Page 1

DOC0935 (26 July 2022 12:02)

www.keit.co.uk Back to Table of Contents

Table of Contents

1. Safety ............................................................................................................................3

1.1. General safety ........................................................................................................3

1.2. Lifting instructions...................................................................................................3

1.3. Electrical safety.......................................................................................................3

1.4. Pressure and temperature limits .............................................................................3

1.5. Operating environment limits ..................................................................................4

2. How to Power, Purge and Connect the IRmadillo...........................................................5

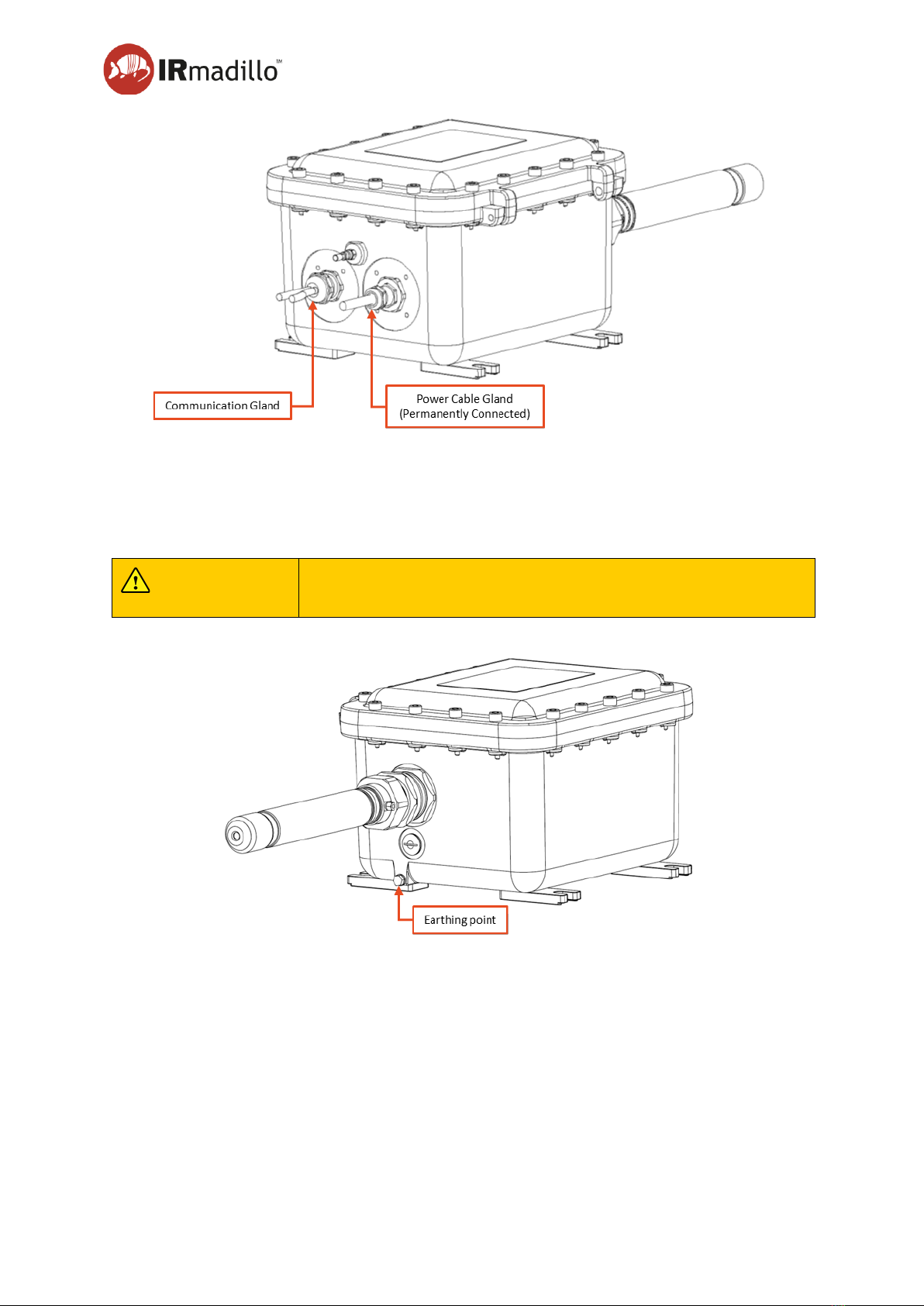

2.1. Powering the IRmadillo...........................................................................................5

2.1.1. Uninterruptible power supply (UPS).................................................................5

2.1.2. Power cable.....................................................................................................5

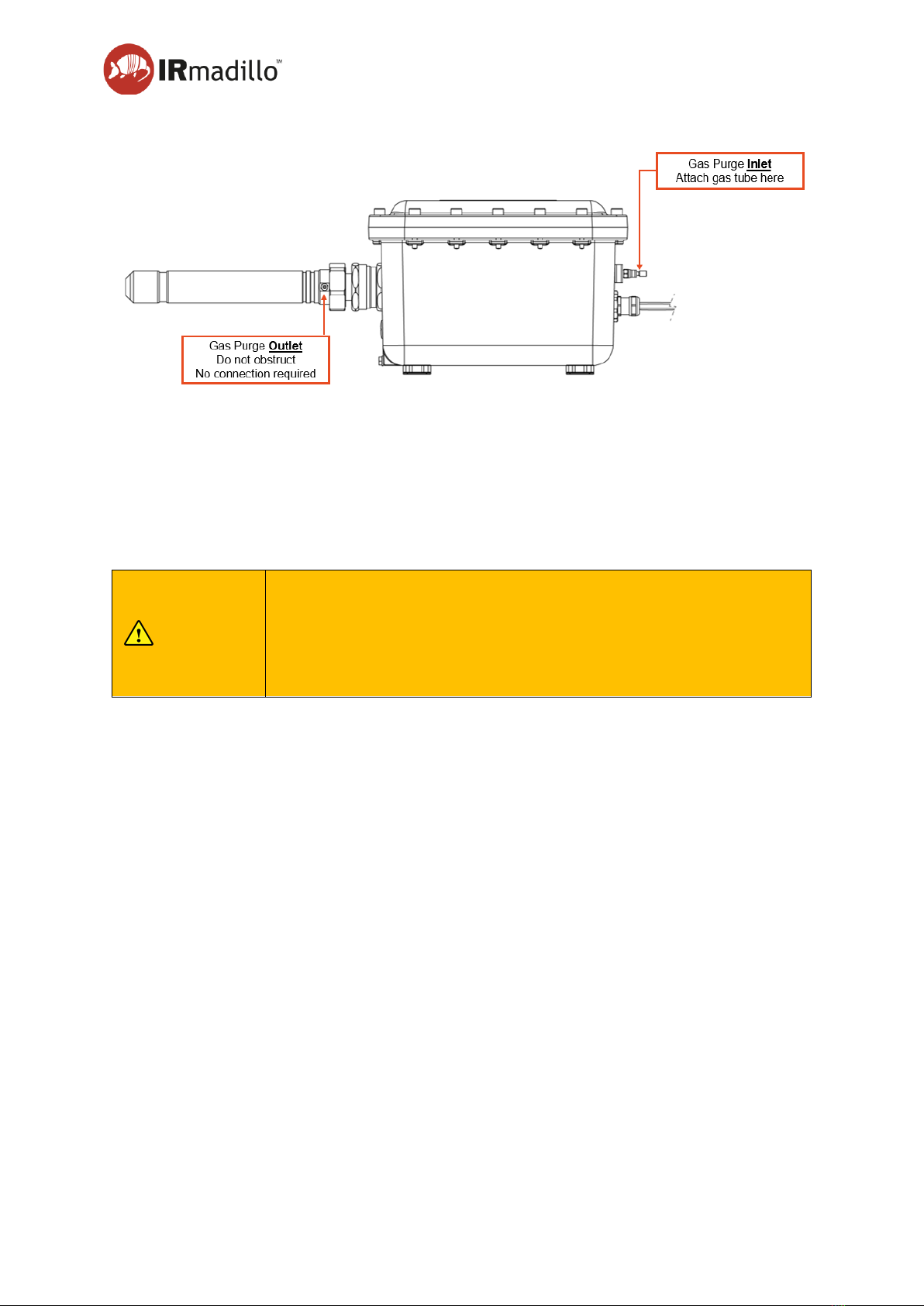

2.2. Purging the IRmadillo..............................................................................................6

2.3. How to connect data communications.....................................................................7

2.3.1. Connecting to the internal controller.................................................................8

2.4. Checking for warnings and checking the probe is clean........................................10

2.4.1. Cleaning instructions......................................................................................10

2.4.2. Recognising if the probe is clean ...................................................................11

2.5. Taking a background ............................................................................................12

2.6. Installation best practice........................................................................................12

3. Maintenance................................................................................................................14

3.1. Service and support contacts................................................................................14

3.2. Maintenance & support programme (MSP)...........................................................14

3.3. Spectrum health....................................................................................................14

3.3.1. Use at high temperature ................................................................................15

3.3.2. Emitter ageing................................................................................................15

3.4. Remote health check............................................................................................16

4. Components ................................................................................................................17

4.1. IRmadillo spectrometer.........................................................................................17

4.1.1. Dust caps.......................................................................................................19

4.2. Controller specifications........................................................................................19

4.3. Storage conditions................................................................................................19

5. Accessories .................................................................................................................20

5.1. Sample cell - ASM1398 ........................................................................................20

5.1.1. Maintenance..................................................................................................20

5.1.2. Cleaning ........................................................................................................20

5.2. Flow cell................................................................................................................21

5.2.1. High flow cell - ASM1396...............................................................................21