Evolution Aircraft REV X Manual

1

EVOLUTION AIRCRAFT INC.

REV X

Operating and Maintenance

Instruction Manual

Version 1.0

Released 04/01/2019

2

INTRODUCTION

REV X is a STOL (short takeoff and landing) single seat trike powered by a Rotax 582 with

E box. Its most notable key features are NO FRONT STRUT, All wheel suspension and it

Folds onto its REV X trike dolly cart for set up and storage in under 10 minutes.

Components used are of the highest quality and technology on the market today. From the

battery to the engine, from the bolts to the Powder Coat, only the Best of the Best is used.

The Rotax 582 engine is dual ignition, liquid cooled, with a gear box. This system has

proven to be the highest quality, best running engine in its class. The Rotax provides a

surplus of power at 65 HP for impressive climb and continuous cruise.

Stopping power comes from the Black Max Super STOL braking system utilizing 2 calipers

and 4 brake pads all on one rotor!

The suspension comes from 4 "flex rods". The entire front end is a swing arm giving the

nose wheel equal travel. The entire front end disconnects and "unplugs" to fold the trike in

lieu of a folding mast. In its folded form the rear wheels are lifted off the ground creating a

counterbalance effect which makes putting the wing up and down quite effortless.

Instrumentation comes from a super bright color display from MGL. The Xtreme EFIS

provides valuable information about the engine and flight.

Standard features include:

1. Cantilever mast with no front strut required

2. All wheel suspension

3. Quick fold cart for easy storage

4. MGL Xtreme color instrument panel

5. Tundra tires

6. Electric start and pull start

7. Earth X lithium battery

8. Dual hydraulic disc brake

9. 4130 Chrome Moly high reinforcements in high stress areas

10. Real Aircraft seat belt

11. Extra padded seat cover

12. ¾” chrome moly front axle

13. AN aircraft hardware throughout

14. Tefzel aircraft wire

15. Cannon plug for quick disconnect

3

ROTAX 582 ENGINE

DESCRIPTION

•2-cylinder

•2-stroke liquid cooled engine with rotary

valve intake

•dual electronic ignition

•integrated water pump and thermostat

•exhaust system

•carburetors

FACTS

Over 35.000 units of this popular Rotax 2-

stroke engine have been sold. This engine type

is well regarded for its easy maintenance and

robustness.

VERSION PERFORMANCE TORQUE MAXRPM

kW hp 1/min Nm hp 1/min 1/min

582 Mod. 48 65 6500 75 55.3 6000 6800

WEIGHT kg lb

engine 29.1 64.0

2 carburetors 1.8 4.0

exhaust system 5.1 11.2

electric starter 3.5 7.7

propeller speed reduction unit “B“/ i = 2.58 4.5 9.9

propeller speed reduction unit “C“/ i = 2.62/3.0/3.47/4.0 8.0 17.6

propeller speed reduction unit “E“/ i = 2.62/3.0/3.47/4.0 11.2 24.7

ENGINEDATA

ENGINETYPE582| 65 hp(UL)

BORE STROKE DISPLACEMENT

76 mm 2.99 in 64 mm 2.52 in 580 cm

3

35.4 cu. in.

FUEL MIXINGRATIO

min. MON 83 RON 91*

min. AKI 87* API-TC-Classific

at ion 1:50

or optional with fresh oil pump

* leaded, unleaded, AVGAS 100LL or Ethanol 10

AIRCRAFT ENGINES

WWW.FLYROTAX.COM © 201 BRP-Rotax GmbH & Co KG. All rights reserved. ®, TM and the BRP logo are trademarks of Bombardier Recreational Products Inc. (BRP) or its affiliates.

picture: 582 with options

4

Engine Lubrication

Oil Injection Pump

Use Husqvarna 2-Cycle Synthetic Blend Oil (Commonly sold at Lowes Home Improvement)

CAUTION:

Many 2 stroke oil brands can be used however the REV X is set up at the

factory with this oil and it is highly recommended NOT to change oils unless a

complete oil reservoir flush is done.

5

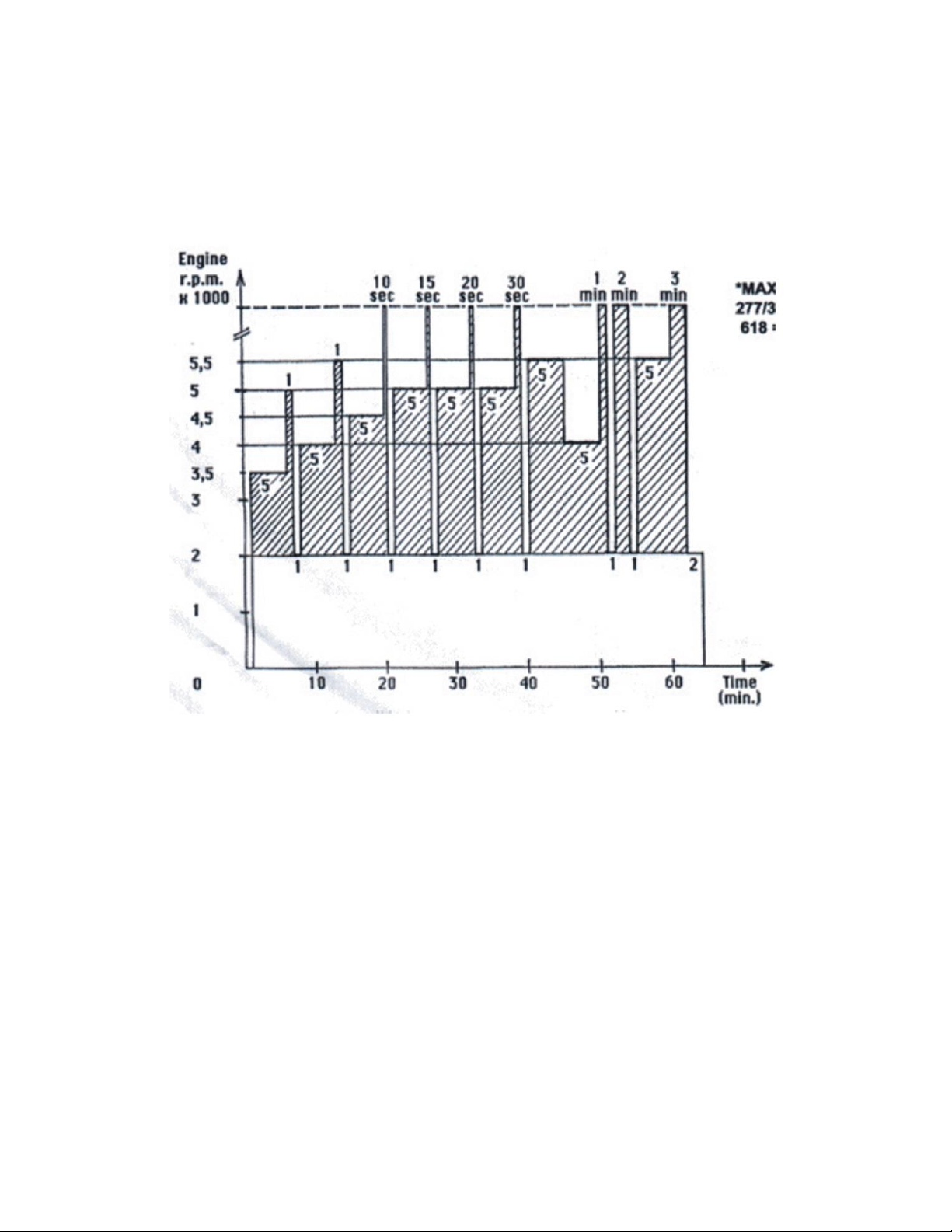

Break in Procedure

6

PROPELLER

Any running propeller can present a potential danger for the pilot, the passenger and/or

the spectators. Never let non pilots touch the propeller, even when the engine is stopped.

Always be extremely careful as soon as an engine equipped with a propeller may turn.

WARNING

Before turning the propeller with the hand, always verify attentively that the

driving ignition is off.

NOTE:

Each prop blade as well as the prop crush plate has a colored dot which must line up

for the purpose of dynamic balance.

Torque and Pitch Maintenance

Torque: 100 inch pounds

10 minutes after first assembly, engine warm.

After the first flight hour.

As many as necessary, and at minimum every 25 hours and/or every 3

months.

Before each flight:

Visual inspection of the propeller and checking of the screws.

If an incident or prop strike require repair, this must be approved by Helices E-PROPS in

its workshops, or by a specialist after discussion with the E-PROP Team.

All the blades have a reference number and a serial number. These references are

important for determining with the E-PROP team what modifications or the possible

replacement in necessary. The final checks of the propeller, and in particular balancing, are

made by Helices E-PROPS before the delivery. Any modification of the propeller can

damage the balancing and generate vibrations which could damage the engine.

8

Basic Features

Powerful 32 bit ARM processor

4.3” high resolution 480x272, sunlight readable, wide viewing angle, 600 nits TFT

LCD display

LED backlight (brightness can be adjusted for low light flying conditions)

SD Card interface for data recording, user splash screens, checklists, graphic

information pages, firmware upgrades, navigation and route files etc

1/8” NPT female fittings for Altitude and Airspeed pitot tube connections

Rotary control plus 5 independent buttons for easy menu navigation and user input

External active GPS antenna connection

Built in RTC (Real Time Clock)

Wide input supply voltage range of 8 to 30V DC

Built in voltage reversal and over voltage protection for harsh electrical

environments

Light weight design

Optional Features

Optional MGL Avionics compass sensor unit (SP2/SP6)

Optional MGL Avionics AHRS sensor unit (SP4/SP5/SP7)

9

System Overview

The RDAC (where all the sensors run to) is located behind the pilot seat just opposite of

the battery. This design keeps all of the sensor leads short and without the need of

extension cables and keeps the wiring lighter and simpler. This RDAC (brain box) is easily

accessible by removing the pilot seat by removing the 4 bolts that secure it to the frame.

NOTE due to imperfection in the seat mold, the rear left seat bolt corner has 2 washers that

shim the seat in order to make the seat perfectly straight. Be sure to reinstall these washers

when putting the seat back in Most of the sensor wires are very small gauge and can come

loose during the life of the machine. Simply retighten any loose sensor wires if a sensor

appears to fail. The RDAC is completely labeled making it very simple to figure out. The

RDAC has a green blinking light which indicates it is getting power when the key is turned

on. If it is not blinking green it is probably not getting power and will not work without

being powered. There are only 3 wires which are bundled together in a single shielded

cable that connect the RDAC to the EFIS (monitor). If an RDAC fail notice displays on the

EFIS, it is referring to a connection break between the EFIS and the RDAC or lack of power

to the RDAC. All of the parameters (VNE caution temperatures and warnings are fully

programmable under the menu settings. There are 5 different screens to scroll through,

but it is recommended to turn off 3 of the 5 screens which are not useful for the REV Xs set

up. These other screens include satellite info and artificial horizon. This leaves a screen

with large, easy to read round dials for flight instruments and a screen with mostly easy to

read bar graphs for engine monitoring. When only 2 screens display it allows the user to

use the left square button to toggle between the 2 screens instead of having to go through

all 5 screens to get back to the other useful screen.

10

Using the EFIS

Pressing the left button will scroll between screens.

Pressing the round knob in will bring up a menus. Turning the knob to highlight and then

pushing in to select will allow you to navigate the system.

Barometric pressure is located in the top right corner of the EFIS display. Turn the rotary

control to change the local pressure setting. The local pressure can be displayed in “mB”or

in “HG”. This is used to set the altimeter to MSL or AGL.

NOTE:

This must be checked and adjusted before each flight in order for it to be accurate.

CHT (cylinder head temperature) and EGT (exhaust gas temperature) alternate in the

same location. CHT must remain below 270°F and EGTs must remain below 1200°F.

Coolant must remain below 175°F. These are important to monitor. If one of these

temperatures goes too high a red WARNING box will appear and flash on the screen.

Tachometer is displayed on the right side of the screen. Full throttle should yield between

6300-6700 RPM.

Airspeed may or may not be accurate and needs to be calibrated. Using the GPS and

making different headings comparing the GPS to the airspeed it is possible to calibrate the

airspeed. We recommend your airspeed be set to 120% as a base value to get closer to a

correct reading. The value can be adjusted up to 150%.

The Ground Speed is labeled GS EFIS display. The ground speed value will only be

displayed when a valid 2D or 3D GPS fix has been achieved.

VSI is vertical air speed or the rate in which climbing or descending. “+” means it is

climbing an “–“means it is descending.

Hobbs Meter tells the number of hours on the engine which is important for scheduled

maintenance.

Voltage shows the battery voltage when the engine is off and the charging voltage when

the engine is running. Keep in mind the voltage is higher (13.1-13.6 volts) than expected

lead acid battery voltage.

11

Wing

For complete instruction manual click here:

http://northwing.com/Mustang3-Wing-Manual.pdf

Braking System

WARNING

This system does NOT use brake fluid.

The brake system is a combination of a Matco master cylinder which uses an internal

“intensifier kit” with a black Max caliper system.

Bleeding the brakes should be done by pressure bleeding the system with ATF (automatic

transmission fluid). Fluid should be added with some form of a pressurized container

(pump sprayer or oil can) with a hose that secures firmly around the lowest bleed screw

on the caliper. Loosen Allen set screw at top of caliper to allow all air to escape from the

system as ATF fluid is injected into the lowest bleed on the caliper. When all air has

escaped, tighten the top bleed screw. Then loosen the large set screw in the top of the

Master cylinder and continue to pump ATF fluid into the caliper until all the air is out of

the master cylinder. Then tighten large setscrew and the bleed screw supplying the ATF

fluid. Ensure the brake pads are not dragging by elevating the nose wheel and spinning the

wheel. If the wheel does not spin freely, loosen the large setscrew in the master cylinder

while pressing the brake pedal down until a small amount of fluid leaks out. Then tighten

the setscrew and test again. Once the wheel spins freely make sure the pedal is hard and

not spongy

CAUTION:

Tightening the setscrew may cause the caliper to activate the brake pads.

12

Replacing the Brake Pads

1. Elevate the front wheel by putting something under the frame such as a stool with

padding

2. Loosen all 8 Allen head screws in the triple trees (horizontal CNC fork tube clamps)

3. Once fork tube and nose wheel are free, remove the bolt that go through the port

(left) side of the axle

4. Remove the through bolt that secures the caliper to the axle

5. Loosen the setscrew that tightens the caliper to the axle

6. Slide the caliper with the free floating rotor off the axle

7. Separate the rotor from the caliper

8. Remove the piston side brake pad first and then the other

9. Install new pads and reverse steps for reassembly

Support Cables

The 5 support cables on carriage can be removed easily by locating which nut to remove

first. The angle of the bolts that secure the cables are orientated in such a way that as one

of the nuts is loosened it will relax the cable being removed. The tension of the cables is

controlled by twisting the cables. Twisting counterclockwise tightens the cable by

shortening its overall length and clockwise loosens it. This tensioning method is effective

and lighter and simpler than adding a tensioning mechanism. When replacing a cable try

and get the cable snug so that it is difficult to expose only 3-4 threads on the bolt that

secures it. Start the nut by hand onto the 3-4 threads and then carefully tighten down the

nut with a 7/16” socket and wrench which will start to tension the cable even further.

When the nut is all the way down the cable should be extremely tight.

CAUTION:

The X brace behind the pilot seat must be done at the same time in order to not

rack (shift) the frame.

13

EARTH X BATTERY

WARNING

Do NOT charge with a desulfinating battery charger.

Do NOT use Schumacher battery chargers with Earth X batteries.

Recommended to Use the simple noncomputerized 1-2 amp battery charger. These

are readily available as the cheapest chargers on the shelf at Walmart and auto part

stores.

Model: ETX12A

Nominal Voltage

13.2 V

Ah (Lead-acid equivalent)

12

Ah (1 hour discharge rate)

4 (1C rate)

Pulse Crank Amps (PCA)

220A (3 sec @ 25 °C, voltage >9V)

Cold Crank Amps (CCA)

135A (modified SAE test, 3 sec@ 0°F, voltage

>7.2V)

Max Continuous Discharge Amps

40A

Standard Charge Voltage

13.9 - 14.6 V

Maximum Charge Voltage

15 V

Recommended Charger/Maintainer

Amps

.8 - 5A

Max Charge Amps

20A (from vehicle charging system)

Life (Charge cycles)

4000 cycles @ 1C discharge rate, 25°C (20%

depth of discharge)

2000 cycles @10C discharge rate, 25°C (80%

depth of discharge)

Life (Years)

8 Years

Weight

1.3 lb. (.6Kg)

Dimensions

4.5in x 2.6in x 3.7in (113mmX66mmX95mm)

Environmental Rating (resistance to

water intrusion)

IP 66 (wash down with a high pressure washer)

Operating Temperature

-30 °C to +60 °C

Storage Temperature

-40 °C to +70 °C

14

List of Chargers

Model

Safe to

Use

BMS

Reset

Suggested Use

TecMate/

Optimate

Lithium TM-

271/TM-291

Yes

Yes

Use as charger, maintainer and it will

reset EarthX’s BMS over-discharge

protection

TecMate/

Optimate

Lithium TM-

271/TM-485

Yes

Yes

Use as charger, maintainer and will

reset EarthX’s BMS over-discharge

protection

Battery

Minder

Any model

No

No

Do not use, as full time de-sulfating

mode will damage a lithium battery

Black N

Decker

BM3B

Yes

No

Use as charger

Black N

Decker

BC15BD

No

No

Do not use, as full time desulfinating

charger

Christie

All Models

No

No

Do not use, as full time de-sulfating

mode will damage a lithium battery

CTEC

Lithium US

Yes

Yes

Use as charger, maintainer and it will

reset EarthX’s BMS over-discharge

protection

Deltran

Battery Tender Jr

Yes

No

Use as charger, maintainer, but will not

reset EarthX’s BMS over-discharge

protection

Deltran

Battery Tender

(original)

Yes

No

Can be used for charging only.

Maintenance voltage is too low.

Deltran

Battery Tender

Plus

Yes

No

Can be used for charging only.

Maintenance voltage is too low.

Duraboost

Duraboost 750

Yes

No

Can be used for charging. Cannot find a

maintenance voltage in manual so if it is

less than 13.3V, too low.

Duraboost

Duraboost 1000

Yes

No

Can be used for charging. Cannot find a

maintenance voltage in manual so if it is

less than 13.3V, too low.

H-D

Tender Jr

Yes

No

Use as charger, maintainer, but will not

reset EarthX’s BMS over-discharge

protection

Moose

Tender Jr

Yes

No

Use as charger, maintainer, but will not

reset EarthX’s BMS over-discharge

protection

15

NOTE:

This is not an all-inclusive list.

Lithium batteries have a very low self-discharge rate which means the battery, if

disconnected from your trike, could “hold its charge” for a year.

The ETX Lithium battery is compatible with most “modern” lead-acid battery chargers or

4cell LiFePO4 battery chargers. By “modern” we mean a charger that automatically turns

off when the battery is fully charged, a charger with a micro-processor, or a charger with

multiple mode charging. The “full charge” voltage for the ETX Lithium battery is 13.3V or

higher. Some lead-acid battery trickle chargers maintenance mode voltage can be below

13.3V, which is too low for a lithium battery. For example, the Battery Tender JR has a

maintenance mode voltage of 13.3V which is compatible, whereas the original Battery

Tender has a maintenance mode voltage of 13.2V which is too low for a lithium battery.

Never charge a faulty battery (a battery that will not accept a charge or hold a charge).

Never use the de-sulfate setting on your charger. Be sure the charger’s output voltage level

does not exceed 15V. If the charger does not display the voltage reading, then use a

voltmeter to check the voltage while charging. If the battery gets hot while charging,

discontinue charging and use. Do not charge battery in temperatures above 140°F (60°C),

NOCO Genius

All Models except

the lithium

specific one

No

No

Do not use, as full time de-sulfating

mode will damage a lithium battery

Tenergy

4cell LiFePO4

Smart Charger

Yes

Yes

Use as charger, maintainer and it will

reset EarthX’s BMS over-discharge

protection

ODYSSEY

Ultimizer

Yes

No

Use as charger and maintainer

Pulsetech

Xtreme XC100

Yes

No

Can be used for charging only. While in

operating, verify the pulse output is off.

TecMate/Opti

mate

All lead acid

charger models

No

No

Do not use, as full time de-sulfating

mode will damage a lithium battery

CTEC (like

Multi XS

3600)

All lead acid

charger models

No

No

Do not use, as full time de-sulfating

mode will damage a lithium battery

Schumacher

Any model

No

No

Do not use, as full time de-sulfating

mode will damage a lithium battery

Yuasa

Smart Shot 900

No

No

Can be used for charging. Cannot find a

maintenance voltage in manual so if it is

less than 13.3V, too low.

Yuasa

Smart Shot

1.5mA

No

No

Do not use, as full time de-sulfating

mode will damage a lithium battery

16

or in direct sunlight. When charging a battery, place it on a non-flammable surface, and

remove any flammable items nearby. For maximum battery and vehicle starting system

life, do not crank an engine for more than 10 seconds within any 1 minute period.

Troubleshooting

The ETX Lithium battery is an extremely reliable battery with a longer useful life than

comparable lead-acid batteries.

Despite the high reliability, you may encounter situations where the battery does not

operate as expected. Here are some potential issues you may encounter with the

appropriate troubleshooting procedures.

Problem

The charger shuts down during the first few seconds of charging.

Possible Causes and Solutions

Are you using a Constant Voltage (CV) charger? CV chargers may trip when first connected

to a drained battery due to a high inrush of current. If this happens, reset the charger and

try again. If the problem continues, try using a different charger.

Problem

Zero voltage at the terminals or un-stable voltage (voltage reading drifts slowly to zero).

With a lead-acid battery, finding a very low voltage at the terminals often indicates the

battery has reached the end of its life. With an ETX Lithium battery this may not be true.

Possible Causes and Solutions

The ETX series lithium battery has built-in over-discharge protection circuitry, which

automatically disconnects the battery if the voltage drops below 11.5 volts (98%

discharged). When the battery is “disconnected”, the voltage at the battery terminal should

be zero.

Some volt-meters may initially indicate a voltage, but it will decay to zero within ten

seconds or so. For a drained battery, simply connect the battery to a charger to restore

charge (charge with 2A for 20-30 minutes), and then re-check the voltage. If the voltage is

12.8V or greater, the battery should be ok and can be fully charged. Not all chargers will

charge a battery that displays zero volts, so check our website for a list of compatible

chargers, and specifically chargers that will work for recharging an “over-discharged”

battery for which the BMS’s over-discharge protection has activated. This condition is

sometimes referred to as a BMS reset.

17

Problem

The battery seems to suddenly stop working.

Possible Causes and Solutions

A lithium battery voltage remains relatively constant while discharging, but when the

battery runs out of power it does so abruptly. Try charging the battery for 30-60 minutes

at 1 –2 Amps. If the battery still does not work, or the measured voltage is less than 12V,

the battery may be permanently damaged and needs to be replaced.

Problem

The battery does not hold a charge.

Possible Causes and Solutions

There may be a problem with the engine charging system: While the charging system is in

operation, it should output approximately 13.9 -14.6 volts. If the voltage is below this level,

the charging system needs to be repaired.

18

FOLDING THE TRIKE

1. Disconnect throttle and wiring.

2. Lift nose wheel and slide the cart underneath the REV X.

3. Use bungee cord to lift the front of the cart and attach it to the swan catch to help

line up pins that secure cart to frame.

4. Install 2 cart/frame pins.

5. Release bungee cord and allow cart to lock its rear wheels against drag links of the

REV X’s suspension.

6. Secure control bar into the chalices of the cart.

7. Remove front end of trike by removing the 2 speed pins that hold it on.

8. Lower the cart to the ground.

9. Remove the tip battens.

10. Fold in the sprogs.

11. Loosen the haul back cable.

12. Remove all battens except for the nose battens and the longest root battens

13. Ensure the prop is vertical and Ensure engine is cool to the touch.

14. Fold wing back (Chock wheels on dolly cart for ease) Either using 2 people walk the

tips back towards each other or connect both ends of a 40’ rope to each wing tip

strap and pull the center of the rope back for single person folding.

15. Once the wing is folded, carefully pull the fabric up and over to the outside of the

folded wing.

16. Insert wing standoffs between the cross tube and the roll cage mast at the very rear

of the trike.

17. Roll up fabric and secure with straps.

18. Secure front end in cart for storage.

19. Tie wings together to press and hold the wing standoffs in position.

19

Click the link below to watch a video on how to fold the Rev X trike.

https://youtu.be/zLQO0Ci-JaQ

20

OWNER MANUALS

ENGINE

https://www.cps-parts.com/cps/pdf/d04495.pdf

MAINTENANCE MANUAL

https://www.cps-parts.com/cps/pdf/d00288.pdf

Illustrated PARTS CATALOGUE

https://www.cps-parts.com/cps/pdf/d05246.pdf

MGL Xtreme EFIS

http://mglavionics.com/html/xtreme_efis.html

WING

http://northwing.com/Mustang3-Wing-Manual.pdf

PROPELLER

https://ppg.e-props.fr/docs.php Click on NG-D Propellers –pdf file

In case of incident, please contact Helices E-PROPS as soon as possible at:

Hlices E-PROPS Arodrome de Sisteron 04200 Vaumeilh – France 33 (0)4 92 34 00 00

FOLDING THE WING

https://youtu.be/zLQO0Ci-JaQ

Table of contents