evoheat Solace 2.5 User manual

SOLACE SERIES

SWIMMING POOL DEHUMIDIFIER

Installation & Operation Manual

CONTENT

1

2

2

2

2

3

4

4

5

6

7

8

9

10

11

13

13

15

16

16

6

7

1. Preface

1

Fig.1

main unit wall suspension bar manual

Thank you for choosing Swimming Pool Dehumidifier for controlling the climate in you pool

area. This product strictly complies with design and production standards to provide perfect

performance, high reliability and good adaptability for you.

Read the entire manual before the initial start-up of the unit. It is important to know the correct

operating procedures for the unit and all safety precautions to prevent the possibility of

property damage and/or personal injury. Do not modify or intervene on the unit by yourself

only as this could create dangerous situations and the manufacturer will not be responsible

for any damage caused.

This instruction must be kept carefully and must always accompany the appliance. If it is

lost or damaged, please contact the local technical service center.

1.1 Fail to comply with these recommendations will invalidate the warranty.

¡This unit must be installed by an authorized installer.

¡All repair or maintenance interventions must be performed by the technical service

department or by professionally qualified personnel.

¡All repair or maintenance interventions must be performed in the specified period and

times.

¡Use the spare parts ONLY provided by the manufacturer.

1.2 In case of system leakage, disconnect the power to the unit and call the technical service

department or other professionally qualified personnel as soon as possible, and do not

intervene personally on the appliance.

If the unit is not used for a long time, you should disconnect the power to the unit.

1.3 Packing List (Fig.1)

1. Preface

2.

2.1 Marks

2.2 Icons

2.3

3. Specifications

3.1 Parameters

3.2 Performance Curve

3.3 Dimensions

3.4 Working Principle

3.5 Product Features

3.6 Hygrostat Control

4. Installation

5.Usage

5.1 Instruction for Operation Panel

5.2 Operation Instruction

6.Maintenance

7.1 PCB I/O Port

7.2 Wiring Diagram

Safety Precautions

Warnings

2.4 Attention

4.1 Installation Precautions

4.2 Positioning

4.3 Minimum Installation Distances

4.4 Drainage

6.2 Troubleshootings

7.Appendix

6.1 Maintenance

expansion bolts

8

8

10

17

8

CONTENT

1

2

2

2

2

3

4

4

5

6

7

8

9

10

11

13

13

15

16

16

6

7

1. Preface

1

Fig.1

main unit wall suspension bar manual

Thank you for choosing Swimming Pool Dehumidifier for controlling the climate in you pool

area. This product strictly complies with design and production standards to provide perfect

performance, high reliability and good adaptability for you.

Read the entire manual before the initial start-up of the unit. It is important to know the correct

operating procedures for the unit and all safety precautions to prevent the possibility of

property damage and/or personal injury. Do not modify or intervene on the unit by yourself

only as this could create dangerous situations and the manufacturer will not be responsible

for any damage caused.

This instruction must be kept carefully and must always accompany the appliance. If it is

lost or damaged, please contact the local technical service center.

1.1 Fail to comply with these recommendations will invalidate the warranty.

¡This unit must be installed by an authorized installer.

¡All repair or maintenance interventions must be performed by the technical service

department or by professionally qualified personnel.

¡All repair or maintenance interventions must be performed in the specified period and

times.

¡Use the spare parts ONLY provided by the manufacturer.

1.2 In case of system leakage, disconnect the power to the unit and call the technical service

department or other professionally qualified personnel as soon as possible, and do not

intervene personally on the appliance.

If the unit is not used for a long time, you should disconnect the power to the unit.

1.3 Packing List (Fig.1)

1. Preface

2.

2.1 Marks

2.2 Icons

2.3

3. Specifications

3.1 Parameters

3.2 Performance Curve

3.3 Dimensions

3.4 Working Principle

3.5 Product Features

3.6 Hygrostat Control

4. Installation

5.Usage

5.1 Instruction for Operation Panel

5.2 Operation Instruction

6.Maintenance

7.1 PCB I/O Port

7.2 Wiring Diagram

Safety Precautions

Warnings

2.4 Attention

4.1 Installation Precautions

4.2 Positioning

4.3 Minimum Installation Distances

4.4 Drainage

6.2 Troubleshootings

7.Appendix

6.1 Maintenance

expansion bolts

8

8

10

17

8

23

Remember that some fundamental safety rules should be followed when using this product:

1. This appliance is not intended for use by persons(including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play with the appliance.

2. It is forbidden to touch the appliance with wet hands or body when barefoot.

3. It is forbidden to carry out any cleaning before having disconnected the appliances from the

electricity mains supply by turning the system master switch to OFF.

4. It is forbidden to modify the safety or adjustment devices or adjust without authorization and

indication of the manufacturer.

5. It is forbidden to pull, cut or knot the electrical cables coming out of the appliance, even if it is

disconnected from the mains supply.

6. If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard.

7. It is forbidden to poke objects or anything else through the inlet or outlet grills.

8. It is forbidden to dispose of or leave in the reach of children the packaging materials which

could become a source of danger.

9. It is forbidden to climb onto the appliance or rest any object on it.

10. It is forbidden to touch the unit with hands directly as the external parts of the appliance can

reach temperatures of more than 70→.

11. The appliance shall be installed in accordance with national wiring regulations.

INSTALLATION

Fix the unit

Need circuit breaker Make sure that there is circuit breaker for the unit. Lack of

circuit breaker can lead to electrical shock or fire.

Prohibit

Please use the suitable fuse.

If copper or icon is used to replace the fuse, it will cause

failure, even fire.

Ö Ì µ ° ×

OPERATION

Check the installation

basement

Disconnect the power

Please check the installation basement regularly to avoid

any decline or damage which may hurt people or damage

the unit.

Please disconnect the power to the unit for clean or

maintenance.

Make sure that the basement of the unit is strong enough

to avoid any decline or fall down.

Meaning

Meaning

2.4 Attention

Mark Meaning

A wrong operation may lead to death or heavy injury on people.

A wrong operation may lead to harm to people or loss of property.

WARNING

ATTENTION

Entrust a specialized personnel for installation. Wrong installation

may cause leakage, personnel electric shock or fires.

Confirm whether wether the unit is with correct earthing. Wrong

connection may cause personnel shock.

INSTALLATION

PROFESSIONAL

INSTALLER IS REQUIRED

EARTHING

IS REQUIRED

Icon Meaning

Prohibition. What is prohibited will be nearby this icon.

Compulsory implement. The listed actions need to be taken.

Attention(include warnings)

Please pay attention to what is indicated.

Do not put fingers or others into the fan or evaporator of the unit,

otherwise harm may be occurred.

OPERATION

PROHIBITION

SHUT OFF

THE POWER

When the unit needs to be moved or installed again, please entrust

dealer or qualified person to carry it out. Improper installation may lead to

water leakage, electrical shock, injury or fire.

It is prohibited to repair the unit by the user himself, otherwise electrical

shock or fire may occur.

When the unit needs to be repaired, please entrust dealer or qualified

person to carry it out. Improper movement or repair on the unit may lead to

water leakage, electrical shock, injury or fire.

MOVE AND REPAIR

ENTRUST

ENTRUST

PROHIBIT

2.1 Marks

2.2 Icons

2.3 nWar ings

When there is something wrong or strange smell from the unit, please cut

off the power to the unit immediately.

2. Installation Precautions 2. Installation Precautions

Warinng:

23

Remember that some fundamental safety rules should be followed when using this product:

1. This appliance is not intended for use by persons(including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play with the appliance.

2. It is forbidden to touch the appliance with wet hands or body when barefoot.

3. It is forbidden to carry out any cleaning before having disconnected the appliances from the

electricity mains supply by turning the system master switch to OFF.

4. It is forbidden to modify the safety or adjustment devices or adjust without authorization and

indication of the manufacturer.

5. It is forbidden to pull, cut or knot the electrical cables coming out of the appliance, even if it is

disconnected from the mains supply.

6. If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard.

7. It is forbidden to poke objects or anything else through the inlet or outlet grills.

8. It is forbidden to dispose of or leave in the reach of children the packaging materials which

could become a source of danger.

9. It is forbidden to climb onto the appliance or rest any object on it.

10. It is forbidden to touch the unit with hands directly as the external parts of the appliance can

reach temperatures of more than 70→.

11. The appliance shall be installed in accordance with national wiring regulations.

INSTALLATION

Fix the unit

Need circuit breaker Make sure that there is circuit breaker for the unit. Lack of

circuit breaker can lead to electrical shock or fire.

Prohibit

Please use the suitable fuse.

If copper or icon is used to replace the fuse, it will cause

failure, even fire.

Ö Ì µ ° ×

OPERATION

Check the installation

basement

Disconnect the power

Please check the installation basement regularly to avoid

any decline or damage which may hurt people or damage

the unit.

Please disconnect the power to the unit for clean or

maintenance.

Make sure that the basement of the unit is strong enough

to avoid any decline or fall down.

Meaning

Meaning

2.4 Attention

Mark Meaning

A wrong operation may lead to death or heavy injury on people.

A wrong operation may lead to harm to people or loss of property.

WARNING

ATTENTION

Entrust a specialized personnel for installation. Wrong installation

may cause leakage, personnel electric shock or fires.

Confirm whether wether the unit is with correct earthing. Wrong

connection may cause personnel shock.

INSTALLATION

PROFESSIONAL

INSTALLER IS REQUIRED

EARTHING

IS REQUIRED

Icon Meaning

Prohibition. What is prohibited will be nearby this icon.

Compulsory implement. The listed actions need to be taken.

Attention(include warnings)

Please pay attention to what is indicated.

Do not put fingers or others into the fan or evaporator of the unit,

otherwise harm may be occurred.

OPERATION

PROHIBITION

SHUT OFF

THE POWER

When the unit needs to be moved or installed again, please entrust

dealer or qualified person to carry it out. Improper installation may lead to

water leakage, electrical shock, injury or fire.

It is prohibited to repair the unit by the user himself, otherwise electrical

shock or fire may occur.

When the unit needs to be repaired, please entrust dealer or qualified

person to carry it out. Improper movement or repair on the unit may lead to

water leakage, electrical shock, injury or fire.

MOVE AND REPAIR

ENTRUST

ENTRUST

PROHIBIT

2.1 Marks

2.2 Icons

2.3 nWar ings

When there is something wrong or strange smell from the unit, please cut

off the power to the unit immediately.

2. Installation Precautions 2. Installation Precautions

Warinng:

3.1 Parameters

Swimming Pool Dehumidifier

3. Specifications

4

Test condition: Ambient temperature: 27→,Relative humidity: 60%.

Solace 1.75

Solace 1.25

Unit

L/h

3

m /h

dB(A)

/

kW

A

kW

A

%RH

¡

mm

kg

/

MPa

Mpa

mm

Solace 1.25

1.25

400

44

0.78

3.3

1.1

4.9

40~100

Solace 1.75

1.75

500

46

1.08

4.7

1.4

6.1

40~100

220-240V~/50Hz

10 ~ 36

See nameplate/ package label

R410A/600g

See 3.3

Operation Pressure( Side)High

Operation Pressure( Side)Low

Condensation Pipe Diameter

4.4

2.1

16

4.4

2.1

16

3. Specifications

5

Model

Rated Capaclty

Air Volume

Nolse Level

Rated Voltage/Freq

Rated Power Input

Rated Running Current

Max Power Input

Max Running Current

Relative Humidity

Temperature

Dimensions(L/W/H)

Net Weight

Refrigerant/Volume

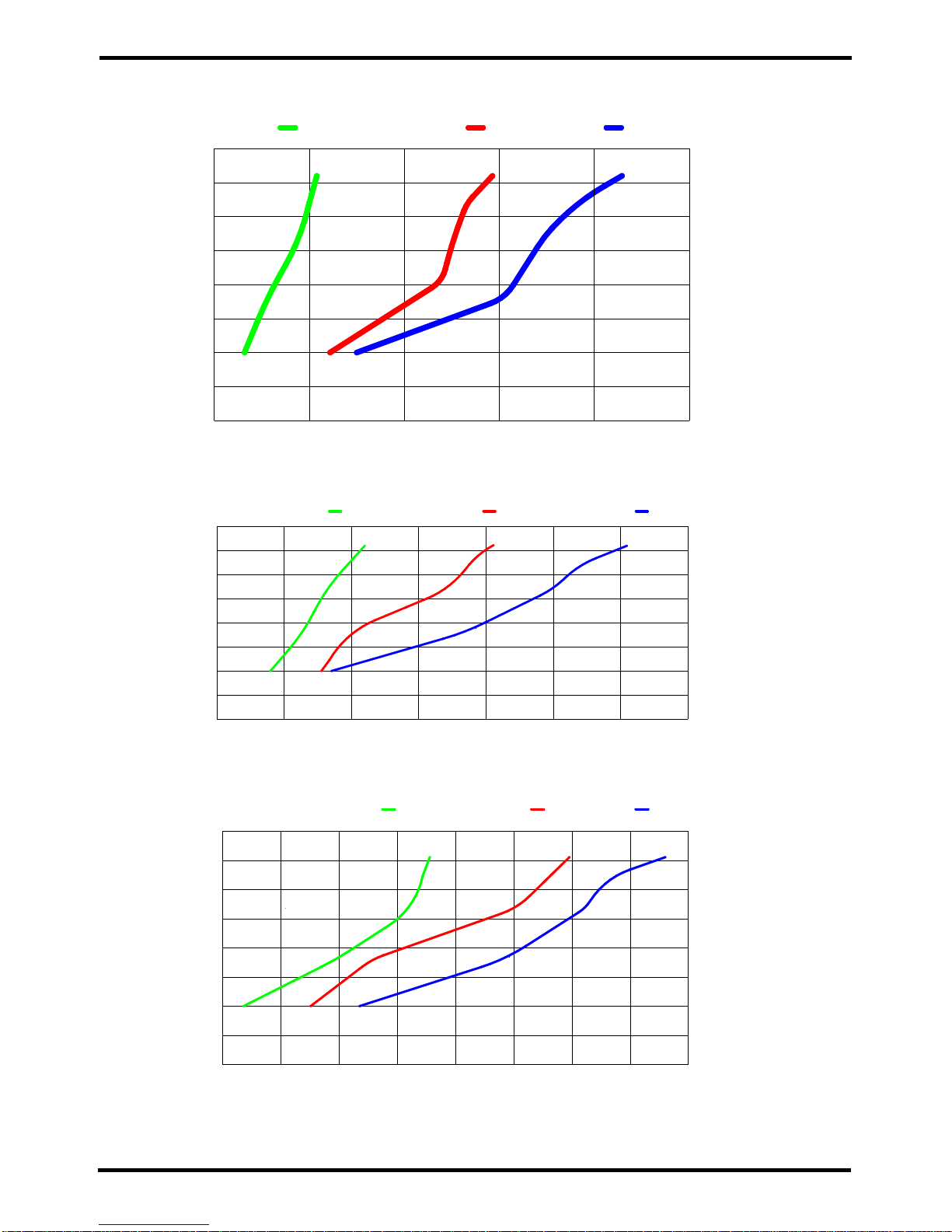

3.2 Performance Curve

4.4

2.1

16

Solace 2.5

Solace 2.5

2.5

750

47

1.55

6.7

2.1

9.1

40 100~

R410A/800g R410A/1050g

40

35

30

25

20

15

10

5

00 0.5 1.0 1.5 2.0 l/h

C

040%RH

2.5

60%RH 80%RH

40

35

30

25

20

15

10

5

00 0.5 1.0 1.5 2.0 l/h

C

040%RH

3.5

60%RH 80%RH

2.5 3.0

40

35

30

25

20

15

10

5

00 0.5 1 1.5 2 2.5 3 3.5 l/h

C

0

4

40%RH 60%RH 80%RH

3.1 Parameters

Swimming Pool Dehumidifier

3. Specifications

4

Test condition: Ambient temperature: 27→,Relative humidity: 60%.

Solace 1.75

Solace 1.25

Unit

L/h

3

m /h

dB(A)

/

kW

A

kW

A

%RH

¡

mm

kg

/

MPa

Mpa

mm

Solace 1.25

1.25

400

44

0.78

3.3

1.1

4.9

40~100

Solace 1.75

1.75

500

46

1.08

4.7

1.4

6.1

40~100

220-240V~/50Hz

10 ~ 36

See nameplate/ package label

R410A/600g

See 3.3

Operation Pressure( Side)High

Operation Pressure( Side)Low

Condensation Pipe Diameter

4.4

2.1

16

4.4

2.1

16

3. Specifications

5

Model

Rated Capaclty

Air Volume

Nolse Level

Rated Voltage/Freq

Rated Power Input

Rated Running Current

Max Power Input

Max Running Current

Relative Humidity

Temperature

Dimensions(L/W/H)

Net Weight

Refrigerant/Volume

3.2 Performance Curve

4.4

2.1

16

Solace 2.5

Solace 2.5

2.5

750

47

1.55

6.7

2.1

9.1

40 100~

R410A/800g R410A/1050g

40

35

30

25

20

15

10

5

00 0.5 1.0 1.5 2.0 l/h

C

040%RH

2.5

60%RH 80%RH

40

35

30

25

20

15

10

5

00 0.5 1.0 1.5 2.0 l/h

C

040%RH

3.5

60%RH 80%RH

2.5 3.0

40

35

30

25

20

15

10

5

00 0.5 1 1.5 2 2.5 3 3.5 l/h

C

0

4

40%RH 60%RH 80%RH

3. Specifications

3.5.1 Ultra-low noise

With the advanced air ducting technology and the super quiet cross-flow fan, the unit can

operate with ultra-low noise.

3.5.2 Ultra-thin casing

With the ultra-thin casing of 200mm, which is the result of compact design, the unit can

save more space for you when it is compared with the common dehumidifierswith the

thickness of 400mm.

3.5.3 Fashionable appearance

With noble &fashion arc frame and elegant & graceful snow white color, the unit will be

perfectly combined with your pool house.

3.5.4 Newly design controller.

With simple operating display, the newly developed controller makes the unit operation

easier and more user-friendly.

3.6.1 The dehumidifier is controlled by a built-in hygrostat set on one side of the unit and

the target RH value can be set ranges from 30% to 90%.

3.6.2 The unit will not start to dehumidify until the actual RH is beyond the setting value.

3.6.3 We recommend that an external hygrostat should be installed to ensure a constant

measure of the humidity in the pool area.

3.6.4 The location of hygrostat is as the following Fig.4:

3.6 Hygrostat Control

3.5 Product Features

7

Built-in hygrostat

Fig.4

Warm damp air

Warmer & dehumidified air

3.4 Working Principle:

6

Fig.3

The unit works by drawing moist air over a refrigerated coil with a small fan. The cold coil of

the refrigeration device condenses the water, which is removed, then the air is reheated by the

hot coil. This process works most effectively with higher ambient temperatures with a high

dew point temperature(Fig.3).

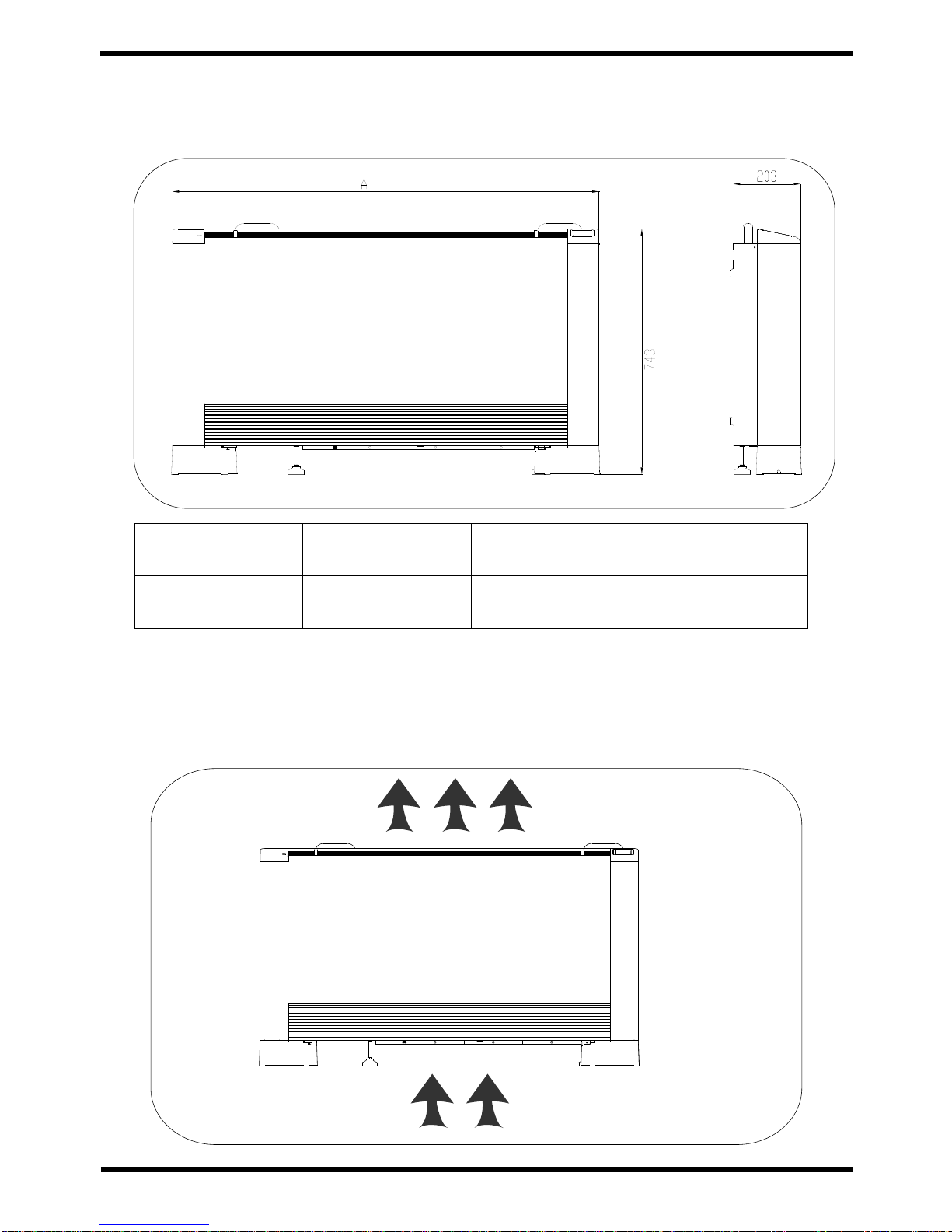

Model Solace 1.75

Solace 1.25

Length: A 1300 1500

3.3 Dimensions

3.3.1 Model: Solace 1.25/1.75/2.5

Fig.2

3. Specifications

1500

Solace 2.5

3. Specifications

3.5.1 Ultra-low noise

With the advanced air ducting technology and the super quiet cross-flow fan, the unit can

operate with ultra-low noise.

3.5.2 Ultra-thin casing

With the ultra-thin casing of 200mm, which is the result of compact design, the unit can

save more space for you when it is compared with the common dehumidifierswith the

thickness of 400mm.

3.5.3 Fashionable appearance

With noble &fashion arc frame and elegant & graceful snow white color, the unit will be

perfectly combined with your pool house.

3.5.4 Newly design controller.

With simple operating display, the newly developed controller makes the unit operation

easier and more user-friendly.

3.6.1 The dehumidifier is controlled by a built-in hygrostat set on one side of the unit and

the target RH value can be set ranges from 30% to 90%.

3.6.2 The unit will not start to dehumidify until the actual RH is beyond the setting value.

3.6.3 We recommend that an external hygrostat should be installed to ensure a constant

measure of the humidity in the pool area.

3.6.4 The location of hygrostat is as the following Fig.4:

3.6 Hygrostat Control

3.5 Product Features

7

Built-in hygrostat

Fig.4

Warm damp air

Warmer & dehumidified air

3.4 Working Principle:

6

Fig.3

The unit works by drawing moist air over a refrigerated coil with a small fan. The cold coil of

the refrigeration device condenses the water, which is removed, then the air is reheated by the

hot coil. This process works most effectively with higher ambient temperatures with a high

dew point temperature(Fig.3).

Model Solace 1.75

Solace 1.25

Length: A 1300 1500

3.3 Dimensions

3.3.1 Model: Solace 1.25/1.75/2.5

Fig.2

3. Specifications

1500

Solace 2.5

9

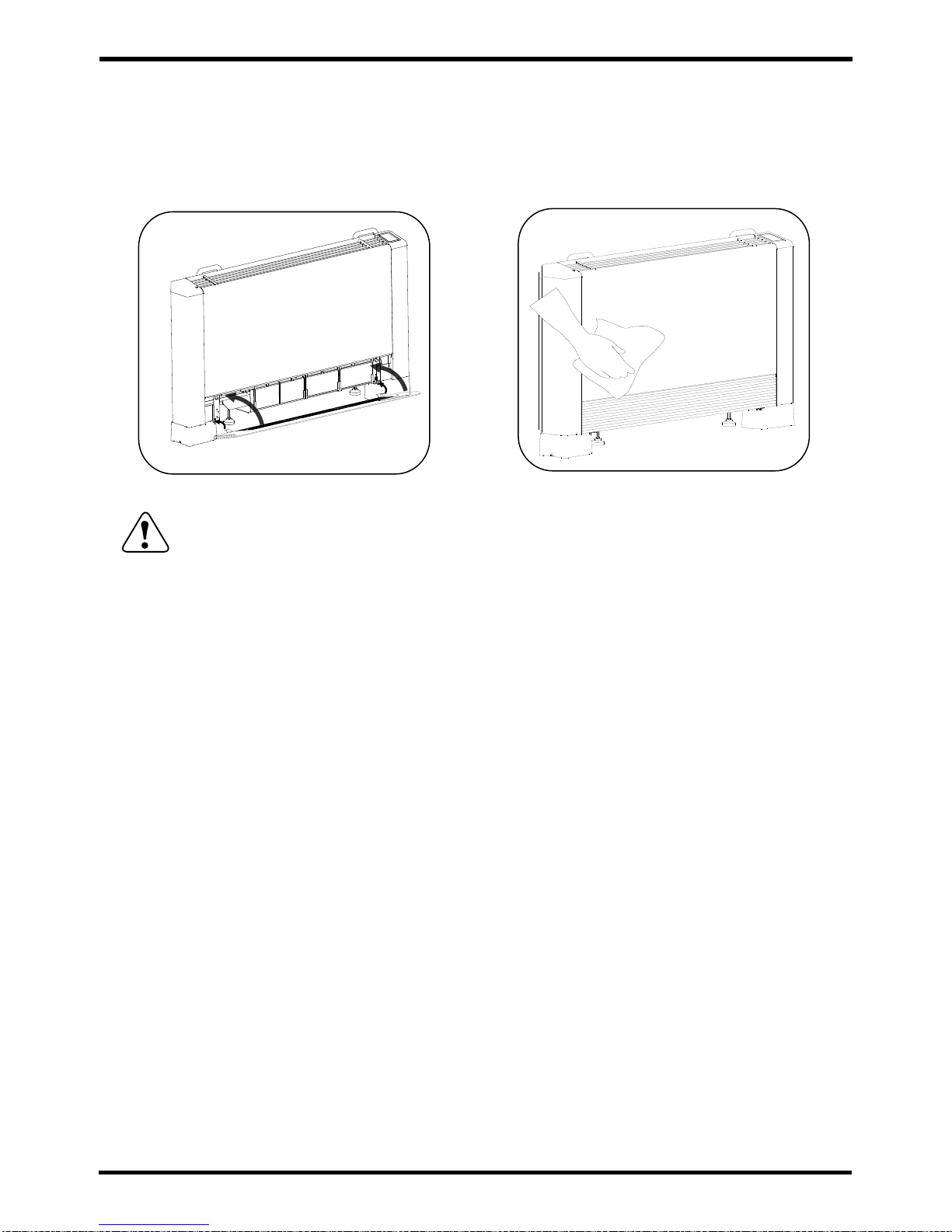

4.3.3 Wall mounted installation

Insert 5 expansion bolts into holes which are bored by ¦10 drill and fix the wall suspension

bar horizontally(Fig.6).

Attention£

If the condensation water discharges directly into a container, the condensate outlet

should above the container to avoid immersing in the container.

Select a suitable size hose to connect to the built-in hose if it is needed(Fig.7).

Condensate drainage hose

4.4 Drainage

Fig.6

Fig.7

4. Installation

Expansion bolt

Wall

Wall suspension bar

4. Installation

8

0.2m

0.5m

0.2m

0.5m

Fig.5

4.1 Installation Precautions

4.1.1 To ensure that the installation is performed correctly and that the appliance will perform

perfectly, please carefully follow the instructions indicated in this manual. Fail to respect the

rules indicated not only can cause malfunctions of the appliance but also invalidate the

warranty, hence our company shall not respond for any damage to persons, animals or

property.

4.1.2 It is important that the electrical installation is made according to the laws in force,

respects the data indicated in the technical sheet and the unit is correctly earthed.

4.1.3 The appliance must be installed in a position that allows the routine maintenance, such

as filter cleaning.

4.2 Positioning

4.2.1 Avoid installing the unit in proximity to:

-positions subject to exposure to direct sunlight;

-sources of heat;

-in places with oil fumes

-places subject to high frequencies.

4.2.2 Make sure that:

-the wall on which the unit is to be installed is strong enough to support the weight;

-the part of the installation wall does not have pipes or electric wires passing through;

-the installation wall is perfectly flat;

-there is an area free of obstacles which could interfere with the inlet and outlet air flow;

-it is preferably that there is an outside perimeter-wall to allow the discharge of condensation

outside;

4.3 Minimum Installation Distances

4.3.1

4.3.2 Fig. 5 indicates the minimum mounting distances between the wall-mounted swimming

pool dehumidifier and furniture in the room.

When the unit is for wall-mounted installation, please take off the all feet for floor

standing installation.

9

4.3.3 Wall mounted installation

Insert 5 expansion bolts into holes which are bored by ¦10 drill and fix the wall suspension

bar horizontally(Fig.6).

Attention£

If the condensation water discharges directly into a container, the condensate outlet

should above the container to avoid immersing in the container.

Select a suitable size hose to connect to the built-in hose if it is needed(Fig.7).

Condensate drainage hose

4.4 Drainage

Fig.6

Fig.7

4. Installation

Expansion bolt

Wall

Wall suspension bar

4. Installation

8

0.2m

0.5m

0.2m

0.5m

Fig.5

4.1 Installation Precautions

4.1.1 To ensure that the installation is performed correctly and that the appliance will perform

perfectly, please carefully follow the instructions indicated in this manual. Fail to respect the

rules indicated not only can cause malfunctions of the appliance but also invalidate the

warranty, hence our company shall not respond for any damage to persons, animals or

property.

4.1.2 It is important that the electrical installation is made according to the laws in force,

respects the data indicated in the technical sheet and the unit is correctly earthed.

4.1.3 The appliance must be installed in a position that allows the routine maintenance, such

as filter cleaning.

4.2 Positioning

4.2.1 Avoid installing the unit in proximity to:

-positions subject to exposure to direct sunlight;

-sources of heat;

-in places with oil fumes

-places subject to high frequencies.

4.2.2 Make sure that:

-the wall on which the unit is to be installed is strong enough to support the weight;

-the part of the installation wall does not have pipes or electric wires passing through;

-the installation wall is perfectly flat;

-there is an area free of obstacles which could interfere with the inlet and outlet air flow;

-it is preferably that there is an outside perimeter-wall to allow the discharge of condensation

outside;

4.3 Minimum Installation Distances

4.3.1

4.3.2 Fig. 5 indicates the minimum mounting distances between the wall-mounted swimming

pool dehumidifier and furniture in the room.

When the unit is for wall-mounted installation, please take off the all feet for floor

standing installation.

5.2 Operation Instruction

5.2.1 Unit ON/OFF

You can turn ON/OFF the unit by just pressing " " when the unit is connected to the power.

When the unit is turned on, you can see the actual relative humidity shown on the display. At

the same time, the mode indicator and the light for the ON/OFF button will be on.

Press " "to turn

the unit ON/OFF

OFF ON

5.2.2 Set the target value of relative humidity

Press" "

or " "

to check the

target relative

humidity

ÖÈÖÀ

µ·Ö·

11

ÖÈ

ÖÀ

µ·

%RH

ÖÈ

ÖÀ

µ·

%RH

Actual relative humidity

The selected mode

ÖÈ

ÖÀ

µ·

%RH

ÖÈ

ÖÀ

µ·

%RH

Press " "

or " " again

to change the

target relative

humidity

ÖÈ

ÖÀ

µ·

%RH

Tips£

1. After the target value has been changed, if there is no operation in 5s, the value will be saved

and the controller will be back to the main interface.

2. After the target value has been changed, when the unit is restarted, system will operate at

the new target value.

5. Usage

Actual relative humidity

of room air Target relative humidity

5. Usage

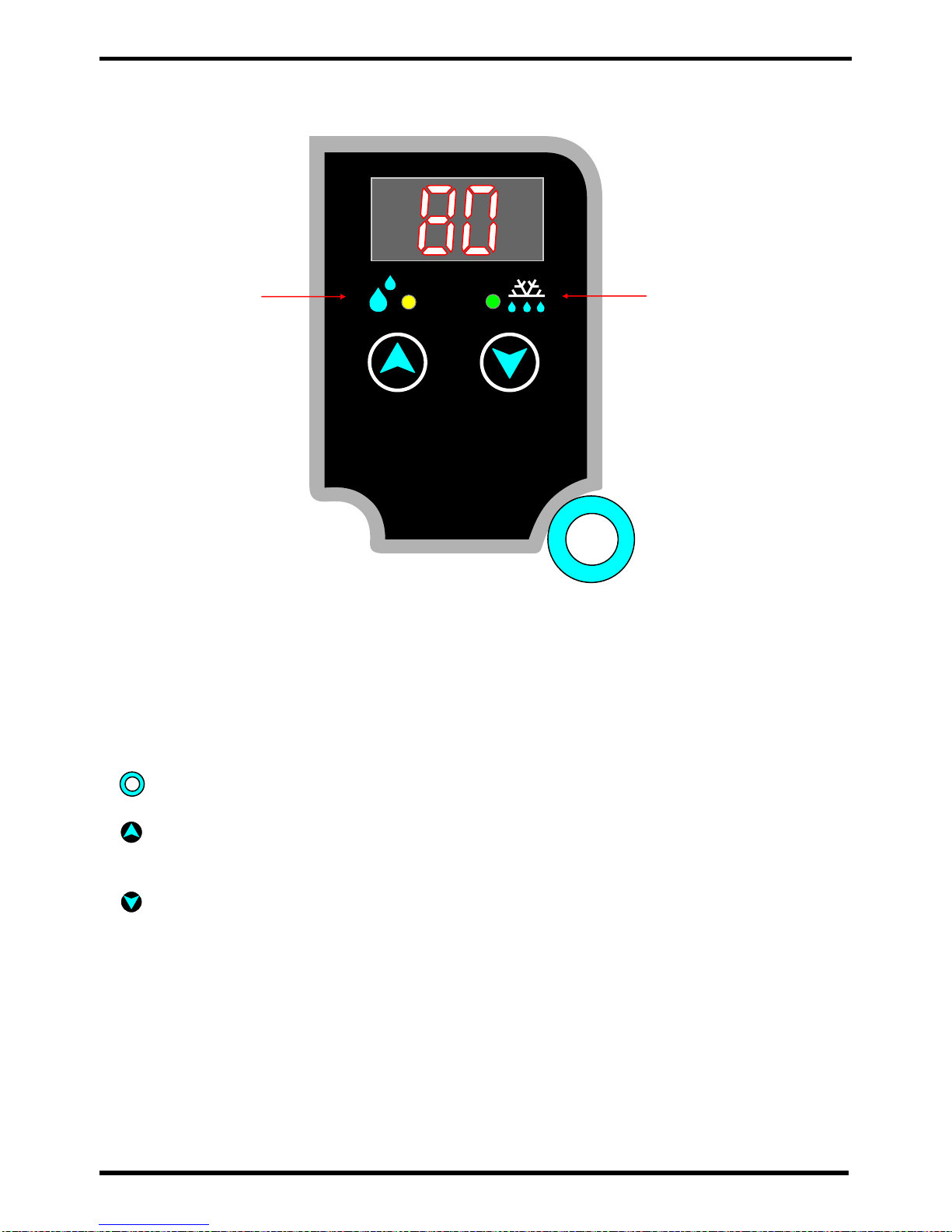

5.1 Instruction for Operation Panel

ÖÈ

ÖÀ

µ·

5.1.1 Buttons

ON/OFF

Press this button to turn the unit on/off.

UP

Press this button once to check the target setting value of relative humidity;

Press it again can increase the target setting value.

DOWN

10

%RH

Defrosting

Dehumidifying

Press this button once to check the target setting value of relative humidity;

Press it again can decrease the target setting value.

Tips:

When the unit is switched on, "8.8" will firstly be shown on the display. Then "1.0"will be

shown which stands for the version of the program. After that, you will find actual relative

humidity of the room air on the display.

5.2 Operation Instruction

5.2.1 Unit ON/OFF

You can turn ON/OFF the unit by just pressing " " when the unit is connected to the power.

When the unit is turned on, you can see the actual relative humidity shown on the display. At

the same time, the mode indicator and the light for the ON/OFF button will be on.

Press " "to turn

the unit ON/OFF

OFF ON

5.2.2 Set the target value of relative humidity

Press" "

or " "

to check the

target relative

humidity

ÖÈÖÀ

µ·Ö·

11

ÖÈ

ÖÀ

µ·

%RH

ÖÈ

ÖÀ

µ·

%RH

Actual relative humidity

The selected mode

ÖÈ

ÖÀ

µ·

%RH

ÖÈ

ÖÀ

µ·

%RH

Press " "

or " " again

to change the

target relative

humidity

ÖÈ

ÖÀ

µ·

%RH

Tips£

1. After the target value has been changed, if there is no operation in 5s, the value will be saved

and the controller will be back to the main interface.

2. After the target value has been changed, when the unit is restarted, system will operate at

the new target value.

5. Usage

Actual relative humidity

of room air Target relative humidity

5. Usage

5.1 Instruction for Operation Panel

ÖÈ

ÖÀ

µ·

5.1.1 Buttons

ON/OFF

Press this button to turn the unit on/off.

UP

Press this button once to check the target setting value of relative humidity;

Press it again can increase the target setting value.

DOWN

10

%RH

Defrosting

Dehumidifying

Press this button once to check the target setting value of relative humidity;

Press it again can decrease the target setting value.

Tips:

When the unit is switched on, "8.8" will firstly be shown on the display. Then "1.0"will be

shown which stands for the version of the program. After that, you will find actual relative

humidity of the room air on the display.

6. Maintenance

13

5.2.4 Defrosting mode

When the ambient temperature is low, for example, 11¡, and after the unit has worked for a

period of time, possibly, the evaporator will start to ice up . So the unit will switch to defrosting

mode automatically. During defrosting, the LED for icon " " . When defrosting is

over, the unit will return to the dehumidifying mode, and operate according to the condition

mentioned above.

lights up

12

ÖÈÖÀ

µ·Ö· ÖÈ

ÖÀ

µ·

%RH

5.2.5 Malfunction

Operation panel will display the failure codes when the unit gets some malfunctions. Please

refer to page15 to check the meaning of failure codes.

ÖÈÖÀ

µ·Ö· ÖÈ

ÖÀ

µ·

%RH

5.2.3 Dehumidifying mode

When the unit is in dehumidifying mode, the LED for icon" " lights up, and£

1. If the hygrostat detects that A(actual relative humidity of room air) ¡ TRH(target

relative humidity) + 5%RH, and this condition has lasted for 30s, the unit will start to

dehumidify.

2 .If the hygrostat detects that A(actual relative humidity of room air) ¡ TRH(target relative

humidity) - 5%RH, and this condition has lasted for 3mins, the unit will halt the

dehumidifying..

5. Usage

Fig.8 Fig.9

Fig.11

A

Fig.10

To guarantee the unit reliable and security operation for a long time, it is suggested to maintain and clean

up the unit every six months.

. Please take the following steps to clean up the strainer regularly:

1)Pull out the grill(A) from the upside of it(Fig.8);

2)After that, pull out the grill(Fig.9),then lift the grill upward(Fig.10);

3)Move away the grill(Fig.11)and take out strainer(Fig.12),then wash the strainer with water Fig.13( ).

6.1 Maintenance

Fig.12

Fig.13

6. Maintenance

13

5.2.4 Defrosting mode

When the ambient temperature is low, for example, 11¡, and after the unit has worked for a

period of time, possibly, the evaporator will start to ice up . So the unit will switch to defrosting

mode automatically. During defrosting, the LED for icon " " . When defrosting is

over, the unit will return to the dehumidifying mode, and operate according to the condition

mentioned above.

lights up

12

ÖÈÖÀ

µ·Ö· ÖÈ

ÖÀ

µ·

%RH

5.2.5 Malfunction

Operation panel will display the failure codes when the unit gets some malfunctions. Please

refer to page15 to check the meaning of failure codes.

ÖÈÖÀ

µ·Ö· ÖÈ

ÖÀ

µ·

%RH

5.2.3 Dehumidifying mode

When the unit is in dehumidifying mode, the LED for icon" " lights up, and£

1. If the hygrostat detects that A(actual relative humidity of room air) ¡ TRH(target

relative humidity) + 5%RH, and this condition has lasted for 30s, the unit will start to

dehumidify.

2 .If the hygrostat detects that A(actual relative humidity of room air) ¡ TRH(target relative

humidity) - 5%RH, and this condition has lasted for 3mins, the unit will halt the

dehumidifying..

5. Usage

Fig.8 Fig.9

Fig.11

A

Fig.10

To guarantee the unit reliable and security operation for a long time, it is suggested to maintain and clean

up the unit every six months.

. Please take the following steps to clean up the strainer regularly:

1)Pull out the grill(A) from the upside of it(Fig.8);

2)After that, pull out the grill(Fig.9),then lift the grill upward(Fig.10);

3)Move away the grill(Fig.11)and take out strainer(Fig.12),then wash the strainer with water Fig.13( ).

6.1 Maintenance

Fig.12

Fig.13

Press the key of "UP" or "Down" to check that if there are more failure codes.

You can find solutions to the problems according to the codes.

15

Solution

Malfunction Code

P1

P2

P3

P5

P6

P7

P8

E0

Reason

Solution to failure P1/P2/P3

1. If P1/P2/P3 appears together with other failures, please solve the others first.

2. If there is no other failures of P3~E0, and P1 & P2 still exist, please disconnect the power to

the unit and connect again after 1 hour.

3. If only P3 exists, please keep the fan running for 30min. If P3 still exist after the running,

please disconnect the power to the unit and connect again after 1 hour.

Note: Please contact with when failures can not be solved.Technical Service Assistance

6. Maintenance

6.2 Troubleshootings

14

High pressure protection

Condenser outlet

temp. overhigh

Evaporator outlet temp.

sensor failure

Humidity sensor failure

Motor feedback

signal failure

Evaporator inlet temp.

sensor failure

Condenser outlet temp.

sensor failure

High pressure protection

has appeared 3 times in

30mins.

High pressure protection

is too frequently.

Condenser coil temp.

is too high

This temp. sensor is

broken or in short circuit

The feedback wiring is in

bad connection.

Or fan motor is damaged.

This temp. sensor is

broken or in short circuit

This temp. sensor is

broken or in short circuit

This humidity sensor is

broken or in short circuit

Discharge pressure

is too high

1.Check the feedback

wiring of fan motor.

2.Or replace the fan

motor.

Check or replace

this temp. sensor

Check the below

solutions to failure

P1/P2/P3

Check or replace

this temp. sensor

Check or replace

this temp. sensor

Check or replace this

humidity sensor

Fig.14 Fig.15

6. Maintenance

4)

.

Set the filter net and the air return grille to the original place. (Fig.14)。

5)Clean up the unit outer with soft and damp rag(Fig.15)To protect the paint-coat of the

unit, please don’t use rough sponge or corrosive detergent to do these.

Warning£Cut off power supply before cleaning or maintaining the unit.

Press the key of "UP" or "Down" to check that if there are more failure codes.

You can find solutions to the problems according to the codes.

15

Solution

Malfunction Code

P1

P2

P3

P5

P6

P7

P8

E0

Reason

Solution to failure P1/P2/P3

1. If P1/P2/P3 appears together with other failures, please solve the others first.

2. If there is no other failures of P3~E0, and P1 & P2 still exist, please disconnect the power to

the unit and connect again after 1 hour.

3. If only P3 exists, please keep the fan running for 30min. If P3 still exist after the running,

please disconnect the power to the unit and connect again after 1 hour.

Note: Please contact with when failures can not be solved.Technical Service Assistance

6. Maintenance

6.2 Troubleshootings

14

High pressure protection

Condenser outlet

temp. overhigh

Evaporator outlet temp.

sensor failure

Humidity sensor failure

Motor feedback

signal failure

Evaporator inlet temp.

sensor failure

Condenser outlet temp.

sensor failure

High pressure protection

has appeared 3 times in

30mins.

High pressure protection

is too frequently.

Condenser coil temp.

is too high

This temp. sensor is

broken or in short circuit

The feedback wiring is in

bad connection.

Or fan motor is damaged.

This temp. sensor is

broken or in short circuit

This temp. sensor is

broken or in short circuit

This humidity sensor is

broken or in short circuit

Discharge pressure

is too high

1.Check the feedback

wiring of fan motor.

2.Or replace the fan

motor.

Check or replace

this temp. sensor

Check the below

solutions to failure

P1/P2/P3

Check or replace

this temp. sensor

Check or replace

this temp. sensor

Check or replace this

humidity sensor

Fig.14 Fig.15

6. Maintenance

4)

.

Set the filter net and the air return grille to the original place. (Fig.14)。

5)Clean up the unit outer with soft and damp rag(Fig.15)To protect the paint-coat of the

unit, please don’t use rough sponge or corrosive detergent to do these.

Warning£Cut off power supply before cleaning or maintaining the unit.

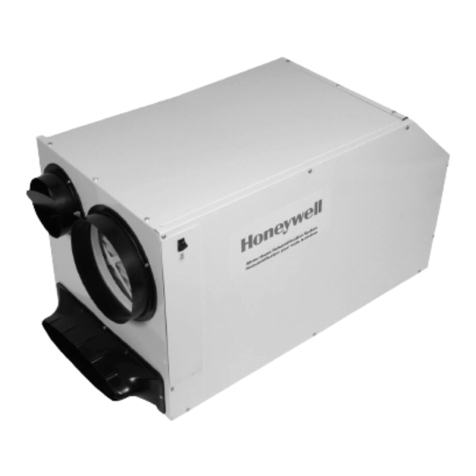

17

7.2 Wiring Diagram

7.Appendix

16

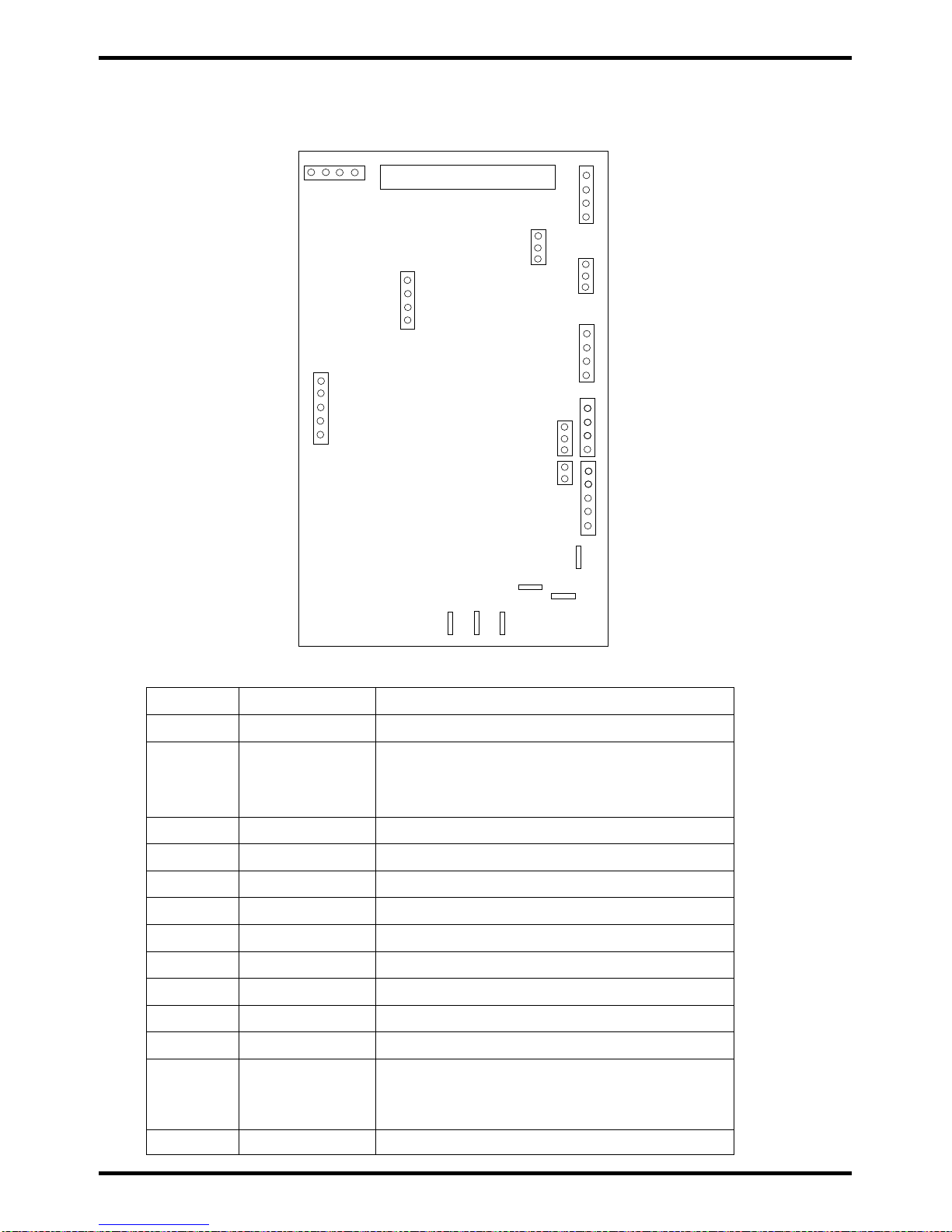

7.1 PCB I/O Port

NET2 TEMP1

CN1

HUMI02

PROG1

TEMP2

FM

EEV

L_Valve

L

L_Comp

N_Comp N1 N_Valve

HUMI01

CN7

Explanation£

7.Appendix

NET1

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

Ports

Cn1

CN4

NET1

NET2

FM

TEMP1

TEMP2

HUMI01

HUMI02

CN7

EEV

PROG1

L

N1

N_Comp

N_Valve

L_Comp

Meaning

To operation panel

Reserved

To fan motor(DC)

To evaporator inlet/outlet temp. sensor

To condenser outlet temp. sensor

To the build-in hygrostat

To the external hygrostat (optional)

To high pressure protection switch

To electronic expansion valve

Program burning port

To the Live Wire of power supply

To the Live Wire of compressor

Neutral Wire

CN4

CODE£ 201210220001

RED

BLK

WHT

N_Comp L

FM

BLU

YEL

N1 N_Valve

L_Comp BRN

BLU

Y/G L

N

220-240V~/50Hz

EvOT

5

CR

COMP

CS

CR CC

CS

BLK

RED

WHT

N

14

RHS

5K EvIT

SS

TEMP2

HUMI01

HUMI02

TEMP1

EEV

CN1

FM

PACC1001

tt

5K

CdOT

t

5K

C1

Operation Panel

TO POWER SUPPLY

HPSCN7

CdOT£Condenser OutletTemperature

SS£SensitiveSwitch

EvOT£Evaporator Outlet Temperature

EvIT£EvaporatorInlet Temperature

HUMIO2£Can connect to an external RHS

FM£Fan Motor(DC)

EEV£Electronic Expansion

Valve

RHS£Sensor of Relative Humidity

HPS£HighPressureProtectionSwitch

PGND

EEV

17

7.2 Wiring Diagram

7. Appendix

16

7.1 PCB I/O Port

NET2 TEMP1

CN1

HUMI02

PROG1

TEMP2

FM

EEV

L_Valve

L

L_Comp

N_Comp N1 N_Valve

HUMI01

CN7

Explanation£

7.Appendix

NET1

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

Ports

Cn1

CN4

NET1

NET2

FM

TEMP1

TEMP2

HUMI01

HUMI02

CN7

EEV

PROG1

L

N1

N_Comp

N_Valve

L_Comp

Meaning

To operation panel

Reserved

To fan motor(DC)

To evaporator inlet/outlet temp. sensor

To condenser outlet temp. sensor

To the build-in hygrostat

To the external hygrostat (optional)

To high pressure protection switch

To electronic expansion valve

Program burning port

To the Live Wire of power supply

To the Live Wire of compressor

Neutral Wire

CN4

CODE£ 201210220001

RED

BLK

WHT

N_Comp L

FM

BLU

YEL

N1 N_Valve

L_Comp BRN

BLU

Y/G L

N

220-240V~/50Hz

EvOT

5

CR

COMP

CS

CR CC

CS

BLK

RED

WHT

N

14

RHS

5K EvIT

SS

TEMP2

HUMI01

HUMI02

TEMP1

EEV

CN1

FM

PACC1001

tt

5K

CdOT

t

5K

C1

Operation Panel

TO POWER SUPPLY

HPSCN7

CdOT£Condenser OutletTemperature

SS£SensitiveSwitch

EvOT£Evaporator Outlet Temperature

EvIT£EvaporatorInlet Temperature

HUMIO2£Can connect to an external RHS

FM£Fan Motor(DC)

EEV£Electronic Expansion

Valve

RHS£Sensor of Relative Humidity

HPS£HighPressureProtectionSwitch

PGND

EEV

Code:20121115-0004

This manual suits for next models

2

Table of contents

Other evoheat Dehumidifier manuals