ+RPH

Fig. 1.

BEFORE INSTALLATION

Make sure you have a copy of your most recent water test results. If your water has not been tested previously you can contact

your supplier of this product to obtain a water sample bottle to be sent to one of our facilities for a free analysis. It is important

that this product not be installed until you have this information.

In all cases where metal pipe was originally used and is later interrupted by poly pipe or the Noryl bypass valve or by physical

separation, an approved ground clamp with no less than #6 copper conductor must be used for continuity, to maintain proper

metallic pipe bonding.

Inspecting and Handling Your EV-ELT Filter*

Inspect the equipment for any shipping damage. If damaged, notify the transportation company and request a damage

inspection. Damage to cartons should also be noted.

Handle the filter unit with care. Damage can result if it is dropped or set on sharp, uneven projections on the floor.

Do not turn the filter unit upside down.

To Insure this Product Functions Properly:

Your feed water line size to the unit must be a minimum of 3/4 inch with an operating pressure of no less than 30

psi and no more than 125 psi.

MECHANICAL:

Do not use petroleum based lubricants such as petroleum jelly, oils or hydrocarbon based lubricants.Use only 100% silicone

lubricants (grease packet provided in parts kit). All plastic connections should be hand tightened only. Teflon tape may be used

on connections that do not use an O-ring seal. Do not use pliers or pipe wrenches except where indicated by Nut shape (eg. pipe

adapters) All plumbing must be completed according to local codes. Soldering connections should be done before connecting

any pieces to the pipe as excessive heat can damage them.

Tools Required for Installation:

NOTE: We recommend installation only be completed by a competent installer or

plumbing professional to insure this product is installed in accordance with local

plumbing codes.

sTwo adjustable wrenches

sAdditional tools may be required if modification to home plumbing is required.

sPlastic inlet and outlet fittings are included with the filter. To maintain full valve flow, 3/4” or 1” pipes to and from the

filter fittings are recommended. You should maintain the same, or larger, pipe size as the water supply pipe, up to the filter

inlet and outlet.

sUse copper, brass, or PEX pipe and fittings.

sSome codes may also allow PVC plastic pipe.

sALWAYS install the included bypass valve, or 3 shut-off valves. Bypass valves let you turn off water to the filter for repairs if

needed, but still have water in the house pipes.

s5/8” OD drain line is needed for the valve drain. A 10’ length of hose is not included with some brands.

NOTE

All government codes and

regulations governing the

installation of these devices

must be observed.

NOTE

If a severe loss in water

pressure is observed when

the filter unit is initially

placed in service, the filter

tank may have been laid on

its side during transit. If this

occurs, backwash the filter

to “reclassify” the media.

*NOTE

Due to transportation

and climatic conditions all

connections including the

valve to the tank need to be

checked at time of

installation and tightened if

necessary.

NOTE

Check your local electrical

code for the correct clamp

and cable size.

CAUTION!

If the ground from the

electrical panel or breaker

box to the water meter or

underground copper pipe

is tied to the copper water

lines and these lines are cut

during installation of the No-

ryl bypass valve and/or poly

pipe, an approved grounding

strap must be used between

the two lines that have been

cut in order to maintain

continuity. The length of the

grounding strap will depend

upon the number of units

being installed and/or the

amount of copper pipe being

replaced with plastic pipe.

See Fig. 1.

12

Make sure both brass

and plastic nuts are

tightened well

PREPARATIONS

1. Media Installation (When Necessary). Models larger than 2.0 CF of media are shipped with separate media in pails or

boxes. Models lower than 1.5 CF of media come loaded with media and this step can be skipped for new installation.

a) Remove the adaptor from the mineral tank.

Grease the bottom oring of the adaptor with

silicone grease provided

b) Temporarily plug the open end of the riser tube to ensure

that no resin or gravel falls down into the distribution. The

riser (distributor) remains inside the tank seated in the

depression at the bottom.

Plug tube with a tape. Remove after media is loaded.

c) Fill support bed first. The media

will not always spill down inside

the tank and may need to be swept

inside.

The large funnel (sold separately

makes lling the tank easier and

neater. (Or an empty 1 gallon or 4

liter container with the bottom cut

out makes a good funnel.)

NOTE

The unit is not ready for

service until you complete

the start-up instructions,

page 15.

NOTE

Never make a direct

connection into a waste

drain. A physical air gap of at

least 1.5” should be used

to avoid bacteria and

wastewater travelling back

through the drain

line into the softener.

CAUTION!

The unit should be

depressurized before

installing or replacing media

Locate Water Conditioning Equipment Correctly

Select the location of your filter tank with care. Various conditions which contribute to proper location are as follows:

1. Locate as close as possible to the water supply source.

2. Locate as close as possible to a floor or laundry tub drain.

3. Locate in correct relationship to other water conditioning equipment. if closer than 10 feet please install check valve in

accordance with local plumbing codes.

4. Conditioners should be located in the supply line before the water heater. Temperatures above 110°F (43°C ) will cause

damage to conditioners.

5. Do not install a filter or filter in a location where freezing temperatures occur. Freezing may cause permanent damage to

this type of equipment and will void the factory warranty.

6. Allow sufficient space around the unit for easy servicing.

7. Keep the filter out of direct sunlight. The sun’’s heat may soften and distort plastic parts.

Plug the Riser

Tube

Upper

Diffuser

a

The riser

(distributor)

remains inside

the tank seated in

the depression at

the bottom

a b c

13

Inlet

Outlet

NOTE

If the plumbing system is

used as the ground leg of

the electric supply, conti-

nuity should be maintained

by installing ground straps

around any nonconductive

plastic piping used in

installation.

NOTE

Before starting installation,

read page 16, Plumbing

System Clean-Up, for in-

structions on some proce-

dures that may need to be

performed first.

Facts to Remember When Planning Your Installation

1. All installation procedures must conform to local and state or provincial plumbing codes.

2. Outside faucets used to water lawns and gardens should not supply untreated water, replace untreated water with feed water

to the unit. If necessary to do this please install check valve, see page 14. A new water line is often required to be connected to

supply untreated water to the inlet of the water lter and to the outside faucets.

3. Make sure the bypass is attached well to the control valve. Connect the straight or elbow connectors to the bypass with red

clips. Connect the inlet and outlet of the water lter to the plumbing of the house.The control valve must not be submitted

to temperatures above 43°C (110°F).When sweat ttings are used, to avoid damaging the control valve, solder the threaded

copper adapters to the copper pipe and then, using Teon tape, screw the assembly into the bypass valve.

Do not use pipe thread compound as it may attack the material in the valve body.

4. Apply Teon Tape and Orings to the ttings

5. Connect Filter to the house plumbing. Any solder joints near the valve must be done before connecting any piping to the valve.

Always leave at least 6”(152 mm) between the valve and joints when soldering pipes that are connected to the valve. Failure to

do this could cause damage to the valve.

6. Drain Line connection: UsingTeon tape, screw the 1/2”hose barb and attach oring into the drain port in the valve. Attach

1/2”drain hose (Supplied with some models and brands) to the hose barb and tighten securely with a hose clamp (Supplied

with some models and brands). Run the drain line to a oor drain or a laundry drain. Complete any necessary plumbing.

7. Using the Allen Key (included), place the unit in the bypass position. Slowly turn on the main water supply. At the nearest cold

treated water tap nearby remove the faucet screen, open the faucet and let water run a few minutes or until the system is free

of any air or foreign material resulting from the plumbing work.

8. Make sure there are no leaks in the plumbing system before proceeding. Close the water tap when water runs clean.

9. Open the brine tank / cabinet salt lid and add water until there is approximately 3”(75 mm) of water in the tank. Do not add

salt to the brine tank at this time.

1. Determine the best location for your water filter, bearing in mind the location of your water supply lines, drain line and 120 volt AC electrical outlet. Subjecting the filter to

freezing or temperatures above 43°C (110°F) will void the warranty.

INSTALLATION STEPS

Please notice the inlet and outlet arrows

on the valve as shown here to determine

the position of the equipment

14

3/8” Brine Tube

Optional

Pipes Fixed

Structure

Brine Valve

Connector Detail

5/8” Overow Line

Brine Tank

Bypass

Assembly

Optional

Overow

Assembly

AC120V/10A

Current Protect Socket

Water Pipe

In

let

Check Valve

Water Pipe Outlet

Drain Elbow

Assembly

Brine Elbow

Assembly

Main Tank

5/8” Clean-Out

Line

Floor drain

Outlet

Inlet

1 1/2 or 2 inch

standpipe

drain

AG100-001

Air Gaps

5/8”

Clean-Out

Line

5/8”

Over Flow

Line

Cold (Raw water)

Cold (Filtered water) Cold (Raw water)

Water Heater

Tee to outside or high demand unltered water

Hot (Soft Water)

Water Rener

Check Valve

(Optional)

In In Out

Out

Cold (Soft Water)

T

o Outside Faucet

WATER CONDITIONER INSTALLATION

Connect Conditioner to the HousePlumbing Any solder joints near the valve must be done before connecting any piping to the valve. Always leave at least 6”(152 mm)

between the valve and joints when soldering pipes that are connected to the valve. Failure to do this could cause damage to the valve.

CAUTION!

Never insert drain line

directly into a drain, sewer line, or trap.

Always allow an air gap between the drain

line and the wastewater to prevent the

possibility of sewage being back-siphoned

into the conditioner.

NOTE

Waste connections or drain

outlet shall be designed and

constructed to provide for

connection to the sanitary

waste system through an

air-gap of 2 pipe diameters

or 1 inch (22 mm) whichever

is larger.

*NOTE

Check local plumbing codes

in regards to requirements

for use of Check Valve or

back flow prevention or

vacuum breaker

15

Start Up Procedures continued on Page 16

2. Screen Display

When power is supplied to the control,

the screen will display“INITIALIZING

WAIT PLEASE”

while it finds the service position.

MENU

SET

System initializing

Please wait

Familiarize with Button

Configuration:

MENU

SET

MENU

SET

This function accepts the values if changed and

advance to the next page in the menu

MENU

SET

MENU

SET

These buttons increase or decrease the value

of the settings while in the programming

mode.

This function enters the basic set

up information required at the time of installation.

Key Pad Configuration

MENU

SET

Date and Time

18-Apr-2018 10:35AM

Gal Remain 1400

Flow Rate 3 gpm/min

The controller will show the

following on the screen: Time,

Date and Gallons Remaining for

Regeneration

Power

Connector

Sample

Connection

Sample

Connection

SERVICE

BYPASS

Sample

Connection

Sample

Connection

SERVICE

BYPASS

Date and Time

Hardness

Manual Regen.

Dealer Information

Main Menu

Regen. Now?

Regen. Tonight?

Press To Cancel

Press To Conrm

Brine Drawing

Any Key 3sTo Next

13:59

18%

18%

Backwashing

Any Key 3S to Next

Rinsing

Any Key 3S to Next

Skip this cycle by

pressing any key for 3

seconds

IMPORTANT!

Complete

the Backwashing cycle

to let the air out of the

system

Complete this cycle to

settle the media

Brine Rell

Any Key 3S to Next IMPORTANT!

Complete this cycle to

let the air out of the

injector system

18%

18%

4. Manually Regenerate the Valve

If screen is locked, press MENU Key

for 5 seconds to unlock

Manually Regenerate theValve and move it to backwash

position. Press MENU Key and Scroll down

using Up and Down Arrow buttons to Manual Regen.

Press SET Select Regen Now

STARTUP INSTRUCTIONS

1. Connect the Transformer to the Valve

Plug the 12-volt transformer into a 120 VAC 60 Hz outlet.

BRINE TANK MODEL – Water to be Added at the

Time of Installation:

BTR-100 (18.1”x 34.7”) - 2.5 US Gallons

3. Add Water to Brine Tank

Open the brine tank Sodium Chloride lid and add

water as per the info below. Do not add Sodium

Chloride to the brine tank at this time.

16

Date and Time

Hardness

Manual Regen.

Dealer Information

Salt Reminder

Main Menu

= = Date and Time = =

17-Feb-2016 12:25pm

Press To Cancel

Press To Conrm

Setting Complete

Press To Return

Auto On

Date and Time

Hardness

Manual Regen.

Dealer Information

Salt Reminder

Main Menu

Setting Complete

Press To Return

Date and Time

Hardness

Manual Regen.

Dealer Information

Salt Reminder

Main Menu

=Hardness =

25 GPG

Press To Cancel

Press To Conrm Nuvia Water Technologies

108 Business Center Dr,

Corona, CA 92880, USA

Setting Complete

Press To Return

Date and Time

Hardness

Manual Regen.

Dealer Information

Salt Reminder

Main Menu

= Main Menu =

Regen. Time Setting

System Capacity

Salt Mode Setting

Advanced Menu

= = Regen. Time = =

02:25AM

Press To Cancel

Press To Conrm

Setting Complete

Press To Return

Date and Time

Hardness

Manual Regen.

Dealer Information

Salt Reminder

Main Menu

Setting Complete

Press To Return

Salt Reminder

ON OFF

Press To Cancel

Press To Conrm

Dealer

information

input letter

by letter

SET UP

REGENERATION

TIME:

SET UP CURRENT

TIME OF THE DAY AND

HARDNESS:

Press

Set Key

till you

hear

“Beep”

5.

ADD SODIUM TO THE

BRINE TANK

Put 88 lbs of crystal water refiner

sodium in the brine tank. The unit

will automatically fill the water to

the correct level when

it regenerates.

START UP AND PROGRAMMING COMPLETE.

UNIT IS NOW OPERATIONAL.

PROGRAMMING THE CONDITIONER

Press“MENU”Key

MENU

SET

and Select“Date and Time”using“SET”

MENU

SET

Button and set for setting the regeneration time, Press“MENU”Key

MENU

SET

and Select Main Menu till you hear

a beep and select Regen time.

NOTE** All units are factory programmed for the correct size and regeneration cycle alteration should only be done by a factory

trained technician or after consultation with one of our technical representatives if you have any questions please contact:

Evince® Direct Phone Number: 951.734.7400

STARTUP INSTRUCTIONS (CONTINUED)

4. Manually Regenerate the Valve (Continued)

4a. Open the inlet on the bypass valve slightly and very slowly allow water to enter the unit. (If the water enters too quickly it will push the media or carbon up into the control

valve and get plugged).

Once the unit has filled sufficiently that water is at least equal to the height of the top of the media shut down the water for 15 – 20 minutes for the carbon to soak. Unplug the

power cable. After the carbon has soaked for the recommended time continue.

4b. Open the inlet on the bypass valve slowly and allow water to enter the unit. (The outlet of the bypass should remain closed to prevent any fines or debris from entering the

plumbing system. Allow all air to escape from the unit before turning the water on fully then allow water to run to drain for 3-4 minutes, or until the water at the drain

appears to be clear of any fines.

5. Plug in the valve and the valve will automatically advance to the SERVICE position. Open the outlet valve on the bypass, then slowly open the nearest treated water faucet and

allow the water to run until clear, close the tap and replace the faucet screen.

6. The Valve is already programmed by the factory. Please continue with set up of current time and hardness.

17

Sample

Connection

Sample

Connection

SERVICE

BYPASS

Sample

Connection

Sample

Connection

SERVICE

BYPASS

BYPASS

DURING REGENERATION

Automatic Water Bypass

The regeneration cycle lasts approximately 1.5 hours to 3.0 hours depending on the specic model, after which treated water service will be restored. During regeneration,

untreated water is automatically bypassed for use in the household. Hot water should be used as little as possible during this time to prevent hard water from lling the water

heater.

IMPORTANT: Automatic regeneration is set for sometime during the night and manual regenerations should be performed when little or no water will be

used in the household.

Manual Water Bypass

In case of an emergency or when performing maintenance, you can isolate your water conditioner from the water supply using the bypass valve located at the back of the control.

In normal operation the bypass is open with the ON/OFF knobs in line with the INLET and OUTLET pipes.To isolate the conditioner, simply rotate the knobs clockwise (as indicated

by the word BYPASS and arrow) until they lock. You can use your water related xtures and appliances as the watersupply is bypassing the conditioner. However, the water you

use will be hard. To resume treated service, open the bypass valve by rotating the knobs counterclockwise. Please make sure bypass knobs are completely open otherwise

the unconditionered water could bypass through the valve.

New Sounds

You may notice new sounds as your water conditioner operates.The regeneration cycle lasts approximately 1.5 hours to 3.0 hours depending on the specic model. During this

time, will be able to hear water running intermittently to the drain, depending on proximity of the unit to sleeping area and time of regeneration.

PLUMBING SYSTEM CLEAN-UP

The following procedures are guidelines only but have proven successful in most instances. Under no circumstances should any procedure outlined below be followed if contrary

to the appliance manufacturer’s instructions. Should there by any questions concerning the advisability of performing a procedure, it is strongly recommended the manufactur-

er’s authorized service outlet be consulted prior to performing the procedure.

Water Heater

If the water heater has been exposed to both iron and hardness for a long period of time, replacement of the heater tank maybe the only practical solution to prevent continued

staining originating from this source. After completing the installation of the conditioner, clean the water heater by following these instructions:

1. Shut o energy supply to water heater and close heater inlet water valve.

2. Drain hot water tank completely. Open inlet water valve allowing heater tank to be relled with iron-free water. Continue ushing until water runs clear to drain.

3. If, after approximately 30 minutes ushing, water does NOT clear, terminate ushing operation. Rell hot water heater with water and pour approximately 1/2 gallon of

household bleach into top of heater tank. Allow bleach solution to stand in tank for 20 to 30 minutes. Flush tank

Dishwasher

Consult owners’handbook and follow manufacturer’s instructions.

Toilet Flush Tanks

Prior to commencing installation of the conditioner system, pour 4 to 6 ounces of resin mineral cleaner Pro-Rust Out or or other suitable cleaner such as CLR that contains a mild

acid into ush tanks and bowls and let stand. When installation is completed, ush toilets several times with conditioned water. If stains or deposits return check that lines are

connected to treated water. Repeat procedure until clear. again until water is clear at drain. Turn energy supply on.

NOTE

If water does not clear in

approximately 10 minutes,

water heater should

probably be replaced.

18

CAUTION!

Never subject your conditioner to

freezing, vacuum or to

temperatures above 43°C (110°F).

Service Schedule

The seals and spacers along with the piston assembly should be inspected/cleaned or replaced every year depending on the inlet water quality and water usage on clean

municipal supplies every 2 - 3 years should be sucient but the rst check should be done after 1 year. See inspection and replacement of Piston assembly and seal and spacer

kit, page 26.

The injectors should be cleaned/inspected or replaced every year depending on the water quality and use. See Clean Injector Assembly, page 27.

Maintenance of your new water conditioner requires very little time or eort but it is essential. Regular maintenance will ensure many years of ecient and trouble free operation.

FAILURE TO FOLLOW BASIC MAINTENANCE SCHEDULE WILL RESULT IN THE UNIT FAILING TO OPERATE PROPERLY AND VOID YOUR

WARRANTY.

CAUTION!

Liquid brine will irritate eyes,

skin and open wounds -

gently wash exposed area

with fresh water. Keep

children away from

your water conditioner.

Bridging

Humidity or the wrong type of Sodium Chloride may create a cavity between the

water and the Sodium Chloride.This action, known as“bridging”, prevents the

brine solution from being made, leading to your water supply being hard.

If you suspect Sodium Chloride bridging, carefully pound on the outside of the

plastic brine tank or pour some warm water over the Sodium Chloride to break

up the bridge.This should always be followed up by allowing the unit to use

up any remaining Sodium Chloride and then thoroughly cleaning out the brine

tank. Allow four hours to produce a brine solution, then manually regenerate the

conditioner.

Cleaning of your Brine / Sodium Chloride tank

Sodium Chloride tanks will build up sludge (undissolved Sodium Chloride) in the bottom of them that will continue to increase as time goes by. Every 2 - 3 years the Sodium

Chloride tank should be cleaned out completely and re started using the original start up instructions.

MAINTENANCE INSTRUCTIONS AND SCHEDULE

System Check List

NOTE** All units are factory programmed for the correct size and regeneration cycle alteration should only be done by a factory

trained technician or after consultation with one of our technical representatives if you have any questions please call:

951.734.7400

4a. Open the inlet on the bypass valve slightly and very slowly allow water to enter the unit. (If the water enters too quickly it will push the media up into the control valve and

get plugged).

Once the unit has lled suciently that water is at least equal to the height of the top of the media shut down the water for 15 – 20 minutes for the media bed to soak. Unplug the

power cable. After the media bed has soaked for the recommended time continue.

4b. Open the inlet on the bypass valve slowly and allow water to enter the unit. (The outlet of the bypass should remain closed to prevent any nes or debris from entering the

plumbing system. Allow all air to escape from the unit before turning the water on fully then allow water to run to drain for 3-4 minutes, or until the water at the drain

appears to be clear of any nes.

4c. Plug in the valve. Allow the valve to continue its cycles until complete and back in service

4d. TheValve is already programmed from factory. Please set up date and time of day and feedwater iron as shown below:

19

Salt

Water

Checking the Sodium Chloride Level

Check the Sodium Chloride level monthly. Remove the lid from the cabinet or brine tank, make sure Sodium Chloride level is

always above the brine level.

Add Sodium Chloride to the Brine Tank

Put 40 kgs of crystal water conditioner Sodium Chloride in the brine tank. The unit will automatically ll the water to the correct

level when it regenerates. Use only clean Sodium Chloride labeled for water conditioner use, such as crystal, pellet, nugget,

button or solar. The use of rock Sodium Chloride is discouraged because it contains insoluble silt and sand which build up in the

brine tank and can cause problems with the system’s operation. Add the Sodium Chloride directly to the tank, lling no higher

than the top of the brine well.

NOTE :THE WATER LEVEL SHOULD BE BELOW THE Sodium Chloride LEVEL ALL THE TIME

CAUTION!

Incorrect start up, water

above the Sodium Chloride

level, (not enough Sodium

Chloride in tank) will both

effect the units capacity and

result in hardness slippage.

Should either of these situa-

tions happen or the unit fails

to regenerate for any other

reason please first correct

the problem. Then regen-

erate the unit manually 2

times in a row to restore the

reserve capacity and bring

the media bed back up to

specification.

IMPORTANT WARRANTY AND MAINTENANCE INFORMATION

Model number:

Serial number:

Valve Serial number:

Date installed:

Please have the information below lled out and available when calling in for parts or warranty:

Additional notes:

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

MAINTENANCE INSTRUCTIONS AND SCHEDULE

20

5/8" hole in brine

well cap

Res-up feeder

1/4” Holes

Care of Your Conditioner

To retain the attractive appearance of your new water conditioner, clean occasionally with a mild soap solution. Do not use abrasive cleaners, ammonia or solvents. Never subject

your conditioner to freezing or to temperatures above 43°C (110°F).

Servicing Components

The injector assembly should be cleaned or replaced every year depending on the inlet water quality and water usage.

The seals and spacer should be inspected/cleaned or replaced every year depending on the inlet water quality and water usage.

Please refer to the servicing section of this manual for step by step procedure.

Not following the above will void all warranty on the control valve.

Resin Cleaner

An approved resin cleaner MUST be used on a regular basis if your water supply contains iron.The amount of resin cleaner and frequency of use is determined by the quantity of

iron in your water (consult your local representative or follow the directions on the resin cleaner package).

Res-up Feeder Bottle (Chemical sold Separately)

The 12 cc feeder (Part # 33010) is for conditioners up to 64,000 grains (2 ft3 of

resin).

The 30 cc feeder (Part # 33018) is for larger conditioners over 64,000 grains.

Pro-Res Care Chemicals

Item #45147 Pro-ResCare - Gallon

Item #45148 Pro-ResCare - Quart

1. Install the grid and brine well inside the tank. 3. Mark the location of the holder and drill.2. Measure 2 inches from the top of the tank beside

the oblong molding.

RES-UP®FEEDER INSTALLATION INSTRUCTIONS

(OPTIONAL)

Res-Up Feeders attach to your brine tank and automatically dispense the Res-Up cleaner into the brine solution where it

cleans the resin during the regeneration cycle.

The feeder hooks onto the tube inside your brine tank and you just pour some chemical in it and your water conditioner

should last signicanly longer. A res-up feeder is essential if your raw water contains measurable amounts of iron.

Install Resup Feeder

This manual suits for next models

3

Table of contents

Other Evince Water Filtration System manuals

Popular Water Filtration System manuals by other brands

LifeSource

LifeSource ScaleSolver SSC-4025 Installation, operation and maintenance manual

Tetrafauna

Tetrafauna ReptoFilter instructions

Watts

Watts OneFlow OF1260-30TM Installation, operation and maintenance manual

Graf

Graf MINIMAX 340060 Installation and maintenance instructions

Buhler

Buhler AGF-VA-350 Installation and operation instruction

Watts

Watts OneFlow OF110-1 Nstallation, operation and maintenance manual